WET Products · a screw conveyor fed by rotating paddles that skim the surface into linear troughs...

Transcript of WET Products · a screw conveyor fed by rotating paddles that skim the surface into linear troughs...

Our patent-pending multi-stage Circular Zoned Dissolved Air Flotation unit is the core of our modular wastewater treatment technology. WET’s CZDAF design incorporates economic manufacturability, ship ability, and precision process control that provides the ultimate water treatment solution with the lowest chemical use.

Segmented construction for convenient container transport, WET CZDAFs are quickly erected on-site, and can be easily re-deployed.

WET Products

Multi-stage Circular Zoned DAF Unit (CZDAF)

Three Zone CZDAF

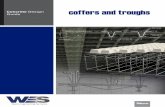

Structural integrity and mechanical stability are assured using state-of-the-art finite element analysis. This essential engineering step provides for optimum materials usage and reduced waste.

WET CZDAF Engineered for Integrity

WET CZDAF Three Zone Process Flow

Wastewater enters Zone 1, the central core of the WET CZDAF allowing up to 99% of oil to be recovered using an adjustable decanter.

Remaining effluent enters concentric Zone 2 for chemical precipitation to remove metals and other chemical contaminants.

Flow proceeds to Zone 3 where coagulants for flocculation, pH adjustment, and disinfection can be added as needed.

Throughout the flow, material floated to the surface due to dissolved air flotation is removed by a screw conveyor fed by rotating paddles that skim the surface into linear troughs in each zone.

Heavies that do not float are collected in each zone due to the conical bottom design and discharged though ports to sludge processing storage tanks.

Two Stage CZDAF

Bio-DAF Unit

Our patent-pending Bio-DAF system can effectively remove Biological Oxygen Demand (BOD), Total Suspended Solids (TSS), ammonia, Total Nitrogen (TN), and Total Phosphate (TP) from wastewater. It provides integrated physiochemical and biological treatment processes in one unit. This system includes a primary DAF unit, anoxic bio-media reactor, multi-stage aerobic bio-media reactors, a secondary DAF unit, and aerobic sludge digester. Adding ozone in the primary DAF unit partially oxidizes organic matter and improves the raw wastewater biodegradability. Ozone injection in the secondary DAF unit helps disinfect bacteria in the treated effluent and control odors. The bio-media reactors are used to remove BOD and TN and are divided into a number of functional zones. Each functional zone can develop and accumulate optimized bacteria species and microorganisms based on incoming wastewater BOD and nutrient levels, maximizing BOD and TN removal efficiency to produce high-quality effluent with reduced operating costs. The secondary DAF section intercepts and removes excess biomass and TSS, and also effectively removes total phosphorus through chemical precipitation.

Bio-DAF Applications:

• Municipal and domestic wastewater treatment and reuse• Industrial wastewater treatment and reuse• Poultry and meat processing wastewater pretreatment• Brown grease disposal station wastewater treatment

Our patent pending continuous cleaning grease trap (CCGT) is a compact, and state-of-art system to effectively intercept, remove, and recover fat, oil, and grease (FOG) from restaurant and food service establishments wastewater. Coagulant and flocculant are added to maximize removals of FOG, BOD, TSS, and colloidal particulates at the point of source. Small amount of ozone is introduced to improve FOG removal and recovery efficiency as well as for odor control during FOG recovery process. CCGT can be operated continuously. Since the removed FOG can be concentrated up to 12-15% consistency, the FOG trucking costs and disposal costs will be significantly reduced to contribute great savings for restaurants and food service establishment daily operations.

Continuous Cleaning Grease Trap (CCGT)

• Flowback & Produced Water Treatment & Reuse

• Tank Bottom & Oily Sludge Dewatering andManagement

• Drilling Mud Recovery & Closed Loop DrillingProcess

Oil & Gas Industries

WET Services

Ideal for smaller operations, The WET three-stage CZDAF system features complete management of liquids and solids. Chemical treatments are tailored to the characteristics of produced water and flowback streams. This design features a twin wire press which allows continuous sludge dewatering. The treated water can be reused for drilling operations as well as making clear heavy brine water.

Oil & Gas Industry Applications

Flowback and Produced Water Treatment & Reuse

Transportable, Modular Design for Water Reuse: 20,000 bbl/day

WET systems are engineered with a modular design for rapid deployment to provide solutions for any operation. Four-unit CZDAF design is ideal for terminal ends of water collection/distribution networks in dense oilfield applications. Solids management is achieved using two meter twin-wire belt press.

Transportable, Modular Design for Water Reuse: 20,000 bbl/day

Transportable design, 10,000 bbl/day for water reuse.

Ideal for smaller operations, our three-stage skid-mounted mini DAF system features complete management of liquids and solids. Chemical treatments are tailored to the source of produced water and flowback streams. This design features a twin wire belt press which allows continuous sludge dewatering.

Mobile Design, 10,000 bbl/day for Water Reuse.

Ideal for distributed operations, our three-stage trailer-mounted mini DAF system features complete management of liquids and solids. Chemical treatments are tailored to the source of produced water and flowback streams. This design features a twin wire belt press which allows continuous sludge dewatering.

Centralized Treatment Design, 60,000 gpd

Tank Bottom / Oily Sludge Management

• Hot water pre-soak• Oil sludge washing• Three phase separation• CZDAF oil recovery and water treatment• Belt press sludge dewatering• Bio-remediation of dewatered sludge

CZDAF Unit

Hot-water Washing

&Oil Separator

Oily Sludge

Makeup Water

Hot Water

Boiler

Oily Water

Oil Tank

Filters

Belt Press

Dewatered Sludge

Biodegradation of Residual Oil

Recovered Oil

Road Pavement & Agricultural

Uses

Sludge Holding Tank

Tank Bottom Sludge

DAF Effluent

Clear Water Tank

Filtrate

Recycled Water

Drilling Mud Recovery & Closed Loop Drilling

Slurry Pump

Shale Shaker

Mud Tank

Specific Gravity

Adjustment

Fine Cuttings

Drilling Fluid

Cuttings/ Drilling Debris

During Mud Phase

Press Feed Tank

Grinder

Filtrate Tank

CZDAF Unit

40-50% Dry Solidsto Road Pavement

TreatedEffluent

Reused For Drilling Mud

Makeup

New Drilling Mud

Drilling MudInjection

Oil Rigs

20 MicronsDrum Filter

Super Fines

Sludge

• Compact and effective• Easily integrated with existing shale shaker and mud

tank• Intercept and retain the specific compositions of

drilling mud• Maintain the homogenous status of drilling mud• Effectively remove the super fine particles and allow

water reuse• Dewater wasted fluid up to 45-50% dry solids content

• Residential and Communities

• Man Camp

• BOD and TSS removal

• Nitrification & Denitrification

• Total phosphorus removal

• Existing plant retrofit

• Wastewater reclamation

Municipal Wastewater Treatment and Reuse

Pressurized Bio-media Reactors

(Ideal For Strip Malls/Man Camps)

Bio-DAF Unit

(50,000-250,000 GPD)

• Compact and effective

• Onsite assembling in three days

• Ideal For small communities

10,000 GPD

7,500 GPD6,000 GPD

4,500 GPD

3,000 GPD1,500 GPD

• Partial BOD reductions

• Effective TSS removal

• FOG recovery

• Phosphorus removal and struvite fertilizerproduction

• Yellow grease and animal feed productions

Poultry And Meat Processing FOG Recovery and Wastewater Treatment And Reuse

From Meat or Food

Processing Plant

Circular Zoned

DAF UnitTreated

Effluent to Sewer or

City WWTP

Recovered FOG Tank

Tricanter #1

Recovered Yellow Grease

Dry solids to animal feeds

Stick Water

To CZDAF

Granular

struvite fertilize

r

Pick Heater

#2

1st ZoneFOG Scum

Sludge Holding Tank

Struvite

Slurry Tank

2nd ZoneSludge

3rd ZoneSludge

Recovered Biodiesel

Feedstocks

2nd ZoneCoagulant

/Flocculant

3rd ZoneMgCl2/

Flocculant

Dry solids to Fertilizer

Tricanter #2

Pick Heater

#1

Steam

Steam

DecantTo

CZDAF

DecantTo

CZDAF

DecantTo

CZDAF

Parameter Poultry Beef Discharge Limits (No

Surcharges)

Secondary Discharge

Limits

Flow 7 gallons/bird 4500 Liter/1000 kg LWK

TSS, mg/L 811 4,100 250* 30

BOD, mg/L 1,904 6,290 250* 30

FOG, mg/L 402 3,700

TN, mg/L 62.9

TP, mg/L 21 5

• Turnkey brown grease handling facilities

• Biodiesel feedstock productions

• Wastewater pretreatment

Brown Grease Recovery and Wastewater Treatment

Centralized Brown Grease Recovery Plant-100,000 GPD

Inlet Screen

EQ Tank

Primary DAF Unit

Bio-DAF System

Treated Effluent to

WWTP

FOG Pre-heating Tank

Tricanter

Recovered oil to biodiesel feedstock

Dry solids to composting or fertilizer

Trap Grease Hauler

Slick Water

Bio-DAF Feed Tank

Finished Oil Tank

• Continuously clean grease trap;• Inline installation;• Eliminate plugs in pipe and septic tanks;• Eliminate surcharges from downstream POTW.

Advanced Trap Grease Collection System

Model CCGT-7500 CCGT-12000 CCGT-36000 CCGT-60000

Flow, gpd 7,500 12,000 36,000 60,000

Service Person 400 600 2,000 3,000

Diameter, ft 3 4 6.67 10

Height, ft 402 3,700

Electricity 3 Phase, 240/480 VAC

3 Phase, 240/480 VAC

3 Phase, 240/480 VAC

3 Phase, 240/480 VAC

CCGT-12000

Underground Installation

CCGT-12000

Aboveground Installation

Advanced Trap Grease Collection System

CCGT-36000 Underground

Installation

CCGT-36000

Aboveground

Installation

• Virgin Pulp Mill & Recycle Pulp Mill

• Food & Beverage

• Dairy & Rendering wastewater pretreatment

• Mining Wastewater Treatment and Sludge Dewatering

• Chemical and Pharmaceutical

• Mining Camps

• Chicken farm phosphorus removal

Industrial Wastewater Treatment And Reuse

WET CZDAOF installed in paper pulp industry

![1 “Disaster Lights” & “Disaster Heavies:” Relevant Emergency Preparedness Information for People with Disabilities [ILRU Webcast 2 Parts], 11/9,16/2007.](https://static.fdocuments.in/doc/165x107/551b6cbb550346a10a8b471e/1-disaster-lights-disaster-heavies-relevant-emergency-preparedness-information-for-people-with-disabilities-ilru-webcast-2-parts-119162007.jpg)