Welding Carbon Steel

Transcript of Welding Carbon Steel

8/8/2019 Welding Carbon Steel

http://slidepdf.com/reader/full/welding-carbon-steel 1/12

WELDING CARBON STEEL

The following information is not intended to be a guide to welding structures in

Industry. It is intended as a basic introduction to a complex subject known as

Metallurgy. In many Industrial settings the procedure to be followed when welding a

given type and grade of metal is established through testing to a specific Code or

Standard or through practical experience. However; it may be useful for the welder tounderstand the affects of welding on metal. One of the most widely welded

classifications of metal is the group of carbon steels.

WHY DOES THE WELDER NEED TO KNOW ANYTHING ABOUT THE STEEL

HE IS ASKED TO WELD?

In many cases the welder needs only to know the techniques of actual welding and

does not need to be concerned about the type or grade of steel being welded. This is

because a large amount of steel used in fabricating a metal structure is low Carbon

or plain carbon steel (also called mild steel). When welding these steels with any of

the common arc welding processes like Stick Mig or Tig there are generally few

precautions necessary to prevent changing the properties of the steel.Steels that have higher amounts of Carbon or other alloys added may require

special procedures such as preheating and slow cooling, to prevent cracking or

changing the strength characteristics of the steel. The welder may be involved in

following a specific welding procedure to ensure weld metal and base metal have the

desired strength characteristics.

WHAT ARE THE TERMS USED TO DESCRIBE THE CHARACTERISTICS OF

METAL?

Before reviewing the weldability of steel we need to understand the terms used to

describe the changes that may occur due to welding the steels.Review the definitions below as an introduction and refer back to them as necessary.

MECHANICAL PROPERTIES OF STEEL

Mechanical properties are the properties of the steel reacting to some load or

mechanical working such as bending, machining, or shaping. Mechanical properties

affect how the metal will react when fabricating a structure. While Iron is a

relatively soft metal that can be easily shaped or formed, other elements may be

added to the iron to give it a specific strength or enhanced mechanical properties.

The terms used to describe these properties are as follows:

STRESS

Stress is defined as the load per unit area and is measured in pounds per square

inch. Stress is pressure acting on a weld or metal to pull it apart, twist it, compress

it, or shear it, depending on the direction and type of load. In some cases one or

more of the above loads may be applied in varying degrees.

8/8/2019 Welding Carbon Steel

http://slidepdf.com/reader/full/welding-carbon-steel 2/12

STRAIN

Strain is the resulting deformation of the applied stress. For example: If a piece has

stress acting to bend it, the amount or degree to which the piece bends is the

measure of the strain. In other words stress and strain go together, for instance; if

you stress your back by lifting or carrying a heavy load the resulting pain or damage

is the strain.

ELASTICITY

Elasticity is the property of a material that when stressed or has a force applied

allows the shape to return to its original shape. In other word when the load is

removed there is no appreciable strain or deformation. Metals have a limit of

elasticity and when the load increases beyond the limit deformation or strain will

occur.

PLASTICITY

Plasticity is the ability of a metal to be deformed or shaped without rupture. For

example a piece of plain carbon steel can be shaped easier then a piece of tool steelwithout rupturing or breaking.

STRENGTH

Strength is the ability of a material to resist deformation. Plasticity and strength

work together since plasticity is the ability to take the applied load its strength is the

ability to withstand or resist deforming under the load. Metals with high strength

will deform less than metals with lower strength.

TENSILE STRENGTH

The tensile strength is the ability of a metal to withstand forces acting to pull it

apart and is measured in pounds per square inch. For example: the E-7018 electrode

produces a weld with a tensile strength of 70,000 pounds per square inch as shown

by the first two digits of its number.

DUCTILITY

Ductility is the ability of a metal to be easily shaped or elongated without failure or

rupture. Generally metals with high tensile strength are tougher but have lower

ductility and ductile metals are softer and have lower tensile strength. Ductility is

the property that allows metals such as aluminum and copper to be drawn into wire

forms.

HARDNESS

Hardness is defined as the ability of a material to resist indentation and is a function

of its elastic and plastic properties. The harder the metal the more it is able to resist

wear and tear.

8/8/2019 Welding Carbon Steel

http://slidepdf.com/reader/full/welding-carbon-steel 3/12

MALLEABILITY

Malleability is the ability of a metal to be shaped by compressive forces without

rupture. Metals with good malleability can be rolled into thin sheets. For example

gold has high malleability and can be rolled and shaped into thin sheets.

BRITTLENESS

Brittleness is basically a term used to describe the lack of plasticity or ductility. A

brittle metal cannot be easily deformed or shaped. For example: a hardened steel or

cast iron may be brittle and show very little resistance to impact or shock.

PHYSICAL PROPERTIES OF STEEL

Physical properties are related to the structure and nature of the steel or Alloy and

include density, electrical conductivity, heat conductivity, melting point, magneticproperties, reflectivity, and coefficient of thermal expansion.

Of the above properties, one of the most important is the coefficient of thermal

expansion. Steel when heated increases in length, width, and thickness. The increase

in unit length when a metal is heated one degree is called its coefficient of thermal

expansion. When welding takes place a localized area is heated to melting

temperature and begins cooling, steel that has a high coefficient of thermal

expansion such as Stainless Steel will warp or change dimensionally more than

regular steel. Distortion or warping due to welding will be covered in a later lesson.

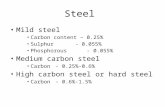

CARBON STEELS

WHAT IS CARBON STEEL?

Carbon Steel is principally a mixture (or Alloy) of Iron and Carbon with small

amounts of silicon, sulfur, phosphorous, and manganese. Other elements may be

added to the steel to impart a specific quality to enhance its usefulness.

An Alloy may be thought of as a recipe, similar to a recipe for chicken soup that has

ingredients to enhance the flavor, Iron has other elements or ingredients to enhance

the properties of the Iron.

In plain carbon steels it is the Carbon additive that has the greatest effect on the

strength and weldability of the steel.

The carbon is added to the Iron in varying amounts to harden or strengthen the

steel. As carbon content increases the hardness and tensile strength increases and

the ductility, plasticity, and malleability will decrease.

The reason the carbon content or carbon recipe varies is to produce a family of

steels that exhibit the desired characteristics for a given application.

HOW DOES THE AMOUNT OF CARBON AFFECT WELDABILITY OF

STEELS?

8/8/2019 Welding Carbon Steel

http://slidepdf.com/reader/full/welding-carbon-steel 4/12

In general as the carbon content increases the weldability (how easily welded)

decreases. In other words the higher the carbon content the more likely special

procedures such as preheating, interpass temperature control and postheating are

necessary.

The following chart groups carbon content, typical uses and weldability.

Group Content % Typical usage Weldability

Low

carbon

steel

0.15

Maximum

Welding electrodes, rivets

and nails

softer easily formed shapes.

Excellent weldability with all processes usually no

preheat interpass or postheat necessary

Mild

steel

Plain

carbon

0.15 to 0.30 Plate, angle, and bar stock

for general fabrication.

Mild steel accounts for a

large segment of welded

parts of Industry where

good plasticity and ductility

is required.

Readily weldable with all processes without

preheat, interpass, or postheat except for very

thick sections.

Medium

carbon

steel

0.30 to 0.50 Used for Machine parts,

gears, and where parts may

be hardened by heat

treating.

Parts may be readily welded with all process if

preheat, interpass temperature controls, and post

heat recommendations are followed.

Use Low hydrogen Electrodes and appropriatefiller wire.

Heat treating after welding may be applied

High

carbon

steels

0.50 To 1.0

Springs, Dies, Railroad

Track, Many tools, Band

saws, and Knives. Also used

where a sharp edge is

required.

Usually require preheat interpass temperature

control and postheat. Special heating and cooling

procedures in a furnace such as normalizing may

be required to restore the properties of the metal

after welding. High carbon Electrodes designed

for welding tool steels or the specific alloy are

readily available from welding supply companies.

Note: As carbon increases steel toughness and welding precautions increase

8/8/2019 Welding Carbon Steel

http://slidepdf.com/reader/full/welding-carbon-steel 5/12

8/8/2019 Welding Carbon Steel

http://slidepdf.com/reader/full/welding-carbon-steel 6/12

widely used 1020 steel, the first digit indicates carbon steel the second digit indicates

no predominant alloy other than carbon and the last two digits indicate .20 carbon

content.

The following shows some of the AISI SAE series designations of steel with xx

representing the range of carbon content for the group.

SERIES DESIGNATION TYPE OF STEEL

Carbon Steels

10xx Plain Carbon

11xx Machining Resulferized

12xx Machining Resulferized Phospherized

Manganese Steels

13xx Manganese 1.75Nickel Steels

31xx Nickel 3.5

25xx Nickel 5.0

Nickel Chromium Steels

31xx Nickel 1.25 Chromium 0.60

32xx Nickel 1.75 Chromium 1.00

33xx Nickel 3.5 Chromium 1.5

34xx Nickel 3.0 Chromium 0.77

Molybdenum Steels

40xx Molybdenum Carbon

41xx Molybdenum Chromium

43xx Molybdenum Nickel ChromiumNickel Chromium Molybdenum Steels

43xx Nickel Chromium Molybdenum

Nickel Molybdenum Steels

46xx Nickel Molybdenum

48xx Nickel Molybdenum

Chromium Steels

50xx Chromium

51xx Chromium

As shown by the above chart the first group of steels are the Carbon steels. The

other groups of steels have additional elements ( alloys) added to enhance their

properties in some specific way.

HOW DOES THE ADDITIONAL ELEMENTS IN THE ABOVE CHART AFFECT

THE STEEL AND WELDABILITY?

Low alloy steels are Carbon steels that have additional elements added (alloyed) to

produce a classification of steel that has a specific benefit for production use.

Although Carbon is the main alloy that affects hardenability and weldability other

8/8/2019 Welding Carbon Steel

http://slidepdf.com/reader/full/welding-carbon-steel 7/12

elements also harden steel and play a role in the weldability of steel. For example

Manganese and Molybdenum aid in hardening steels. For this reason a formula may

be applied to a classification of steel to roughly determine the hardenability and

hence the weldability and need for pre-heating. One example of a formula is shown

below.

Carbon equivalent for alloy steels

CE = % C + %Mn + Ni + Cr + Mo + V

6 15 6 4 5

CE = Carbon Equivalent

C = Carbon

Mn = Manganese

Ni = NickelCr = Chromium

Mo = Molybdenum

V = Vanadium

Manganese

Manganese is used to harden steels and increase its toughness and strength. High

manganese content coupled with increased carbon content lowers the ductility and

weldability. Consideration of preheat and or postheat techniques usually apply.

Molybdenum

May be used in conjunction with other elements to aid in hardening and provide

steel with good strength at elevated temperatures. Preheating may be required for

welding and they are often heat treated after welding.

Nickel

Nickel may be used to Increase toughness and impact strength and improve

corrosion resistance. Good strength and ductility may be obtained even with lower

carbon content. Depending on the amount added special procedures may be

necessary when welding.

Chromium

Chromium helps improve the hardenability of steels and improves wear resistance,

heat resistance, and corrosion resistance. Depending on the amount added special

procedures may be necessary when welding.

Chromium and Chromium Nickel are used in the production of Stainless Steel.

8/8/2019 Welding Carbon Steel

http://slidepdf.com/reader/full/welding-carbon-steel 8/12

The Strength and Mechanical properties of carbon and alloy steels may be changed

or shaped for a specific application by heat treating in furnaces or ovens. When two

pieces of metal are welded using any of the commonly used arc welding processes:

Stick, Mig, Or Tig the metals and filler are heated to the melting temperature underthe arc and allowed to solidify to form the weld.

HOW DOES THE WELDER KNOW HOW TO WELD A GIVEN STEEL

STRUCTURE?

The best way for a welder to know how to weld a particular steel or steel

classification is through the use of a Welding Procedure Specification (WPS). A

WPS is a written set of instructions (specifications) detailing the welding procedure,

joint preparation, filler metal, current type and range as well as any required

preheat, interpass temperature controls and postheat treatments. Whenever possible

welders request and use a Welding Procedure Specification for the type and grade of metal they are welding.

A welding Procedure Specification is developed by engineering or inspection

personnel using qualified welders to weld a specific type of metal and joint

configuration that will be used on the job, while recording the welding parameters

and variables. The completed joint is then tested in accordance with a specific Code

or Standard. The resulting information is written on a form called a Procedure

Qualification Record. The information from the Welding Procedure Qualification

Record is used to write the Welding specification and as long as the procedure is

carefully followed the resulting welded products will have the required strength

characteristics.

Some companies that do not have a formal Welding Specification have through

practical experience developed a set of instructions that the welder must follow to

successfully weld the given project.

If no Welding Procedure is provided at a minimum the welder MUST know what

the base metal is and find out if special precautions are necessary for welding.

There should always be some method of traceability for metals used to fabricate

parts. Metals sections and shapes should be stamped color coded or made from

known materials. There are ways to test unknown metals through appearance,

magnetic properties or spark testing; however, these test are subjective and may not

be reliable for all cases. When you can trace the material through purchase orders

or metal identification you know or can find out how to weld it.

WHAT IS THE HEAT AFFECTED ZONE AND HOW DOES IT AFFECT

WELDABILITY?

The heating and cooling action that occurs when welding is a form of heat treating

in the localized area of the puddle and weld joint that may result in changes to the

mechanical properties of the base metal and surrounding area. The area most

8/8/2019 Welding Carbon Steel

http://slidepdf.com/reader/full/welding-carbon-steel 9/12

affected by heating and cooling during welding is called the HEAT AFFECTED

ZONE (HAZ)

THE HEAT AFFECTED ZONE

The heating and cooling rate of welding directly under the arc is from the melting

temperature to normal temperatures and may occur relatively quickly or methods

may be used to slow the cooling rate of the joint. These methods include postheating

the weld area with an oxy-fuel torch, blanketing the weld area, or using a precise

heating and cooling method in a furnace or industrial setting.

The more expensive and precise method of using a furnace under controlled

conditions restores the mechanical properties of the weld joint and the surrounding

base metal.

The area surrounding the joint is heated to various temperatures depending on the

distance from the arc, the heat input of the process and the number of weld passes.

This area is referred to as the Heat Affected Zone.

The grains structure in the melted weld area may form a desirable size and shape,

while the grain structure of the surrounding heat affected area may change to a less

desirable shape and size and may cause cracking when welding on medium or high

carbon steels. Often when welding a hardenable steel the heat affected area can

harden to undesirable levels, while welding an already hardened steel may result in

a softened heat affected zone with loss of desired hardness.

The heat affected zone may also have locked in stresses that can lead to problems

when the welded structure is in service. Some industries employ a heat treating

process called stress relieving to relieve residual stresses due to working or welding

the structure.

It is imperative to use the correct electrode for the application so that weld metal is

compatible with the base metal and fewer changes occur due to the carbon or alloy

content of the filler wire. Electrodes are available for welding tool steels and Cast

iron.

8/8/2019 Welding Carbon Steel

http://slidepdf.com/reader/full/welding-carbon-steel 10/12

When welding thick sections, medium carbon, high carbon, and high alloy steels

check the recommended procedures for control of the heating and cooling rate

There are heat treating options such as annealing or normalizing that may be used

to restore the grain structure of the welded piece.

When welding low carbon, mild steels and most low alloy steels the heat affected

area does not change the properties of the metal enough to become a problem

regardless of the cooling rate.

The heating and cooling that occurs in the heat affected area and surrounding metal

may also lead to heat distortion of the parts being joined.

Procedures may be used before, during, and after welding to minimize distortion.

WHAT IS HEAT DISTORTION?

Steel when heated increases in length, width, and thickness. The increase in unit

length when a metal is heated one degree is called its coefficient of thermal

expansion. I f a small square block of steel were heated evenly under ideal

conditions it would expand with the heat and contract when cooling relatively

evenly. When welding a piece of steel only the joint and surrounding area is heated

and cooled. This cause uneven expansion and cooling and the piece begins to warp

or distort. Uncontrolled Distortion may lead to a serious dimensional defect or lead

to failure of the part. Steps may be taken before, during, and after welding to

minimize or control the effects of heat distortion.

WHAT ARE SOME OF THE THINGS A WELDER CAN DO BEFORE WELDING

TO LIMIT HEAT DISTORTION?

Joint Preparation

The joint should be planned and prepared to limit the amount of weld and weld

passes. For example: Wide angle V grooves welded from one side would distort more

than double V grooves welded from both sides.

Select the proper Equipment

Higher welding speeds using iron powder electrodes (E-7018) and larger diameters

may reduce the amount and effect of heat distortion. Semi-automatic and fully

automatic welding processes limit the heat input and distortion.

Use Clamps Jigs and Fixtures

Jigs and fixtures with clamps hold parts in alignment and reduce the free movement

of parts from heat expansion. The clamps are left in place until the parts are welded

and cooled. In addition to clamps pieces called stiffeners may be temporarily added

to areas that tend to distort and removed when the part cools.

8/8/2019 Welding Carbon Steel

http://slidepdf.com/reader/full/welding-carbon-steel 11/12

WHAT ARE SOME OF THE THINGS A WELDER CAN DO DURING WELDING

TO LIMIT HEAT DISTORTION?

Sequencing Welding

Use a skip or backstep method of welding to distribute the heat around the joint.

This involves making shorter welds at different locations of the joint then joining

them together.

Welding the joint

If possible two welders weld opposite sides of the joint at the same time.

Use the smallest size fillet welds practical to reduce heat input.

If solid welding is not necessary for strength use intermittent welding and stagger

the sequence.

8/8/2019 Welding Carbon Steel

http://slidepdf.com/reader/full/welding-carbon-steel 12/12

Weld flat or horizontal positions with larger size electrodes that allow for more weld

deposit at faster speeds whenever practical. Vertical positions and multiple pass

welds result in more heat input.

CONTROL OF DISTORTION AFTER WELDING

Distortion is more difficult to control after welding. Techniques like alternating

heating and cooling to remove warpage called straightening require a degree of skill

and practice. Postheating to remove stresses and warpage in controlled

environments such as normalizing and annealing, often involving the use of furnaces

is usually done by qualified personnel.

SUMMARY

Although the vast majority of carbon steels used in fabricating parts are mild steelor low carbon and presents little difficulty in welding, some carbon steels that have

more carbon such as tool steels, high alloy steels and cast Iron require special

procedures to prevent cracking and weld failure. The welder should know the type

of steel he is asked to weld to prevent problems that may lead to questions of his or

her ability. If you are unsure ask questions and research the type of steel and its

weldability.