Weld Joints. Butt Joint Corner Joint Outside Inside.

-

Upload

malcolm-berry -

Category

Documents

-

view

245 -

download

4

Transcript of Weld Joints. Butt Joint Corner Joint Outside Inside.

Electrode #’sElectrode #’s

Tensile Strength

60 = 60,000 psi

70 = 70,000 psi

80 = 80,000 psi

90 = 90,000 psi

Welding Position

1 = All Positions

2 = Flat/Horizontal

3 = Flat Only

Special Characteristics

0 = Deep/DC + / Fast Freeze

1 = Deep/AC/DC + / Fast Freeze

3 = Shallow /AC/DC+/DC-

8 = Medium / AC/DC+/Low Hydro

E 60 1 1

Electrode

X 1000 lbs sq inch Tensile Strength

Position

Special Characteristics•Current Type

•Flux Characteristics

•Metal Type

•Penetration

E 60 11E 60 11

E 60 1 1

Electrode

60,000 psi

All Position

Special Characteristics•Deep Penetration

•Cellulose Potassium flux

•Fast Freeze

•AC/DC+ (current)

E 60 1 0E 60 1 0

E 60 1 0

60,000 psi

All Position

Electrode

Special Characteristics•Deep Penetration

•Cellulose sodium flux

•Fast Freeze

•DC+ (current)

E 70 1 8 E 70 1 8

E 70 1 8

70,000 psi

All Position

Electrode

Special Characteristics•Medium Penetration

•Iron Powder Low Hydrogen flux

•AC/ DC+ (current)

E 60 1 3E 60 1 3

E 60 1 3

60,000 psi

All Position

Electrode

Special Characteristics•Shallow Penetration

•Titania Potassium flux

•AC / DC+ / DC - (current)

Electrode #’s Quiz SlideElectrode #’s Quiz Slide

Tensile Strength

60 = 60,000 psi

70 = 70,000 psi

80 = 80,000 psi

90 = 90,000 psi

Welding Position

1 = All Positions

2 = Flat/Horizontal

3 = Flat Only

Special Characteristics

0 = Deep/DC + / Fast Freeze

1 = Deep/AC/DC + / Fast Freeze

3 = Shallow /AC/DC+/DC-

8 = Medium / AC/DC+/Low Hydro

E Electrode

8080,000 psi tensile strength 2 Flat/Horizontal

Position 1 Fast Freeze

Deep Penetration

AC/DC +

E Electrode

60

60,000 psi tensile strength 3 Flat Position

Only8

Low Hydrogen Flux

Medium Penetration

AC/DC +

Arc LengthArc Length

Distance between the tip of the Distance between the tip of the electrode and the base metal. Also electrode and the base metal. Also known as Arc Gap.known as Arc Gap.

Long Arc = large GapLong Arc = large Gap Short Arc = Small GapShort Arc = Small Gap

Shorter the Gap = Cooler the ArcShorter the Gap = Cooler the Arc Longer the Gap = Hotter the ArcLonger the Gap = Hotter the Arc

Shielding GasesShielding Gases

Carbon Dioxide (C02)Carbon Dioxide (C02)

Co2/Argon Mix (Mixed Gas)Co2/Argon Mix (Mixed Gas) 75%/25%75%/25% 85%/15%85%/15% 90%/10%90%/10%

Wire SpeedWire Speed

Speed in Inches Per Minute (IPM) that Speed in Inches Per Minute (IPM) that the wire spools through lead cable the wire spools through lead cable out the nozzle.out the nozzle.

Changes the Amp in the Circuit Changes the Amp in the Circuit (Current)(Current)

Wire Stick-outWire Stick-out

Distance the wire protrudes past Distance the wire protrudes past electrode tip/nozzleelectrode tip/nozzle

Can:Can: Increase spatter Increase spatter (Too long or short)(Too long or short)

Burn tip/wire together Burn tip/wire together (create too much (create too much resistance)resistance)

Be adjusted to get smooth current Be adjusted to get smooth current (Volts/Amps)(Volts/Amps)

Gun AngleGun Angle

Angle the Gun/Tip is held from the Angle the Gun/Tip is held from the base metalbase metal

1)Base Angle (BA)1)Base Angle (BA)

2)Direction of Travel Angle (DOTA)2)Direction of Travel Angle (DOTA)

Forehand/backhandForehand/backhand

Forehand: Pushing the puddleForehand: Pushing the puddle 80 Degree Push80 Degree Push

Backhand: Dragging puddle Backhand: Dragging puddle 80 Degrees DOT. 80 Degrees DOT.

PorosityPorosity Gas Pocket in/on the weld that is a Gas Pocket in/on the weld that is a

defect in the weld. defect in the weld.

Causes:Causes: Long arcLong arc Dirty base metalDirty base metal Shielding Gas Off (needs to be 20 CF)Shielding Gas Off (needs to be 20 CF)

Gas OffGas Off To Low of PressureTo Low of Pressure To High of Pressure (causes Turbulence)To High of Pressure (causes Turbulence) Wind/WeatherWind/Weather

Non Ferrous=

Metal that does not contain Iron

Example: Aluminum/Copper, brass, lead, nickel, tin, titanium

Ferrous MetalFerrous Metal

Metal containing Iron

Example: mild steel Metal/Stainless, carbon steel/AR plate

Electrical TermsElectrical Terms

12. The arc is extinguished every 12. The arc is extinguished every half-cycle as the current passes half-cycle as the current passes through zero, usually at the rate of through zero, usually at the rate of 120 times per second.120 times per second.

Alternating CurrentAlternating Current

Current (electrons) is traveling in Current (electrons) is traveling in both directions back and forth.both directions back and forth.

Current is changing from positive-Current is changing from positive-NegativeNegative

Hertz: sign wave electrical currentHertz: sign wave electrical current

DC CurrentDC Current

DC: Direct CurrentDC: Direct Current Current is traveling in one directionCurrent is traveling in one direction

Polarity: Changing direction current flowsPolarity: Changing direction current flows

Ground to Electrode or Electrode to groundGround to Electrode or Electrode to ground

DC PolarityDC Polarity

DC + electrode is Positive and electrons DC + electrode is Positive and electrons will flow from neg to pos therefore will go will flow from neg to pos therefore will go from neg Ground to positive electrode. from neg Ground to positive electrode. Reverse polarity/DCEP/DC+Reverse polarity/DCEP/DC+

DC - Electrode is negative and electrons DC - Electrode is negative and electrons will flow from Neg to positive therefore will flow from Neg to positive therefore go to the positive ground clamp. go to the positive ground clamp. Straight polarity/DCEN/DC-Straight polarity/DCEN/DC-

AmpsAmps

The measure of Electrical FlowThe measure of Electrical Flow

1) electrons traveling 1) electrons traveling 2) Water running out of a garden 2) Water running out of a garden

hose hose would be compared to Amps would be compared to Amps 3) Water Flow/Electrical Flow3) Water Flow/Electrical Flow

VoltsVolts

Measure of Electrical PressureMeasure of Electrical Pressure

1) Force of electrons1) Force of electrons 2) Compared to your finger over a 2) Compared to your finger over a

running running garden hose to generate garden hose to generate more more pressure.pressure.

3) water pressure/Electrical pressure3) water pressure/Electrical pressure

CCCC

Constant CurrentConstant Current Amps (Current) stays constant (Vary Amps (Current) stays constant (Vary

Slightly) and there are change in voltage Slightly) and there are change in voltage during welding process.during welding process.

?? What changes Voltage??? What changes Voltage?

Typical processes: SMAW/GTAWTypical processes: SMAW/GTAW

CVCV

Constant VoltageConstant Voltage

Voltage stays constant (Varies slightly) Voltage stays constant (Varies slightly) and there are changes in Current (Amps) and there are changes in Current (Amps) during welding process.during welding process.

?? What changes Amperage??? What changes Amperage?

Typical processes: GMAWTypical processes: GMAW

D. There are four positions used D. There are four positions used when welding:when welding:

OverheadOverhead

D. There are four positions used D. There are four positions used when welding:when welding:

Horizontal Horizontal

D. There are four positions used D. There are four positions used when welding:when welding:

VerticalVertical

Flat Flat

The flat position produces welds that The flat position produces welds that are stronger than in any other are stronger than in any other position.position.

D. There are four positions used D. There are four positions used when welding:when welding:

9. The double V butt joint is 9. The double V butt joint is excellent for all load conditions and excellent for all load conditions and is often used on metal sections over is often used on metal sections over

¾ inch in thickness.¾ inch in thickness.

7. The single V butt joint is often used 7. The single V butt joint is often used on plate steel 3 /8 inch to ¾ inch in on plate steel 3 /8 inch to ¾ inch in

thickness. This joint is strong in loads thickness. This joint is strong in loads with tension forces but weak in loads with tension forces but weak in loads that bend at the weld root. The that bend at the weld root. The weld weld root root is the bottom of the weld groove is the bottom of the weld groove

opposite the weld face.opposite the weld face.

8. The single-bevel butt joint is used 8. The single-bevel butt joint is used on metals from 1/8 inch to ½ inch in on metals from 1/8 inch to ½ inch in

thickness and the bevel is 45 thickness and the bevel is 45 degrees.degrees.

4. The plug and slot welds are 4. The plug and slot welds are used to join pieces that used to join pieces that

overlap. The welds are placed overlap. The welds are placed in plug or slot holes. These in plug or slot holes. These

types of welds commonly take types of welds commonly take the place of rivets in welded the place of rivets in welded

structures.structures.

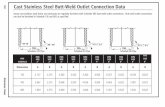

![One platform Multiple options...GOST Butt weld DIN Butt weld ANSI Butt weld Socket weld Female 1 pipe thread F-con. ) butt weld GOST Butt weld [mm] [in.] D A SOC FTP F G D A SOC FTP](https://static.fdocuments.in/doc/165x107/5fe23d7adfe1ef18be65fa23/one-platform-multiple-options-gost-butt-weld-din-butt-weld-ansi-butt-weld-socket.jpg)