· Web viewThe plat e of the rudder of a vessel requires extensive welding repairs and as a Second...

Transcript of · Web viewThe plat e of the rudder of a vessel requires extensive welding repairs and as a Second...

APRIL 2017

NAVAL ARCHITECTURE TIME ALLOWED - 3 HOURS

Instructions 1. Answer SIX questions only. Not more

than THREE from each section 2. All questions carry equal marks.3. Neatness in handwriting and clarity in

expression carries weightage 4. Illustration of an answer with clear

sketches / diagrams carries weightage5. All unused pages of answer

script must be cancelled out by two lines (X) across the pages.

Q1. A. Describe the preparation necessary before the application (in day dock) of sophisticated or approved long life coating to the underwater surface of the hull; B. State the significance of the roughness profile. C. List the different sophisticated costing which are available.

Answer:- Repeat Question. Refer to Q4 NA FEB 2017

Q2. The plate of the rudder of a vessel requires extensive welding repairs and as a Second Engineer you are requested to supervise – A. Suggest a suitable type of welding process; B. State with reasons FOUR common welding defects that can occur there; C. State what tests may be carried out before returning the rudder to service.

Answer:- (a)The rudder plating has cracked and around the region of the crack the metal has wasted considerably. The attending surveyor has recommended renewal of the corroded

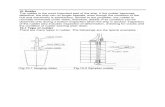

portion of the plating. The sketch showing the repair and the welding sequence is given below.

Repair sequence:- (1)The damaged portion of the plating is marked with white paint as approved by surveyor and then cropped and removed in pieces, since the plating is attached to the internal frames by plug welding

(2)The pieces of plugs sticking to the frames are to be gouged (burnt) out and the frame edges exposed to be ground smooth so the insert plate piece will enter flush.

(3) The material or specification of the rudder plating is given in the rudder drawing obtained from ship. Plating of same specification and thickness has to be used from which the piece will be cut out ,rolled to the correct curvature and then corners

Rounded, edges bevelled to suit the welding edge angle.

(4)The edges on the cut portion of the rudder are to be suitably bevelled and corners rounded.

(5)Since welding has to be done from one side only a backing strip has to be place inside under the welding joint and these four pieces are placed and held in place by suitably cutting the

frame edges to hold the backing strips as shown in the sketch. The thickness of the backing strips is 5 mm.

(6)The insert piece is placed in position and welding penetration (gap) allowance adjusted and the plate held firmly by clamps welded and wedged .

(7) Welding of the welding gap is commenced and is completed in three or four runs of welding. The plug holes marked on the insert plate are drilled with counter sinking and the holes are welded. Finally the protruding weld material is ground flush to smoothen the surface.

(b) The four common defects in welding are :-

i and ii. - To achieve a good quality join it is essential that the fusion zone extends the full thickness of the sheets being joined. Thin sheet material can be joined with a single pass and a clean square edge will be a satisfactory basis for a join. However thicker material will normally need edges cut at a V angle and may need several passes to fill the V with weld metal. Where both sides are accessible one or more passes may be made along the reverse side to ensure the joint extends the full thickness of the metal. Lack of fusion results from too little heat input and / or too rapid traverse of the welding torch (gas or electric). Excess penetration arises from to high a heat input and / or too slow transverse of the welding torch (gas or electric). Excess penetration - burning through - is more of a problem with thin sheet as a higher level of skill is needed to balance heat input and torch traverse when welding thin metal.

iii. Porosity - This occurs when gases are trapped in the solidifying weld metal. These may arise from damp consumables or metal or, from dirt, particularly oil or grease, on the metal in the vicinity of the weld. This Refer to Question S no 10 can be avoided by ensuring all

consumables are stored in dry conditions and work is carefully cleaned and degreased prior to welding.

iv. Inclusions - These can occur when several runs are made along a V join when joining thick plate using flux cored or flux coated rods and the slag covering a run is not totally removed after every run before the following run.

(c)Tests :- After the repair the rudder is subjected to a hydrostatic test by filling the rudder hollow space from the top plug hole , with a rubber pipe connected to the plug hole and extending the pipe end to the tropical load line level. the pipe end is fitted with a large funnel through which water is filled in till the water is retained at the funnel surface. The repair area is checked by hammering the weld joints and ensuring that the weld joints are in good condition and no leaks found.

Q3: With reference to fatigue of engineering components explain the influence of stress level and cyclical frequency on expected operating life; B. Explain the influence of material defects on the safe operating life of an engineering component; C. State the factors which influence the possibility of fatigue cracking of a bedplate transverse girder and explain how the risk of such cracking can be minimized.

Answer:-Repeaat Question. Refer to Q 3 NA JAN 2017

Q4: With regard to the carriage of crude oil and its associated products: i. Sketch and describe the operation of an explosimeter suitable for testing pump rooms or tanks; ii. State why false readings are likely to be given by the explosimeter. iii. State the publication that gives guidance on safety.

Answer:- The combustible gas indicator shown diagrammatically (Figure) consists of a wheat stone bridge with current supplied from a battery. When the bridge resistances are balanced, no current flows through the meter. One resistance is a hot filament in a combustion chamber. An aspirator bulb and flexible tube are used to draw a gas sample into the camber. The gas will burn in the presence of the red hot filament causing the temperature of the filament to rise. Arise of temperature increases the resistance of the filament and this change of resistance unbalances the bridge. Current flow registers on the meter which is scaled in percentage (LEL) or p.p.m.

A lean mixture will burn in the combustion chamber, because of the filament. The instrument and batteries must be tested before use and the samples are taken from as many places as possible particularly from the tank bottom. It is possible to obtain a reading for any hydrocarbon but other combustible gases on an instrument which is scaled for hydrocarbons, false readings would be obtained. Detection of other vapours must be by devices intended for the purpose (see below).

The explosimeter is primary a combustible gas detector but will also give guidance with regard to the safety of a space for entry by personnel. If a space has been ventilated to remove vapours. The remaining concentration can be measured by the explosimeter, provided that it is below the lower flammable or explosive range. Generally any needle deflection above Zero is taken as indicating a

toxic condition.

(2) False readings are likely when oxygen content of the sample is low or when inert gas is present.

The instrument is designed for detecting vapour in a range up to the lower flammable limit and with large percentages of gas (rich mixture) a false zero reading may also be obtained.

(3) The publication which gives information on safety matters is the code of safe working practices published by the IMO.

Q5 . SAME AS Q3. SECTION II

Q6. Describe how water tightness is maintained where bulkheads are pierced by longitudinal beams or pipes. B. A triangular bulkhead is 7 m wide at the top and has a vertical depth of 8 m. Calculate the load on the bulkhead and the position of centre of pressure if the bulkhead if flooded with sea water on only side - (i) to the top edge; (ii) with 4 m head to the top edge.

Answer:- (A) Refer to Q 4 NA FEB 2017

(B) FOR SOLUTION REFER TO P f10ch 1 test examples REEDS NA.

Q7: An oil tanker 160m long and 22m beam floats at a draught of 9m in seawater. Cw is 0.865. The midships section is in the form of a rectangle with 1.2m radius at the bilges. A midship tank 10.5m long has twin longitudinal bulkheads and contains oil of 1.4m3/t to a depth of 11.5m. The tank is holed to the sea for the whole of its transverse section. Find the new draught.

Answer:- For solution refer to EX 15 CLASS 1 EXAMINATION QUESTIONS REEDS NA.

Q8: What is meant by the Admiralty Coefficient and the Fuel Coefficient? B. A ship of 14900 tonne displacement has a shaft power of 4460 Kw at 14.55 knots. The shaft power is reduced to 4120 Kw and the fuel consumption at the same displacement is 541 kg/h. Calculate the fuel coefficient for the ship

Answer:- (A)It is sometimes necessary to obtain an approximation to the power of a ship without resorting to model experiments, and several methods are available. One system which has been in use for several years is the Admiralty Coefficient method. This is based on

the assumption that for small variations in speed the total resistance may be expressed in the form:

Rt ἀρ*S*Vn

It was earlier seen that S ἀ∆2/3

Hence with constant density

Rt ἀ∆2/3*Vn

But power ἀ Rt*V

ἀ ∆2/3Vn+1

or power =( ∆2/3Vn+1)/ a coefficient

The coefficient is known as Admiralty coefficient.

If we put n=2 , the formula reduces to

Admiralty constant = ( ∆2/3V3)/ shaft power P

(B) Fuel Coefficient:-The Fuel consumption of a ship depends upon the power developed, indeed the overall efficiency of power plant is often measured in terms of the specific fuel consumption which is the consumption per unit of power, expressed in kg/h. Efficient diesel engines may have a specific fuel consumption of about 0.20 kg/kW h, while that for a steam turbine may be about 0.30 kg/kW h. The specific fuel consumption of a ship at different speeds follows the form shown in Fig.

Fuel consumption per day = ( ∆2/3V3)/ Fuel coefficient.

(B) The problem is from REEDS NA class 1 examination questions ex 39 . refer to solution on page 348.

Q9. The ½ ordinates of a water plane at 15m intervals, commencing from aft, ar. 1, 7, 10.5, 11, 11, 10.5, 8, 4 and 0m. Calcul ate: i. TPC; ii. Distance of the centre of flotation from midships. Iii. Second moment of area of the water plane about a transverse axis through the centre of flotation.

Answer:- The problem is from REEDS NA class 1 examination questions ex 46 . refer to solution on page 353.

Q10: The following data are available from the hydrostatic curves of a vessel

Q10: The following data are available from the hydrostatic curves of a vessel.

DRAUGHT (M) KB(M) KM(M) I(M4) 4.9 2.49 10.73

65.25*102

5.2 2.61 10.79 68.8 *102

Calculate the TPC at a draught of 5.05M

Answer:- KM-KB =BM

Hence at 4.9 M draught BM = 10.73-2.49 =8.24 M

The displacement volume = 65.25 *102/8.24= 791.87 M3

The displacement volume at 5.2 M draught = 68.8*102/(10.79-2.61) = 841 M3

The difference in volume at these two draughts = 841-791.87=491.3 M3

The mean draught between 5.2 and 4.9 metres is 5.05 M. The waterplane at this draught is the mean waterplane and its area = 491.3/0.3 = 1637.7 M2

The required TPC= (1637.7/100)*1.025 = 16 78 TONNES.

( note This example is not copied correctly . I have modified the data to give a realistic answer.)