WE LOVE THAT YOU ARE PART OF THE GENIE STORY.

Transcript of WE LOVE THAT YOU ARE PART OF THE GENIE STORY.

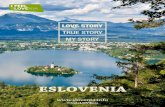

FROM HUMBLE BEGINNINGS TO GLOBAL SUCCESS

© 2016 Terex Aerial Work Platforms. All rights reserved.

No part of this publication may be reproduced or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or by any information storage or retrieval system, without written permission of the copyright holder.

Published by Terex Aerial Work Platforms.

Published by : Imprimerie CPN 28320 Gallardon, France Created By : The Genie Team and his partners (Nimbus, HSE & E. Pasty)

OUR STORYDiscover some of the most extraordinary examples of

how Genie has helped build the future over the past 50 years...

WE LOVE THAT YOU ARE PART OF THE

GENIE STORYGENIE STORYGENIE STORYGENIE STORYGENIE STORYGENIE STORYGENIE STORYGENIE STORYGENIE STORYGENIE STORY

Thank you for joining the global Genie Team in celebrating 50 Years serving aerial markets around the world. We love that you are part of the Genie Story, helping us grow from Bud Bushnell’s garage in 1966 to the 4,500 team members serving you today. You trusted us, and together we’ve built this industry and defi ned it with Genie aerials, taking people safely to heights.

From the very beginning you, our Genie customers, have been the center of our world. We learned to measure our success by how Genie aerials performed in the real world, every day. We learned tough lessons, made some mistakes, and found that you multiplied our successes when we worked together to build new and better ways of providing access. You taught us there are always more opportunities, new applications, rental markets, and products. Together, we grew into the premier full line boom, scissor, telehandler, material lift, and light tower manufacturer, serving hundreds of markets on every continent. This is the story of a team that is with you when and where you need us.

Fifty years is just the beginning. As you take some time to look through our story, know that we are fi rmly committed to growing on the values our founders taught us years ago. The best is yet to come and we celebrate the opportunity to build the future with you.

Thank you for your business,

Matt Fearon President of Terex Aerial Work Platforms

“Taking You Higher is what Genie is about. Our tagline is an ever-present reminder of our unwavering focus on customer needs and our continued development of safe, innovative aerial solutions that get the job done.”Genie Marketing, Redmond USA.

76

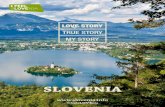

A MASSIVE FRAMEWORK: LOUIS VUITTON FOUNDATION

GENIE® Z™ BOOMS SUPPORTED THE CONSTRUCTION OF THE LOUIS VUITTON FOUNDATION FOR CREATION IN PARIS, FRANCE

Contemporary art has found a new Parisian home. Housed fi ttingly in a building designed by world-renowned architect Frank Gehry, the Louis Vuitton Foundation for Creation opened its doors to the public in 2014, welcoming art lovers and architecture buffs to a striking structure located in the Bois de Boulogne, adjacent to the appealing attractions of the Jardin d’Acclimatation. Perhaps the most notable feature of the building is its 145,313 sq ft (13,500 m2) of glazed surfaces, consisting of 3,430 individually shaped glass panes, no two of which are alike, and whose installation posed a formidable challenge.

FEATURES THAT MADE ALL THE DIFFERENCE

A small army of Genie® diesel articulating booms worked tirelessly at the Foundation’s site, performing numerous tasks – including, of course, the extremely delicate installation of the glass panels. Their fully proportional controls, operated by an ultra-� exible magnetic-� eld joystick, made these platforms particularly ef� cient for jobs that required deft and precise manoeuvres amid a forest of beams and girders, even when the booms were extended to their maximum working height of 52.5 to 141 ft (16 to 43 m).Genie® Z™-135/70 boom: time-saving, work-easing kinematics.

98

“An important aspect of our role is to give a global voice to local needs so component inventory and global vendor management better support customers here.”Supply Chain Manager EMEAR.

AIRPORTS’ EXTENSION FOR RIO OLYMPIC GAMES

GENIE RUNS FOR MAJOR SPORTS EVENTS IN RIO DE JANEIRO, BRAZIL

The 2016 Olympic Games have been boosting the investment and execution of large infrastructure projects. A good example lies in the expansion and modernization of the country’s main airports. Many of these infrastructures rely on the performance and reliability of Genie equipment.

MULTI TASK PERFORMANCE ALL DAY LONG

Genie® Z™-45/25J articulating booms are assisting in the welding, painting and assembly of metal structures being installed in the new terminals of Manaus (AM) and Foz do Iguaçu (PR) airports.

Like the Z-45/25J, Genie® GS™-2646 electric scissor lifts were chosen for Guarulhos (SP) and Galeão (RJ) airports thanks to their ability to work hard all day long in con� ned environments where engine emissions, noise and tyre marks are not permissible.

1110

PROVIDING BRITISH ANTARCTIC SURVEY THE PERFORMANCE REQUIRED IN EXTREME CONDITIONS

The Halley Research Station is one of British Antarctic Survey’s (BAS) scientific research stations on and around the Antarctic continentis used for gaining a global perspective on ozone depletion, atmospheric pollution, sea level rise and climate changes. Five Halley stations have been built since 1956. The first four have all been buried by the immense snow accumulation and crushed until they were uninhabitable. Halley V was built on steel platforms that had to be raised annually to keep the structure above the snow surface.

A design competition was launched in June 2004 to provide an innovative design for the new Halley VI research station. Construction started during the 2007-2008 research season.

PERFORMING IN ANTARCTICA: HALLEY RESEARCH STATION

The solution: Genie® Z™-60/34 booms with four independent Loegering® track systems working hard in tough conditions.

“Genie Z-60/34 articulating booms had an advantage over other self-propelled machines when operating on snow and ice. Equipped with Loegering® QTS track system, wheel spin is eliminated, point loading and ground pressure are reduced by spreading the weight of the machine over a larger track surface area. Having no outriggers greatly reduced the overall work time of the task at hand, a great benefit considering the extreme weather conditions.”

Gary Fearon, Managing Director at Central Access. (2010)

1514

UNDERSCORED RELIANCE: QINGDAO BEIHAI SHIPYARD

GENIE® BOOMS AT THE CORE AT QINGDAO BEIHAI SHIPYARD, CHINA

If you trace the origins of aerial work platforms (AWP) in the Chinese market, you will fi nd shipbuilding and Genie booms at the core. One of the earliest companies to realize the advantages of working at height safely was Qingdao Beihai Shipbuilding Heavy Industry Co., Ltd (BSIC) based in the Qingdao, Shandong Province. Over the years, BSIC has purchased over 100 Genie telescopic booms which underscores their reliance and trust in the Genie name, including Genie S™-3200 and S™-3800 telescopic booms to meet the harsh conditions of the shipbuilding environment in China.

SAFELY DESIGNED FOR A SEVERE ENVIRONMENT

In 1996, BSIC was one of the � rst companies to contact Genie about self-propelled booms for shipbuilding.

The self-propelled booms offered the advantages of jobsite versatility, safety and ef� ciency that was readily adopted and helped to play a role in the rapid growth of China’s shipbuilding industry.

The S-3200 and S-3800 telescopic booms (renamed Genie S-100HD and S-120HD) equipped with high strength steel tubing, extruded handrails, cushioned bumpers, steel meshing, heavy-duty foot switches and steel platform rotator protection to avoid damage caused by salt air, welding slag and cutting debris.

“Genie® equipment has contributed to the success of our company. Plus, the after sales service provides us with a particularly quick response. Without the use of these booms, the shipyard is equipped with scaffolding and project time can take several months. The application of the booms has improved the effi ciency greatly and helps to ensure workers’ safety as well.’’

Mr. Liang, department head of BSIC. (2012)

16 17

ANTI-CORROSIVE COATINGON MUDDY GROUND IN GERMANY

With thirty-fi ve oil tanks that individually hold up to 26 million US GAL (100 million litres) on a 18.3 million ft (1,700,000 m2) site, application of an anti-corrosive coating to each structure was costly and time consuming for Die Nord-West Oelleitung GmbH, a holding facility that supplies crude oil to several refi neries across Germany. With contractors on-site for up to a year, the company needed equipment that would speed the project’s completion on challenging terrain.

FASTER MAINTENANCE OF GIANT OIL TANKS

FINISHING THE JOB SOONER AND BETTER

The solution was a Genie® S™-65 TraX telescopic boom, featuring a working height of 71 ft 5 in (21.86 m) and a four-point track system with a low ground pressure of 9.67 lb/sq in (0.68 kg/cm2) made light work of sodden and steep terrain.

During the painting process, the machine‘s full height drive function enabled the workers to reposition the S-65 TraX rapidly without needing to descend the boom. This cut man-hours considerably, compared to a static solution.

“We added Genie S-TraX models to our fl eet as, like elsewhere in Northern Europe, wet weather and mud are common in Germany, driving customer demand in many types of worksite.”

Ingo Horstmann of Ulferts & Wittrock, the site’s rental equipment provider. (2011)

20 21

AN ARTICULATING BOOM HELPSAN ARTICULATED GIANT IN SCOTLAND

Big Man Walking is a jaw dropping project created by The Puppet Lab and Puppet Animation, Scotland. Funded by the Scottish Arts Council ‘Inspire Fund’, the collaborative group created an amazing 26 ft (8 m) high giant called the Big Man. The giant walked with long strides across Scotland visiting fi ve different communities, each of which created its own local event to celebrate the Big Man‘s arrival.

HELPING BIG MAN WALKING!

“We approached Terex AWP because Genie is a leading brand in the access industry and we needed a product we could rely on due to the nature of live performances.”

Jon Clarke, Associate Producer for the project. (2009)

The Big Man is pretty big: 8 m (26 ft) and for one day only he lives his life on the street of Kirkcaldy.

CHOOSING THE RIGHT MACHINE

Part of the performance involved the dressing of the giant puppet, so the production team turned to Terex AWP for help in accessing different points of the Big Man. After consultation, a Genie® Z™-45/25J RT was selected.

This articulating Z™-boom’s working height (52 ft 3 in/16.07 m) and up-and-over clearance (24 ft/7.37 m) provided the production crew with the � exibility to access the puppet safely in a variety of different settings.

22 23

GENIE® TELEHANDLERS TAKE THE POLE POSITION

The fi rst Indian Grand Prix was held in 2011 at the new Buddh International Circuit in Greater Noida, India. It performed the highest viewer ratings of any Formula One event to-date, with an estimated global television audience of 500 million. For this special occasion, the event organisers required extremely reliable handling equipment offering high precision positioning. A fl eet of Genie hydrostatic transmission telehandlers, including a compact GTH™-3007 were chosen for the task.

INDIA’S FIRST F1 GRAND PRIX

“I would like to thank Genie for contributing to the success of the inaugural F1 Grand Prix of India. The telehandlers performed fl awlessly and the support provided by Genie was excellent.”

Farhan Vohra, General Manager of Operations at Jaypee Sports International Ltd., owners of the Buddh International Race Circuit. (2011)

“Sales sells the fi rst Genie, our service sells the rest. What I hear customers say about our product support is that it really is the benchmark of the industry.”Technical Support Manager EMEAR.

24 25

TOUGH ENVIRONMENT FOR A TOUGH GENIE® MACHINE IN BREMERHAVEN, GERMANY

Bremen-based Willenbrock Arbeitsbühnen (WAB) GmbH & Co. KG was the fi rst company in Europe to acquire a Genie® S™-3800 telescopic boom lift. Shortly after receiving the new machine, it was immediately rented for six months to Bremerhaven-based BLG WindEnergy Logistics for inspection work and to perform fi nal acceptance testing on offshore wind turbine tripods and components up to 197 ft (60 m).

CAREFUL WORK AT HEIGHT ON OFFSHORE WIND TURBINE

The BLG team was specifi cally trained to operate the Genie S™-3800 by WAB, and currently uses the boom lift to perform welding, and inspect welds and threaded joints on the tripods.

DESIGNED PRIMARILY FOR THE SHIPYARD MARKET

This heavy-duty unit has a working height of 126 ft 6 in (38.58 m), a horizontal reach of 73 ft (22.26 m), and a lift capacity of 750 lb (340 kg). The S™-3800 comes equipped with a Hostile Environment Kit as a standard feature. This provides reliable protection of controls, platform structure, and all cables from the harsh elements associated with working on ships, ports and offshore locations.

The platform is not only designed to resist salt air and the related heavy oxidation, but is also resistant to welding slag, swarf, cutting and other falling debris. Joystick guards and a sealed control box cover with an angled lid make the controls not only remarkably user-friendly, but also help ensure that they are effectively protected.

2726

RECORD BREAKING HEIGHT FOR LEGO 80TH ANNIVERSARY

OLYMPIC ACHIEVEMENT WITH A GENIE® BOOM IN PRAGUE, CZECH REPUBLIC

The year 2012 marked the 80th anniversary of the fi rst Lego toy, put together in Denmark. To celebrate this

special occasion, in September Lego arranged a supply of more than half a million of its legendary bricks to be

delivered to the center of Prague. The mission: Breaking the record of the highest Lego tower built earlier in

Britain (105 ft/32 m). Maybe it only beat the older tower by inches, but it beat anyway!

10,000 CHILDREN WORKED ON THE GROUND SUPPORTED IN THE AIR BY A GENIE Z™-135/70

Lego required an aerial work platform offering an impressive working height range to hit the record. The Z-135/70 was the perfect solution. Equipped with an articulated jib providing smooth movements and a robust, reliable structure to avoid rocking the platform close to the tower’s peak.

Finally, an exceptional, record-breaking building came to stand out of the Prague skyline: the Lego tower was built in four days and reached 106 ft (32.30 m) high, beating the previous record by inches, an Olympic achievement!

“A half century of aerial experience is a rare commodity, but it is ‘standard equipment‘ when you are with the Genie team.”Genie Sales Manager, Singapore.

28 29

“Receiving a personal message of thanks from a customer is the

greatest of all achievements.”Business Services Manager, UK.

VALUABLE PARTNERS FOR EASYJET

PERFORMING ON AIRCRAFT MAINTENANCE AT LUTON AIRPORT, UK

The maintenance hub at Luton Airport is a large aircraft hanger where easyJet engineers perform ‘E’ checks. These checks are scheduled for each aircraft every 600 hours and require an overnight downtime. Luton Airport, the original easyJet base, had been used historically to maintain a fl eet of Boeing aircraft, but recently the airline embarked on a project to include Airbus aircraft into the hangar there for maintenance.

HIGH-PRECISION ACCESS AND MANOEUVRABILITY OVERNIGHT

With a working height of 52 ft 2 in (15.92 m) the Z™-45/25J Bi-Energy articulating boom was selected for its excellent positioning and up-and-over clearance 22 ft (6.73 m) capabilities as well as its ability to work seamlessly in bi-energy mode (DC + diesel generator). This enables engineers to work for more than 8 hours and reach over the wings to access the tail � n and inspect the length of both the Boeing and Airbus aircraft from above.

3332

GENIE® SX-180 BOOM LIFT AT WORK IN WASHINGTON, D.C., USA

Cianbro Construction, a well-known contractor for handling projects that are a bit out of the ordinary, erected the “Capital Wheel” in National Harbour, a multi-use waterfront development just south of Washington, D.C. At 175 ft (53 m) high, this structure boasts some of the most iconic vantage points imaginable, offering views of the White House, Capitol building, National Mall and Arlington National Cemetery.

A SUPER BOOM FOR THE “CAPITAL WHEEL”

“The Genie SX-180 boom, which we call ‘The Monster Lift’ was instrumental in the assembly of the tower legs themselves, but one of the most crucial areas of the construction involved setting the wheel’s ‘spokes’ into the hub or axle.”

Aric Dreher, Project Manager, Cianbro. (2014)

ACCESSING PLACES OTHER MACHINES COULD NOT

With construction of the base completed, the structure’s tower legs were erected, followed by the installation of other ride components such as the axle, spokes, ring beams and lights.

This pre-determined construction sequence — and being located at the end of a 600 ft (182 m) pier — essentially dictated the manner in which the balance of the project could proceed.

While the actual height of the tower legs and components to be assembled could, in a normal setting, be reached using one of Cianbro’s existing standard-sized booms, access was another matter entirely: Only two spots were left from which a boom could operate to have access to both sides of the wheel. And on one of those sides the machine is set back more than 85 ft (26 m) and needs to reach 90 ft (27 m) into the air over the top and in between the tower legs — far more than a conventional piece of equipment could achieve.

With its 186 ft (57 m) working height, the Genie SX-180 boom � lled that gap and its impact on the job site was felt immediately.

3534

“A major consideration has been the site itself. This is a hard job to work on as there are weight restrictions and the site, being in the center of Adelaide, is tight. Again the Genie Z-135/70 fi ts the site perfectly for our client.”

Greg Lees, Account Manager, Access Hire S.A. (2013)

REACHING HIGH FOR COMPLEX GLASS WORK

GENIE® Z™-135/70 BOOM LIFTS PERFORM IN ADELAIDE, AUSTRALIA

Provided by Access Hire S.A., Australia, three Genie Z-135/70 boom lifts were involved in the construction of an extraordinary new building in Adelaide: The South Australian Health and Medical Research Institute. One of their jobs was to support a major contractor who installed the aluminium and glass façade to the building. This was an extensive and complex process with the glass work reaching from the ground all the way to the top fl oor, then over a curved parapet in a bird‘s nest design.

“Knowing we are the leaders of the access industry drives motivation and commitment. With these qualities comes the satisfaction of contributing to our customers’ success. Genie fosters a sense of community that keeps me coming to work and striving to reach new heights. I am very proud to be part of the supportive team that is Genie Australia.”Field Service Rep, Australia.

38 39

GENIE® TELEHANDLERS PLAY A MAJOR ROLE

Each year, Monster Jam electrifi es crowds all over the world with breath taking stunts performed by a custom-designed fl eet of gigantic, powerful trucks. The machines are pushed up to, and frequently beyond, turbo-engineered physical limits to outperform competitors and show off the driver’s skills.

SMASHING SUCCESS ON LEGENDARY MONSTER JAM TOUR

KEEPING THE SHOW RUNNING

On the UK leg of the tour, a pair of Genie® GTH™-4013EX telehandlers were put to work, selected for their considerable lift capacity and agile manoeuvrability. Their mission was to help the event crew construct and dismantle giant obstacle circuits of piled scrap vehicles, in addition to keeping the show running during each event’s mayhem.

Under the watchful eyes of thousands of spectators, the crew worked to reposition the obstacle course, and sometimes the trucks themselves, weighing up to four tonnes and costing more than $ 250,000 US (240 000 €) each.

Two Genie® GTH™-4013EX telehandlers in action on the track.

4140

A HIGH SCORING GENIE TEAM PROVES EXTRAORDINARY AGILITY IN GERMANY

Commercial boat traffi c on the River Main, which is used to transport more than 100 million US tons (90 million MT) of goods annually, was shut-down in 2012 as part of a 3.3 million US $ (3 million €) refurbishment and maintenance project on the Trans-European water way between the North and Black Sea.

After 60 years of continuous use to control a 29.5 ft (9 m) deep, 984 ft (300 m) long and 39 ft (12 m) wide water channel, three sets of obsolete lock gates, with a weight of about 20 US tons (18 MT) per section, were exchanged. Specially constructed replacement gates were positioned by a crane, which was also used to lift three Genie access models into the channel to secure and fi nalise the work.

BACK TO ‘SHIP-SHAPE’ FOR THE TRANS-EUROPEAN CANAL

TIGHT TIME SCHEDULE FOR VARIOUS TASKS

Construction company Maschinenfabrik Thale GmbH had a tight time schedule and needed to complete several different kinds of work within the drained channel.

The GS™-2669RT was used for electric, welding and sealing tasks and work on the giant new lock gates.

Thanks to the telescopic S™-45 and articulating Z™-45/25J RT and their respective tight 10 ft 6 in (3.23 m) and 15 ft 7 in (4.8 m) turning radiuses, the machines were able to maneuver easily at different heights inside the dry lock to access areas that would otherwise have been impossible to reach. Offering a horizontal reach of 37 ft (11.2 m), the ability of the S-45 to reach below grade also proved to be a strong bene� t.

“The innovative design features, serviceability and durable quality of Genie work platforms will undoubtedly reinforce our company‘s reputation.”

Herr Möller, of rental company Möller Manlift. (2012)

42 43

“I recently went to Disneyworld and I saw a S-60X used to clean up the ears of the statue of Mickey Mouse. There was a kind of magic to it!”Genie Finance Manager, France.

“The ZX-135/70 boom lift provided an ideal solution that would have been impossible to handle using a truck mounted boom, or other similar types of equipment.”

Ernst Hadinger, Aerial Work Platform Manager, Obermair. (2015)

HIGH PRECISION PAINT JOB ON HISTORICAL TOWER GATE

TIGHT ACCESS AND TOUGH TIMELINEFOR A GENIE® ZX™-135/70 IN AUSTRIA

Obermair Transporte-Erdbau GmbH recommended a Genie ZX-135/70 articulating boom lift to help painting specialist Daniel Zauner and his team repair the belfry and restore the paintwork of the southern tower of the walled mediaeval town of Vöcklabruck in Upper Austria. To this day, the 118 ft (36 m) tall southern gate tower, and a similar edifi ce on the opposite side of an enclosed square, are the only means of access to the town’s historic center. The narrow 8 ft 6 in (2.60 m) entrance added challenges to this historical renovation jobsite. On this particular application, besides the height and outreach required to perform the task, the machine‘s dimensions were essential to ensure access through the tower‘s tight entrance.

Smooth positioning and precision enabled painters to work effi ciently and confi dently.

44 45

SPONSORING STREET ART

GENIE® MACHINES MAKE HEART RHYME WITH ART IN SÃO PAULO, BRAZIL

Genie sponsored the fi rst edition of the Street Art O.bra Festival. Fifteen platforms were made available for the artists. The brand provided participants with the fl exibility they needed to paint the facades of high buildings safely – as part of a street art exhibition at Largo do Arouche, in São Paulo, from October 23-25, 2015.

FIFTEEN MACHINES DEDICATED TO THE SAFE PERFORMANCE OF EIGHTEEN INTERNATIONAL ARTISTS

Anyone walking around the town center was able to watch artists working from platforms up to 98 ft (30 m) high, in conditions that demonstrated the machines’ versatility.

Genie and Mills - a rental equipment company, provided a broad mix of Genie Z™-booms, S™-booms and GS™ scissors lifts in just the right time.

“This event fi tted in well with our company’s values of Respect, Citizenship, and Continuous Improvement. We are very proud

to have had the opportunity to support the O.Bra, and to help put emphasis on Brazil’s artistic heritage.

Our goal was to provide the artists the best conditions to complete their paintings safely within a tight schedule.”

General Manager, Terex AWP in Latin America. (2015)

46 47

CHALLENGING A TILT-WALL CONSTRUCTION PROJECT

BRINGING VALUE ON A CONGESTED SITEIN CALIFORNIA, USA

Steel contractor CW Services faced an extremely challenging tilt-wall construction project in Torrance, south of Los Angeles, CA, USA. Faced with daunting access issues, the company turned to American Rentals that provided a series of articulating boom lifts from Genie. CW offi cials report that, with as many as fi ve different Genie® booms onsite at once – four of them articulating models – they were able to tackle some critical facets of the construction, keeping the project moving along and their reputation for quality, on-time work, intact.

GENIE® Z™-45 AND Z™-60 ARTICULATING BOOMS PERFORMED BOTH INDOORS AND OUTDOORS

What made this job challenging was the fact that it involved placing and bolting or welding more than 1,200 separate I-beams. With those in place, the tilt wall sections were raised and held in place with shoring. Then, the operators had to begin bolting and doing a series of critical full-pin welds which involved coming in from the back through the shoring. So, during the early phases of construction, most of the work was done on the inside of the structure rather than the outside.

“During each facet of the project, the Genie Z-booms were a key component, largely because of the accessibility they provided. The design of the boom with the jib on the end of it, made the process of reaching in and getting around things much easier than we’d imagined.”

Reuben Salcedo, CW Services’ Project Manager. (2012)

48 49

GREAT TEAM WORK IN VIETNAM

In November 2012, the Ministry of Transport in Vietnam announced the project of building a 8.3 mile (13.4 km) road tunnel through the Ca Mountain Pass in the south-central provinces of Phu Yen and Khanh Hoa. Estimated cost: 690 million US $ (617 million €).

Purpose: To support the development of industrial zone, big-scale economic hub and tourism site projects in the 2 regions. It also contributes to minimize accidents on Highway 1A and to save at least 10 million US $ (8.9 million €) in transport costs each year.

INSIDE THE BOWELS OF A TUNNEL

GENIE® GTH™-844 AND GENIE® Z™-45/25 WORKING AS A NON-STOP TEAM

After the main construction work was completed, the next stage was the installation of mechanical and electrical components inside the structure.

One of the main jobs was the positioning of air ducts. Due to their huge size and to the complexity of the installation, one Genie telehandler and two Genie booms were used to complete the task together.

Four operators were working on the booms, while assisted with another one in the telehandler. The machines had to coordinate their efforts in a tight space.

Genie® GTH™-844 AND Z™-45/25 working hand to hand.

5150

HELPING BUILD “THE KELPIES”

EIGHT GENIE® BOOM LIFTS PERFORM IN SCOTLAND

In 2013, Easi UpLifts, owners of one of the largest fleets of Genie® equipment in the UK and Ireland, provided its customer SH Structures with a brigade of eight Genie articulating and telescopic boom lifts to help build “The Kelpies.” Created by Glasgow artist Andy Scott, the monumental 98 ft 4 in (30 m) high, 600 t, two-headed horse sculpture is part of The Helix, a huge parkland project connecting communities between Falkirk and Grangemouth in Scotland.

Thanks to their four-wheel drive and four-wheel steer option and high ground clearance, the eight Genie boom lifts maneuvered rapidly together among a considerable number of obstacles to fetch and fix the bolts used to hold the intricate maze of girders firmly together.

High-precision access, outstanding manoeuvrability and high level of efficiency.

“Our customer’s operators were so impressed that they would not have wanted to be without them. They also remarked on the smoothness of the platform’s movements and the high precision of the machines proportional control system which enabled them to progress efficiently and rapidly with seamless results.”

Alan Gordon, Area Sales Manager based at the Easi UpLifts Glasgow depot. (2013)

52 53

COMPACT SIZE AND LOW WEIGHT ADDRESS NIMBLE DEMANDS IN BIRMINGHAM, ENGLAND

The redevelopment of the MAC Arts Centre in Birmingham in the UK, has enabled a broader range of events. The new high ceiling environment, with narrow suspended walkways, as well as newly remodeled dance surfaces and mezzanine fl oors, demanded compact, light-weight equipment for work at height throughout the complex. Following an onsite consultation with the regional Genie® dealer, Workplatform Ltd., a Genie® AWP™-20S, with a working height of 26.6 ft (8.12 metres), was selected.

ARTFUL ACCESS IN THE MAC ARTS CENTER

‘FLAT FORMAT’ PERFORMANCE TO GO ANYWHERE AROUND THE BUILDING

With a weight of 750 lb (340 kg), it was suitable for any studio or performance space, as it could be pushed into elevators, and over light � oor-load areas installed throughout the building for ‘� at format’ performances.

Simple design and controls made the Genie AWP-20S easy for any trained MAC staff member to set-up and operate in minutes, including maintenance personnel for lighting and electrical work, and facilities staff who installed and cleaned exhibits and signage. The stage crew also used the full working height of the machine to construct theater installations and maintain the venue’s state-of-the-art professional lighting and sound systems that had been awkward to position and service using ladders.

You may not see what we are doing every day behind the scene, but you should know Genie is aimed to be your partner ‘in safety’. Safety Manager, EMEAR.

5756

TWO GENIE® NARROW ELECTRIC ARTICULATINGBOOM LIFTS CHOSEN FOR THEIR PERFORMANCE, HUNGARY

Aircraft maintenance involves carrying out swift checks directly on the tarmac, and a wide range of heavier, longer-term duties in the hangar. All of these activities need to be performed to extremely high technical and safety standards on a strict time schedule. For Lufthansa, the Genie® Z™-34/22N combines the high level of performance that the company was looking for.

MAINTAINING HIGH STANDARDS FOR LUFTHANSA

HIGHLY MANEUVERABLE AND PRODUCTIVE

Featuring a narrow system width of just 58 inches (1.47 m), the Genie Z-34/22N boom lift notably combines zero tailswing and the ability to maneuver rapidly in con� ned areas. Well-suited to aircraft maintenance, an articulating boom and rotating jib provide fast, easy access in conjunction with a working height of up to 40 ft 6 in (12.52 m), a maximum horizontal reach of 22 ft 3 in (6.78 m) with an up-and-over clearance of 15 ft 2 in (4.62 m).

“We fi rst started renting Genie lifting equipment with Huntraco about nine years ago. For us, the Genie Z-34/22N articulating boom lift proved to be both fast, highly maneuverable and safe, which is precisely what we need. The expert sales and service support provided by Huntraco was also an important factor in our purchase decision.”

Krisztián Radó, Tools, GSE & Calibration Specialist and Lift Equipment Administrator for Lufthansa in Budapest. (2013)

GENIE® SX-180 PREMIERE IN AUSTRALASIA

Rich Rigging, a New Zealand based company, is an acknowledged expert in the assembly, erection, disassembly, relocation and maintenance of ship-to-shore gantry cranes. Even with an impressive specialised equipment inventory of cranes, access equipment and general heavy rigging equipment Rich Rigging was still encountering logistical challenges with the access and reach needed for many facets of this specialized work.

ACCELERATING THE ERECTION OF A SHIP-TO-SHORE GANTRY CRANE

NEW REACH, NEW BENEFITS, NEW ACHIEVEMENTS

With a speci� c project in mind, the assembly of a new ship-to-shore gantry crane at Lyttelton, Port of Christchurch (LPC), Rich Rigging ordered a Genie SX-180 boom with the Genie New Zealand distributor, Youngman Richardson & Co.

The Genie SX-180 boom lift was central to the safe work method detailed for this contract and the task of putting the 1700 pieces of the crane together with tight deadlines was no small feat.

On the work site, the operators found the unit easy to manoeuvre as the SX-180 has the capability to move while fully extended.

Immediately after the machine arrived on site, the pace of the crane assembly accelerated and the project was completed on schedule.

“Genie has a proud and impressive history. We‘re a brand built on integrity, innovation, quality and our ability to meet customer needs. Now, we are building upon this rich tradition and taking our brand to new heights.”Genie Product Management, Redmond USA.

60 61

PLAYING A KEY ROLE IN GANTRY CRANE UPTIME, UK

Just 25 miles from London, London Gateway is situated in the core of the United Kingdom’s consumer market and is operated by DP World, an international marine terminal operator. London Gateway combines a deep-sea container port with Europe’s largest logistics park, using world-leading technology to increase productivity and reduce costs. The gantry cranes are designed to operate 24 hours a day, seven days a week and will be able to handle 3.5 million TEU (standard unit for describing a ship’s cargo capacity) a year. One of the fi rst Genie® ZX™-135/70 articulating boom lifts is playing a key role at this unique site and will be used on the 24 giant gantry cranes for which uptime is fundamental to service ships at the London Gateway.

SERVICING CRANES AT LONDON GATEWAY

“Space was not an issue on the vast site with 2,700 meters of quay and 9 million square foot of logistics park. But the adaptability on a high capacity and busy location, was another appealing feature of the ZX-135/70 unit, enabling it to meet multiple and specifi c heavy jobsite requirements.”

Neil Bellinger, London Gateway Workshop & Mobile Equipment Manager. (2014)

6564

THE TALLEST GANDHI MURAL IN INDIA

In January 2014, India’s capital was transformed into an open air art gallery as artists from all over the world converged in a six-week street art festival. The slogan of the New Delhi police department being “shanti, seva, nyaay” (peace,

service, justice), when the artists submitted their proposal to senior police offi cials, it was felt that a giant portrait of Gandhi would be appropriate.

German graffi ti artist Hendrik Beikirch (also known as ECB), and up-and-coming Delhi-based artist Anpu Varkey, took on the challenge of painting a gigantic black and white portrait of Mahatma Gandhi onto a 50x12 m (150 x 38 ft) bare wall overlooking New Delhi’s Police headquarters.

GANDHI’S PORTRAIT SMILES DOWN ON NEW DELHI

GENIE® S™-125 LIFT, A SAFE AND HIGHLY MANEUVERABLE SOLUTION

Designed to meet the challenges of some of today’s highest construction and industrial applications, particularly in congested areas, the Genie S-125 telescopic boom lift proved to be a solution well suited for the artists’ high-reaching task. The four-wheel drive and steer capabilities of the S-125 lift combined with the high vertical and horizontal reach required to work close to the high wall safely helped overcome the obstacles of the con� nes of the wall‘s location, heavy traf� c and crowds of curious on-lookers.

For � ve solid days, elevated above the hustle and bustle of the city beneath them, the spacious platform of the Genie S-125 boom lift provided the artists all the room they needed to move around freely among the many pots of paint, ink and aerosols required to complete their masterpiece.

The S-125 lift features a long telescopic boom that can be extended or retracted in less

than three minutes.

“After being a Genie customer for many years I developed a passion for the Genie blue products and the brand itself. When an opportunity arose to join the team I seized it.I love being part of the Genie team, I am proud of the products we sell and I love the Genie blue.”Regional Sales Manager, Australia.

66 67

THE QUEEN BEE OF THE ARENAS IN SOUTH AFRICA

The most breath-taking events were set at the newly-built Green Point Stadium in Cape Town, host to the competition semi-fi nals, and the newly-reconstructed ‘Soccer City’ outside Johannesburg, which witnessed the electrifying fi rst and fi nal matches. From the initial stage of the projects, the site managers were conscious of the diffi culty in accessing work areas on these very large structures, with capacities of 70,000 and 90,000 respectively, and the need for specialized equipment.

AT WORK FOR THE 2010 FOOTBALL WORLD CUP

“The project required a combination of height, reach and manoeuvrability that made the Genie Z-135/70 boom the ideal machine for the job.”

George Landsberg, Managing Director of Hi-Reach Manlift (Pty) Ltd. (2010)

HIGH REACH AND AGILITY MADE THE DIFFERENCE

The constraints of the environment meant a work platform was needed that could go “up and over,” in addition to providing an up reach of over 131 ft (40 m) required to scale the stadia exteriors. The Genie® Z™-135/70 model selected to tackle this feat offered the largest working envelope in the articulating boom market. Aided by its distinctive Jib-eXtend™ feature, to provide the fully extended height of 141 ft (42.9 m), horizontal outreach of 69 ft 9 in (21.3 m) and up-and-over clearance of 75 ft 6 in (23 m), the work platform could be positioned through gaps, even at the highest points of the structure, to rivet the external panels to the building.

70 71

global

trustworthy

passion

teamwork

support

respect

quality leadership

innovation

blueleadership

blueleadership

success

Building the future...As Terex and the Genie team focus on the future you can expect to see us expand our innovative product offerings to meet the needs of our customers. We’ll create leading technologies that make it easier for our customers to do business.

We will continue to represent quality in everything we do: safe, dependable products backed by unsurpassed support. Customers will remain our primary focus. The success of Genie is based on the success of our customers—today and in the future.

Effective Date: April, 2016. Product specifi cations and prices are subject to change without notice or obligation. The photographs and/or drawings in this document are for illustrative purposes only. Refer to the appropriate Operator’s Manual for instructions on the proper use of this equipment. Failure to follow the appropriate Operator’s Manual when using our equipment or to otherwise act irresponsibly may result in serious injury or death. The only warranty applicable to our equipment is the standard written warranty applicable to the particular product and sale and we make no other warranty, express or implied. Products and services listed may be trademarks, servicemarks or trade-names of Terex Corporation and/or its subsidiaries in the USA and other countries. All rights are reserved. Terex, Genie and Taking You Higher are trademarks owned by Terex Corporation or its subsidiaries. © 2016 Terex Corporation.

GENIELIFT.COM