Water Pumps & Treatment Solutions | Applied Process Equipment

WATER TREATMENT SYSTEMS AND EQUIPMENT - Commercial_Industrial_Catalog… · WATER TREATMENT SYSTEMS...

Transcript of WATER TREATMENT SYSTEMS AND EQUIPMENT - Commercial_Industrial_Catalog… · WATER TREATMENT SYSTEMS...

WATER TREATMENTSYSTEMS AND EQUIPMENT

Place your industrial and commercialwater treatment needs in the hands

of a global leader.

FILTRATION AND POTABILIZATION Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

7

PRE-TREATMENTSOLUTIONS

MEMBRANESOLUTIONS

DEIONIZATIONSOLUTIONS

STORAGESOLUTIONS

DISTRIBUTIONSOLUTIONS

REUSESOLUTIONS

SELF-CLEANING FILTERS 15

DYNAMIC SEPARATORS 16

WATER SOFTENING 17

DOSING SYSTEMS 21

INSTRUMENTATION AND CONTROLS 22

U.V. STERILIZATION 26

AERATION TOWERS 27

MICROFILTRATION 28

ULTRAFILTRATION 29

REVERSE OSMOSIS 30

DEMINERALIZATION 37

DISINFECTION 42

WASTE WATER 44

SERVICE 46

4 CULLIGAN

THE MASTERIN WATERTREATMENT

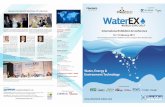

CULLIGAN HAS LED THE WATER TREATMENT INDUSTRY IN INNOVATION AND SERVICE FOR

MORE THAN 75 YEARS. CULLIGAN EXPERIENCE STARTED WITH THE STANDARD WATER

TREATMENT TO OBTAIN POTABLE WATER, AND HAS BEEN IMPROVED TILL THE MORE

SOPHISTICATED SYSTEMS FOR WATER REUSE, FROM PROJECT AND MANUFACTURE OF

EQUIPMENT TILL START-UP AND AFTER-SALES MAINTENANCE. CULLIGAN IS THE GLOBAL

LEADER FOR WATER TREATMENT SOLUTIONS FROM A SINGLE SOURCE.

Water is unique, limited and non reproducible and isvital to human life and activities. Only a rational andsustainable approach will preserve this essentialresource for future generations.

Thanks to his wide experience in designing andmanufacturing equipment for water softening,filtration, desalination (via reverse osmosis or ionexchange) and chemical dosage, Culligan hasavailable an unmatched range of efficient anddependable products (fully described in ourtechnical literature), designed to meet therequirements of a vast number of applications.Products are constantly updated to incorporate thelatest technological innovations, so you’re alwaysguaranteed to buy state-of-the-art equipment.All components are field-tested by our engineers, alarge majority of them are actually designed andmanufactured in our factories under exactingquality control, like hydraulic valves, controllers,instrumentation and many other components.

This catalogue includes the entire range of CulliganCommercial and Industrial products currentlyavailable, with product applications and technicalcharacteristics, and is a useful tool for the initialselection of the equipment required for a specificproject, which can then be later finalized inconsultation with our Application Engineeringdepartment.

CULLIGAN 5

Mobile emergency drinkingwater system

Seawaterdesalination/potabilizationsystem

Deionization system withpre-treatment, skidassembled

Reverse Osmosis systemfor process water

Potabilizationsystem

Deionization system withpolishing mixed bed on skid

1 2

3 4

5 6

1

2

3

4

5

6

Besides, Culligan can project any kind of specific water treatment processes, designing completesystems in accordance to the current Standards in force in each destination countries.

Our skilled engineers can manage all projects by following the required Standards, for the specificmarkets and applications.

Among the most important ones for Culligan there are:

••

•••

•

Municipal waterworks, requiring potable water treatmentIndustrial market, for specific water production for food, power, electronics, painting industries,services, agricultural and oil industriesHospitals, for specific water treatment for haemodialysis, laboratories and steam generatorsCommercial, for touristic resortsEmergency, for public authorities such as army, civil protection, etc. These units can work in emergencyconditions following the highest international StandardsReuse of drain water for irrigation and industrial purposes.

Seawater desalinationsystem with pre-treatment,skid assembled

Surface water filtrationsystem for municipal watersupply

Arsenic removal plant formunicipal water supply

Filtration system formunicipal water supply

Electrodeionization unit

Ultrafiltration system forwaste water reuse

7 8

9 10

11 12

7

8

9

10

11

12

For Culligan it is important to give a full service to his customers, by offering a complete after-sales serviceworldwide. Culligan sales and service networks are distributed all over the world, in order to reply tocustomers’ requirements in a very short time.

Besides ISO 9001:2008 Quality Certification for “design, manufacture, trade, installation and maintenanceof water treatment plants and equipment”, Culligan is also certified to SOA, UDT, GOST and Medical DeviceCE0434 Standards, and bid for public tenders around the world.

6 CULLIGAN

FILTRATION AND POTABILIZATION 7

Each model of Culligan filters can be selected witha choice of filtration media suitable for the specificapplication (see table on following page).

• FILTR-CLEER Multi-layer media typicallyemployed for the elimination of turbidity,suspended solids and low concentrations of heavymetals (e.g. Iron and Manganese).The main components are “Cullcite”, granular lowdensity anthracite in the upper layer of the filter,and “Cullsan”, long-lasting pure and chemicallyinert silica sand in the bottom layer.

• CULLAR Used for the removal of Chlorine,unpleasant tastes and odours. Cullar is a GranularActivated Carbon especially selected for itsextremely fine porosity and outstandingabsorption capacity.

• CULLNEU Used for neutralising acidic water,raising hardness level and reducing the corrosivecharacteristics of water. Cullneu is mostlycomposed by granular Calcium Carbonate, whichdissolves in water in direct proportion to theacidity removed; it therefore requires periodicrefilling.

• SUPER IRON Selective catalytic multi-layermedia for removing Iron, Manganese and Arsenic,which is activated using various oxidants.

• G.A.C. Granular Activated Carbon-based filter,designed specifically for adsorbing organics,pesticides, heavy metals and other hazardoussubstances.

• BIOFILTER Special filter designed for the removalof Ammonia through accelerated nitrification by abiomass of aerobic bacteria (Nitrosamonas andNitrobacter) supported by a layer of quartz-basedmedia. Biofilters can also oxidise and remove lowconcentrations of Iron and Manganese.

• UFX Specific media for the adsorption of Arsenicand Vanadium. The media cannot be regeneratedand must be replaced when exhausted. It is ideallyused for polishing water that has been pre-treatedwith less expensive processes.

• FHT Manual sand filters, suitable for heating andconditioning waters to eliminate Iron oxides,sludges and deposits that can cause a bad watercirculation in the entire circuit.

• OFSY® Double-stage filtration system, exclusiveto Culligan, ideally suited to remove elevated andvariable quantities of suspended solids. Theunique feature of this filter is its capacity todirectly treat water with elevated concentrationsof suspended solids, without any previousclarification.

FILTRATION ANDPOTABILIZATION

FILTRATION IS USED IN MANY APPLICATIONS.

REMOVE SUSPENDED SOLIDS FROM WATER, COARSE PARTICLES TO COLLOIDS•

ADSORBE AND REMOVE COLOURS, UNPLEASANT TASTES AND ODOURS, AS WELL AS•

ORGANIC AND INORGANIC CONTAMINANTS

REMOVE IRON, MANGANESE, ARSENIC AND OTHER HEAVY METALS •

NEUTRALISE WATER ACIDITY•

REMOVE AMMONIA THROUGH ACCELERATED NITRIFICATION IN BIOLOGICAL FILTERS•

THE APPROPRIATE MEDIA AND CHEMICAL CONDITIONING SHOULD BE SELECTED FOR THE

SPECIFIC APPLICATION.

MODELS

8 FILTRATION AND POTABILIZATION

Culligan’s pressure vessels are entirely fabricatedin our factories from high grade carbon steel withinternal linings of food-grade epoxy resins (250-300 µm), and external corrosion protection usingpolyurethane paint (80-100 µm).

HE Series automatic filters and FHT manual filtersare in reinforced fiberglass, corrosion proofmaterial. HE filter tanks only can be constructedaccording to Culligan Quadra-Hull™ system.

The automatic operation of filters is achieved viahydraulic diaphragm valves, driven by a pilot valveconnected to an electronic controller thatalternates service and wash cycles.Culligan HE automatic filters are controlled viahydraulic piston valve.Time, duration and frequency of wash cycles canbe programmed from the control panel.

An optional communication kit advises if the filterneeds service maintenance. The Culligan

controller (available for all Culligan MatrixSolutions™ filters) allows an easy checking andoperation of the unit.

Automatic flow regulators limit the water flow ratein the different phases, preventing any loss ofminerals during backwash and optimising filtrationefficiency during service.

MATERIALS

OPERATION

NOTE: details of each standard model are listed in the Technical Specifications tables.

HOW TO CHOOSE THE MOST APPROPRIATE FILTRATION MEDIA FOR YOUR NEEDS

NOTE: in addition to standard products, Culligan can design and supply customised units for larger applications and packagedcomplete systems either skid mounted or installed inside ISO containers. All systems are designed to the highest Standardsincluded DIN, ASME, RINA, etc.

Filtr-Cleer

UF

HE

HF6

Cullar

UR

Cullneu

UU

Super Iron

UFP

UFX FHT Bio-

filter

GAC OFSY

HF9 HE

HF6

HF9 HE

HF6

HF9 HE

HF6

HF9 HF9 BF

Turbidity uu uu uu uuu

Elevated and/or variable turbidity u uu uuu

Taste u uu

Odour u uu

uuu

uuu

Colour u uu

Atrazine and similar u

uuu

uuu

Tri-tetrachloroethylene and similar

Acidity uu

u uuu

uuu

Iron

Manganese

u uu uu uuu uu uu uuu

uu uu uuu uu uuu

Arsenic and Vanadium

Ammonia

u u uu u uu

u uuu u

uuu

u Acceptable uu Good uuu Excellent

HI-FLO 3e

HE

FHT

FILTRATION AND POTABILIZATION 9

MODEL FLOW RATE FITTINGS DIMENSIONS WEIGHTservice backwash in / out width depth height in operation shipping

max Ø

m3/h m3/h ” mm mm mm kg kg

FHT 500 0.5 1.5 ¾ 250 - 680 - 70

FHT 1000 1 3 ¾ 330 - 980 - 90

FHT 2500 2.5 4 1½ 700 850 1010 - -

NOTE Weights are approximate. • Dimensions may vary by ± 2%.

MODEL FLOW RATE FITTINGS DIMENSIONS WEIGHTservice backwash in / out width depth height in operation shipping

max Ø

m3/h m3/h ” mm mm mm kg kg

FILTR-CLEER (Turbidity)UF 12 2.6 2.3 1 ½ 356 610 1575 190 148

UF 14 3.6 3.4 1 ½ 356 610 1905 250 179

UF 16 4.7 4.5 1 ½ 406 610 1905 340 255

UF 21 8.1 6.8 1 ½ 533 610 1600 470 322

CULLAR (Taste - Odour - Colour)UR 12 1.8 1.8 1 ½ 356 610 1575 165 123

UR 14 2.5 2.3 1 ½ 356 610 1905 250 179

UR 16 3.2 3.4 1 ½ 406 610 1905 315 231

UR 21 5.4 5.7 1 ½ 533 610 1600 395 247

CULLNEU (Acidity)UU 12 1.8 1.8 1 ½ 356 610 1575 165 115

UU 14 2.5 2.3 1 ½ 356 610 1905 225 145

UU 16 3.2 3.4 1 ½ 406 610 1905 290 197

UU 21 5.4 6.8 1 ½ 533 610 1600 434 286

SSUPER IRON (Iron - Manganese)UFP 12 1.8 1.8 1 ½ 356 610 1575 190 140

UFP 14 2.1 3.4 1 ½ 356 610 1905 300 220

UFP 16 2.5 3.4 1 ½ 406 610 1905 365 272

UFP 21 3 6.8 1 ½ 533 610 1600 484 336

NOTE Weights are approximate. • Dimensions may vary by ± 2%.

MODEL FLOW RATE FITTINGS DIMENSIONS WEIGHTservice backwash in / out width depth height in operation shipping

max Ø

m3/h m3/h ” mm mm mm kg kg

FILTR-CLEER (Turbidity)UF 24 6.7 10 2 610 - 2179 650 505

CULLAR (Taste - Odour - Colour)UR 24 6.7 4.5 2 610 - 2179 560 411

UR 30 11 6.8 2 762 - 2179 955 655

SUPER IRON (Iron - Manganese)UFP 24 4.5 7 2 610 - 2179 710 561

UFP 30 7 10 2 762 - 2179 1130 880

CULLAX (Arsenic - Vanadium)UFX 21 3 3 2 533 - 1925 450 376

UFX 24 4.5 4.5 2 610 - 2179 720 561

UFX 30 6.8 6.8 2 762 - 2179 1160 905

NOTE Weights are approximate. • Dimensions may vary by ± 2%.

HI-FLO 9

10 FILTRATION AND POTABILIZATION

MODEL FLOW RATE FITTINGS DIMENSIONS WEIGHTservice backwash in / out width depth hight in operation shipping

max Ø

m3/h m3/h mm mm mm kg kg

FILTR-CLEER (Turbidity)UF 20 4.7 7.9 1 ½” 710 735 1950 770 470

UF 24 6.7 10.9 1 ½” 710 835 1985 1100 680

UF 30 11 15.9 1 ½” 765 985 2050 1700 1030

UF 36 17 27.3 2 ” 975 1215 2131 2980 1910

UF 48 27 40.9 2 ½” 1258 1436 2235 4490 2790

UF 54 37 56 2 ½” 1432 1632 2367 4800 3100

UF 60 42 61.3 DN 80 1500 1760 2700 5500 4050

UF 72 60 90.8 DN 100 1800 2150 2782 6400 5450

UF 84 80 129.4 DN 100 2100 2450 3090 10650 7700

UF 90 86 147.7 DN 100 2300 2630 3100 12450 9010

UF 100 117 174.9 DN 150 2500 2950 3364 16100 11700

UFe 100 117 174.9 DN 100 2500 2850 3314 16100 11700

UF 120 170 250 DN 150 3000 3490 3600 32000 18800

CULLAR (Taste - Odour - Colour)UR 20 4.7 3.4 1 ½” 710 735 1950 760 460

UR 24 6.7 4.5 1 ½” 710 835 1985 1030 600

UR 30 11 6.8 1 ½” 765 985 2050 1600 930

UR 36 17 10.9 2” 975 1215 2131 2720 1650

UR 48 27 18.2 2” 1258 1465 2235 3500 2410

UR 54 37 25 2 ½” 1432 1626 2367 4250 2950

UR 60 42 27.3 DN 80 1500 1760 2700 4500 3350

UR 72 60 40.9 DN 80 1800 2100 2782 5550 4600

UR 84 80 52.2 DN 100 2100 2450 3090 8100 5900

UR 90 86 61.8 DN 100 2300 2630 3100 9806 7600

UR 100 117 79.5 DN 100 2500 2850 3314 11100 9400

UR 120 170 114 DN 150 3000 3490 3600 29000 15250

SUPER IRON (Iron - Manganese)UFP 20 3 5.7 1 ½” 710 735 1950 770 470

UFP 24 4.5 7.9 1 ½” 710 835 1985 1100 680

UFP 30 7 13.6 1 ½” 765 985 2050 1700 1030

UFP 36 11 20.5 2” 975 1215 2131 2980 1910

UFP 48 18 31.9 2 ½” 1258 1436 2235 4490 2790

UFP 54 25 45.8 2 ½” 1432 1632 2367 4800 3100

UFP 60 28 52.2 DN 80 1500 1760 2700 5700 4300

UFP 72 40 68 DN 100 1800 2150 2782 7000 5900

UFP 84 52 95.5 DN 100 2100 2450 3090 11700 8700

UFP 90 58 114 DN 100 2300 2630 3100 14000 10560

UFP 100 79 143 DN 150 2500 2950 3364 17900 13200

UFPe 100 79 143 DN 100 2500 2850 3314 17900 13200

UFP 120 112 200 DN 150 3000 3490 3600 34600 20500

NOTE Weights are approximate. • Dimensions may vary by ± 2%.

HI-FLO 9

FILTRATION AND POTABILIZATION 11

MODEL FLOW RATE FITTINGS DIMENSIONS WEIGHTservice backwash in / out width depth height in operation shipping

max Ø

m3/h m3/h mm mm mm kg kg

CULLAX (Arsenic - Vanadium) UFX 20 3 3 1 ½” 710 735 1950 760 460

UFX 24 4.5 4.5 1 ½” 710 835 1985 1020 600

UFX 30 6.8 6.8 1 ½” 765 985 2050 1590 930

UFX 36 10.9 10.9 2” 975 1215 2131 2550 1650

UFX 48 17 17 2” 1258 1465 2235 4060 2410

UFX 54 25 25 2 ½” 1432 1626 2367 5050 2950

UFX 60 27.3 27.3 DN 80 1500 1760 2700 5975 3350

UFX 72 40 40 DN 80 1800 2100 2782 8350 4600

UFX 84 52.2 52.2 DN 100 2100 2450 3090 11150 5900

UFX 90 61.8 61.8 DN 100 2300 2630 3100 13900 7600

UFX 100 75 75 DN 100 2500 2850 3364 16900 9400

UFX 120 105 105 DN 100 3000 3490 3600 24750 13250

BIOLOGICAL FILTERS (Ammonia - Iron - Manganese)BF 48 17 36 2” 1258 1465 2235 4150 2500

BF 54 22.5 47 2 ½” 1432 1626 2367 5150 3050

BF 60 26 54 DN 80 1500 1760 3200 6325 3700

BF 72 38 80 DN 80 1800 2100 3282 8650 4900

BF 84 52 108 DN 100 2100 2450 3590 11350 6100

BF 90 62 126 DN 100 2300 2630 3660 14200 7900

BF 100 72 144 DN 100 2500 2850 3814 17300 9800

BF 120 106 216 DN 100 3000 3490 4100 25200 13700

CULLNEU (Acidity)UU 20 3 7.9 1 ½” 710 735 1950 830 530

UU 24 4.5 10.9 1 ½” 710 835 1985 1150 725

UU 30 7 15.9 1 ½” 765 985 2050 1780 1110

UU 36 11 27.3 2” 975 1215 2131 3030 1955

UU 48 18 40.9 2 ½” 1258 1436 2235 4785 3085

UU 54 25 56 2 ½” 1432 1632 2367 5100 3250

NOTE Weights are approximate. • Dimensions may vary by ± 2%.

12 FILTRATION AND POTABILIZATION

MODEL FLOW RATE FITTINGS DIMENSIONS WEIGHTservice backwash in / out width depth height in operation shipping

max Ø

m3/h m3/h DN mm mm mm kg kg

FILTR-CLEER (Turbidity)UF 60 36,2 61.3 80 1500 1760 2200 4640 3290

UF 72 52 90.8 100 1800 2150 2282 6455 4655

UF 84 70.4 129.4 100 2100 2450 2340 8325 5825

UF 90 81.6 147.7 100 2300 2630 2350 12250 7250

UF 100 101.2 174.9 150 2500 2950 2614 13445 9145

UFe 100 101.2 174.9 100 2500 2850 2564 13445 9145

UF 120 145 250 150 3000 3490 2890 27000 15500

CULLAR (Taste - Odour - Colour)UR 60 36.2 27.3 80 1500 1760 2200 4395 2795

UR 72 52 40.9 80 1800 2100 2282 6025 3875

UR 84 70.4 52.2 100 2100 2450 2340 8190 5190

UR 90 81.6 65 100 2300 2630 2350 11200 6080

UR 100 101.2 79.5 100 2500 2850 2564 12250 7750

UR 120 145 114 150 3000 3490 2890 25000 13400

CULLNEU (Acidity)UU 60 22.7 61.3 80 1500 1760 2200 4640 3290

UU 72 32.7 90.8 80 1800 2150 2282 6455 4655

UU 84 40.9 129.4 100 2100 2450 2340 8325 5825

UU 90 47 147.7 100 2300 2630 2350 12290 7250

UU 100 59 174.9 150 2500 2950 2614 13445 9145

UUe 100 59 174.9 100 2500 2850 2564 13445 9145

UU 120 80 250 150 3000 3490 2890 27000 15500

SUPER IRON (Iron - Manganese)UFP 60 28 52.2 80 1500 1760 2200 4800 3310

UFP 72 40 68 100 1800 2150 2282 6750 4750

UFP 84 52 95.5 100 2100 2450 2340 8600 6100

UFP 90 58 114 100 2300 2630 2350 12500 7500

UFP 100 79 143 150 2500 2950 2614 12900 9500

UFPe 100 79 143 100 2500 2850 2564 12900 9500

UFP 120 112 200 150 3000 3490 2890 27250 15750

HI-FLO 6

NOTE Weights are approximate. • Dimensions may vary by ± 2%.

FILTRATION AND POTABILIZATION 13

MODEL FLOW RATE FITTINGS DIMENSIONS WEIGHTservice backwash in / out width depth height in operation shipping

max Ø

m3/h m3/h DN mm mm mm kg kg

HI-FLO 6 TWINTWIN - FILTR-CLEER (Turbidity)UF 248 41 41 65 2600 1536 2125 9000 5500

UF 260 72.4 61.8 100 3300 1880 2140 9300 6600

UF 272 104 90.8 100 3900 2110 2260 12930 9350

UF 284 140.8 129.4 150 4580 2360 2385 16500 11700

UF 290 163.8 150 150 4980 2600 2460 24530 14550

UF 2100 202.4 174.9 150 5300 2970 2640 26900 18300

UF 2120 290 250 150 6400 3395 2845 54000 31000

TWIN - CULLAR (Taste - Odour - Colour)UR 248 41 18.2 65 2600 1536 2125 8100 4600

UR 260 72.4 29 100 3300 1880 2140 8800 5600

UR 272 104 40.9 100 3900 2110 2260 12070 7770

UR 284 140.8 52.2 150 4580 2360 2385 16400 10400

UR 290 163.2 68 150 4980 2600 2460 22420 12200

UR 2100 202.4 79.5 150 5300 2970 2640 24530 15530

UR 2120 290 114 150 6400 3395 2845 50030 26850

TWIN - SUPER IRON (Iron - Manganese)UFP 248 36 31.9 65 2600 1536 2125 9100 5700

UFP 260 56 52.2 100 3300 1880 2140 9550 6800

UFP 272 80 68 100 3900 2110 2260 13200 9600

UFP 284 104 95.5 150 4580 2360 2385 17200 12000

UFP 290 116 114 150 4980 2600 2460 25000 15000

UFP 2100 158 143 150 5300 2970 2640 27500 19000

UFP 2120 224 200 150 6400 3395 2845 55000 31500

NOTE Weights are approximate. • Dimensions may vary by ± 2%.

MODEL FLOW RATE FITTINGS DIMENSIONS WEIGHTservice backwash in / out width depth height in operation shipping

max Ø

m3/h m3/h DN mm mm mm kg kg

HI-FLO 9 TWINTWIN - FILTR-CLEER (Turbidity)UF 260 72.4 61.9 100 3300 1880 2610 10900 7500

UF 272 104 90.8 100 3900 2110 2760 12700 10700

UF 284 140.8 129.4 150 4580 2360 3135 21200 15300

UF 290 163.2 150 150 4980 2600 3210 29074 17800

UF 2100 202.4 174.9 150 5300 2970 3390 31500 22700

UF 2120 290 250 150 6400 3395 3595 63300 36900

TWIN - CULLAR (Taste - Odour - Colour)UR 260 72.4 29 100 3300 1880 2610 8900 6600

UR 272 104 40.9 100 3900 2110 2760 11000 9100

UR 284 140.8 52.2 150 4580 2360 3135 16100 11700

UR 290 163.2 61.2 150 4980 2600 3210 18760 13650

UR 2100 202.4 79.5 150 5300 2970 3390 21500 18100

UR 2120 290 114 150 6400 3395 3595 57300 29800

TWIN - SUPER IRON (Iron - Manganese)UFP 260 56 52.2 100 3300 1880 2610 11300 8000

UFP 272 80 68 100 3900 2110 2760 13900 11500

UFP 284 104 95.5 150 4580 2360 3135 23200 17000

UFP 290 116 114 150 4980 2600 3210 27800 20500

UFP 2100 158 143 150 5300 2970 3390 35500 26000

UFP 2120 224 200 150 6400 3395 3595 67500 40000

NOTE Weights are approximate. • Dimensions may vary by ± 2%.

14 FILTRATION AND POTABILIZATION

OFSYMODEL FLOW RATE FITTINGS DIMENSIONS WEIGHT

service backwash in / out width depth height in operation shippingmax Ø

m3/h m3/h DN mm mm mm kg kg

OFSY 20 4.5 7.9 1 ½” 1100 880 1960 1320 1050

OFSY 24 5.7 10.9 1 ½” 1200 980 2000 1820 1400

OFSY 30 9.1 15.9 1 ½” 1600 1130 2050 2820 2110

OFSY 36 13.6 27.3 2 ½” 2010 1480 2130 4350 3400

OFSY 48 21.8 40.9 2 ½” 2500 1730 2235 7800 5600

OFSY 54 29.6 56.8 2 ½” 2920 1930 2367 8800 6000

OFSY 60 36.3 61.3 DN 80 3200 1760 2150 10500 7200

OFSY 72 50 90.8 DN 100 3750 2150 2150 15000 10500

OFSY 84 68.1 129.4 DN 100 4350 2450 2160 20000 14000

OFSY 90 82 159 DN 100 4750 2600 2250 25000 17000

OFSY 100 100 174.9 DN 150 5200 2950 2370 29500 21000

OFSY 120 139 250 DN 150 6300 3430 2890 54000 31000

NOTE Weights are approximate. • Dimensions may vary by ± 2%.

NOTE Weights are approximate. • Dimensions may vary by ± 2%.

G.A.C.MODEL FLOW RATE FITTINGS DIMENSIONS WEIGHT

service backwash in / out width depth height in operation shippingmax Ø

m3/h m3/h DN mm mm mm kg kg

G.A.C. 20 3 3.4 1” 500 660 2480 800 500

G.A.C. 24 4.5 4.5 1” 600 760 2515 1100 700

G.A.C. 30 7 7 1 ½” 750 1020 2585 1700 1000

G.A.C. 36 10.8 11 1 ½” 950 1217 2650 2900 1850

G.A.C. 48 18 18 2 ½” 1200 1470 2770 4500 2700

G.A.C. 60 27 28 2 ½” 1500 1770 3000 5600 4000

G.A.C. 72 40 41 DN 80 1800 2100 3110 7500 5500

G.A.C. 84 54 55 DN 80 2100 2400 3160 9800 7000

G.A.C. 90 60 60 DN 100 2300 2705 3370 11200 8500

G.A.C. 100 80 80 DN 100 2500 2850 3420 12500 10000

G.A.C. 120 108 113 DN 100 3000 3430 3890 30000 18000

OPERATING DATAHE HI-FLO 3e FHT HI-FLO 6 / HI-FLO 9 / TWIN / OFSY / G.A.C.

2 barMinimum operating pressure 2 bar 4 bar 1.5 bar

8.3 barMaximum operating pressure 7 bar 4 bar 7 bar up to model 60”

5 bar for the larger models

0.5-49 °COperating temperature 4-50 °C 5-50 °C 5-40 °C

Power supply 110/230/24 V

50/60 Hz

110/230/24 V

50/60 Hz

230/24 V

50/60 Hz

only mod. 2500

230 V 50/60 Hz

22 WPower consumption 10 W only mod. 2500

10 W

10 W

Pressure loss Hi-Flo 6, Hi-Flo 9, TWIN: UF 1 bar; UR 0.3 bar; UU and UFP: 0.5 bar

OFSY and G.A.C. 0.5 bar

UF 1 bar; UR 0.3 bar

UFP and UFX 0.5 bar

0.1-0.9 bar --

Self-cleaning filters remove suspended solids fromwater without replacing filter cartridges. Available infully automatic or semi-automatic versions withdifferent capacities and filtration levels.From 1” to 2½” models, filtering elements aremanufactured in AISI 316 stainless steel woven wiremesh, and cleansing from retained impurities is madeby reverse water jet flow.The cartridges are available in a range from 50 to500 µ.

For high capacity applications EASY MAX self-cleaningfilters with 2” fittings (threaded) and ND 65-80-100(flanged) are available.In semi-automatic models the action of the jet isinitiated by manual adjustment. In fully automaticmodels, a timer-programmer controls the washingintervals, between 1 and 999 hours.EASY-MAX filters, in accordance to CE Standards, aresuitable for civil applications, with electromagneticappliance.

SELF-CLEANING FILTERS ARE A HIGHLY FLEXIBLE, VERSATILE AND ECONOMICAL SOLUTION FOR

ADDRESSING SMALL SCALE WATER FILTRATION PROBLEMS. THEY ARE COMMONLY USED AS

BARRIER AGAINST SUSPENDED SOLIDS FOR PROTECTING SENSITIVE EQUIPMENT.

MODELS

SELF-CLEANINGFILTERS

SELF-CLEANING FILTERS 15

MODEL FLOW RATE FITTINGS DIMENSIONS WEIGHTmax Ø Ø x height shipping

m3/h mm kg

EASY MAXEASY MAX semi-automatic 30 2” 317 x 332 10.5

EASY MAX semi-automatic 38 DN 65 252 x 332 13.5

EASY MAX semi-automatic 50 DN 80 252 x 344 13.5

EASY MAX semi-automatic 52 DN 100 252 x 344 14.5

EASY MAX/A automatic 30 2” 317 x 346 11

EASY MAX/A automatic 38 DN 65 252 x 346 13

EASY MAX/A automatic 50 DN 80 252 x 358 14

EASY MAX/A automatic 52 DN 100 252 x 358 15

NOTE Maximum operating pressure: 16 bar • Maximum temperature water/room: 80 / 40 °CPower supply: 220/24 V - 50 Hz

SELF-CLEANINGFILTER

FAS

MODEL FLOW RATE FITTINGS DIMENSIONS WEIGHTat 0,2 bar Ø Ø x height shipping

m3/h ” mm kg

FAS semi-automatic 6 1 150 x 345 2.7

FAS semi-automatic 8 1 ½ 150 x 345 3.2

EASY semi-automatic 6 1 110 x 300 2.8

EASY semi-automatic 8 1 ½ 110 x 300 3.4

EASY semi-automatic 9.5 2 110 x 300 3.7

EASY A automatic 6 1 110 x 380 4.3

EASY A automatic 8 1 ½ 110 x 380 4.9

EASY A automatic 9.5 2 110 x 380 5.2

NOTE Maximum operating pressure: 16 bar • Maximum temperature water/room: 80 / 40 °CPower supply: 220/24 V - 50 Hz

EASY EASY A

CULLIGAN DYNAMIC SEPARATORS ARE DESIGNED TO REDUCE HIGH TURBIDITY SUSPENDED

SOLIDS FROM WATER, SUCH AS SAND AND GENERAL ORGANIC SUBSTANCES.

IF USED AS PRE-TREATMENT OF THE TRADITIONAL FILTERS, THEY PROLONG FILTRATION CYCLES

AND FILTERING MINERALS USE, AND REDUCE WASH FREQUENCY.

The 5 models with fittings from 1” to 3” areexternally painted carbon steel constructed,suitable for not corrosive water.

Culligan Dynamic Separators are designed toseparate solids from water by means of centrifugalforce. Water enters the top of the unit tangentially and(through internal slots) is drawn into the chamberwhere the separation of solids from water occurs.Water flows down this chamber where thecentrifugal force gives rise to the separation of

those solids having the higher specific weight.These solids fall by gravity and accumulates in thecollection chamber of the unit. Water freed fromsuspended solids is then drawn into the vortex andup to the separator outlet.

MATERIALS

OPERATION

16 DYNAMIC SEPARATORS

DYNAMICSEPARATORS

Maximum operating temperature: 70 °C • Minimum operating pressure: 1 bar • Maximum pressure: 8 bar.

NOTE Weights are approximate. • Dimensions may vary by ± 2%.

MODEL FLOW RATE FITTINGS COLLECTIONCHAMBERCAPACITY

DIMENSIONS WEIGHT

in operation shippingdiameter x heightDrainin / outmaxmin.

m3/h m3/h “ “ litres mm kg kg

DSA 1

DSA 1.5

DSA 1.25

DSA 2

DSA 2.5

DSA 3

4.5 7.5 1 ¾ 1.2 152 x 762 17 11

6.5 11 1¼ ¾ 1.2 152 x 762 17 11

10.5 16 1½ ¾ 1.2 152 x 762 18 11

14.5 24 2 ¾ 3 219 x 854 45 22

21.5 35 2½ ¾ 4.7 219 x 940 50 25

33.5 66 3 ¾ 8.3 273 x 1067 80 46

WATER SOFTENING 17

• HE & HE TWIN, for use in apartment blocks,commercial or light industrial settings, maximumflow rate 8.4 m3/h, with pressure loss 1.7 bar

• HI-FLO 3e, for large commercial and industrialapplications, maximum flow rate 22.7 m3/h

• ULTRA LINE, HA and HB ranges, for industrialapplications, maximum flow rate 227 m3/h

NOTE: details of each standard models are listed in the technicalspecifications tables.

SOFTENING IS THE REMOVAL OF HARDNESS FROM WATER. REMOVAL IS OBTAINED THROUGH

THE EXCHANGE OF CALCIUM AND MAGNESIUM IONS WITH SODIUM, WHICH DO NOT FORM

DEPOSITS OR SCALE. RAW WATER IS PASSED THROUGH A LAYER OF RESIN PREVIOUSLY LOADED

WITH SODIUM, USING SODIUM CHLORIDE. CULLIGAN’S CULLEX FOOD-GRADE EXCHANGE RESIN

IS HIGHLY RESISTANT TO MECHANICAL WEAR, LONG-LASTING, AND SALT-EFFICIENT.

POTASSIUM CHLORIDE CAN ALSO BE USED FOR RESIN REGENERATION, FOR SUITABLE

APPLICATIONS.

MODELS

Exchange resins tanks in the HE & HE Twin rangesare “Quadra-Hull” or PE liner reinforced withfiberglass or epoxy resin.Culligan Quadra-Hull™ tanks are in reinforcedfiberglass, with internal food-grade lining andexternal ABS jacket, against wet and UV rays.Tanks used in Hi-Flo 3e range are in PE linerreinforced with fiberglass or epoxy resin, while theones in the Ultra Line HA and HB range are madefrom high grade carbon steel, internal lining isfood-grade epoxy resins, and external protection ispolyurethane paint.

MATERIALS

Valves are in plastic material for all models of HE,HE Twin and Ultra Line (up to 1550 model) range,while in the Hi-Flo 3e range are in Bronze.For Ultra Line models from 1700, valves are in castiron and flanged piping in stainless steel, internallyand externally protected with epoxy paint.

NOTE Specific resin can be used for Nitrate removal. Our specialist application engineers department willprovide you with appropriate specifications for converting water softeners into Nitrate removal units.

WATER SOFTENING

18 WATER SOFTENING

All Culligan water softeners are fully automatic.HE, HE Twin and Hi-Flo 3e models are suppliedwith a distribution motorized piston valve and witha multi-function programmer for operation phasesmanaging (service, wash, regeneration).All Ultra Line models are supplied with a completebutterfly valve distribution group, and operatingphases (service, wash, regeneration) arecontrolled by an electronic control board whichstarts valves by means of a distribution pilot.Volumetric operation is available, to startregeneration phase in accordance with suppliedwater quantity.A pulse-emitter turbine (or a water meter)controls the water volume, and the electroniccontrol panel starts the regeneration phase whenpreset water volume is reached.Regeneration can also be started manually,without modifying the preset automatic phase.

Duplex and/or Triplex softeners are also available,allowing (once resins are exhausted) to activate asecond unit while the other starts regenerationphase.In addition, for HE range the Progressive Flowmodels are available, which allow to managemultiple softening columns in parallel, to satisfypeak demand for treated water softener withouthaving to oversize the softener itself.With these features it is possible to ensurecontinuous flow of softened water.

Disinfecting systems for water softeners areavailable as an option.

All water softeners can be equipped with BrineSystem (salt container) of different size accordingto available space and operational requirements.

OPERATION

• cooling systems• hot water producers• low pressure boilers• textile industry• food industry• ceramic industry• pharmaceutical industry

PRINCIPAL APPLICATIONS

• professional kitchens• hotels• restaurants• bakeries• professional laundries and cleaners• car wash• animal farms

MODEL FITTINGS EXCHANGE CULLEX DIMENSIONS WEIGHTin / out CAPACITY resin tank salt tank

Ø max H Ø height Ø in operation shipping

” m3 •°f litres m3/h @ bar mm mm mm kg kg

NOTE Weights are approximate. • Dimensions may vary by ± 2%. • Available for Duplex installations.

HEHE 20 1 150 20 2.8 @ 1 229 1067 457 260 55

HE 40 1 356 40 2.8 @ 1 254 1372 457 290 77

HE 60 1 401 56 2.8 @ 1 305 1321 610 490 115

HE 90 1 589 85 2.8 @ 1 356 1651 610 560 152

HE 60 1 ½ 395 56 8.4 @ 1.7 356 1321 610 525 112

HE 90 1 ½ 621 85 8.4 @ 1.7 406 1321 610 550 135

HE 120 1 ½ 887 113 8.4 @ 1.7 406 1651 610 735 170

HE 150 1 ½ 977 142 8.4 @ 1.7 533 1346 762 1030 240

HE 210 1 ½ 1521 198 8.4 @ 1.7 533 1575 762 1180 295

SERVICEFLOW RATE

@PRESSURE LOSS

H The exchange capacity is calculated assuming water hardness equal to 40 °f (400 ppm CaCO3) andsalinity equal to 500 ppm, free from colour, oil, and turbidity, at continuous operation flow rate. Capacitymay vary in accordance to other parameters, such as the percentage of Chlorides, water pressure, andthe purity and type of regenerant.

NOTE Weights are approximate. • Dimensions may vary by ± 2%. • Available for Duplex installations.

MODEL FITTINGS EXCHANGE CULLEX SERVICE DIMENSIONS WEIGHTin / out CAPACITY FLOW RATE resin tank salt tank

Ø max H Ø height Ø in operation shipping

” m3 •°f litres m3/h mm mm mm kg kg

HI-FLO 3eHB 175 2 1164 170 17.7 533 1346 762 452 252

HB 200 2 1361 198 18.3 533 1575 762 508 308

HB 300 2 1944 283 19.3 610 1829 762 704 424

HB 480 2 2916 424 22.7 762 1829 762 1084 644

HB 600 2 4074 595 22.7 914 1829 762 1494 894

H The exchange capacity is calculated assuming water hardness equal to 40 °f (400 ppm CaCO3) andsalinity equal to 500 ppm, free from colour, oil, and turbidity, at continuous operation flow rate. Capacitymay vary in accordance to other parameters, such as the percentage of Chlorides, water pressure, andthe purity and type of regenerant.

WATER SOFTENING 19

MODEL FITTINGS EXCHANGE CULLEX DIMENSIONS FOR TANK WEIGHTin / out CAPACITY FOR resin tank salt tank

Ø max H F/TANK TANK Ø height Ø in operation shipping

” m3 •°f litres m3/h @ bar mm mm mm kg kg

NOTE Weights are approximate. • Dimensions may vary by ± 2%.

HE TWINHE 60 1 401 56 2.8 @ 1 305 1321 610 630 215

HE 90 1 589 85 2.8 @ 1 356 1651 610 765 290

HE 60 1 ½ 395 56 8.4 @ 1.7 356 1321 610 690 206

HE 90 1 ½ 621 85 8.4 @ 1.7 406 1321 610 710 250

HE 120 1 ½ 887 113 8.4 @ 1.7 406 1651 610 960 315

HE 150 1 ½ 977 142 8.4 @ 1.7 533 1346 762 1560 450

HE 210 1 ½ 1521 198 8.4 @ 1.7 533 1571 762 1600 555

H The exchange capacity is calculated assuming water hardness equal to 40 °f (400 ppm CaCO3) andsalinity equal to 500 ppm, free from colour, oil, and turbidity, at continuous operation flow rate. Capacitymay vary in accordance to other parameters, such as the percentage of Chlorides, water pressure, andthe purity and type of regenerant.

SERVICEFLOW RATE

@PRESSURE LOSS

NOTE Weights are approximate. • Dimensions may vary by ± 2%. • Available for Duplex installations.

MODEL FITTINGS EXCHANGE CULLEX SERVICE DIMENSIONS WEIGHTin / out CAPACITY FLOW RATE resin tank salt tank

Ø max H Ø height Ø in operation shipping

” m3 •°f litres m3/h mm mm mm kg kg

ULTRA LINE HAHA 200 1 ½ 1188 198.2 18 500 1915 715 495 395

HA 230 1 ½ 1359 226.5 18 500 1915 715 530 425

HA 290 2 1698 283 26 600 1930 850 715 570

HA 320 2 1869 311 26 600 1930 850 750 600

HA 430 2 2550 424.5 30 750 1980 1025 1080 860

HA 510 2 3060 510 30 750 1980 1025 1160 930

HA 770 2 4587 764 34 950 2056 1070 1830 1470

HA 850 2 5097 849 34 950 2056 1070 1940 1550

HA 1200 2 7136 1217 34 1200 2172 1580 2800 2240

HA 1400 2 8325 1415 34 1200 2172 1580 3000 2420

H The exchange capacity is calculated assuming water hardness equal to 40 °f (400 ppm CaCO3) andsalinity equal to 500 ppm, free from colour, oil, and turbidity, at continuous operation flow rate. Capacitymay vary in accordance to other parameters, such as the percentage of Chlorides, water pressure, andthe purity and type of regenerant.

OPERATING DATAHE / HE TWIN HI-FLO 3e ULTRA LINE HA e HB

Minimum operating pressure

Maximum operating pressure

Operating temperature

Pressure loss

Power supply

Power consumption

1.4 bar for models 1”

1.7 bar for models 1.5”2 bar 2 bar

8.6 bar for models 1”

8.3 bar for models 1.5”8.5 bar 7 bar from mod. 200 to mod. 2100

5 bar for other models

0-49 °C for models 1”

4.4-38 °C for models 1.5”1-40 °C 1-40 °C

from 0.8 to 1 bar for models 1”

from 1 to 1.7 bar for models 1.5”

~0.5 bar at medium flow rate

~1.5 bar at maximum flow rate

~0.5 bar at medium flow rate

~1.5 bar at maximum flow rate

230/24 V - 50/60 Hz 230/24 V - 50/60 Hz 110/230/24 V - 50/60 Hz

8.4-21.61 W 20 W 20 W

NITRATE REMOVAL

2 bar

7 bar for models up to 1700

5 bar for model 2500

2-40 °C

0.3 - 0.6 bar

110/230/24 V - 50/60 Hz

10 W

20 WATER SOFTENING

MODEL FITTINGS EXCHANGE CULLEX SERVICE DIMENSIONS WEIGHTin / out CAPACITY FLOW RATE resin tank salt tank

Ø max H Ø height Ø in operation shipping

” m3 •°f litres m3/h mm mm mm kg kg

ULTRA LINE HBHB 770 2 ½ 4587 764 50 950 2056 1070 1840 1480

HB 850 2 ½ 5097 849 50 950 2056 1070 1950 1550

HB 1200 2 ½ 7136 1217 50 1200 2172 1580 2810 2250

HB 1400 2 ½ 8325 1415 50 1200 2172 1580 3010 2430

HB 1550 2 ½ 8825 1500 60 1400 2392 1580 4200 2580

HB 1700 4 10430 1568 114 1500 2620 1580 6105 3355

HB 2100 4 11390 1904 114 1500 2620 1580 6354 3644

HB 2500 4 16050 2296 114 1800 2660 BRINE MAKERu 8480 4500

HB 3000 4 18480 2632 114 1800 2660 BRINE MAKERu 8760 4790

HB 4500 6 28500 4032 227 2100 3030 BRINE MAKERu 13080 7300

HB 6600 6 42900 6020 227 2500 3100 BRINE MAKERu 19585 10485

NOTE Weights are approximate. • Dimensions may vary by ± 2%. • Available for Duplex installations.

u See separate Data Sheet for concrete Brine Maker dimensions.

H The exchange capacity is calculated assuming water hardness equal to 40 °f (400 ppm CaCO3) andsalinity equal to 500 ppm, free from colour, oil, and turbidity, at continuous operation flow rate. Capacitymay vary in accordance to other parameters, such as the percentage of Chlorides, water pressure, andthe purity and type of regenerant.

MODEL FITTINGS EXCHANGE CULLEX SERVICE DIMENSIONS WEIGHTin / out CAPACITY FLOW RATE resin tank salt tank

Ø max H Ø height Ø in operation shipping

l g NO3/kg salt litres m3/h mm mm mm kg kg

NITRATE REMOVALHB 200 2 ” 3000/40 200 4 600 2000 850 885 460

HB 300 2 ½ ” 5200/70 350 7 750 2050 850 1330 665

HB 600 3 ” 9000/120 600 12 950 2130 1070 2375 1305

HB 1000 3 ” 15000/200 1000 20 1200 2400 1580 3660 1780

HB 1700 DN 100 25500/340 1700 34 1500 2620 1580 6105 3355

HB 2500 DN 100 37500/500 2500 50 1800 2660 BRINE MAKERu 8480 4500

NOTE Weights are approximate. • Dimensions may vary by ± 2%.

u See separate Data Sheet for concrete Brine Maker dimensions.

l Fittings: threaded 2” and 3”; flanged DN 100 and 150. The diameters indicated refer only to Nitrateremoval unit pipework and not to connections to piping systems

H The exchange capacity is calculated assuming water hardness of 100 ppm max as NO3, salinity equal to500 ppm, free from color, oil, and turbidity, at continuous operation flow rate. Capacity may vary inaccordance to other parameters, such as the percentage of sulphates, alkalinity, Nitrates, water pressure,treated water drawing, purity and type of regenerant.

TO COMPLETE WATER TREATMENT SYSTEMS, CULLIGAN HAS DEVELOPED AND CUSTOMIZED A

RANGE OF DOSING SYSTEMS, WHICH INCLUDE SPECIFIC ELECTROMAGNETIC PUMPS

(ANALOGUE INTERFACE), STORAGE TANKS, CHEMICALS AND DOSING ANALYSIS CONTROL

BOARDS.

DOSING SYSTEMS

For each model the following accessories areavailable:

• chemical tanks, of various sizes, depending onapplication

• minimum level switch for Chemicals tank

Accessories• wall-mounting brackets

• water meter with pulse emitter

• anti-syphon kit

Dosing pumps are widely used in water treatment.Correct dosing of chemical products is the basefor good operation of any water treatment wherewater quality is critical, for potabilization, boilers,pool conditioning, and any other industrial orprivate systems.Culligan produces solenoid driven meteringpumps with analogue or digital interface.All parts in contact with water are made incorrosion resistant material, like PVDF, Viton, PTFEand ceramics.

The following models are available:

• BASIC2 Continuous operation or controlled viaON-OFF switch.

• PROP2 Continuous operation, controlled via ON-OFF switch or pulse emitter.

• LOGIC2 Continuous operation, controlled viapulse emitter, or proportional to regulating4-20 mA signal.

DOSING PUMPS

DOSING SYSTEMS 21

NOTE Power supply 110/240 V - 50/60 Hz - single phase • Protection degree IP 65

MODELS NOMINALCAPACITY

l/h

BASIC2 40 • PROP2 40 • LOGIC2 40

BASIC2 130 • PROP2 130 • LOGIC2 130

BASIC2 80 • PROP2 80 • LOGIC2 80

BASIC2 400 • PROP2 400 • LOGIC2 400

4

6

13

40

PRESSUREmax

bar

10

8

8

2

VOLUME/STROKE

cm3

0.55

0.83

0.72

2.22

STROKESPER MINUTE

max

120

160

300

300

POWERCONSUMPTION

W

17

18

32

30

WEIGHT

kg

3.6

4.1

4.1

4.1

OPERATION: BASIC2 continuous or ON/OFF switchPROP2 continuous or pulse emitterLOGIC2 continuous or 4-20 mA signal

22 INSTRUMENTATION AND CONTROLS

INDUSTRIAL WATER TREATMENT PROCESSES REQUIRE CLOSE CONTROL AND MONITORING OF

SEVERAL CRITICAL PARAMETERS TO ENSURE WATER QUALITY. THE MOST IMPORTANT BEING

TEMPERATURE, pH, CONDUCTIVITY, REDOX, RESIDUAL CHLORINE.

CULLIGAN OFFERS A COMPLETE RANGE OF MONITORING INSTRUMENTS FOR USE IN WATER

TREATMENT SYSTEMS.

pH-METER Mod. S508-pH (CONTROL PANEL)

Technical data• Standard range: 0-14 pH• Display: LCD• Power output: 2 off 0-20/4-20 mA dc. load ≤ 600 Ohm• Protection degree: IP 54

Mod. S507-pH (WALL) - S507-pH (PANEL)

Technical data• Standard range: 0-14 pH• Display: LCD• Power output: 2 off 0-20/4-20 mA dc. Maximum load 600 Ohm• Protection degree: IP 66

The Automatic Blow Down for Cooling Towers includes a programmingcontrol board, a conductivity meter, a conductivity cell for a constantconductivity projection, a motorized valve, a dosing pump for shock biocidedosing, a test sample, electric and hydraulic interconnections.

Technical data• Power supply: 230V~ ± 10% 50-60Hz• Operating power: 7VA (conductivity meter only), 40VA (conductivity

meter + dosing pump), 15VA (conductivity meter + solenoid valve)• Liquid temperature: 40 °C max• Dimensions: 495 x 300 x 655 mm (width x depth x height)• Shipping weight: 15 kg

BLOW DOWN

INSTRUMENTATIONAND CONTROLS

INSTRUMENTATION AND CONTROLS 23

Mod. S508-Rx (CONTROL PANEL)

Technical data• Standard range: -1000 a +1000 mV• Display: LCD• Power output: 2 off 0-20/4-20 mA dc. load ≤ 600 Ohm• Protection degree: IP 54

Mod. S507-Rx (WALL) - S507-Rx (PANEL)

Technical data• Standard range: -1000 a +1000 mV• Display: LCD• Power output: 2 off 0-20/4-20 mA dc. Maximum load 600 Ohm• Protection degree: IP 66

REDOX-METER

Mod. C2-C2000 S508 (CONTROL PANEL)

Mod. C2-C2000 S507 (WALL)

Technical data• Standard range: 0-2000 µS• Display: LCD• Power output: 2 off 0-20/4-20 mA dc. Maximum load 600 Ohm• Protection degree: IP 54 (CONTROL PANEL); IP 66 (WALL)

Mod. S507 / S508 (CONTROL PANEL) - S507 (WALL)

Technical data• Standard range: -1000 a +1000 mV• Display: LCD• Power output: 2 off 0-20/4-20 mA dc. Maximum load 600 Ohm• Protection degree: IP 54 (CONTROL PANEL); IP 66 (WALL)

TURBIDITYMETER

Potentiostatic or Amperometric models

Mod. S508 (CONTROL PANEL)

Technical data• Standard range: 0-2 ppm of free Cl2• Display: LCD• Power output: 2 off 0-20/4-20 mA dc. Maximum load 600 Ohm• Protection degree: IP 54

Mod. S507 (WALL) - S507 (PANEL)

Technical data• Standard range: 0-2 ppm of free Cl2• Display: LCD• Power output: 2 off 0-20/4-20 mA dc. Maximum load 600 Ohm• Protection degree: IP 66

RESIDUAL CHLORINEMETER

CONDUCTIVITYMETER

RW08 remote control via web, with 1.5-m cableTechnical data• Power supply: 230 V 50 Hz• Watertight tank: cam 20x20, 11 cm depth• Protection degree: IP 56

MONITORINGDOSING SYSTEM

24 INSTRUMENTATION AND CONTROLS

MC-10 Control BoardAvailable with amperometric or potenziostatic cellTechnical data• Power supply: 230 Vac ± 10% 50-60 Hz• Operating power: 7 VA max• Display: 2 off alphanumeric LCD displays with 2 lines (16 digits), back-light• Protection degree: IP 65

CONTROL BOARD

Mod. S508 (CONTROL PANEL)Technical data• Standard range: 0,005 - 2 ppm as ClO2; 0,05 - 20 ppm as ClO2• Display: LCD• Power output: 2 off 0-20/4-20 mA dc. Maximum load 600 Ohm• Protection degree: IP 54

Mod. S507 (WALL) - S507 (PANEL)Technical data• Standard range: 0,005 - 2 ppm as ClO2; 0,05 - 20 ppm as ClO2• Display: LCD• Power output: 2 off 0-20/4-20 mA dc. Maximum load 600 Ohm• Protection degree: IP 65

CHLORINE DIOXIDEANALYSER

Chlorine Dioxide DetectorTechnical data• Power supply: 10-30 Vac• Dimensions: 160x122x76 mm• Power output: 4-20 mA• Protection degree: IP 65

DETECTOR

Mod. C500 (CONTROL PANEL)

Technical data• Up to 3 programmable inputs• Up to 6 programmable inputs• Prints on paper• Protection degree: IP 54

RECORDER

INSTRUMENTATION AND CONTROLS 25

Two types of controllers are available depending on application:

Electronic Timer PLF - 2K (PROGRAMMABLE LOGIC FUNCTION):for single units.

Electronic Timer PLM - 2K (MULTITASK):for multiple units and systems.All Culligan controllers in the Commercial/Industrial Series use a 24 V - 50 Hzpower feed.An appropriate transformer is available as an option.

ELECTRONIC TIMER

Analyser suitable for softener monitoringTechnical data• Power supply: 230V 50Hz + earth• Dimensions: 120 x 120 x 220 mm (width x depth x height)• Weight: 0,5 kg• Protection degree: IP 54

SOFTENINGCONTROL

TestomatTechnical data• Standard measuring range:

0,09-0,89 °f; 0,45-4,48 °f; 1,79-17,90 °f; 4,4-4,44 °f • Programmable measurements interval 5/10/20 or 30 minutes• Pressure: 10 bar max• Temperature: 45 °C max• Parts in contact with water are in corrosion proof material

WATER HARDNESSMONITOR

MODEL MAXIMUM UNIT LAMP WEIGHTFLOW RATE POWER POWER

CONSUMPTION in operation shipping

m3/h V W kg kg

U.V. 20S 4.0 100 2 x 40 19 15

U.V. 40S 11.5 * 210 4 x 40 51 45

U.V. 60S 17.0 * 300 6 x 40 60 52

U.V. 40L 23.0 ** 350 4 x 75 82 75

U.V. 60L 34.0 ** 500 6 x 75 150 102

U.V. 80L 45.5 ** 650 8 x 75 158 110

U.V. 100L 57.0 ** 800 10 x 75 215 132

U.V. 120L 68.5 ** 900 12 x 75 228 145

U.V. 16L 91.5 ** 1200 16 x 65 240 150

U.V. 20L 114.5 ** 1450 20 x 65 336 210

U.V. 24L 137.0 ** 1800 24 x 65 400 250

U.V. 32L 171.0 ** 2300 32 x 65 600 350

U.V. 40L/0 229.0 ** 2900 40 x 65 750 440

U.V. 48L 274.5 ** 3480 48 x 65 950 500

ULTRAVIOLET

* For inlet water with Transmittance T10>96% the dosage is 400 J/m2

** For inlet water with Transmittance T10>94% the dosage is 400 J/m2

Maximum operating pressure 8 bar

Operating temperature room 4-45 °C; water 2-80 °C

Pressure loss at maximum flow rate 0.14 bar for 20S model - 0.2 bar for other models

Power supply 230V - 50/60 Hz

OPERATING DATA

Ultraviolet systems have a high disinfectingcapacity: U.V. rays at 254 nm (nanometer) destroy99.9% of pathogens.They are available in different models, as per tablehere below.Models 40 S, 60 S, and from 40 to 120 L areavailable only with display area.

They are mainly used for point of use disinfectionof sanitary circuits, and as a bacteria preventionon closed circuits. In addition, they are suitable asReverse Osmosis pre-treatment, and whereverdisinfection is necessary, and it is preferred toavoid Chemicals use.

U.V. (ULTRAVIOLET) RAYS ARE GENERATED BY SPECIAL LAMPS EMITTING THE APPROPRIATE

WAVELENGTH OF LIGHT FOR KILLING/INACTIVATING MICROORGANISMS. U.V. TECHNOLOGY IS

OFTEN SELECTED WHEN AN EFFICIENT SYSTEM FOR ELIMINATING PATHOGENS WITHOUT USING

CHEMICALS IS PREFERRED. SOMETIMES U.V. IS USED IN CONJUNCTION WITH OTHER

OXIDANTS/DISINFECTANTS (OZONE, OXYGEN, ETC.) TO INCREASE THEIR EFFECTIVENESS.

MODELS

U.V. STERILIZATION

26 U.V. STERILIZATION

CULLIGAN AERATION TOWERS ARE DESIGNED TO REDUCE, THROUGH FORCED DRAFT AERATION,

THE CONCENTRATION OF DISSOLVED GAS IN WATER. FORCED AERATION OXIDIZES WATER AND

REMOVES GASES SUCH AS METHANE (CH4), CARBON DIOXIDE (CO2) AND HYDROGEN SULFIDE

(H2S). DEGASSERS ARE INSTALLED ABOVE WATER COLLECTING TANKS AND ARE EQUIPPED WITH

A SPECIAL FLANGE FOR EASY INSTALLATION.

Aeration towers models 400, 600, 1000 and 1400are entirely manufactured in polypropylene (PP),while model 1800 is in high grade carbon steel,with a food-grade epoxy resins internal lining and

external corrosion protection using polyurethanepaint.Packing rings for all models are in polypropylene(PP).

Aeration towers are equipped with electric fans thatforce air from the bottom towards the fine waterdroplets falling from the top, thereby separating gasfrom water which is expelled through a vent.

A specially designed device at the base of theaeration tower prevents air from dispersingtowards the water collecting tank.

MATERIALS

OPERATION

The efficiency of aeration towers can be improvedwith the following optional accessories, which areavailable for all models:

• DROP-STOP FILTERS: reduces the amount ofwater carried over by the air stream and areinstalled just prior to the gas outlet.

• SPRAY NOZZLES: designed for maximum waternebulization, are installed on the inlet distributor.

OPTIONAL ACCESSORIES

MODEL CAPACITY* ELECTRIC FAN AIR DIMENSIONS WEIGHT220/380V - 50 Hz - 3 ph FLOW RATE

(1) (2) power max head width depth height in operation shipping

m3/h m3/h kW mm H2O m3/min mm mm mm kg kg

F.D.A. 400 4 10 0.55 ~ 140 13 560 1180 2620 220 110

F.D.A. 600 9 22 1.5 ~ 140 29 780 1475 2620 350 148

F.D.A. 1000 24 60 3 ~ 140 80 1120 1920 2620 1000 335

F.D.A. 1400 50 120 5.5 ~ 140 160 1545 2400 2620 1600 540

F.D.A. 1800 80 200 11 ~ 140 260 1960 2785 3310 3000 1400

* Operating temperature: 5-60 °C • (1) Hydrogen Sulphide and Trihalomethanes (THM’s) • (2) Methane and Carbon Dioxide.

NOTE – Weights are approximate. • Dimensions may vary by ± 2%.

– In addition to the standard models above, aeration towers for larger volumes of water and/or for removingspecific gasses are designed upon request.

AERATION TOWERS

AERATION TOWERS 27

28 MICROFILTRATION

MODEL FLOW RATE CARTRIDGES FITTINGS DIMENSIONS WEIGHT Ø Ø height shipping

withstand*

m3/h no. ” mm mm kg

FGX3

NOTE Operating pressure: 8 barTest pressure: 11.4 bar

FGX3 125 7.5 3 x 500 mm 1 ½ gas 168.3 1115 20

FGX3 150 9 3 x 750 mm 1 ½ gas 168.3 1365 22

FGX3 250 15 3 x 1000 mm 1 ½ gas 168.3 1620 24

FGX3 415 24.9 7 x 750 mm 2 ½ gas 219.1 1371 27

FGX3 580 34.8 7 x 1000 mm 2 ½ gas 219.1 1630 34

FGX3 750 45 9 x 1000 mm 3 gas 273 1780 44

* The figures may change, according to the tripod adjustment.

GARD SYSTEM

NOTE See separate sheets for Gard System technical data.

The diagram shows some out of the many arrangements, which can be obtained with 2, 3 and4 elements.

GARD SYSTEMSingle or multiple filters with ¾”, 1” or 1½” BSPT-Ffittings.A highly versatile modular system, combining filtersinto various configurations (parallel, series, series-parallel, parallel-series) for removal of coarsesuspended solids, activated carbon filters and toprevent corrosion. Gard System cartridges areavailable in the following models:

• STRAINER: with filtration element in washablestainless steel woven wire mesh, for the removal ofsuspended solids up to 10 µm.

• MONOSTAGE or MULTISTAGE: polypropylene food-grade filtering element, for the selective removal ofturbidity.Depending on the type of cartridge used, the filtrationrange varies from 1 to 80 µm.

• IO-CHEM SP12: Crystal phosphate cartridge, forcorrosion prevention.

• CULLAR D: active carbon cartridge, for theabsorption of organics and dechlorination.

FGX3Multiple cartridge filters for medium flow ratesapplications, with AISI 316 stainless steel enclosures,inlet–outlet threaded fittings UNI 338. This systemallows the installation of cartridges of differentfiltration levels (1 - 5 - 20 µm), in standard lengths of10, 20, 30, and 40 inches (250, 500, 750, 1000 mm).Cartridge replacement is easy and rapid thanks to theclamp opening system.The filter is supplied with tripod support for floorinstallation.

MECHANICAL FILTERS ARE A HIGHLY FLEXIBLE, VERSATILE AND ECONOMICAL SOLUTION FOR

ADDRESSING SMALL SCALE WATER FILTRATION PROBLEMS. THEY ARE COMMONLY USED AS

BARRIER AGAINST SUSPENDED SOLIDS FOR PROTECTING SENSITIVE EQUIPMENT.

MODELS

MICROFILTRATION

ULTRAFILTRATION IS A PROCESS OF SEPARATION UNDER PRESSURE, ABLE TO SEPARATEINSOLUBLE PARTICLES FROM WATER AND ABLE TO TOTALLY REMOVE SUSPENDED SOLIDS.THE HEART OF THE ULTRAFILTRATION SYSTEM IS FORMED BY THE MODULES THAT CARRY OUTTHE REAL PROCESS OF SEPARATION: THEY HAVE A HIGH CAPACITY TO WITHHOLD COLLOIDS,SILT, BACTERIA AND MOST VIRUSES.

NOTE Power supply 380 V - 50 Hz 3-phase + earth.

MODEL

ULF 10

ULF 40

ULF 20

ULF 60

ULTRAFILTRATION

Ultrafiltration systems are available in differentmodels, with flow rates from 6 to 112 m3/h. Themodules are made to attain high resistance to

mechanical stress from rubbing and arecomposed of a double layer of hollow fibres(capillaries) made of PVDF.

MODELS

MODULES

No.

1

2

4

6

FLOW RATEmax

m3/h

6

12

24

38

INSTALLEDPOWER

2.2

2.2

3

4

HYDRAULICFITTINGS

DN 40

DN 40

DN 50

DN 65

DIMENSIONS(length x width x height)

mm

1800 x 2150 x 2350

1800 x 2150 x 2350

1800 x 2150 x 2350

2300 x 2150 x 2350

ULF 80

ULF 100

8

10

50

62

4

5.5

DN 80

DN 80

2300 x 2150 x 2350

2750 x 2150 x 2350

ULF 120

ULF 140

12

14

75

87

7.5

7.5

DN 80

DN 80

2750 x 2150 x 2350

3200 x 2150 x 2150

ULF 160

ULF 180

16

18

100

112

11

15

DN 100

DN 100

3200 x 2150 x 2150

3400 x 2150 x 2350

kW

The completely automated system performsscheduled washes during the production cycle.In addition it is equipped with a differentialpressure, able to detect a too high loss of head(caused by the membranes clogging) and to beginthe washing cycle.

The system is fully automated with an electricpanel complete with a PLC, controlling all pumps(metering, washing, etc.) and taking informationfrom pressure and flow measuring instruments.

OPERATION

• Filtering water contaminated by colloids,microbiological impurities and suspended solids

• Production of potable water from surface, springor well water

PRINCIPLE APPLICATIONS

• Pretreatment for Reverse Osmosis systems• Tertiary filtering in waste treatment systems to

obtain water of suitable quality for reuse innon-potable uses

ULTRAFILTRATION 29

30 REVERSE OSMOSIS

The range of standard available R.O. units are listedbelow:

• E1, M1, G1 SERIEScapacity from 40 to 350 l/h

• AQUA-CLEER PROFESSIONAL(designed for dental laboratories) capacity 12 l/h

• AQUA-CLEER SB 200capacity up to 200 l/h

• AQUA-CLEER NFC SERIES(designed for use with industrial dishwashers)capacity 180 l/h

• AQUA-CLEER MFP 4-44 SERIES * capacity from 400 to 3600 l/h

• AQUA-CLEER R.O.2 SERIES*capacity from 400 to 1600 l/h

• AQUA-CLEER SW SERIEScapacity from 300 to 6000 l/h

• AQUA-CLEER IW E & IW L SERIEScapacity from 5000 to 36000 l/h

Compact Systems

• AQUA-CLEER S.D.S.*(for home-based dialysis) capacity from 80 to100 l/h

• PHARMA(for the production of pure water for laboratories)capacity from 35 to 160 l/h

* Models in the MFP 4-44, R.O.2 and S.D.S. range are alsoavailable as “Medical Device”.

NOTE: R.O.2 models are composed by two reverse osmosis units,which are normally operated simultaneously in series (doublepass R.O. or product staging), in emergency the units can beoperated one at the time (single pass R.O.). These units aresuitable for use in hemodialysis and other critical applications.In addition to standard units, it is possible to design customizedunits, for higher flow rates.

REVERSE OSMOSIS (THE ACRONYM R.O. IS COMMONLY USED) IS THE PROCESS OF FORCING

WATER FROM A COMPARTMENT OF HIGH SALT CONCENTRATION THROUGH SEMIPERMEABLE

MEMBRANES TO A COMPARTMENT OF LOWER SALT CONCENTRATION.

OSMOTIC MEMBRANES ARE THE FINEST FILTERS ACTING AS A BARRIER FOR SALTS AND

ORGANICS WITH MOLECULAR WEIGHT ABOVE 100 DALTON, AND ARE AN OUTSTANDING

PROTECTION AGAINST MICRO-POLLUTANTS, PESTICIDES, PYROGENS, VIRUSES AND BACTERIA.

REVERSE OSMOSIS IS A PHYSICAL PROCESS, AND DOES NOT REQUIRE CHEMICALS’ USE.

THE REVERSE OSMOSIS PROCESS IS VERY SIMPLE AND RELIABLE, AND IN RECENT YEARS THE

AVAILABLE MEMBRANES HAVE BEEN DEVELOPED TO GIVE A LOWER ENERGY CONSUMPTION.

MEMBRANES ARE OF HIGH QUALITY AND RELIABILITY, ALSO FOR SPECIFIC WATER APPLICATION.

MODELS

REVERSE OSMOSIS

Hot water DisinfectionSystem

REVERSE OSMOSIS 31

Aqua-Cleer R.O. units are equipped with fullyautomatic control systems for operations andquality control (by means of relevant indicators),and safety.

A number of accessories specifically designed fordialysis are available, meeting current regulatorystandards, including the Discharge Device forartificial kidney, with internal siphon to avoid therise of bacteria from the drain network to thekidney machine.

It is manufactured in AISI Stainless steel and it iscomplete with fast connection.

Hot water production systems are also availablefor thermal sanitization of water distribution loops,as well as cabinets for sound proofing the R.O.units.

Semipermeable membranes are the very heart ofany R.O. unit. Culligan’s Aqua-Cleer systems usespiral wound membranes, selected in accordancewith the characteristics of the water to be treatedand the required capacity.For Sea Water R.O. units, membranes suitable forhigh salinity (up to 45000 ppm) are used.

MATERIALS

OPERATION AND ACCESSORIES

Materials used in fabrication, particularly for partsin contact with water, are food-grade and selectedfor high resistance to corrosion (AISI 316 stainlesssteel, PVC and polyethylene).

Sound proofenclosurefor BI-OMOSISMedical Device

DischargeDevice forartificial kidney

PLC Control Panel

32 REVERSE OSMOSIS

MODEL INSTALLED FITTINGS NOMINAL DIMENSIONS WEIGHT POWER in out FLOW RATE width depth height shipping

feeding product HØ Ø

kW mm mm l/h mm mm mm kg

E1 M1 G1 SERIES

NOTE Weights are approximate. • Dimensions may vary by ± 2%.

R.O. UNITS FOR BRACKISH WATERS

H Average values based on the following standard conditions: water temperature 25 °C;raw water TDS 500 ppm as NaCl; product water pressure 0 bar; new membranes.

For use in applications where high level ofchemical and bacteriological water purity isrequired, and in contrast to traditional deionizationsystems there is no handling or discharge ofhazardous chemicals.

• desalination for potable water production frombrackish or sea water

• pure water for medium to high pressure boilers

• humidifiers

• microchip rinsing for the micro-electronicindustry

• pharmaceutical and cosmetic industry

• textile industry• food production

PRINCIPAL APPLICATIONS

• restaurants, for best dishwasher performance• pre-treatment for boiler deionization system• potable water for ice production• offset printing, to maximise quality and improve

production yield• chemical laboratories, for rinsing instruments

and glassware• floriculture• dialysis applications using “Medical Device”

models, as per UNI CEI EN ISO 13485 Norm,certified to CE0434

• … and in many other applications where purewater is required

E1 Series

M1 Series

G1 Series

E1-1S 0.25 10 10 40 885 312 948 29

E1-2S 0.25 10 10 80 885 312 948 34

E1-3S 0.25 10 10 120 885 312 948 39

E1-2L 0.56 10 10 190 885 312 948 43

E1-3L 0.56 10 10 270 885 312 948 50

E1-4L 0.56 10 10 350 979 312 1090 57

M1-1S 0.25 10 10 40 885 312 948 29

M1-2S 0.25 10 10 80 885 312 948 34

M1-3S 0.25 10 10 120 885 312 948 39

M1-2L 0.56 10 10 190 885 312 948 43

M1-3L 0.56 10 10 270 885 312 948 50

M1-4L 0.56 10 10 350 979 312 1090 57

G1-2S 0.25 10 10 80 955 312 948 35

G1-3S 0.25 10 10 120 955 312 948 40

G1-2L 0.75 10 10 190 955 312 948 44

G1-3L 0.75 10 10 270 955 312 948 51

G1-4L 0.75 10 10 350 1048 312 1090 59

E1 SERIES

M1 SERIES

G1 SERIES

REVERSE OSMOSIS 33

MODEL INSTALLED FITTINGS NOMINAL DIMENSIONS WEIGHT POWER in out FLOW RATE width depth height shipping

feeding product HØ Ø

kW “ “ l/h mm mm mm kg

AQUA-CLEERSB 200

NOTE Weights are approximate. • Dimensions may vary by ± 2%.

H Average values based on the following standard conditions: water temperature 20 °C;raw water TDS 500 ppm as NaCl; product water pressure 0 bar; new membranes.

R.O. UNITS FOR BRACKISH WATERSSB 200 1.5 1 ½ 200 800 650 1600 221

MODEL INSTALLED FITTINGS NOMINAL DIMENSIONS WEIGHT POWER in out FLOW RATE width depth height shipping

feeding product HØ Ø

kW “ “ l/h mm mm mm kg

AQUA-CLEERPROFESSIONAL

NOTE Weights are approximate. • Dimensions may vary by ± 2%.

H Average values based on the following standard conditions: water pressure 6.2 bar with booster pump;water temperature 25 °C; TDS 500 mg/l without counter-pressure with new membrane.

POTABLE WATER SYSTEMProfessional - ¼ ¼ 12 410 310 565 10

NOTE Weights are approximate. • Dimensions may vary by ± 2%.

H Average values based on the following standard conditions: water temperature 20 °C;raw water TDS 500 ppm as NaCl; product water pressure 0 bar; new membranes.

MODEL INSTALLED FITTINGS NOMINAL DIMENSIONS WEIGHT POWER in out FLOW RATE width depth height shipping

feeding product HØ Ø

kW “ “ l/h mm mm mm kg

NFC SERIESR.O. UNITS FOR BRACKISH WATERSNFC 99 0.42 ½ ½ 180 570 460 605 48

34 REVERSE OSMOSIS

MODEL INSTALLED FITTINGS NOMINAL DIMENSIONS WEIGHT POWER in out FLOW RATE width depth height shipping

feeding product HØ Ø

kW “ “ l/h mm mm mm kg

R.O.2

R.O. UNITS FOR PURE WATER PRODUCTIONR.O.2 400 1.5 + 1.5 1 ½ 400 1000 700 1850 220

R.O.2 800 2.2 + 2.2 1 ½ 800 1000 700 1850 260

R.O.2 1200 3 + 3 1 ½ 1200 1000 700 1850 310

R.O.2 1600 4 + 4 1 ½ 1600 1000 700 1850 350

MODEL INSTALLED FITTINGS NOMINAL DIMENSIONS WEIGHT POWER in out FLOW RATE width depth height shipping

feeding product HØ Ø

kW “ “ l/h mm mm mm kgkg

SWSEA WATER R.O. UNITSSW 300 5.5 1 ½ 300

SW 600 5.5 1 ½ 600

SW 900 15 1 ½ ¾ 900

SW 1500 18.5 1 ½ 1 1500

SW 2000 18.5 1 ½ 1 2000

SW 3000 37 2 1 ½ 3000

SW 4000 45 2 ½ 1 ½ 4000

SW 6000 55 2 ½ 1 ½ 6000

NOTE Weights are approximate. • Dimensions may vary by ± 2%.

H Average values based on the following standard conditions: water temperature 20 °C;raw water TDS 500 ppm as NaCl; product water pressure 0 bar; new membranes.

NOTE Weights are approximate. • Dimensions may vary by ± 2%.

H Average values based on the following standard conditions: water temperature 20 °C;raw water TDS 500 ppm as NaCl; product water pressure 0 bar; new membranes.

MFP 4-44

NOTE Weights are approximate. • Dimensions may vary by ± 2%.

H Average values based on the following standard conditions: water temperature 20 °C;operating pressure 200 or 261 psi (14 or 18 bar); recovery ratio 75%; raw water TDS 500 ppm as NaCl;product water pressure 0 bar; new membranes.

MODEL INSTALLED FITTINGS NOMINAL DIMENSIONS WEIGHT POWER in out FLOW RATE width depth height shipping

feeding product HØ Ø

kW “ “ l/h mm mm mm kg

R.O. UNITS FOR BRACKISH WATERS400 1.5 1 ½ 400 500 660 1550 115

800 1.5 1 ½ 800 500 660 1550 140

1200 2.2 1 ½ 1200 500 660 1550 170

1600 2.2 1 ½ 1600 500 660 1550 190

2200 4 1 ¾ 2000 500 660 1800 220

2800 4 1 ¾ 2400 500 660 1800 250

3300 4 1 ¾ 2800 500 660 1800 280

3600 4 1 ¾ 3200 500 770 1800 280

4000 4 1 ¾ 3600 500 770 1800 280

CHANGES ACCORDING

TO CONFIGURATION

REVERSE OSMOSIS 35

MODEL INSTALLED FITTINGS NOMINAL DIMENSIONS WEIGHT POWER in out FLOW RATE width depth height shipping

feeding productØ Ø

kW mm mm l/h mm mm mm kg

S.D.S.

MODEL INSTALLED FITTINGS NOMINAL DIMENSIONS WEIGHT POWER in out FLOW RATE width depth height shipping

feeding productØ Ø

kW mm mm l/h mm mm mm kg

PHARMA

NOTE Weights are approximate. • Dimensions may vary by ± 2%.

NOTE Weights are approximate. • Dimensions may vary by ± 2%.

R.O. UNIT FOR HOME-BASED DIALYSISS.D.S. 0.39 8 6 80-100 375 365 900 50

PURE WATER FOR LABORATORIESPharma 20 0.25 10 6 35 380 440 920 80

Pharma 45 0.42 12 8 80 500 500 1450 123

Pharma 80 0.42 12 8 120 500 500 1450 130

Pharma 120 0.42 12 8 160 500 500 1450 140

MODEL INSTALLED FITTINGS NOMINAL DIMENSIONS WEIGHT POWER in out FLOW RATE width depth height shipping

feeding product HØ Ø

kW “ “ l/h mm mm mm kg

IW E • IW LR.O. UNITS FOR BRACKISH WATERSIW E/L 5 7.5 2 1 ½ 5000 4850 1200 1700 650

IW E/L 8 7.5 2 2 8000 3850 1200 1700 710

IW E/L 12 11 2 2 12000 3850 1200 1700 950

IW E/L 16 11 2 2 16000 4850 1200 2100 1280

IW E/L 20 15 3 2 20000 6850 1200 2100 1370

IW E/L 23 15 3 2 23000 6850 1200 2100 1600

IW E/L 26 18.5 3 2 ½ 26000 4850 1200 2250 1850

IW E/L 30 22 3 2 ½ 30000 6850 1200 2250 2100

IW E/L 36 22 3 2 ½ 36000 6850 1200 2250 2100

NOTE Weights are approximate. • Dimensions may vary by ± 2%.

H Average values based on the following standard conditions: water temperature 20 °C;raw water TDS 1500 ppm as NaCl; product water pressure 0 bar; new membranes.

OPERATING DATA

In hospitals it is often necessary to installequipment quickly and within limited space.Dual Box is the answer: a packaged systemhoused in two steel free standing industrialenclosures, containing pre-treatment and Bi-Osmosis units, fully pre-assembled with allconnections and hydraulic and electronic controls.

DUAL BOX

These systems are “plug and play”, you only needto connect water inlet, outlet and drain and powersupply.Bi-Osmosis units are equipped with PLC controlpanel, for managing all operational functions.Enclosures are lockable for complete security.

36 REVERSE OSMOSIS

E1 - M1 - G1 SERIESAQUA-CLEER PROFESSIONAL

AQUA-CLEER SB 200NFC SERIES

Minimum inlet water pressure

E1 - M1 - G1 Series: 1.4 bar

Aqua-Cleer Professional: 2.8 bar

Aqua-Cleer SB 200: 2 bar

NFC Series: 1 bar

2 bar

MFP 4-44 / R.O.2 / SWIW E / IW L

S.D.S. / PHARMA

S.D.S.: 1 bar

Pharma: 1.5 bar

Operating pressure

Aqua-Cleer Professional: 6.2 bar

Aqua-Cleer SB 200: 13 bar

NFC Series: 12 bar

MFP e R.O.2: 14 bar up to 1600 model

18 bar for other models

SW: > 35 bar - IW E / IW L: 14 bar

S.D.S.: 1 bar

Pharma: 1.5 bar

Power supply

E1 - M1 - G1 Series: 230 V - 50 Hz

Aqua-Cleer Professional: 24/230 V - 50 Hz

Aqua-Cleer SB 200: 380 V - 50 Hz

NFC Series: 24/230/110 V - 50 Hz

380 V - 50 Hz 380 V - 50 Hz

TDS (maximum salinity as NaCl) 500 ppm3000 ppm up to 1600 model

1500 ppm for other models1500 ppm

E1 - M1 - G1 Series: 40-50%

Aqua-Cleer Professional: 25%

Aqua-Cleer SB 200: 75%

NFC Series: 20-60%

75% max

S.D.S.: 50%

Pharma 20: 20-25%

Pharma 45-80-120: 20-30%

Recovery ratio

Operating pressure for

membranes’ feedingE1 - M1 - G1 Series: 10.5 bar - -

DEMINERALIZATION 37

The “continuous Electrodeionization” is the latestaddition to the Culligan range. EDI produces highquality water with no need for regenerants, suchas acid and caustic, typical of demineralizationsystems with ion exchange resins.

To attain the ultra-high quality standards, the EDIsystem uses electricity, selective membranes andion exchange resins.

DEMINERALIZATION (OR DEIONIZATION) IS A PROCESS MEANT TO REMOVE SALTS FROM WATER

THROUGH ION EXCHANGE RESIN.

WATER IS PASSED THROUGH CATION AND ANION RESIN, EITHER SEPARATE OR MIXED TOGETHER.

POSITIVELY CHARGED IONS (CATIONS) AND NEGATIVELY CHARGED IONS (ANIONS) ARE

RETAINED BY CATION RESIN AND ANION RESIN RESPECTIVELY.

ONCE RESIN BECOMES SATURATED WITH RETAINED SALTS, REGENERATION WITH

HYDROCHLORIC ACID AND SODIUM HYDROXIDE IS NECESSARY TO RESTORE THE EXCHANGE

CAPACITY.

Electrodeionization is a technology for theproduction, without using chemicals products, ofultrapure water, thanks to the combined use ofspiral-wound membranes and ion-exchangeresins. A continuous electric current source is connectedto an anode and a cathode which keeps the resinactivated and, thanks to the magnetic field

between anode and cathode, improves the waterelectrolysis and the separation of the dissolvedions.Thanks to this process is possible to produce highpurity water (18 MOhms) starting from waterwhich has been already demineralized by adouble-pass reverse osmosis system or a doubleresins bed.

The construction materials used and especiallythose of the parts in contact with the water are allof proven resistance to corrosion and do not giverise to any phenomena of transfer.

MATERIALS

OPERATION

DEMINERALIZATION

The models in the EDI Culligan line are designedand made according to the highest standards ofquality, safety and silence.

The EDI has a general electrical panel completewith PLC so it is independently managed.

The brine injection system, complete with tankand recirculation pump with the front panelcomplete with flow rate and pressure gauges,makes the system complete and compact.

MODELS

EDI

38 DEMINERALIZATION

• Electronic

• High pressure boiler

• Painting

• Printing

PRINCIPAL APPLICATIONS• Preparation and dilution of liquors

• Pharmaceutical

• Cosmetic

• Make-up water

The “portable Electrodeionization” line includessmall ion exchange demineralization systems of

easy maintenance, and makes use of resin notsuitable for on-site regeneration.

Culligan deionizers are fully automatic, withprogrammable service, and regeneration cycles.D and MB Deionizers can be connected to thewater supply via flexible hoses included in thepackaging.A monitoring device will indicate when resin isexhausted. Regeneration is carried out in Culliganpremises.Pharma has been conceived with criteria ofrationality and simplicity: given that the system isto be fed with potable water, and using, in the re-finishing phase, «single-use» resins, since theyoffer better exchange characteristics compared tonormal regenerative resins, and they eliminate the

bother and costs associated with handling thecontainers for periodic regeneration.A device for partial recycling and timing providesfor continuous or intermittent use, alwaysmaintaining the quality of product water at thehighest levels.A second timer signals, with an acoustical andvisual alarm, when it is advisable to replace thepre-filtration cartridges.The quality of product water is constantlymonitored by a conductivity meter, which can testeither the purity of the treated water or of theosmotic water.

Resin vessels in the Deionizer Serie D and MB aremanufactured in fiberglass.MB fiberglass vessels are protected by externalABS jacket.Refill Line vessels are available in stainless steel orPVC.

MATERIALS

OPERATION

Pharma is a compact system, with characteristicsof safety, compactness, transportability andquietness. All the hydraulic components arecorrosion proof, and suitable for food and medicaluse. They have designed to withstand, by a largemargin, the normal operation of the system.

These standard models are available:

• Deionizer D 25 P, MB 9 and MB 16, mixed bedportable exchange.

• Refill Line, high-capacity single-use mixed bedresin cartridge ideal for low volume applications.

• Pharma for ultrapure water production, for thespecific requirements of analyses’ laboratories.

MODELS

• Pharmaceutical

• Cosmetic

• High pressure boiler

PRINCIPAL APPLICATIONS• Laboratories

• Printing

• Preparation and dilution of liquors

PEDI

Demineralization automatic systems are oftenincluded in Culligan Matrix Solutions proposals,when great volume of high quality water isrequested.

Culligan on-site regenerable deionizers are fullyautomatic, with programmable service, andregeneration cycles.DS Deionizers are equipped with two automaticvalves (one per column) and one common controlpanel.

Deyolit series Deionizers are equipped with acontrol panel (including conductivity meter)designed to monitor the process andautomatically initiate regeneration when waterquality deteriorates beyond a pre-determinedlimit.

Resin vessels in the Deionizer DS line aremanufactured in fiberglass.Deyolit resin vessels are manufactured in highgrade carbon steel, internally coated in ebonite

MATERIALS

OPERATION

(hard rubber) and externally painted with corrosionproof paint. Valves in Noryl and piping in PVC areideally suited to withstand extreme pH conditions.

• Deionizer DS separate exchange columns (cationand anion), with automatic on-site resinregeneration.

• Deyolit NRC, separate exchange columns andcounter-current regeneration, for high qualitywater and low regenerant consumption.

• Deyolit AMB, mixed bed unit, for completeremoval of salts from water (ideal for polishingwater already treated by separate two beddeionizers or RO units).

MODELS

• Electronic

• High pressure boiler

• Printing

• Preparation and dilution of liquors

• Food and beverage

PRINCIPAL APPLICATIONS• Painting

• Pharmaceutical

• Cosmetic

• Product water

• Water-jet cut

AUTOMATIC DEMINERALIZATION

DEMINERALIZATION 39

NOTE Dimensions may vary by ± 2%.

MODEL

EDI 10

EDI 30

EDI 20

EDI 40

MODULES

No.

1

2

3

4

FLOWRATEmax

m3/h

2.2

4.5

6.5

9

DIMENSIONS(length x width x height)

mm

1700 x 1200 x 1500

1700 x 1200 x 1500

1700 x 1200 x 1500

1700 x 1550 x 1500

EDI 60 6 13 1700 x 1550 x 1500

EDIPOWER

kW

2

3.5

5

7

10

HYDRAULIC FITTINGS

1½”

2”

2”

2”

2”

Supply

1”

1”

1”

1½”

1½”

Product

tube Ø 6

tube Ø 6

tube Ø 6

tube Ø 6

tube Ø 6

Electrolyte

1”

1”

1”

1”

1”

Concentrate

MODEL EXCHANGE SERVICE FITTINGS DIMENSIONS WEIGHT CAPACITY FLOW RATE in/out Ø height in operation shippingPER CICLE Ø

kg (CaCO3) l/min. ” mm mm kg kg

DEIONIZER D

NOTE Weights are approximate. • Dimensions may vary by ± 2%.

D 25 P 0.16 3 ¼ 190 600 20 16.2

MODEL EXCHANGE SERVICE FITTINGS DIMENSIONS WEIGHT CAPACITY FLOW RATE in/out Ø height in operation shippingPER CICLE Ø

kg (CaCO3) l/min. ” mm mm kg kg

DEIONIZER MB

NOTE Weights are approximate. • Dimensions may vary by ± 2%.

MB 9 0.7 15 ½ 255 1450 80 58.5

MB 16 2.2 50 ½ 406 1620 200 150

PHARMA

NOTE Weights are approximate. • Dimensions may vary by ± 2%.

REFILL LINEMIXED BED10-l resin 220 250H ≥ 2 MΩ 80% of cycle - 0.5 MΩ end of cycle TDS ≤ 500 ppm

20-l resin 450 500H ≥ 2 MΩ 80% of cycle - 0.5 MΩ end of cycle TDS ≤ 500 ppm

SOFTENER10-l resin 600 500 TH < 5 °f TH ≤ 35 °f

20-l resin 1500 1000 TH < 5 °f TH ≤ 35 °f

ACTIVATED CARBON10-l carbon depending on charge 400 free of Chlorine Chlorine ≤ 3 ppm

20-l carbon depending on charge 1200 free of Chlorine Chlorine ≤ 3 ppm

QUANTITY EXCHANGE FLOW RATE TREATED WATER OPERATINGOF RESINS CAPACITY QUALITY LIMITS

OR CARBON

litres g (CaCO3) l/h drinking water

HWhen the unit is fed with R.O. water, the flow rate can be doubled.Treated water quality improves as well.

NOTE See separate sheets for technical data.

PHARMA 20

MODEL

kg (CaCO3)

EXCHANGECAPACITY

PER CYCLE

0.22

PHARMA 45 0.22

PHARMA 80 0.22

PHARMA 120 0.22

l/min.

SERVICEFLOW RATE

35

80

120

160

mm

DIMENSIONS

380

500

500

500

mm

440

500

500

500

mm

920

1450

1450

1450

width depth height

kg

WEIGHTshipping

80

123

130

140

40 DEMINERALIZATION

OPERATING DATA

MODEL EXCHANGE SERVICE FITTINGS DIMENSIONS WEIGHT CAPACITY FLOW RATE in/out width depth height in operation shipping

PER CYCLE Ø

kg (CaCO3) m3/h ” mm mm mm kg kg

DEYOLIT NRCNRC 12/12 12 6.5 2 2000 1000 2950 1625 1300

NRC 20/20 20 11 2 2100 1100 3000 3063 2450

NRC 30/30 30 16 2 2280 1270 3050 4500 3600

NRC 50/50 50 23 2 2480 1470 3100 7000 5600

NRC 80/80 80 40 2 ½ 2980 1720 3250 10500 8400

MODEL EXCHANGE RAW D.I. FITTINGS DIMENSIONS WEIGHT CAPACITY WATER WATER in/out width depth height in operation shipping

PER CYCLE FLOW RATE FLOW RATE Ø

kg (CaCO3) m3/h m3/h ” mm mm mm kg kg

DEYOLIT AMBAMB 3000 3 3.4 7.9 1 ½ 830 750 2710 600 350

AMB 5000 5 4.5 10.9 2 1000 850 2800 700 400

AMB 7500 7.5 6.8 15.9 2 1000 1000 3200 880 500

NOTE Weights are approximate. • Dimensions may vary by ± 2%.