WATER SUPPLY AND SEWERAGE - Home - Logan City · PDF file“Planning Guidelines for Water...

Transcript of WATER SUPPLY AND SEWERAGE - Home - Logan City · PDF file“Planning Guidelines for Water...

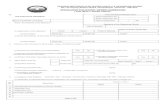

1

BEAUDESERT SHIRE COUNCIL

WATER SUPPLY AND

SEWERAGE

INFRASTRUCTURE GUIDELINES

2006

File No. 070-020-000019

Updated March 2007 Datworks DOC SET 1735572

2

Table of Contents

1. INTRODUCTION ..................................................................................................................6

1.1 DEFINITIONS ...................................................................................................................................................................6

1.2 PURPOSE .........................................................................................................................................................................6

1.3 BASIS OF GUIDELINES ................................................................................................................................................7

1.4 SCOPE...............................................................................................................................................................................8

1.5 GENERAL .........................................................................................................................................................................8

1.6 DEDICATION OF LAND, EASEMENTS & PERMITS TO ENTER ..........................................................................8

1.7 EXTENT OF INFRASTRUCTURE ................................................................................................................................9

1.8 CONNECTIONS TO THE LOCAL GOVERNMENT’S INFRASTRUCTURE..........................................................9

2 WATER SUPPLY INFRASTRUCTURE ..............................................................................10

2.1 GENERAL .......................................................................................................................................................................10

2.2 WATER SERVICE TYPES ...........................................................................................................................................10

2.3 WATER SERVICE AREAS ..........................................................................................................................................11

3 SEWERAGE INFRASTRUCTURE......................................................................................12

3.1 GENERAL .......................................................................................................................................................................12

3.2 SEWERAGE COLLECTION SYSTEMS ....................................................................................................................12

3.3 SEWERAGE SERVICE AREAS..................................................................................................................................12

3.4 UNCONVENTIONAL INFRASTRUCTURE ...............................................................................................................12

3.5 SEWAGE TREATMENT PLANT .................................................................................................................................12

3.6 SEWAGE PUMPING STATIONS ................................................................................................................................13

3.7 PRIVATE SEWAGE PUMPING STATIONS & PRESSURE MAINS .....................................................................13

APPENDIX 1. ADDENDUM TO WSA 03 - 2002 ...................................................................15

WSA03 – 1 GENERAL ........................................................................................................................................................15 WSA03 – 1.5 DESIGN RESPONSIBILITIES ...............................................................................................................15 WSA03 – 2 SYSTEM PLANNING .................................................................................................................................16 WSA03 - 2.2 DEMANDS .................................................................................................................................................16 WSA 03 - 2.3 SYSTEM CONFIGURATION .................................................................................................................18 WSA 03 - 2.4 SYSTEM HYDRAULICS.........................................................................................................................19 WSA 03 - 2.5 WATER QUALITY ...................................................................................................................................19 WSA 03 - 2.6 PUMPING STATIONS ............................................................................................................................19

3

WSA 03 - 2.7 SERVICE RESERVOIRS........................................................................................................................20 WSA 03 - 2.10 CONCEPT PLAN...................................................................................................................................22

WSA 03 - 3 HYDRAULIC DESIGN....................................................................................................................................22 WSA 03 - 3.2 SIZING OF MAINS ..................................................................................................................................22 WSA 03 - 3.7 PIPE AND FITTINGS PRESSURE CLASS.........................................................................................23

WSA 03 - 4 GENERAL DESIGN........................................................................................................................................23 WSA 03 - 4.1 GENERAL REQUIREMENTS................................................................................................................23 WSA 03 - 4.3 LOCATION OF WATER MAINS ...........................................................................................................23 WSA 03 - 4.4 SHARED TRENCHING...........................................................................................................................24 WSA 03 – 4.6 RIDER MAINS .........................................................................................................................................24 WSA 03 - 4.7 CONNECTION OF NEW MAINS TO EXISTING MAINS ..................................................................24 WSA 03 - 4.8 TERMINATION POINTS.........................................................................................................................24 WSA 03 - 4.9 PROPERTY SERVICES .........................................................................................................................25

WSA 03 - 6 APPURTENANCES........................................................................................................................................25 WSA 03 – 6.2 STOP VALVES .......................................................................................................................................25 WSA 03 - 6.8 HYDRANTS ..............................................................................................................................................25

WSA 03 - 7 DESIGN REVIEW AND DRAWINGS...........................................................................................................26 WSA 03 - 7.2 DESIGN DRAWINGS..............................................................................................................................26 WSA 03 - 7.3 RECORDING OF WORKS AS CONSTRUCTED INFORMATION..................................................26

WSA 03 - 8 PRODUCTS AND MATERIALS OVERVIEW.............................................................................................26

WSA 03 -12 PRODUCTS AND MATERALS ...................................................................................................................27 WSA 03 -12.1 AUTHORISED PRODUCTS AND MATERIALS ...............................................................................27

WSA 03 – 15 PIPE LAYING AND JOINTING..................................................................................................................27 WSA 03 - 15.10 MARKING TAPES ..............................................................................................................................27 WSA 03 - 15.16 LOCATION MARKERS......................................................................................................................27

WSA 03 - 19 ACCEPTANCE TESTING ...........................................................................................................................27

WSA 03 - 20 DISINFECTION .............................................................................................................................................27

WSA 03 - 22 CONNECTIONS TO EXISTING WATER MAINS ....................................................................................27

WSA 03 - 24 WORK AS CONSTRUCTED DETAILS ....................................................................................................28

WSA 03 - PART 4 STANDARD DRAWINGS ..................................................................................................................28

APPENDIX 2. ADDENDUM TO WSA 02 – 2002 ..................................................................30

WSA 02 - 1 GENERAL ........................................................................................................................................................30 WSA 02 - 1.3 PLANNING AND DESIGN RESPONSIBILITIES AND INTERFACES ...........................................30

WSA 02 - 2 SYSTEM PLANNING .....................................................................................................................................30 WSA 02 - 2.2 PLANNING PRINCIPLES ......................................................................................................................30 WSA 02 - 2.3 PLANNING PARAMETERS...................................................................................................................31

WSA 02 - 3 FLOW ESTIMATION ......................................................................................................................................31 WSA 02 - 3.2 DESIGN FLOW ESTIMATION METHOD ............................................................................................31

WSA 02 - 4 DETAIL DESIGN.............................................................................................................................................31 WSA 02 - 4.2 DETAIL DESIGN CONSIDERATIONS ................................................................................................31 WSA 02 - 4.3 HORIZONTAL ALIGNMENT OF SEWERS ........................................................................................32 WSA 02 - 4.5 PIPE SIZING AND GRADING ...............................................................................................................32 WSA 02 - 4.6 VERTICAL ALIGNMENT OF SEWERS...............................................................................................33

4

WSA 02 - 5 PROPERTY CONNECTION..........................................................................................................................34 WSA 02 - 5.3 METHODS OF THE PROPERTY CONNECTION ..............................................................................34 WSA 02 - 5.7 Y - PROPERTY CONNECTIONS..........................................................................................................34

WSA 02 - 6 MAINTENANCE STRUCTURES ..................................................................................................................34 WSA 02 - 6.3 SPACING OF MAINTENANCE STRUCTURES.................................................................................34 WSA 02 - 6.4 SPECIAL CONSIDERATIONS FOR LOCATION OF MAINTENANCE STRUCTURES .............34 WSA 02 - 6.6 MAINTENANCE HOLES (MH) ..............................................................................................................34 WSA 02 - 6.7 MAINTENANCE SHAFTS (MS) ............................................................................................................35

WSA02 - 7 ANCILLIARY STRUCTURES ........................................................................................................................35 WSA02 - 7.9 OVERFLOWS / EMERGENCY RELIEF STRUCTURES (ERS) .......................................................35

WSA 02 - 9 DESIGN REVIEW AND DRAWINGS...........................................................................................................35 WSA 02 - 9.2 DESIGN DRAWINGS..............................................................................................................................35 WSA 02 - 9.3 DRAFTING STANDARDS......................................................................................................................36

WSA 02 - APPENDIX A ESTIMATION OF EQUIVALENT POPULATION (EP) .......................................................36

WSA 02 - APPENDIX B FLOW ESTIMATION FOR UNDEVELOPED AREAS. ......................................................36

WSA 02 - 10 PRODUCTS AND MATERIALS OVERVIEW...........................................................................................36

WSA 02 - 13 GENERAL CONSTRUCTION.....................................................................................................................37 WSA 02 - 13.2 ORDER OF CONSTRUCTION, TESTING AND COMMISSIONING.............................................37

WSA 02 - 14 PRODUCTS AND MATERIALS .................................................................................................................37 WSA 02 - 14.1 AUTHORISED PRODUCTS AND MATERIALS ..............................................................................37

WSA 02 - 17 PIPE LAYING AND JOINTING...................................................................................................................37 WSA 02 - 17.2 HORIZONTAL AND VERTICAL DEFLECTION OF SEWERS ......................................................37 WSA 02 - 17.7 PROPERTY CONNECTION SEWERS ..............................................................................................37

WSA 02 - 22 ACCEPTANCE TESTING ...........................................................................................................................37

WSA 02 - 24 CONNECTION TO EXISTING SEWERS ..................................................................................................37

WSA 02 - PART 4 STANDARD DRAWINGS ..................................................................................................................37

APPENDIX 3. ADDENDUM TO WSA 04 - 2001 ...................................................................40

WSA 04 - 1 GENERAL ........................................................................................................................................................40 WSA 04 - 1.1 SCOPE AND OBJECTIVES ..................................................................................................................40

WSA 04 - 2 FACILITY NEEDS...........................................................................................................................................40 WSA 04 - 2.7 STAGING ..................................................................................................................................................40

WSA 04 - 3 OVERALL DESIGN CRITERIA ....................................................................................................................40 WSA 04 - 3.1 PUMPING SYSTEM ................................................................................................................................40 WSA 04 - 3.5 OUTPUT SYSTEM ..................................................................................................................................40

WSA 04 - 4 DETAILED DESIGN CRITERIA ...................................................................................................................41 WSA 04 - 4.2 PUMPING SYSTEM ................................................................................................................................41 WSA 04 - 4.3 POWER SYSTEM....................................................................................................................................41 WSA 04 - 4.4 CONTROL AND TELEMETRY SYSTEM ............................................................................................42 WSA 04 - 4.5 INPUT SYSTEM.......................................................................................................................................44 WSA 04 - 4.6 OUTPUT SYSTEM ..................................................................................................................................45 WSA 04 - 4.9 DOCUMENTATION .................................................................................................................................45

WSA04 - PART 2 MATERIALS .........................................................................................................................................46

5

WSA 04 - PART 3 CONSTRUCTION................................................................................................................................46

WSA 04 - PART 4 STANDARD DRAWINGS ..................................................................................................................49

APPENDIX 4A. AUTHORISED PRODUCTS LIST – WATER SUPPLY ...............................52

APPENDIX 4B. AUTHORISED PRODUCTS LIST – SEWERAGE.......................................57

6

1. INTRODUCTION 1.1 DEFINITIONS The Shire means Beaudesert Shire. Water Agency, Local Government, BSC or Council means Beaudesert Shire Council. The Guidelines means this document, the Beaudesert Shire Council’s Water Supply and Sewerage Infrastructure Guidelines. Realisation of Infrastructure means any or all aspects of the planning, design, construction, supervision of construction, testing and commissioning of water supply and sewerage infrastructure. Developer means the person whom has made a planning application requiring the Realisation of Infrastructure or utilisation of existing water supply and sewerage infrastructure. WSAA Codes means the Water Supply Code of Australia (WSA 03), Sewerage Code of Australia (WSA 02) and Sewage Pumping Station Code of Australia (WSA 04) published by the Water Services Association of Australia (WSAA) as amended from time to time. Designer has the same meaning as in the WSAA Codes and in addition, means an Engineer whom is qualified in Queensland (This qualification is currently met by a person being a Registered Professional Engineer in Queensland [RPEQ]) and is competent to perform Realisation of Infrastructure. Constructor has the same meaning as in the WSAA Codes. Superintendent has the same meaning as in the WSAA Codes. Headworks Contributions Policy means The Local Government’s “Policy on Water Supply and Sewerage Headworks Contributions” as amended from time to time. IPA means the Integrated Planning Act 1997 IDAS means the Integrated Development Application system under IPA D & C Manual means Beaudesert Shire Council’s Design & Construction Manual dated 1st September 1999. DNRM Guidelines means the Queensland Department of Natural Resources and Mines. “Planning Guidelines for Water Supply and Sewerage – March 2005”. 1.2 PURPOSE The purpose of the Guidelines is to set out the Local Government’s requirements for the Realisation of Infrastructure in the Shire. The Guidelines fulfill the function of the “Water Supply and Sewerage Guidelines” referred to in the following sections of the Beaudesert Planning Scheme 2006:

• Policy 7, Part 6 – Standards for Sewerage

7

• Policy 7, Part 8 – Water Supply 1.3 BASIS OF GUIDELINES Except as modified in the Guidelines, the Realisation of Infrastructure shall be carried out in accordance with the following codes (WSAA Codes) published by the Water Services Association of Australia (WSAA) as amended from time to time.

• Water Supply Code of Australia WSA 03-2002 • Sewerage Code of Australia WSA 02-2002 • Sewage Pumping Station Code of Australia WSA 04-2001

Reference is also made to the Queensland Department of Natural Resources and Mines “Planning Guidelines for Water Supply and Sewerage – March 2005” (DNRM Guidelines) as amended from time to time. The Guidelines will serve as an interim document until the South East Queensland versions of the WSAA Codes are published. The Guidelines replace the following sections/clauses of the D & C Manual. Clause 2.2.5 Design Drawings – Water Reticulation Clause 2.2.6 Design Drawings – Sewerage Reticulation Section 2.6 Design Requirements - Water Reticulation Section 2.7 Design Requirements - Sewerage and CED Reticulation Clause 3.2.5 Inspections - Water Reticulation Clause 3.2.6 Inspections - Sewerage Reticulation Section 3.6 Specifications & Construction - Water Section 3.7 Specifications & Construction - Sewerage Reticulation Section 3.9 Standard Specification for Electrical Equipment/Switchboards for

Submersible Sewerage Pump Stations. Section 3.10 Standard Specification for Pump and Mechanical Equipment for

Submersible Sewerage Pump Stations. Drawings 50600 to 50639 inclusive (Water) 50700 to 50739 inclusive (Sewerage) The Guidelines shall be read in conjunction with the D & C Manual, in particular, the following Sections/Clauses. Part 1 Applications & approvals Section 2.1 Introduction Clause 2.2.1 Drawing Basis and Design Survey required Clause 2.2.2 Drawings – general Clause 2.2.8 Erosion and Sediment Control Section 2.11 Easements – Drainage, Water, Sewer/C.E.D Section 3.1 Introduction Section 3.2 Inspections (except Clauses 3.2.5 & 3.2.6) Section 3.11 Works Permits Conditions for Council Controlled Roads Section 3.12 Works Permits Conditions for Subdivisions Part 4 As Constructed

8

Part 5 Appendices The provisions of these Guidelines shall take precedence over the provisions of the above mentioned Codes, Guidelines and Manuals. 1.4 SCOPE The Guidelines have the following functions:

• To specify administrative matters that are not the subject of the WSAA Codes pertaining to operational works applications made in accordance with the IPA.

• To nominate the WSAA Codes as the general requirement to be met for the Realisation of Infrastructure.

• To specify those parameters, requirements and functions contained in the WSAA Codes that the Water Agency is to nominate.

• To specify technical requirements not covered by the WSAA Codes. • To identify materials, solutions and methods permitted by the WSAA Codes that are

not acceptable to the Local Government. • To specify preferred options where the WSAA Codes provide for several methods to

deal with a particular issue.

1.5 GENERAL It is the Designer’s responsibility to ensure that the current version of the Guidelines is used. The Guidelines may be downloaded from the Local Government’s website. The Local Government will not permit the connection of new Infrastructure to the Local Government’s infrastructure unless the new infrastructure has been designed, constructed and supervised to the Local Government’s satisfaction. 1.6 DEDICATION OF LAND, EASEMENTS & PERMITS TO ENTER

General infrastructure

The Local Government requires all pumping stations, storage tanks, reservoirs, water towers and the like to be located on land that is owned by or will be dedicated to the Local Government, except that small underground pumping stations may, with State Government’s approval, be located on land that is or will become road reserve. Pumping stations that are not sited in road reserves shall be provided with a 5-metre wide access dedicated to the Local Government in fee simple.

Pipelines

The Local Government requires easements to be registered in its favour in accordance with Section 2.11 of the D & C Manual.

In the event that works are to be constructed through properties not under the control of the Developer, the Developer shall submit with the Operational Works Application:

• A ‘Permit To Enter’ letter, signed by each property owner through whose property the infrastructure is to be constructed, consenting to the construction of the works.

• Proof of the registration of easements in favour of the Local Government.

9

1.7 EXTENT OF INFRASTRUCTURE Water mains shall be constructed along the full frontage of the development site.

Where possible, sewers shall be extended through the development site to the boundary of any upstream properties at a depth specified by the Local Government sufficient to service the upstream properties.

If a reconfiguration of a lot results in water service or sewerage connection to any existing building being at any point outside the new lot containing the building then the Developer shall realign the services to be situated wholly within the new lot boundary. A separate plumbing works application will be required. The extent of the infrastructure to be provided by the Developer, the extent of infrastructure to be provided by the Local Government from Developer contributions and arrangements for offsetting infrastructure built for the Local Government by the Developer against Developer contributions are described in the Beaudesert Planning Scheme 2006 Policy 5, Part 2 – Infrastructure Contributions for Water Supply Infrastructure and Sewerage Infrastructure. 1.8 CONNECTIONS TO THE LOCAL GOVERNMENT’S INFRASTRUCTURE The connection of new water supply and sewerage reticulation to the Local Government’s existing systems forms part of the Realisation of Infrastructure to be carried out at the Developer’s expense. The Local Government will undertake all live connections to its existing infrastructure. Before the Local Government makes the live connection, an estimate of cost will be provided to the Developer and the connection will not be made until payment is received.

10

2 WATER SUPPLY INFRASTRUCTURE 2.1 GENERAL The planning, design and construction of water supply infrastructure shall be in accordance with the Guidelines. Those aspects of modification or clarification of the WSAA Codes detailed in clause 1.4 above in respect of water supply are detailed in this Section 2 of the Guidelines and in Appendix 1 of the Guidelines, which relates to the Water Supply Code of Australia (WSA 03). 2.2 WATER SERVICE TYPES Three types of water services are in use in the Local Government Area.

• On Demand (OD) • Restricted Demand (RD) • Mixed Demand (MD)

The nature of the water service to a particular development project is subject to the Local Government’s decision. On Demand (OD) services provide water at pressure to the property and are generally restricted to the following precincts in the Beaudesert Planning Scheme 2006 that are declared water areas:

• Town Centre Core • Frame • Mixed Use • Business • Minor convenience Centre • Industry • Medium Density Residential • Residential • Village Centre • Village

Restricted Demand (RD) services require the property to have two tanks, one for town water and one for rainwater, and a pumping system for water delivery from the two tanks. The town water tank is filled at a constant flow rate of two litres per minute (nominal 2,900 litres per day) controlled by a valve at the property boundary. RD services are typically found in Rural Residential precincts in the Shire’s declared water areas. From 2003, all new service connections in these precincts are Mixed Demand service connections. Mixed Demand (MD) services provide an on-demand pipeline to the kitchen sink only. One rainwater tank (31,500L min) is required, the lower third being devoted to town water filled via a float valve at a restricted flow rate of one litre per minute (nominal 1,500 litres per day) from the town supply. The top two thirds of the tank is filled by rainwater and the householder must install a pumping system from the tank for all household supply except cold water to the kitchen sink. MD services are generally now required to all new connections in Rural Residential precincts that are declared water areas. In some areas, the Local Government may require a higher on-site storage capacity in order to maintain reasonable levels of service.

11

RD & MD services are collectively referred to as Constant Flow (CF) services in these Guidelines. CF options for non domestic uses will be assessed prior to the Local Government approval of the development application. 2.3 WATER SERVICE AREAS There are six water service areas in the Local Government area.

• Northern Area – Treated water supplied from Logan City Council. (OD) • Lower Logan – Raw water from Logan River treated at South Maclean (OD & CF) • Beaudesert – Raw water from Logan River treated at Beaudesert (OD & CF) • Kooralbyn – Raw water from Logan River treated at Kooralbyn (OD) • Rathdowney – Raw water from Logan river treated at Rathdowney and, (OD) • Canungra – Raw water from Canungra Creek treated at Canungra (OD & CF)

Future service areas may include Bromelton and Tamborine Village

12

3 SEWERAGE INFRASTRUCTURE 3.1 GENERAL The planning, design and construction of sewerage infrastructure shall be in accordance with the Guidelines. Those aspects of modification or clarification of the Codes detailed in clause 1.4 above in respect of sewerage reticulation are detailed in this Section 3 of the Guidelines and in Appendix 2 of the Guidelines, which relates to the Sewerage Code of Australia (WSA 02). Those aspects of modification or clarification of the Codes detailed in clause 1.4 above in respect of sewage pumping stations are detailed in this Section 3 of the Guidelines and in Appendix 3 of the Guidelines, which relates to the Sewage Pumping Station Code of Australia (WSA 04). 3.2 SEWERAGE COLLECTION SYSTEMS Two types of sewerage collection systems are in use in the Local Government area.

• Conventional Gravity Sewerage (CGS) • Common Effluent Drainage (CED)

For descriptions of each type, refer to DNRM Guidelines, Chapter 7, Table 5.13. 3.3 SEWERAGE SERVICE AREAS There are six sewerage service areas in the Local Government area:

• Logan Village - part CGS and part CED • Flagstone - CGS • Jimboomba - part CGS and part CED • Beaudesert - part CGS and part CED • Canungra - part CGS and part CED • Kooralbyn - CGS

For a particular development, the Local Government will determine the type of sewerage collection system to be adopted. 3.4 UNCONVENTIONAL INFRASTRUCTURE The Local Government may consider other unconventional infrastructure where it is appropriate. The use of unconventional infrastructure shall require special approval and may require extended maintenance periods and a higher value for performance bonds. Unconventional infrastructure includes small bore systems of any kind, including vacuum systems, grinder pumps serving small clusters of properties and the like, proprietary maintenance structure systems that do not permit entry by personnel, and any other unconventional or unusual systems. 3.5 SEWAGE TREATMENT PLANT Should a temporary or permanent sewage treatment plant be required, an IDAS application will be required and the Environmental Protection Agency will be a concurrence agency under the provisions of IPA. Upon referral of the application to the EPA, the applicant will be advised of the criteria to be addressed in an Environmental Impact Statement (EIS). It shall be the responsibility of the Developer to satisfy all information requests by the Local

13

Government and any other referral agency. All approvals shall be obtained by the developer at the Developer’s expense. 3.6 SEWAGE PUMPING STATIONS The developer is responsible for the supply and installation of all equipment and materials associated with the sewage pumping stations. This includes the concrete benching in wet well base, pumps, electrical cabinet and associated wiring, level control, telemetry, internal pipe work and well washer. 3.7 PRIVATE SEWAGE PUMPING STATIONS & PRESSURE MAINS Where a gravity sewer connection is not available to a development, the Local Government may approve a private sewerage pumping station which will discharge to the existing sewerage system via a private pressure main. The private sewage pumping station and pressure main shall be designed in accordance with the requirements of WSA 04 and appendix 3 of these Guidelines. The costs associated with the connection of the private system to the existing sewerage system (system analysis, design and upgrade to provide capacity) shall be borne by the developer. If the connection point is an existing sewer MH, the Local Government may require the provision of a non corrosive pipe installed for the length of sewer to the next downstream MH and an inlet lining to all internal surfaces of the discharge MH. Where the connection point is to an existing pressure main, these works shall be provided by the Local Government at full cost to the developer. As the private sewage pumping station is a component of the internal plumbing and drainage, the design shall comply with the current Acts and Plumbing and Drainage standards. The pressure main route shall be approved by the Local Government before construction commences and as constructed details shall be submitted following construction.

14

APPENDIX 1

Beaudesert Shire Council

ADDENDUM TO

WATER SUPPLY CODE OF AUSTRALIA

WSA 03-2002

Second Edition

Version 2.3

15

APPENDIX 1. ADDENDUM TO WSA 03 - 2002 NOTES: 1.The clause numbers and table numbers given in this addendum correspond with the clause numbers and table numbers given in the Water Supply Code of Australia WSA 03— 2002, Version 2.3. 2.Where the “Water Agency” is mentioned in the Code, it shall mean the “Local Government” in the Guidelines, viz Beaudesert Shire Council WSA03 – 1 GENERAL WSA03 – 1.5 DESIGN RESPONSIBILITIES Prior to proceeding with detailed design, the Designer shall liaise with the Local Government to ascertain whether a network analysis (to determine the optimum size of the internal mains) is required by the Local Government as part of the design submission for the development. For the design of water reticulation schemes and where the Local Government requires a network analysis, they shall be completed by the Local Government at the Developers cost following discussions with the Designer. If a network analysis is required, the following information is required by the Local

Government from the Designer:-

1) An electronic copy of the total proposed estate layout in AutoCAD Release14 / 97LT format, which shall include the following information:

a) Road layout with road-reserve boundaries in a layer called Pro_Subdiv_Road i. Do not use polylines in this layer;

b) Road centrelines are also requested for update of the street directory, to be included in a layer called Road_Centre_Lines

i. Do not use polylines in this layer c) Allotment boundaries.(excl. road-reserves bdys) in layer called

Pro_Subdiv_Lot; i. Do not use polylines in this layer ii. Boundary dots are not required, but if included shall be drawn as circles

inserted as “wblocks”s with insertion-point at the centre of the circle d) Proposed building envelopes in a layer called Pro_Build_Envelope e) All proposed estate boundaries to be contained in a layer called

Pro_Subdiv_Stage_Bdy i. Do not use polylines in this layer

f) Land-use zone boundaries in a layer called Pro_Land_Use i. Use only closed polylines in this layer

g) Water main alignment in a layer called Water_Network_Lines i. Nodes are to be provided at all water main:

(1) tees (2) low points (scours) (3) ends of lines (4) estate stage boundaries (5) each side of road-crossings (i.e. at change-of-material).

ii. Polylines shall be used, but must start and finish at Nodes. iii. Nodes shall be drawn as crosses comprising four lines with a common

end-point inserted as “wblock”s with the insertion-point at the centre of the cross.

16

h) Contributing-lots-boundary for each water node in layer Water_Model_Node_Bdy

i. Do not use polylines in this layer i) All text shall go into layer Lottext j) The electronic drawing shall be on AMG co-ordinates (GDA 94 Current Zone

56), with the estate extremities tied in to the cadastre. The above layer convention shall be strictly followed. Other information such as contours and drawing title blocks shall not fall on the above layers. A copy of the Excel spreadsheet is to be inserted in the drawing as an embedded object. The use of graphical entities such as ellipses should be avoided, as there is an apparent problem with dxf conversion.

2) A hard copy of the above drawing with contours, including RL’s – A1 size. 3) A table of water network is to be provided in Microsoft Excel spreadsheet format on a

worksheet tab called Nodes_Table. The table is to include the following information for each in separate columns: a) Unique Node ID starting from 1 (NodeID). b) AMG Easting (E); c) AMG Northing (N) d) AHD Natural Surface Level (Z) e) Tally of lots contributing to this node (Lots)

4) A separate table of contributing lot data is to be provided in the Microsoft Excel spreadsheet on a separate worksheet tab called Lots_Table. The table is to have two columns – LotNo and NodeID – giving the NodeID to which each individual lot contributes.

5) A separate table of pipe data is to be provided in the Microsoft Excel spreadsheet on a separate worksheet tab called Pipes_Table. The table is to have three columns – NodeID1, NodeID2 and Length – giving the end nodes of each pipe and the length of pipe in between each node (measured along the pipe).

The Local Government will process the data and advise the Designer of the required water main sizing. An update of this information is to be provided at the time of signing and sealing of the final plan of survey and the table is to include the unique lot-on-plan identifier to the Local Government’s specifications. WSA03 – 2 SYSTEM PLANNING WSA03 - 2.2 DEMANDS In this Appendix 1:-

• An Equivalent Person (EP) is defined as a person, resident in a detached house. An Equivalent Tenement (ET) is defined as a detached house

• The adopted EP/ET ratios for design purposes are as follows: >Northern Area; Lower Logan 3.1

>Beaudesert; Kooralbyn; Rathdowney; Canungra 2.7 • The equivalent population densities for other defined uses (other than detached house)

as a multiple of ET are to be in accordance with Schedule 2 of Policy 5 of the Beaudesert Planning Scheme 2006.

17

• The following table lists the key planning parameters used in this part of the Guidelines.

Water Supply Planning Parameters Parameter Abbreviation Definition Average Day Demand AD The average water demand per day during the

year Mean Day Maximum Month MDMM The highest 30 day moving average daily water

demand during a year Peak Day Demand PD The highest daily water demand during a year. Peak Hour Demand PH The highest hourly water demand during a year Minimum Residual Pressure MRP The minimum residual water pressure at the

property boundary at PH when the service reservoir is at minimum operating level

Maximum Operating Pressure MOP The Maximum water pressure at the property boundary when the service reservoir is full.

• The following table details the minimum standard of service that the Local Government

aims to provide to consumers at the property boundary. Standards of service Criteria Northern Area &

Lower Logan Beaudesert Kooralbyn &

Rathdowney Canungra

On Demand Services AD (litres/ET/day) 800 700 700 700 MDMM 1.4 x AD 1.4 x AD 1.4 x AD 1.4 x AD PD 2.0 x AD 2.0 x AD 2.7 x AD 2.0 x AD PH 4.0 x AD 4.0 x AD 4.0 x AD 4.0 x AD MRP (metres) 22 22 22 22 MOP (metres) 80 80 80 80 Constant Flow Services AD (litres/ET/day) 560 515 450 MDMM 1.4 x AD 1.4 x AD 1.4 x AD PD 2.0 x AD 2.0 x AD 2.0 x AD PH (litres/hour) 70 70 70 MRP (metres) 10 10 10 MOP (metres) 80 80 80

• All hydraulic calculations should include an allowance of 100 litres per connection per day for Non Revenue Water with a peaking factor of 1.0

• Fire fighting flows, durations and residual pressures shall conform with the following table.

18

Fire Flow, Duration and Residual Pressure Requirements (adapted from DNRM Guidelines Chapter 6, Clause 5.7) Water Service Area

Water Service Planning Scheme Precinct Fire Flow and Residual Pressure

OD Town Centre Core Frame Mixed Use Industry

30 L/sec for 4 hours 12 m residual pressure

OD, CF Minor Convenience Centre Residential Community Facilities

15 L/sec for 2 hours 12m residual pressure

CF Park Living Rural Residential

5 L/sec for 2 hours 9m residual pressure

Northern Area and Lower Logan

CF Other No fire flow requirements

OD Town Centre Core Frame Industry

30 L/sec for 4 hours 12 m residual pressure

OD, CF CF

Minor Convenience Centre Medium Density Residential Residential Community Facilities Rural Residential

15 L/sec for 2 hours 12m residual pressure 5L/sec for 2 hours 9 m residual pressure

Emerging Community Subject to future planning

Beaudesert and Canungra

CF Other No fire flow requirement

OD Business Industry

30 L/sec for 4 hours 12 m residual pressure

OD Residential Rural Residential Community Facilities Equestrian

15 L/sec for 2 hours 12 m residual pressure

Emerging Community Subject to future planning

Kooralbyn

OD Other No fire flow requirement

Rathdowney OD Village Community Facilities

15 L/sec for 2 hours 12 m residual pressure

• Additional fire fighting capacities required to meet the requirements of Australian

Standards or the Building Code of Australia shall be provided through on-site sources. WSA 03 - 2.3 SYSTEM CONFIGURATION Transfer (trunk) and distribution mains are the major components of the Local Government’s water supply scheme deemed necessary to provide water on a regional and district basis and are generally referred to as Headworks mains. Design and construction of these mains shall generally be co-ordinated by the Local Government. Transfer and distribution mains shall be free of service connections with a separate reticulation main provided for this purpose.

19

WSA 03 - 2.4 SYSTEM HYDRAULICS Refer to the above tables for service pressures. WSA 03 - 2.5 WATER QUALITY Test points may be required at isolated sections within a reticulation system. The Designer shall confirm test point requirements with the Local Government prior to lodgement of engineering documentation. The typical detail of a test point is shown on BSC Standard Drawing 50643. WSA 03 - 2.6 PUMPING STATIONS Pumping Station infrastructure includes pumps, electrical cabinet and wiring, pressure control, internal pipe work, telemetry control, housing and access. In addition to the factors listed in this clause to be addressed by the Designer, the following parameters from the DNRM Guidelines, Chapter 7, Table 5.8 shall form the basis of design for the sizing of pumps. Component Sizing Comments Raw Water Pumps MDMM over 20 hours The period of operation can be

confirmed/amended through modelling and risk assessment.

Treated water pumps feeding a ground level reservoir

MDMM over 20 hours The period of operation can be confirmed/amended through modelling and risk assessment.

Treated water pumps feeding an elevated reservoir

Capacity (L/s)= 6PH – Reservoir operating volume 6 x 3600 Volume in litres

Reticulation booster pumping station

PH + Fireflow

Pumped System Peak instantaneous flow + fireflow This situation may exist in smaller systems if variable speed pumps would replace any elevated storage. In these instances it would be necessary to calculate instantaneous flow based on concurrent demand. This would exceed PH by a significant margin.

Standby pumps Standby pump capacity to match the largest single unit pump capacity

In urban and residential areas, in-line submersible booster pumps in a concrete chamber are preferred. Where pumps are installed above ground, they are to be housed in a vandal resistant brick building with internal acoustic lining to reduce noise emissions. In residential areas, care should be taken to ensure pumping stations have an aesthetic appearance and do not cause any noise nuisance. The pipe work inside pumping stations shall include sufficient valves and fittings to ensure each pump can be removed for future repairs and maintenance.

20

Where pumping stations are not readily accessible from a public road, particular attention to the following criteria is required:

• Vehicle access and site manoeuvrability • Access road cross section and drainage • Width of land required for access road • Dedication of land for pumping station and access road to the Local Government in fee

simple. • Landscape and security fencing

The power supply to pumping stations shall have 50% spare capacity for future upgrading and be electrically configured such that the pumping station can operate from an emergency generator supply at times of power failure (thus, a provision of space in the switchboard for a manual or automatic change over panel is required). The mechanical and electrical facility including electrical cabinet, telemetry and associated wiring shall be carried out by the Designer to the requirements of the Local Government and the relevant electrical authority. At the completion of the design of the mechanical/electrical facilities the Designer is required to submit the following for approval prior to commencement of any work on the station:

• Pump curves and schedules of technical details for the selected pumps (3 off) • The design drawing of the control cabinet including schematic drawings detailing,

components to be installed as well as telemetry drawings and radio survey report where required (3 off)

• An Energex application for power, fully completed, for signing by the Local Government as the owner of the station

The Developer will be responsible for payment of all fees associated with the pumping station fit out, including those for power. WSA 03 - 2.7 SERVICE RESERVOIRS Reservoir infrastructure includes the reservoir, pipework, control valves, telemetry, re chlorination facilities, overflow, access road, housing, security fencing and any other works directed by the Local Government. Concrete service reservoirs are preferred. In addition to the factors listed in this clause, to be addressed by the Designer, the following parameters from the DNRM Guidelines, Chapter 7, Table 5.8 shall form the basis of design for the sizing of reservoirs.

21

Component Sizing Comments Surface Reservoirs 3 (PD-MDMM) + (greater of

Emergency Storage/Firefighting Storage

This sizing relates to operating level. Emergency storage subject to risk assessment by service provider. Fire fighting storage would need to be incorporated for smaller reservoirs.

Elevated and Standpipe Reservoirs

6 (PH – MDMM) + firefighting 12 reserve

A firefighting reserve should be determined through network modelling and subject to risk assessment by the service provider based on the proven capability of variable speed pumps and pressure cells, elevated reservoirs may not be economically viable. The planner should determine the optimal combination of inflow/storage and capacity/demand based on lifecycle cost analysis. The frequency/duration of power failures should also be considered.

The firefighting storage/reserve will depend upon the Planning Scheme Precincts that are serviced by the Reservoirs under consideration. Subject to the risk assessment, the storage/reserve shall be sized for the highest order Precinct being serviced in the following table. (adapted from DNRM Guidelines, Chapter 6 Clause 5.7).

Planning Scheme Precinct (highest to lowest order) Total ET serviced by Reservoir/s

Town Centre Core Frame Mixed Use Business Industry

Minor Convenience Centre Medium Density Res. Residential Community Facilities Village Centre Village

Rural Residential Interim Rural Res.

<300 108 kilolitres (15l/s x 2 hrs)

36 kilolitres 5l/s x 2 hrs

300 to 1600 432 kilolitres (30l/s x 4 hrs)

108 kilolitres (15l/s x 2 hrs)

36 kilolitres (5l/s x 2 hrs)

>1600 540 kilolitres (30l/s x 4 hrs + 15l/s x 2 hrs)

210 kilolitres (2 x 15l/s x 2 hrs)

72 kilolitres (2 x 5l/s x 2 hrs)

All reservoirs shall incorporate solenoid control valves, level switches and telemetry equipment all appropriately linked to ensure the reservoir does not overfill and to control the starting and stopping of supply pumps. Road access shall be detailed on the engineering drawings. Where reservoirs are not readily accessible from a public road, particular attention to the following criteria is required:-

• Vehicle access and site manoeuvrability • Access road cross section and drainage • Width of land required for access road • Dedication of land for reservoir and access road to the Local Government in fee simple

22

WSA 03 - 2.10 CONCEPT PLAN Where the Local Government requires a network analysis of a development, the following information shall be provided:

• A report with all assumptions and results in A4 format • A concept plan for each of the Max Hr and firefighting analysis and pumping mode

where applicable. The concept plan shall show:

• Layout of mains together with development layout • Sizing details of mains • Velocities in the mains • Flow rate in the mains • Nodal details elevation, piezometric pressure, outflows, numbers of lots/EP • Reservoir details (water levels) • Pump duties (if applicable) • Special valving arrangements • Supply point details supplied by the Local Government • Legend of Planning Scheme Precincts

WSA 03 - 3 HYDRAULIC DESIGN WSA 03 - 3.2 SIZING OF MAINS WSA 03 - 3.2.2 Minimum pipe sizes In Constant Flow service areas, where mains terminate in short runs such as a cul-de-sac, the following minimum size mains may be acceptable subject to the Local Government approval. DN 63 Up to 150m from permanent end of main DN 80 Up to 350m from permanent end of main WSA 03 - 3.2.3 Empirical sizing of reticulation mains Subject to clause 3.2.2, reticulation mains shall be the following standard diameters: DN100, DN150, DN200, DN250, DN300. Table 3.1 may be used for small developments with On Demand services, and as a first pass for the network analysis. For Rural Residential developments with Constant Flow services, the following table may be used for small developments and as a first pass for the network analysis.

Nominal size of main Capacity of main – Rural Residential Lots

DN 63 DN 80

DN 100

15 30

100

23

WSA 03 - 3.2.4 Fire flows System should be capable of meeting fire fighting flows. Refer WSA 03 - 2.2, 2.6 and 2.7 above. WSA 03 - 3.2.5 Sizing by analysis For headloss calculations, the Hazen-Williams formula is generally used. The formula is:

87.4852.1

852.1652.10DC

LQH ××=

Where H = headloss in metres L = total length in metres Q = flow rate in m3/s D = diameter in metres C = Hazen-Williams factor Hazen - Williams ‘C’ Values for Water Mains

Transfer/Distribution Mains Pipe Diameter Reticulation

Mains Treated Water Untreated Water

<DN 200 100 120 110 DN 200 – 250 110 120 110

DN 300 110 130 120 DN 375 – 600 NA 130 120

>DN 600 NA 135 125 The above values take into account loses for pipe fittings such as bends, valves, tees etc and the effect of ageing. WSA 03 - 3.7 PIPE AND FITTINGS PRESSURE CLASS WSA 03 - 3.7.2 Minimum pressure class The minimum pressure class for reticulation pipes and fittings shall be class 16. The minimum pressure class for property service pipes and fittings shall be class 12. WSA 03 - 4 GENERAL DESIGN WSA 03 - 4.1 GENERAL REQUIREMENTS WSA 03 - 4.1.1 Design tolerances Refer to the D & C Manual Section 4 for the preferred co-ordinate systems. WSA 03 - 4.3 LOCATION OF WATER MAINS WSA 03 - 4.3.1 General Wherever possible, water mains up to DN300 shall be located in the footpath verge, on the low side of the road reserve, or on the opposite side to that used for sewerage reticulation. The allocated alignment is between 1.2 metres and 2.0 metres from the R.P. boundary, in accordance with the BSC Standard Drawing 50400. Water mains of diameter larger than DN300 shall be located on an alignment approved by the Local Government.

24

WSA 03 - 4.3.2 Water Mains in road reserves Water mains under road pavements (including road crossings) shall be DICL class K9 with R.R.J. or shall be located within a conduit in accordance with Drawing WAT-1212. WSA 03 - 4.3.3 Water mains in easements The construction of water mains in easements over private property will only be considered by the Local Government when all other alternatives including widening of road reserves and provision of pathways have been exhausted. The minimum width of easement for a water main shall be 4.0 metres. Refer also to Clause 1.6 of the Guidelines. WSA 03 - 4.4 SHARED TRENCHING Shared trenching of water and telecommunications cable may be approved at the discretion of the Local Government except where PE water mains are proposed/installed. The minimum separation between the two utilities shall be 300mm. Shared trenching with any other service/utility will not be permitted. WSA 03 – 4.6 RIDER MAINS A temporary rider main may also be required by the Local Government to ensure that water quality is maintained in the early stages of a development. To this end, the Local Government may require a DN 63 rider main be laid in the same trench as the following trunk mains. Residential precincts > DN 150 Rural Residential precincts ≥ DN 150 The temporary rider main shall be effectively sealed at each end to prevent ingress of soil etc. The Local Government will arrange for the interconnection of the rider main as required. The Designer should check with the Local Government for its requirements on rider mains for a particular development. WSA 03 - 4.7 CONNECTION OF NEW MAINS TO EXISTING MAINS All connections to existing water mains shall be made by the Local Government at the developer’s expense. Refer also to Clause WSA03-22. WSA 03 - 4.8 TERMINATION POINTS WSA 03 - 4.8.3 Temporary ends of water mains At temporary ends of water mains which are longer than the width of one property, a temporary bleed/test pipe of DN25 PN12.5 MDPE shall be installed and extended from adjacent the end cap to a temporary bleed & test point. The temporary bleed pipe shall then discharge to the nearest available stormwater manhole, culvert headwall, inlet pit or other approved stormwater structure and a vermin/frog flap shall be provided at the discharge point. The temporary bleed pipe may be installed in the same trench as the reticulation main. Refer to BSC Standard Drawings 50642 & 50643.

25

WSA 03 - 4.9 PROPERTY SERVICES All property service connections including tapping bands, service pipes & fittings shall be made by the Local Government. Property service connections shall only be installed on reticulation mains <= DN300. Conduits shall be provided under all roads by the Developer for future property services across roads. They shall be located to match the common boundary of lots to be serviced and aligned at 90° to the water main in accordance with BSC Standard Drawing 50641. For the following Planning Scheme Precincts, one DN100 Class PN12 uPVC conduit allowing for a maximum of two (2) property services per conduit shall be provided.

• Residential • Rural Residential (including Interim Rural Residential) • Village

For all other Planning Scheme Precincts, one DN150 Class PN12 uPVC conduit allowing for two (2) property services per conduit shall be provided. It is the Designer’s responsibility to ensure that water mains and property service conduits do not conflict with other underground public utility services and conduits. Power conduits shall be located at alternate boundaries to water conduits. WSA 03 - 6 APPURTENANCES WSA 03 – 6.2 STOP VALVES WSA 03 – 6.2.5 Stop valves – location & arrangements At street intersections, stop valves shall be located on all branches of the water main (eg for a tee intersection, there should be three stop valves, one per branch). A hydrant shall be located between the stop valves. Refer BSC Standard Drawing 50642. WSA 03 - 6.8 HYDRANTS WSA 03 - 6.8.3 Hydrant types Hydrants shall be DN80 spring hydrants on a DN80 hydrant riser suitable for use as launch and exit sites for <= DN150 swabs. Hydrants on mains >DN200 shall be DN80 spring hydrants attached to the flange of an isolating valve assembly. WSA 03 - 6.8.7 Hydrant spacing For On Demand areas, the maximum spacing between hydrants shall be 80 metres except in Rural and Rural residential precincts where the maximum spacing may be increased to 200 metres. For Constant Flow areas, hydrants shall be located at intersections, or at spacings not greater than 500 metres in mains of DN100 or larger.

26

WSA 03 – 6.8.8 Hydrant location Hydrants shall be located at all intersections in combination with the stop valves on each branch (refer WSA03 – 6.2.5). WSA 03 - 7 DESIGN REVIEW AND DRAWINGS WSA 03 - 7.2 DESIGN DRAWINGS WSA 03 - 7.2.2 Composition of Design Drawings (a & b) Where the proposed development consists of two or more stages, a master (layout) plan showing the boundaries of all stages (which shall be identified by numbering) shall be provided by the Designer. The Plan shall also show the proposed locations of trunk mains, treatment plants and reservoirs, where relevant. Allotment layout need not be provided. However, the proposed number of allotments in each stage shall be provided. Contours shall be shown at a 1 metre nominal interval. (c) Where pumping stations and/or reservoirs form part of the works, such infrastructure shall be fully detailed including design calculations, certified by a Registered Professional Engineer, Queensland. (d) Long sections are required for mains > DN150. Conflict points with other services are to be detailed on the long sections. WSA 03 - 7.2.4 Contents of Design Drawings The design drawings shall also show:

• Water service conduits and other cross road conduits • Location of the proposed metered water services (with a cross). • A schedule of all standard drawing numbers and titles to be used.

WSA 03 - 7.3 RECORDING OF WORKS AS CONSTRUCTED INFORMATION As constructed information shall conform with the requirements of the D & C Manual, Section 4. WSA 03 - 8 PRODUCTS AND MATERIALS OVERVIEW The Local Government’s requirements for pipeline materials are given in the following table. Type of Pipe Jointing Method Class of Pipe MPVC, uPVC or OPVC Rubber ring seal Minimum PN16, Series 2

PE Electrofusion or Butt fusion

Minimum PN16 for reticulation. Minimum PN 12.5 for property services.

Dl (Cement Mortar Lined )**

Rubber ring sealed, flanged

K9 for socket and spigot pipes, K12 for flanged pipes,

Notes **All pipes and fittings shall be sleeved in polyethylene in compliance with the manufacturer’s recommendations. Seal coats shall be provided where specified by the Local Government.

27

Subject to this list, all the products and materials used for water infrastructure shall comply with the Product and Material Information and Guidance and Purchase Specifications on the WSAA website. WSA 03 -12 PRODUCTS AND MATERALS WSA 03 -12.1 AUTHORISED PRODUCTS AND MATERIALS Refer to Appendix 4A for the Local Government’s Authorized Products List for water supply. WSA 03 – 15 PIPE LAYING AND JOINTING WSA 03 - 15.10 MARKING TAPES Detectable marking tape shall be installed over all water mains >DN150 and wherever smaller mains are outside the water main allocated alignment (including road crossings). WSA 03 - 15.16 LOCATION MARKERS Where there is kerb and channel, hydrants, valves and other fittings shall be marked with marker posts (type A) and kerb marking. Where there is no kerb and channel, marker posts only are required. In addition, hydrant retro-reflective pavement markers are required for all hydrants. WSA 03 - 19 ACCEPTANCE TESTING In addition to the requirements of this clause, for water mains, the Local Government will undertake random audit inspections during construction and the Local Government inspector must be advised 24 hours before the pressure testing of each water main prior to connection to existing water mains. For other water supply structures, the Local Government’s requirements shall be determined prior to commencement of construction. WSA 03 - 20 DISINFECTION Disinfection and bacteriological testing of all new mains is required before acceptance by the Local Government and connection to the existing water mains. The Superintendent may, after achieving a satisfactory pressure test of the new mains, engage the Local Government to sterilize, flush and connect. WSA 03 - 22 CONNECTIONS TO EXISTING WATER MAINS After all the requirements of acceptance testing have been satisfied and works as constructed details have been provided to the Local Government, the superintendent shall arrange for the Local Government to carry out the live connection and the commissioning of the new mains. Connection to the live main must occur within thirty days of the satisfactory bacteriological test. If for any reason, connection cannot occur within this period, then the new main must be re-tested for compliance. Costs associated with the re-testing and possible additional sterilisation will be born by the Constructor.

28

WSA 03 - 24 WORK AS CONSTRUCTED DETAILS As constructed information shall conform to the D & C Manual, Section 4. WSA 03 - PART 4 STANDARD DRAWINGS The standard drawings listed in Part 4 of WSA 03 are accepted for use in the Local Government area EXCEPT as described below: WSA 03 Drawing No. Comment WAT-1106 Not applicable. Refer BSC standard drawing 50641 WAT-1107 Not applicable. Refer BSC standard drawing 50641 WAT-1108 Not applicable. Refer BSC standard drawing 50643 WAT-1109 Not applicable. Refer BSC standard drawing 50643 WAT-1300 Marker Posts shall be type “A” WAT-1303 The surface fitting installation shall be Type A1 WAT-1304 The surface fitting installation shall be Type H1 WAT-1305 The surface fitting installation shall be Type A2 WAT-1306 The surface fitting installation shall be Type H2 The following Beaudesert Shire Council (BSC) standard drawings are also applicable: BSC Drawing No. Title 50400 Typical Footpath Verge, Allocation of Public Utilities 50640 Sample Drawing, “As Constructed” Water Reticulation 50641 Road Crossings, Service Conduits 50642 Standard Details for Intersections and Temporary Ends 50643 Water Connection Details, Temporary Bleed and Test Point Details

29

APPENDIX 2

Beaudesert Shire Council

ADDENDUM TO

SEWERAGE CODE OF AUSTRALIA

WSA 02 - 2002

SECOND EDITION

VERSION 2.3

30

APPENDIX 2. ADDENDUM TO WSA 02 – 2002

WSA 02 - 1 GENERAL WSA 02 - 1.3 PLANNING AND DESIGN RESPONSIBILITIES AND INTERFACES WSA 02 - 1.3.2. Planning responsibilities Prior to proceeding with detailed design the Designer shall:- (a) Obtain from the Local Government “as constructed” sewer information relevant to the proposed development and the approved connection points for the development. (b) Liaise with the Local Government to ascertain whether a Concept Plan is required. WSA 02 - 1.3.4 Consultation with other parties Where works encroach on other lands, refer to Clause 1.6 of the Guidelines WSA 02 - 2 SYSTEM PLANNING WSA 02 - 2.2 PLANNING PRINCIPLES WSA 02 - 2.2.2 Concept Plan Where the Local Government requires a concept plan, it shall be completed by the Designer and shall include the following information:-

• Location, size and alignment of sewers and pump mains • Location, of pumping stations • Contour information generally at 5m intervals (1 m is prefereable) • Approved sewer connection points • Staging (if applicable) • Contributing catchments (internal and external) showing the equivalent population (EP) • The flow contributing to each section of main including the estimated design capacity

See example below:-

EP 965 Flow 15.4 l/secPipe Size 225 diameter Max Pipe Capacity 25 l/sec

Access for maintenance of the system should be considered when locating maintenance structures, pumping stations, etc.

NOTES: 1.The clause numbers and table numbers given in this addendum correspond with the clause numbers and table numbers given in the Sewerage Code of Australia WSA 02 – 2002, Version 2.3 2. Where the “Water Agency” is mentioned in the code, it shall mean the “Local Government” in the Guidelines, viz Beaudesert Shire Council.

31

WSA 02 - 2.3 PLANNING PARAMETERS WSA 02 - 2.3.1 Loading per serviced property In this Appendix 2,

• An Equivalent Person (EP) is defined as a person, resident in a detached house • An equivalent Tenement (ET) is defined as a detached house • The adopted EP/ET ratios for Planning & Design purposes are as follows

> Logan village, Flagstone, Jimboomba 3.1 > Beaudesert, Canungra, Kooralbyn 2.7

• The Average Dry Weather Flow (ADWF) per person for Planning and Design purposes shall be 200 litres per EP per day for CGS and CED systems.

WSA 02 - 2.3.2 Assessment of future loads The equivalent population densities for defined uses (other than detached house) as a multiple of ET., are to be in accordance with Schedule 2 of Policy 5 of the Beaudesert Planning Scheme 2006. WSA 02 - 3 FLOW ESTIMATION WSA 02 - 3.2 DESIGN FLOW ESTIMATION METHOD For CGS sewers, the design flow shall be estimated using the “ historical Queensland approach” described in the DNRM Guidelines, Chapter 5, Clause 5.2.2, viz:-

• PDWF = C2 X ADWF where C2 = 4.7 x (EP) -0.105 • Design Flow = PWWF = (5 x ADWF) or (C1 x ADWF), whichever is the larger • C1 = 15 x (EP) -0.1587 (note: the minimum value for C1 = 3.5)

In the above formulae, EP is the total equivalent population in the upstream catchment. For CED sewers, the design flow shall be estimated using the formulae.

• Design Flow = PWWF = 3 x ADWF WSA 02 - 4 DETAIL DESIGN WSA 02 - 4.2 DETAIL DESIGN CONSIDERATIONS WSA 02 - 4.2.5 Easements Easements in favour of the Local Government shall be provided as follows:

• Over all sewers (gravity or pressure) in industrial and commercial sites (Note additional accessible manholes may be required where there is total site coverage)

• Local Government maintained sewers (gravity or pressure) in group title developments • Any gravity main located more than 1.5 metres off a residential property boundary or

located in any position which could be legally built on within an allotment (this excludes sewers constructed outside building envelopes)

• All pressure mains located other than within the footpath verge The minimum acceptable easement width shall be 4.0 metres. The actual width of the easement shall be determined subject to consideration of the following:

• Size of main • Depth of main • Location of main • Soil conditions

32

• Topography • Vehicle access requirements

Refer also to clause 1.6 of the Guidelines. WSA 02 - 4.3 HORIZONTAL ALIGNMENT OF SEWERS WSA 02 - 4.3.1 General The preferred alignment of sewers (in order of preference) is as follows:

• Within the road reserve on a 1.9 metre alignment on the high side of the road and on the opposite side to the water reticulation and other services.

• Elsewhere within the road reserve but preferably not in the traffic lanes. • Within other reserves under the Local Government’s control • At the front or rear of private property 1.5m from and parallel to the boundary. • At the low side of the private property side boundary, 1.5m from and parallel to the side

boundary. Unless approved by the Local Government, sewer alignments should be above the defined flood level. If a sewer alignment is below flood level, filling may be required in the vicinity of maintenance structures. WSA 02 - 4.3.2 Roads, reserves and open space Where an alternative alignment is proposed other than 1.9m, it must be approved by the Local Government and any other relevant Public Utility Authority affected. For footpath verge allocation of public utilities, refer to BSC Standard Drawing 50400. Common trenching with other Utilities is not permitted. WSA 02 - 4.3.4 Public and private property. Where building envelope restrictions apply to a development, the Local Government may give approval for non standard sewer alignments. In such instances, the sewer must be 1.5 metres minimum outside the building envelope. WSA 02 - 4.3.7 Horizontal curves in sewers Manufactured bends are permitted in sewers provided they are close-coupled to maintenance structures. Curved sewers are not permitted. WSA 02 - 4.5 PIPE SIZING AND GRADING WSA 02 - 4.5.3 Minimum air space for ventilation At design flow, the depth of flow in both CGS and CED sewers shall be not more than 75% of pipe diameter. WSA 02 - 4.5.4 Minimum pipe sizes for maintenance purposes For CGS sewers, table 4.3 in WSA02 applies For CED sewers,

33

• the minimum size property connection sewer shall be 100mm • the minimum size reticulation sewer shall be 100mm

WSA 02 - 4.5.5 Maximum EP for reticulation sewers For CGS sewers, table 4.4 in WSA 02 applies. For CED sewers

• >= DN150, table 4.4 in WSA 02 applies. • DN 100, the maximum allowable EP shall be 200.

WSA 02 - 4.5.7 Minimum grades for self-cleansing For CGS sewers, clause 4.5.7 in WSA 02 applies, except that the absolute minimum grades for DN150 reticulation sewers shall be:

• 1.00% for EPs <20 • 0.67% for EPs 20 – 50

For CED sewers,

• Manning Coefficient for UPVC pipe 0.011 • Minimum velocity of flow in sewers > DN100

= 0.3 m/sec at 1.5 ADWF • Absolute minimum grades for reticulation sewers

DN100 1.00% for first 30m 0.40% thereafter DN150 0.25% DN225 0.15%

• Minimum grades for property connection sewers and permanent ends. DN100 1.00% WSA 02 - 4.6 VERTICAL ALIGNMENT OF SEWERS WSA 02 - 4.6.1 General The maximum cover to sewer/CED mains shall be in accordance with the manufacturers’ technical specifications and recommendations for the type and class of pipe used together with bedding trench conditions and soil type and shall preferably not exceed 3.0m. Where the maximum cover to sewers exceeds 3.0m, the Designer shall calculate the full life cycle cost of the section of sewer compared to other solutions and obtain written approval of the Local Government for the deeper sewer. WSA 02 - 4.6.4 Lot servicing requirements Where a septic tank is connected to a CED scheme, the minimum cover at the septic tank shall be 450mm and a filter (Drenco or Zabel or equivalent) shall be installed on the outlet of the septic tank. WSA 02 - 4.6.7 Vertical curves Manufactured bends are permitted in sewers provided they are close-coupled to maintenance structures. Curved sewers are not permitted.

34

WSA 02 - 4.6.8 Compound curves Compound manufactured bends in sewers are permitted in accordance with this clause subject to prior approval of the Local Government. WSA 02 - 5 PROPERTY CONNECTION WSA 02 - 5.3 METHODS OF THE PROPERTY CONNECTION WSA 02 - 5.3.1 General The inspection opening (IO) interface method is adopted. Where property connection sewers cross road carriageways, they shall connect into maintenance structures and be DN150 minimum for CGS (DN100 for CED). WSA 02 - 5.7 Y - PROPERTY CONNECTIONS Y property connections are not permitted WSA 02 - 6 MAINTENANCE STRUCTURES WSA 02 - 6.3 SPACING OF MAINTENANCE STRUCTURES WSA 02 - 6.3.1 General In table 6.1, where the permanent end of a property connection sewer is greater than 30 metres, a maintenance structure is required. WSA02 - 6.3.2 Maintenance structure spacing – Reticulation sewers For CED reticulation sewers, the maximum distance between any two consecutive maintenance structures shall be 200m and subject to the provision of clause 6.3.1. WSA 02 - 6.4 SPECIAL CONSIDERATIONS FOR LOCATION OF MAINTENANCE STRUCTURES In addition to clause 6.4 of WSA 02, the following locations for maintenance structures shall be avoided as far as practicable:

• Within road carriageways, central medians and roundabouts WSA 02 - 6.6 MAINTENANCE HOLES (MH) WSA 02 - 6.6.2 Types of MH construction Precast concrete MHs are permitted, where the proprietary component system has been approved by the Local Government. All holes in precast MH walls shall be drilled or cored. WSA 02 - 6.6.3 Design parameters for MHs All concrete in MHs shall be Grade S25 with a minimum flyash/type A cement ratio of 0.25.

35

WSA 02 - 6.6.5 Diameter of MHs The minimum internal diameter for a MH shall be 1050mm. WSA 02 - 6.6.8 Ladders, step irons and landings Not permitted WSA 02 - 6.6.9 MH covers All MH covers shall be watertight and gastight. WSA 02 - 6.7 MAINTENANCE SHAFTS (MS) Maintenance shafts and terminal maintenance shafts shall be of a propriety brand approved by the Local Government. WSA02 - 7 ANCILLIARY STRUCTURES WSA02 - 7.9 OVERFLOWS / EMERGENCY RELIEF STRUCTURES (ERS) Where it is necessary to install an ERS, the Designer shall obtain all statutory approvals and design the ERS to comply with the requirements of those approvals. Refer to the Environmental Protection Agency Guideline “Framework for Managing Sewerage Infrastructure to Reduce Overflows and Environmental Impact.” See also BSC Standard Drawing 50747. WSA 02 - 9 DESIGN REVIEW AND DRAWINGS WSA 02 - 9.2 DESIGN DRAWINGS WSA 02 - 9.2.1 General In addition, the design drawings shall include:

• A schedule of all standard drawing numbers and titles to be used. All plan views shall be oriented so that the north point is directly up the page. WSA 02 - 9.2.4 Structures In addition, the design drawings shall include:

• Fully detailed pumping station drawings where applicable (Refer WSA04). WSA 02 - 9.2.5 Longitudinal sections (profiles). In addition, longitudinal sections shall include:

• Design finished surface profile along each line with levels at each maintenance structure

• Design invert levels of each property connection sewer branch indicated with an X, the lot number, the type and invert level of the branch, and the design surface level above the branch.

• Equivalent populations, flow and design capacity of all sections of main.

36

WSA 02 - 9.2.7 Other In addition, the design drawings shall include

• Kerb and channel alignments, where applicable • Road centre lines and chainages • Proposed design contours (0.25m intervals) • Existing contours (1 metre intervals)

WSA 02 - 9.3 DRAFTING STANDARDS WSA 02 - 9.3.1 Scale Sewerage detail plans shall be at a scale of 1:500 Longitudinal sections shall be at a scale of 1:1000 horizontally and 1:100 vertically. WSA 02 - 9.3.2 Recording of as-constructed information As constructed information shall conform with the requirements of the D & C manual, Section 4. WSA 02 - APPENDIX A ESTIMATION OF EQUIVALENT POPULATION (EP) Not applicable – Refer to WSA 02 – 2.3.1 and 2.3.2 in this Appendix 2 of the Guidelines. WSA 02 - APPENDIX B FLOW ESTIMATION FOR UNDEVELOPED AREAS. Not applicable – Refer to WSA 02 – 3.2 in this Appendix 2 of the Guidelines. WSA 02 - 10 PRODUCTS AND MATERIALS OVERVIEW Permitted materials for use for gravity and pressure sewer mains are given in the table below.

Class of Pipe Type of Pipe Jointing Method Gravity Sewer Pressure Sewer

MPVC, uPVC or OPVC Rubber ring seal

Minimum Class — SN10 for DN100 and SN8 for larger pipes, Series 2

Minimum PN16, Series 2

PE Electrofusion or Butt fusion Minimum Class SN10** Minimum PN16

Dl (Cement Lined or Calcium Aluminate Special Lining)*

Rubber ring sealed, flanged

K9 for socket and spigot pipes, K12 for flanged pipes

K9 for socket and spigot pipes, K12 for flanged pipes..

*All Dl pipes and fittings shall be sleeved in polyethylene in compliance with manufacture’s recommendations. Dl pipes with normal cement lining shall not be used for gravity sewers, which should be Calcium Aluminate lined. Sections of pressure sewers that are permanently wet may use Dl pipes with normal cement lining subject to the Local Government approval. Sections of pressure main subject to alternate wetting and drying shall have Calcium Aluminate lining ** PE pipe for gravity sewers shall be light beige or black external colour with a co-extruded white internal liner. (Fully black pipe is not acceptable). Sluice valves shall be resilient seated and clockwise opening.

37

WSA 02 - 13 GENERAL CONSTRUCTION WSA 02 - 13.2 ORDER OF CONSTRUCTION, TESTING AND COMMISSIONING The Local Government shall undertake item (e) (Connect to the live sewer) WSA 02 - 14 PRODUCTS AND MATERIALS WSA 02 - 14.1 AUTHORISED PRODUCTS AND MATERIALS Refer to Appendix 4B for the Local Government’s Authorized Products List for sewerage. WSA 02 - 17 PIPE LAYING AND JOINTING WSA 02 - 17.2 HORIZONTAL AND VERTICAL DEFLECTION OF SEWERS Manufactured bends are permitted in sewers provided they are close-coupled to maintenance structures. Curved sewers are not permitted. WSA 02 - 17.7 PROPERTY CONNECTION SEWERS Property connection sewers shall be constructed using the IO Interface method. Reference: Standard Drawing SEW-1106 WSA 02 - 22 ACCEPTANCE TESTING In addition to the requirements for this clause, the Local Government will undertake random audit inspections during construction and the Local Government inspector must be advised 24 hours prior to the following:

• Backfilling of any line (including property connections) • Pressure/vacuum testing of sewers • Testing of concrete MHs • Deflection testing of flexible sewers • CCTV inspection.