Wastewater Treatment System Needs Assessment May 2017 · standby) 15 HP blowers. Flow exits the...

Transcript of Wastewater Treatment System Needs Assessment May 2017 · standby) 15 HP blowers. Flow exits the...

207 North Stewart Street |Geneseo, IL, 61254

Wastewater Treatment System Needs Assessment May 2017

Prepared by:

Donohue & Associates, Inc. 1605 South State Street, Suite 1C |Champaign, IL, 61820 donohue-associates.com

Donohue Project No.: 13173

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page ii

TABLE OF CONTENTS

Chapter 1 – Executive Summary ........................................................................................................... 1

1.1 Overview ............................................................................................................................ 1

1.2 Recommended Upgrades .................................................................................................... 1

1.3 Cost Opinions ...................................................................................................................... 1

Chapter 2 – Project Background ........................................................................................................... 3

2.1 Study Objective ................................................................................................................... 3

2.2 Facility Overview ................................................................................................................. 3

2.3 NPDEs Permit ...................................................................................................................... 5

Chapter 3 – Identified Improvements ................................................................................................... 8

3.1 Headworks .......................................................................................................................... 8

3.2 Excess Flow Pump Station ................................................................................................. 13

3.3 Grit Removal ..................................................................................................................... 14

3.4 Raw Influent Pumping ....................................................................................................... 16

3.5 Primary Treatment ............................................................................................................ 16

3.6 Trickling Filters .................................................................................................................. 18

3.7 Aeration ............................................................................................................................ 20

3.8 Final Clarification .............................................................................................................. 23

3.9 Secondary Control Building ............................................................................................... 24

3.10 Digestion ........................................................................................................................... 25

3.11 Dewatering ....................................................................................................................... 27

3.12 Effluent Pumping .............................................................................................................. 27

3.13 Lift Stations ....................................................................................................................... 28

3.14 Change in Regulations ....................................................................................................... 28

3.14.1 Disinfection ....................................................................................................................... 28

3.14.2 Phosphorus Removal......................................................................................................... 29

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page iii

LIST OF TABLES Table 2-1 Outfall 001 Limits ..................................................................................................................... 6

Table 2-2 Outfall 004 Limits ..................................................................................................................... 7

Table 2-3 Outfall 005 Limits ..................................................................................................................... 7

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page iv

LIST OF FIGURES Figure 2-1 Geneseo WWTP and Excess Flow Lagoon Aerial ...................................................................... 4

Figure 2-2 Geneseo WWTP ...................................................................................................................... 5

Figure 3-1 Headworks Building ............................................................................................................... 8

Figure 3-2 Manual Bypass Bar Screen ...................................................................................................... 9

Figure 3-3 Mechanically Cleaned Bar Screen ............................................................................................ 9

Figure 3-4 Parshall Flume - 12" .............................................................................................................. 10

Figure 3-5 Bar Screening Manual Removal ............................................................................................. 10

Figure 3-6 Proposed Location of New Screenings Washer and Compactor, Aerial View .......................... 11

Figure 3-7 Proposed Location of New Screening washer and Compactor, Outside View ......................... 11

Figure 3-8 Butterfly Valve ...................................................................................................................... 12

Figure 3-9 Concrete Barrier for Flooding Prevention .............................................................................. 13

Figure 3-10 Grit Tank ............................................................................................................................. 14

Figure 3-11 Grit Classifier....................................................................................................................... 15

Figure 3-12 Influent Pumps.................................................................................................................... 16

Figure 3-13 Primary Clarifier .................................................................................................................. 17

Figure 3-14 Primary Clarifier Concrete Spalling ...................................................................................... 18

Figure 3-15 Primary Sludge Pump ......................................................................................................... 18

Figure 3-16 Rock and Plastic Trickling Filters .......................................................................................... 19

Figure 3-17 Filter Feed Pumps ............................................................................................................... 20

Figure 3-18 Aeration Basins ................................................................................................................... 21

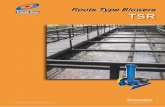

Figure 3-19 Three 15-HP Blowers ........................................................................................................... 22

Figure 3-20 Final Clarifier ....................................................................................................................... 23

Figure 3-21 Primary Digester ................................................................................................................. 25

Figure 3-22 Secondary Digester ............................................................................................................. 26

Figure 3-23 Chlorination Basin ............................................................................................................... 29

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page v

APPENDICES Appendix A – Flow Schematic Appendix B – Hydraulic Profile Appendix C – NPDES Permit Appendix D – Cost Estimates

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page vi

ABBREVIATIONS BOD Biological Oxygen Demand DO Dissolved Oxygen GPD Gallon per Day GPM Gallon per Minute IEPA Illinois Environmental Protection Agency MGD Million Gallons per Day NPDES National Pollutant Discharge Elimination System TSS Total Suspended Solids WWTP Wastewater Treatment Plant

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 1

CHAPTER 1 – EXECUTIVE SUMMARY

OVERVIEW

This study was completed to identify the capital improvements needed at the Geneseo Wastewater Treatment Plant (WWTP), including improvement priority rankings and cost opinions. The study considered the current treatment process and future processes required due to changes in regulation. The Geneseo WWTP was designed and built in the 1970s with the last major improvement occurring in 1984. Much of the current equipment is over 20 years old.

RECOMMENDED UPGRADES

As most of the equipment is over twenty years old, every process requires upgrades, this includes:

Headworks

Excess flow pumping

Grit removal

Influent Pumping

Primary treatment

Trickling filters

Aeration

Secondary clarification

Secondary Control

Digestion

Dewatering

Disinfection

Lift Stations

New phosphorus removal systems are required to meet the expected upcoming phosphorus limit.

COST OPINIONS

The estimated current capital cost opinions for process upgrades, in 2017 dollars, are shown below. In addition, the individual cost estimates are included in Appendix D. These cost opinions were developed from a high level view and are considered planning level cost opinions. For planning and budgeting purposes these planning cost opinions have been developed with a significant contingency to allow for adequate planning for the future. Wastewater Treatment Plant Improvements Headworks $887,600 Excess Flow $450,900 Grit $658,400 Influent Pumping $272,500 Primary Clarification $787,600 Trickling Filters $601,700

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 2

Aeration Basins $275,400 Secondary Clarification $680,900 Secondary Control $353,200 Digestion - Primary $1,116,300 Digestion - Secondary $1,324,500 Dewatering $674,000 Effluent Pumping $407,000 Disinfection - Lagoon $199,200 Disinfection - UV Plant $1,220,000 Phosphorus Removal $399,200 WWTP SCADA $450,000 WWTP Total $10,758,419 Lift Station Improvements Elk Lift Station $330,000 Chicago Lift Station $330,000 Stewart Lift Station $330,000 Crowe Lift Station $330,000 Jazzercise Lift Station $40,000 Edwards Lift Station $40,000 Ash Lift Station $40,000 Cherry Lift Station $40,000 Prairie Lift Station $40,000 Lift Station Total $1,520,000 Overall Wastewater System Total $12,278,419 These costs have been spread out to 2025 on the Capital Plan spreadsheet included in Appendix D. An Excel spreadsheet has been provided to the City so the City can adjust dates on a year by year basis to allocate funds and plan over a shorter time horizon. The early completion projects are as follows: Dewatering Project – This project consists of the installation of a rotary fan press to dewater digested sludge prior to hauling to farm fields for land application. Elk Lift Station – This lift station is under design and will be bid out in 2017. Disinfection – The Illinois EPA (IEPA) has required the City to disinfect all flows to either the Green River or Geneseo Creek. Under previous permits, the City did not need to disinfect due to the option of the two outfalls. A compliance schedule has been negotiated with IEPA with required milestone completion dates. The first key milestone requires plans and specifications, and the IEPA permit to be submitted, by July 1, 2018.

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 3

CHAPTER 2 – PROJECT BACKGROUND

STUDY OBJECTIVE

The objective of this needs assessment is to identify the major capital improvements needed at the Geneseo Wastewater Treatment Plant (WWTP), including improvement priority rankings and high level cost opinions. The report will include current treatment process and future processes required due to changes in regulation.

FACILITY OVERVIEW

The Geneseo WWTP was designed and built in the 1970s with the last major improvement occurring in 1984. Much of the current equipment is over 30 years old and requires replacement due to exceeding the design life of the equipment. The plant was designed for an average flow of 1.5 MGD with a peak flow of 4 MGD.

Flow enters the headworks through a mechanically cleaned bar screen and then enters the plant through a 12” parshall flume. Flow above 4 MGD is diverted via a butterfly gate valve to an excess flow pump station. The flow control valve is located upstream of the mechanical bar screen. Excess flow is pumped to a holding lagoon west of the facility. The lagoon only discharges excess flow to Geneseo Creek 3 to 4 times a year, all other times excess flow is sent back to the plant for treatment after the wet weather event has stopped and the treatment plant capacity is available for treatment.

After screening, wastewater gravity flows into 10’X10’ detritor grit tank, located under the control room. The flow then enters the raw sewage wet well where it is pumped to the primary clarifiers. Grit from the detritor tank is pumped to a grit classifier where it is dewatered and prepared for landfill disposal.

Primary treatment is completed through two 50’ diameter primary clarifiers. After primary treatment flow is divided between a rock (112’ diameter) and plastic (45’ diameter) trickling filter. Effluent from the trickling filters can be recycled back into the plastic trickling filter if necessary. Flow then enters a small aeration basin, with a retention time of roughly one hour. The aeration basin is aerated via 3 (2 duty/1 standby) 15 HP blowers.

Flow exits the aeration basin and receives final clarification via two (2) 55’ diameter secondary clarifiers. Effluent flow from the clarifiers then can either gravity flow to the Geneseo Creek or be pumped to the Green River north of the facility. Pumping to the Green River is done for approximately four months of the year. The sludge produced from the secondary clarifiers is either returned to the aeration basin or sent to digestion. Anaerobic digestion in the plant is completed by two digesters in series. The primary digester is heated and mixed and the secondary digester is unheated and unmixed. Digested sludge is currently removed by liquid hauling to local farm fields for liquid land application. The facility flow schematic can be found in Appendix A, and a hydraulic profile can be found in Appendix B.

An aerial view of the facility can be seen in Figure 2-1 and Figure 2-2.

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 4

Figure 2-1 Geneseo WWTP and Excess Flow Lagoon Aerial

Excess Flow Lagoon

Geneseo WWTP

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 5

Figure 2-2 Geneseo WWTP

NPDES PERMIT

The NPDES Permit limits CBOD and TSS to monthly averages of 20 and 25 mg/L respectively at Outfall 001 and 10 and 12 mg/L respectively at Outfall 004. There are current no effluent limits on total nitrogen or total phosphorus; however, the plant is required to complete a phosphorus removal feasibility study. The Illinois EPA is currently working on new phosphorus requirements that could result in a commitment to achieve chemical phosphorus removal by 2025 or biological phosphorus removal by 2030. Recently the

Final Clarifiers Rock Trickling Filter

Plastic Trickling Filter

Primary Clarifiers

Primary Digester

Secondary Digester

Grit Tank

Aeration Basins

Sludge Drying Beds

Parshall Flume

Inlet Splitter Structure

Excess Flow Pumps

Secondary Control

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 6

WWTP was determined to no longer meet the requirements for disinfection exemption and therefore seasonal disinfection (May to October) will be required. The NPDES permit and the letter from IEPA indicating seasonal disinfection requirement can be found in Appendix C. The effluent limits for Outfall 001, 004 and 005 are shown in Table 2-1, Table 2-2 and Table 2-3. Outfall 001 discharges plant final effluent to the Green River. Outfall 004 discharges plant final effluent to Geneseo Creek. Outfall 005 discharges to Geneseo Creek from the excess flow lagoon. The plant discharges to Outfall 005 approximately 3 to 4 times per year.

Table 2-1 Outfall 001 (Green River) Limits

Outfall 001 Load Limits (lb/day)

DAF (DMF) Concentration Limits (mg/L)

Parameter Monthly Average

Weekly Average

Daily Maximum

Monthly Average

Weekly Average

Daily Maximum

CBOD 250 (667) 500 (1334) 20 40

TSS 313 (834) 563 (1501) 25 45

pH Shall be in range of 6 to 9 standard units

Fecal Coliform

Daily Maximum shall not exceed 400 per 100 mL (May through October)

Chlorine Residual 0.35 0.7 Ammonia Nitrogen: March 19 (50) 48 (127) 64 (170) 1.5 3.8 5.1

April-October 19 (50) 48 (127) 63 (167) 1.5 3.8 5.0

Nov.-Feb. 50 (133) 71 (190) 4.0 5.7

Total Phosphorus Monitor only

Total Nitrogen Monitor only

Monthly Avg. not

less than Daily

Minimum Dissolved Oxygen March-July N/A 6.0 5.0

August-February 5.5 4.0 3.5

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 7

Table 2-2 Outfall 004 (Geneseo Creek) Limits

Outfall 004 Load Limits (lb/day)

DAF (DMF) Concentration Limits (mg/L)

Parameter Monthly Average

Weekly Average

Daily Maximum

Monthly Average

Weekly Average

Daily Maximum

CBOD 125 (334) 250 (667) 10 20

TSS 150 (400) 300 (801) 12 24

pH Shall be in range of 6 to 9 standard units

Fecal Coliform Monitor Only (May through October)

Chlorine Residual 0.05

Ammonia Nitrogen: March 19 (50) 48 (127) 64 (170) 1.5 3.8 5.1

April-May/Sept.-Oct. 13 (33) 38 (100) 1.0 3.0

June-August 13 (33) 35 (93) 38 (100) 1.0 2.8 3.0

Nov. Feb. 33 (87) 71 (190) 2.6 5.7 Total Phosphorus Monitor only

Total Nitrogen Monitor only

Monthly Avg. not

less than Daily

Minimum Dissolved Oxygen March-July N/A 6.0 5.0 August-February 5.5 4.0 3.5

Table 2-3 Outfall 005 Limits

Outfall 005 Concentration Limits (mg/L)

Parameter Monthly Average Weekly Average

BOD 30 45

TSS 30 45

pH Shall be in range of 6 to 9 standard units

Fecal Coliform Daily Maximum Shall Not Exceed 400 per 100 mL

Chlorine Residual 0.75

Ammonia Nitrogen (as N) Monitor Only

Total Phosphorus (as P) Monitor Only

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 8

CHAPTER 3 – IDENTIFIED IMPROVEMENTS

The Geneseo WWTP was designed and built in the 1970’s. It was last upgraded in 1984. Much of the plant process equipment is over thirty years old. The following sections detail the proposed improvements to the facility.

3.1 HEADWORKS

The headworks consists of a mechanically cleaned bar screen, a manual bypass screen and a 12” parshall flume. Currently the screening must be hauled out of the building and up a ramp manual for disposal. The Headworks building is shown in Figure 3-1; the bar screens are shown in Figure 3-2 and Figure 3-3; the parshall flume is shown in Figure 3-4; and the current screening disposal system is shown in Figure 3-5.

Figure 3-1 Headworks Building

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 9

Figure 3-2 Manual Bypass Bar Screen

Figure 3-3 Mechanically Cleaned Bar Screen

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 10

Figure 3-4 Parshall Flume - 12"

Figure 3-5 Bar Screening Manual Removal

It is recommended that the current screen be replaced with a new screen and auger to lift the screening up and out of the building to the west. The screenings would enter a washer and compactor before disposal. See Figure 3-6 and Figure 3-7 for proposed location.

The headworks diverts excess flow (i.e. > 4 MGD) to the lagoon via a flow control valve which is interconnected to the parshall flume flow measurement. The current butterfly gate valve, shown in Figure 3-8, which serves as the control valve, is old and showing signs of corrosion. It is recommended that this valve be replaced with a newer one of the same or equal performance.

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 11

The block around the headworks building needs to be sealed. In addition, the following are also recommended for replacement as they have exceeded their design life: conduit on the outside of the headworks building; roof on the headworks building; the door to the headworks building.

Figure 3-6 Proposed Location of New Screenings Washer and Compactor, Aerial View

Figure 3-7 Proposed Location of New Screening washer and Compactor, Outside View

Proposed location of washer and compactor

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 12

Figure 3-8 Butterfly Valve

In summary, the recommended improvements due to age and deterioration of equipment are as follows:

1. Replace flow control butterfly valve

2. Replace mechanical bar screen and add a washer compactor at grade level

3. Replace the roof and insulation

4. Replace the HVAC equipment for the building

5. Seal block around the block building

6. Replace corroded door and conduit

7. Replace influent composite sampler

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 13

3.2 EXCESS FLOW PUMP STATION

The excess flow pump station consists of three 6400 gpm pumps that can pump a total of 18.4 MGD (2 duty/1 standby). The pumps currently have soft starts that were put in service in 1986. The excess flow is currently pumped 308 feet through a 30” line to manhole #4 where it then flows into 24” line that leads 260 feet into the lagoon. The facility is currently having problems with the manhole over flowing. A concrete surge tower, shown in Figure 3-9, has been built to mitigate the surge. Since the original gravity flow piping was not designed for this pressure condition, there is leakage near the surge tower which is undermining the foundation.

It is recommended that the manhole be removed and either be replaced with an elbow fitting to connect the 30” and 24” pipes or a better designed surge tower to accommodate the short term spike in the hydraulic grade line. It is also recommended to replace the soft starts with VFDs to attenuate the flow surge. A more detailed hydraulic evaluation should be completed to make sure the improvements do not cause a backup to the primary clarifier bypass structure.

Figure 3-9 Concrete Surge Tower

In summary, the recommended improvements due to age and deterioration of equipment are as follows:

1. Replace the current excess flow pumps with new pumps

2. Replace the aged soft starts with new VFD’s for surge attenuation

3. Replace mag meter that controls return flow from the lagoon

4. Hydraulic evaluation and replacement of concrete surge tower to avoid washout and collapse

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 14

3.3 GRIT REMOVAL

Grit removal is currently performed by a 10’x10’ detritor, shown in Figure 3-10. Grit is pumped to a grit classifier via a 210 gpm grit pump, shown in Figure 3-11. All of the grit equipment is original and past the design life. Therefore it is recommended that all grit equipment be replaced with similar equipment. The door and door jamb to the control building where the grit tank is located should also be replaced due to significant corrosion. The gates in the channel to the grit tank will need to be replaced as well.

Figure 3-10 Grit Tank

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 15

Figure 3-11 Grit Classifier

In summary, the recommended improvements due to age and deterioration of equipment are as follows:

1. Replace the current detritor equipment in the lower grit removal tank

2. Replace the grit slurry pump with a new grit slurry pump

3. Replace the grit classifier with a new grit classifier

4. Replace stop gates in the channels with new stop gates to allow grit tank isolation

5. Replace corroded door

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 16

3.4 RAW INFLUENT PUMPING

After grit removal raw influent is pumped to primary treatment via three pumps, two of which are original to the plant and one which was installed in 1986. The two original pumps have capacities of 1250 and 2000 gpm. The newer pump has a capacity of 860/1750 gpm. Due to exceeding their design life it is recommended that all three pumps be replaced and that new VFDs be installed. In addition, all gates, valves and diffusers are recommended for replacement. Influent pumps are shown in Figure 3-12.

Figure 3-12 Influent Pumps

In summary, the recommended improvements due to age and deterioration of equipment are as follows:

1. Replace the current influent pumps with new influent pumps

2. Install VFD’s for the new influent pumps

3. Replace the pump isolation valves

4. Replace the pump check valves

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 17

3.5 PRIMARY TREATMENT

Primary treatment consists of two primary clarifiers, one shown in Figure 3-13, with diameters of 50’. The handrails were originally embedded into the concrete and are causing concrete spalling, as shown in Figure 3-14. In addition, the scum trough is currently held in place via clamps. The primary internal mechanisms were replaced between 2010 and 2012 and are expected to last until at least 2020. It is recommended that the concrete be repaired and the handrails be replaced with a non-embedded aluminum railing. The primary sludge pump should also be replaced at this time due exceeding the design life. Primary sludge pumping is shown in Figure 3-15. In addition the six 6” plug valves in the sludge pit between the two clarifiers are due for replacement.

Figure 3-13 Primary Clarifier

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 18

Figure 3-14 Primary Clarifier Concrete Spalling

Figure 3-15 Primary Sludge Pump

In summary, the recommended improvements due to age and deterioration of equipment are as follows:

1. Replace the current clarifier equipment with new clarifier equipment

2. Replace handrail and repair concrete

3. Replace plug valves and primary sludge pump

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 19

3.6 TRICKLING FILTERS

There are currently two trickling filters in use at the facility. The original 112’ diameter rock trickling filter and the newer 45’ diameter plastic media trickling filter, both are shown in Figure 3-16. The distributor arms for both the rock and plastic media filters were replaced approximately ten years ago. It is recommended that distribution arms be replaced approximately once every ten to fifteen years and therefore a replacement is recommended.

It should be noted that the center assembly may be leaking due to age and wear and tear. For budgetary purposes this should be included as a replacement cost. The plastic media and the rock media are currently not showing signs of sagging which would indicate crushed media below. Therefore the media appears to be in relatively good shape for it’s age.

The fixed film aspect of the trickling filter allows for efficient BOD and ammonia removal with low energy costs. The limitation of this technology is that it will be difficult to achieve biological phosphorus removal and biological nitrogen removal. Since the current strategy by IEPA for phosphorus and nitrogen removal may require phosphorus removal by 2025 and nitrogen removal after 2035, it is recommended to upgrade the current system until nitrogen limits become a reality.

The three filter feed pumps, at 1200 gpm each, are original to the plant and therefore should be replaced due to exceeding the design life. The filter pumps are shown in Figure 3-17. There are currently two Flygt pumps that are greater than 10 years old.

Figure 3-16 Rock and Plastic Trickling Filters

Rock Trickling Filters

Plastic Trickling Filters

Filter Feed Pumps

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 20

Figure 3-17 Filter Feed Pumps

In summary, the recommended improvements due to age and deterioration of equipment are as follows:

1. Replace distributor arms for the rock filter and plastic media filter

2. Replace the center assembly

3. Replace the filter feed pumps

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 21

3.7 AERATION

The current aeration basin has a volume of approximately 9000 cu-ft and an average detention time of one hour. Aeration is provided by three 15-HP blowers, shown in Figure 3-19, all blowers are recommended for upgrades. The existing Wyss diffusors are current being replaced. All channels and gates in both tanks as well as all slide gates are recommended for replacement as well.

Figure 3-18 Aeration Basins

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 22

Figure 3-19 Three 15-HP Blowers

In summary, the recommended improvements due to age and deterioration of equipment are as follows:

1. Replace positive displacement blowers with new blowers

2. Replace gates in aeration tanks

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 23

3.8 FINAL CLARIFICATION

Final clarification is completed by two 55’ diameter clarifiers, which were part of the 1986 construction. One clarifier is shown in Figure 3-20. The clarifier drives were replaced between 2014 and 2015 and do not need replacement. The support arm on the west clarifier is recommended for replacement. Due to exceeding the design life it is recommended that all clarifier mechanisms be scheduled for replacement within the next 10 years.

Figure 3-20 Final Clarifier

In summary, the recommended improvements due to age and deterioration of equipment are as follows:

1. Replace clarifier mechanisms within the next 10 years

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 24

3.9 SECONDARY CONTROL BUILDING

Return activated sludge pumping is completed by three 500 gpm pumps. Waste activated sludge pumping is completed by one 145 gpm pump. The secondary control building houses all of the RAS and WAS pumping, including:

1 waste sludge pump

3 return sludge pumps

VFDs

It is recommended that all sludge pumping be replaced with the same or similar equipment. The control building also contains non-potable water system pumps and a hydropneumatic tank which have reached the end of their design life. It is recommended that the pumps and the tank be replaced.

In summary, the recommended improvements due to age and deterioration of equipment are as follows:

1. Replace RAS and WAS pumps

2. Replace VFD’s with new VFD’s

3. Replace non-potable water system and hydropneumatic tank

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 25

3.10 DIGESTION

Digestion is currently being completed through two stage anaerobic digestion. The primary digester uses heat and mixing, while the secondary digester does not. Both digesters are original to the plant; however the primary digester’s lid was replaced in 1986 as shown in Figure 3-21. It is recommended that the secondary digester’s lid, shown in Figure 3-22, be replaced and that the primary digester’s lid be re-coated. The gas safety equipment for both digesters should be updated and it is recommended that the current budget be modified to include regular digester cleanings.

The digester building also contains:

1 sludge transfer pump

1 sludge heater pumps

Sludge heat exchanger

Gas safety equipment

It is recommended that both pumps be replaced with the same or similar equipment.

Figure 3-21 Primary Digester

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 26

Figure 3-22 Secondary Digester

In summary, the recommended improvements due to age and deterioration of equipment are as follows:

1. Replace secondary digester lid

2. Re-coat primary digester lid

3. Replace sludge heat exchanger with new sludge heat exchanger

4. Replace sludge transfer pump (part of dewatering project)

5. Replace current digester mixing system in the primary digester with new digester mixing system

6. Replace the current gas safety equipment with new gas safety equipment

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 27

3.11 DEWATERING

Dewatering was done in the past using the vacuum assisted drying beds; however, problems with the drying beds have led to sludge being land applied in its liquid state. Due to resistance from the agricultural community a new dewatering system should be installed. The City has already completed a dewatering study, completed by Donohue & Associates, Inc., which recommended the installation of a rotary fan press. Based on the study, the WWTP currently produces 600,000 gallons per year of digested sludge, leading to approximately 200,000 pounds per year of dry solids. The plant staff would like to dewater one day (6-8 hours) every other week for a total of 156 to 208 hours per year. This required a minimum hydraulic capacity of 48 gpm and dry solids capacity of 962 pounds per hour. Both rotary fan presses and screw presses were investigated. Based on economic analysis the rotary fan press would be lower in both capital costs and annual costs. In addition, the fan press has a smaller footprint leading to an easier installation. The fan press initial overall project capital cost including installation would be $674,000, based on a quote from March 2014 converted to December 2016 dollars.

In summary, the recommended improvements for dewatering equipment are as follows:

1. Install rotary fan press dwatering unit

2. Replace sludge transfer pump with new transfer pump to meet the requirements of the rotary

fan press

3. Install a new emulsified polymer addition system for the rotary fan press

3.12 EFFLUENT PUMPING

Effluent pumping is utilized approximately 4 months of the year, November through February, to pump flow to the Green River. Effluent pumping is completed only to exercise the pumps. Currently there are three 1800 gpm pumps that are original to the facility. While these pumps are not used frequently it is recommended that they be replaced with the same or similar equipment and VFDs be installed. Note that a gravity line was added during the 1986 improvements. Due to high water levels in Geneseo Creek during heavy wet weather events, it is sometimes not possible to gravity flow to the Creek. In addition, with the additional future requirement for disinfection, there will be no advantage for discharging to Geneseo Creek versus the Green River. Since the effluent limits at the Green River outfall are less stringent, and since the disinfection system will require pumped flow to function, the effluent pumps will need to be used year round.

In summary, the recommended improvements due to age and deterioration of equipment are as follows:

1. Replace effluent pumps with new effluent pumps

2. Install VFD’s with new effluent pumps

3. Replace the isolation and check valves for each pump

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 28

3.13 LIFT STATIONS

There are currently 9 lift stations throughout the collection system, consisting of 4 dry pit lift stations and 5 submersible pump stations.

The dry pit lift stations include:

Elk Lift Station

Chicago Lift Station

Stewart Lift Station

Crowe Lift Station

The submersible pump stations include:

Jazzercise Lift Station

Edwards Lift Station

Ash Lift Station

Cherry Lift Station

Prairie Lift Station

It is recommended that all of the dry pit lift stations be upgraded to submersible pump stations for ease of maintenance and safety. The control systems at the submersible pump lift stations should be replaced with more modern control systems.

3.14 ELECTRICAL AND CONTROL SYSTEMS

The existing treatment plant was last upgraded in 1986. There have been significant changes to electrical

codes since this upgrade and it is expected that with each individual project significant electrical upgrades

could be required. Therefore, while some dollars for electrical have been accounted for, the contingency

for each project was set at 30% due to the high level nature of the cost opinions for each project.

In terms of SCADA, which stands for Supervisory Control and Data Acquisition, the existing treatment has

very limited SCADA capabilities. We have included a line item in the overall cost opinion to account for a

stand alone SCADA implementation project.

3.15 CHANGE IN REGULATIONS

While the WWTP does not currently have disinfection or phosphorus removal requirements, new NPDES Permit will require seasonal disinfection, as indicated by the letter from IEPA shown in Appendix C, and phosphorus removal. The completion of a phosphorus removal feasibility study in anticipation of an upcoming phosphorus limit is currently being completed.

3.15.1 DISINFECTION

The facility currently has a gas chlorination system, located next to the control building. This system has not been in services for several years and is in considerable disrepair. The gaseous chlorine had been delivered in one ton cylinders in the past. Due to the potential dangers of gaseous chlorine, and the

City of Geneseo May, 2017

Wastewater Needs Assessment Donohue & Associates, Inc. Page 29

considerable revisions to the chemical feed facilities required, the City is desiring to use ultraviolet disinfection to meet the future disinfection requirements.

The excess flow lagoon currently has no disinfection capabilities. During the ultraviolet disinfection improvements, a small chemical feed facility will be installed near the lagoon overflow point to allow for disinfection before it overflows to the Geneseo Creek.

Figure 3-23 Chlorination Basin

3.15.2 PHOSPHORUS REMOVAL

While a phosphorus limit is not currently in place, a phosphorus limit compliance schedule is expected on the next issued NDPES permit. This compliance schedule will most likely require chemical phosphorus removal by 2025. While no upgrades are needed at this time, it is recommended that phosphorus removal alternative be considered during plant upgrades.

Since biological phosphorus removal is not feasible for this treatment plant a chemical addition system will need to be added. It is anticipated this system will consist of a 2,000 gallon storage tank and an alum chemical feed system. The phosphorus removal chemical feed system will be installed in a new chemical feed building.

Chlorination Basin

FLO

WSC

HEM

ATIC

Drawing Number

XX1

XX2

XX3

XX4

Drawing No.

Designed By

Checked By

Filename

Approved By

Project No.

Drawn By

Rev

isio

nN

umbe

rR

evis

ion

Des

crip

tion

Dra

wn

ByD

ate

Che

cked

By

Sheet No.

Project Date

CIT

YO

FG

ENES

EOC

API

TAL

IMPR

OVE

MEN

TPL

AN

GEN

ESEO

WA

STEW

ATE

RTR

EATM

ENT

PLAN

T

13173

02/2017

009N1.DWG

INLET SPLITTER

PLANTINFLUENT

EXCESS FLOWRETURN

MANUAL BARSCREEN

FLOWMEASUREMENTH FLUME

EXCESS FLOWPUMPING

RETURN FLOWMETERING

FLOW CONTROLVALVE

EXCESS FLOW LAGOON

MANUAL BARSCREEN

MECHANICALBAR SCREEN

FLOWCONTROLVALVE 12" PARSHALL FLUME GRIT TANK

PRIMARY CLARIFIERS

PLASTIC MEDIATRICKLING FILTER

ROCK TRICKLINGFILTER

FINAL CLARIFIERS

AERATED CHAMBER

OUTFALL 001TO GREEN RIVER

CHLORINE CONTACT TANKS

INFLUENTPUMPING

GRITPUMPING

GRIT CLASSIFIER/WASHER

GRIT TO LANDFILL FILTER FEEDPUMP

FLOWSPLITTER

AERATED CHANNELBYPASS

EFFLUENTWET WELL

RETURN SLUDGE PUMPING

WASTE SLUDGE PUMPING

RAW SLUDGEPUMPING

TRANSFER SLUDGEPUMPING SLUDGE DISCHARGE

PUMPING

PRIMARYDIGESTER

SECONDARYDIGESTER

SLUDGE HEATINGPUMPING

SLUDGE DRYING BEDS

VACUUM ASSISTEDSLUDGE BEDS

LIQUID SLUDGE TOLAND APPLICATION

DEWATERED SLUDGETO LAND FILL ORLAND APPLICATION

SUPERNATANT RETURNEDTO RAW SEWAGE PUMP STATION

WASTEWATER

SLUDGE

GRITSEPARATOR

(TOTAL CAPACITY: 4.2 MGD)

(VOLUME: 225 CU FT)(DETENTION TIME (ADF) 1.8 MIN)

(2 TANKS, 50' DIAMETER)(VOLUME EACH 183,949 GAL)

(DIAMETER 112', MEDIA DEPTH 18')(MEDIA VOLUME 73.9 KCF)

(DIAMETER 45')(MEDIA DEPTH 7.5')

(MEDIA VOLUME 28.6 KCF)

(2 BASINS, TOTAL VOLUME 9072 CU FT)

(2 TANKS, DIAMETER 55', SWD 14.5')(SURFACE SETTLING RATE (ADF) 316 GAL/D/SQF)

PRIMARYCLARIFIER 1

PRIMARYCLARIFIER 2

SECONDARYCLARIFIER 1

SECONDARYCLARIFIER 2

BYPASS

(3 PUMPS)(CAPACITY EACH 6400 GPM)

(3 PUMPS)(1 @ 1250 GPM)(1 @ 1750 GP,M)(1 @ 2000 GPM)

(1 @ 210 GPM)

(3 @1200 GPM)

(1 @ 145 GPM)

(3 @ 500 GPM)

EFFLUENT PUMPING(3 @ 1800 GPM)

(1 @ 100 GPM)

(1 @ 150 GPM)

(2 @ 150 GPM)

(1 @ 420 GPM, 2 @ 75 GPM)

HYD

RA

ULI

CPR

OFI

LE

Drawing Number

XX1

XX2

XX3

XX4

Drawing No.

Designed By

Checked By

Filename

Approved By

Project No.

Drawn By

Rev

isio

nN

umbe

rR

evis

ion

Des

crip

tion

Dra

wn

ByD

ate

Che

cked

By

Sheet No.

Project Date

CIT

YO

FG

ENES

EOC

API

TAL

IMPR

OVE

MEN

TPL

AN

GEN

ESEO

WA

STEW

ATE

RTR

EATM

ENT

PLAN

T

13173

02/2017

001GX1.DWG

610

620

630

640

650

660

610

620

630

640

650

660

570

580

590

600 600

590

580

570

TOP OF BERM621.20

HWL618.20

LWL609.50

OVERFLOW SPILLWAY620.20

GENESEOCREEK

24"

EXCESS FLOWHOLDING LAGOON

EXCESS FLOW RETURN

30"

MH 4

624.50

TOC 632.00

INLET FLOWSPLITTER ANDEXCESS FLOWBYPASS PUMPS

EXCESS FLOWINFLUENT PUMPS

EXCESS FLOW CHANNELW/ BAR SCREEN ANDH. FLUME

TOC 621.20

TOC 619.22

MECHANICALBAR SCREEN

INV609.14

30"

PLANT INFLUENTS

BYPASSCONTROLVALVE

4"

609.70

12" PARSHALLFLUME

INV 607.64 607.81

INV 607.53

TOC 621.50

GRIT CHAMBER RAW SEWAGEWET WELL

PRIMARY CLARIFIERS TRICKLING FILTERFEED PUMPS

ROCK TRICKLING FILTER PLASTIC MEDIATRICKLING FILTER

AERATEDCHANNEL

AERATEDCHAMBER

AERATEDCHANNEL

FINAL CLARIFIERS

EFFLUENT PUMPS

HWL607.50

LWL603.00 RAW SEWAGE

PUMPS

16"

628.92

632.94POINT OF V-NOTCH WEIR632.00

632.10630.00

628.92

TOC 633.86

16"

621.85

16"

TOC 619.88

TOC 633.00

609.00

16"

INV 607.50607.00

16"

TOC 627.73DIST. ARM 625.70

TOP OFROCK624.90

BOTTOM OFUNDERDRAIN 615.50

30"

BOTTOM OF MEDIA 622.00

BOTTOM OF UNDERDRAIN 616.75

TOP OF MEDIA 640.00

TOC 643.00

30"

INV612.00

609.00

603.00

614.00

TOC 619.53

609.00

24"

TOC 621.20

SET WEIR613.50

590.34

599.10

CHLORINECONTACTTANK

601.50

INV611.92

611.80HWL611.00

LWL604.00

18"

001TO GREENRIVER

TOC621.20

NPDES Permit No. IL0021814

Notice No. SKT:16040801.bah

Public Notice Beginning Date: July 15, 2016

Public Notice Ending Date: August 15, 2016

National Pollutant Discharge Elimination System (NPDES)

Permit Program

PUBLIC NOTICE/FACT SHEET of

Draft Reissued NPDES Permit to Discharge into Waters of the State

Public Notice/Fact Sheet Issued By:

Illinois EPA Division of Water Pollution Control Permit Section 1021 North Grand Avenue East Post Office Box 19276 Springfield, Illinois 62794-9276 217/782-0610

Name and Address of Discharger: Name and Address of Facility:

City of Geneseo 115 South Oakwood Avenue Geneseo, Illinois 61254

City of Geneseo STP 207 North Stewart Street Geneseo, Illinois 61254 (Henry County)

The Illinois Environmental Protection Agency (IEPA) has made a tentative determination to issue a NPDES Permit to discharge into the waters of the state and has prepared a draft Permit and associated fact sheet for the above named discharger. The Public Notice period will begin and end on the dates indicated in the heading of this Public Notice/Fact Sheet. All comments on the draft Permit and requests for hearing must be received by the IEPA by U.S. Mail, carrier mail or hand delivered by the Public Notice Ending Date. Interested persons are invited to submit written comments on the draft Permit to the IEPA at the above address. Commentors shall provide his or her name and address and the nature of the issues proposed to be raised and the evidence proposed to be presented with regards to those issues. Commentors may include a request for public hearing. Persons submitting comments and/or requests for public hearing shall also send a copy of such comments or requests to the Permit applicant. The NPDES Permit and notice numbers must appear on each comment page. The application, engineer's review notes including load limit calculations, Public Notice/Fact Sheet, draft Permit, comments received, and other documents are available for inspection and may be copied at the IEPA between 9:30 a.m. and 3:30 p.m. Monday through Friday when scheduled by the interested person. If written comments or requests indicate a significant degree of public interest in the draft Permit, the permitting authority may, at its discretion, hold a public hearing. Public notice will be given 45 days before any public hearing. Response to comments will be provided when the final Permit is issued. For further information, please call Surinder Tandon at 217/782-0610. The following water quality and effluent standards and limitations were applied to the discharge: Title 35: Environmental Protection, Subtitle C: Water Pollution, Chapter I: Pollution Control Board and the Clean Water Act were applied in determining the applicable standards, limitations and conditions contained in the draft Permit. The applicant is engaged in treating domestic wastewater for the City of Geneseo. The length of the Permit is approximately 5 years. The effluent is discharged to the Green River through outfall 001 or to Geneseo Creek through outfall 004. The seven day once in ten year low flow (7Q10) of Green River is 46.1 cfs. The seven day once in ten year low flow (7Q10) of Geneseo CreeK is 0.03 cfs. The design average flow (DAF) for the facility is 1.5 million gallons per day (MGD) and the design maximum flow (DMF) for the facility is 4.0 MGD. Treatment consists of screening, grit removal, primary clarifiers, activated sludge, trickling filters, final clarifiers and chlorination. Sludge is treated by anaerobic digestion, drying beds and then land applied.

Public Notice/Fact Sheet -- Page 2 -- NPDES Permit No. IL0021814

This Reissued Permit does not increase the facility’s DAF, DMF, concentration limits, and/or load limits. Pursuant to the waiver provisions authorized by 40 CFR § 123.24, this draft permit is within the class, type, and size for which the Regional Administrator, Region V, has waived his right to review, object, or comment on this draft permit action. This Permit recognizes and continues the year-round disinfection exemption approved by the IEPA on June 29, 1989 and included in past NPDES permit actions since that date. It is the IEPA’s tentative decision that under Illinois Pollution Control Board regulations, the following reach of waterbody is not classified for primary contact use activities and is not subject to the fecal coliform water quality standard of 35 Ill. Adm. Code 302.209. This draft permit does not contain requirements for disinfection of the discharge from discharge numbers(s) 004. Geneseo Creek, from the facility discharge in Section 17, T17N, R3E, to the confluence with Green River has been determined to be unsuited to support primary contact activities (swimming) due to physical, hydrologic or geographic configuration. Anyone knowing of primary contact activities occurring within this water segment is invited to submit comments to the IEPA. Comments should give the nature of the activities (i.e swimming, fishing, canoeing, etc.), the location and months of the year when these activities have been observed. The IEPA is also interested in obtaining information on the proximity of residential dwellings and the accessibility of the public to this water segment. Anyone with such information is asked to submit comments to the IEPA on this draft permit action. Instructions for submitting comments are contained earlier in this document. Application is made for the existing discharge(s) which are located in Henry County, Illinois. The following information identifies the discharge point, receiving stream and stream classifications:

Discharge Number

Receiving Stream

Latitude

Longitude

Stream Classification

Integrity Rating

001 Green River 41° 29′ 05″ North 90° 11′ 15″ West General Use Not Rated

004 Geneseo Creek 41° 27′ 38″ North 90° 10′ 02″ West General Use Not Rated

005 Geneseo Creek 41° 27′ 38″ North 90° 10′ 06″ West General Use Not Rated

To assist you further in identifying the location of the discharge(s) please see the attached map.

Green River, Waterbody Segment PB-09, is listed on the draft 2014 Illinois Integrated Water Quality Report and 303(d) List as impaired. The following parameters have been identified as the pollutants causing impairment:

Potential Causes Uses Impaired

Unknown Aquatic life

Outfall 004 from the subject facility discharges to Geneseo Creek at a point where 0.03 cfs of flow exists upstream of the outfall during critical 7Q10 low-flow conditions. Geneseo Creek is classified as a General Use Water at this location. Geneseo Creek (segment PBE-01) is listed on the draft 2014 Illinois Integrated Water Quality Report and Section 303(d) List as an impaired water body for aquatic life use. The causes of impairment are given as alteration of stream-side vegetative cover (non-pollutant) and sedimentation/siltation. Geneseo Creek at this location has not been given an integrity rating in the 2008 Illinois Department of Natural Resources Publication Integrating Multiple Taza in Biological Stream Rating System. Geneseo Creek is not designated as an enhanced water pursuant to the dissolved oxygen water quality standard at this location. The next downstream segment is P-25, Rock River, and is listed on the draft 2014 Illinois Integrated Water Quality Report and Section 303(d) List as impaired for aquatic life and fish consumption uses. The cause of aquatic life use impairment is cause unknown. The causes of fish consumption use impairment are mercury and PCBs. Aesthetic quality use was not assessed. The next downstream segments are on the Mississippi River. All Illinois segments of the Mississippi River are fully supportive of aquatic life and aesthetic quality uses. There are no downstream instances of impairment due to aquatic algae, aquatic plants or dissolved oxygen.

Public Notice/Fact Sheet -- Page 3 -- NPDES Permit No. IL0021814

The discharge(s) from the facility is (are) proposed to be monitored and limited at all times as follows: Discharge Number(s) and Name(s): 001 STP Outfall Load limits computed based on a design average flow (DAF) of 1.5 MGD (design maximum flow (DMF) of 4.0 MGD). The effluent of the above discharge(s) shall be monitored and limited at all times as follows:

LOAD LIMITS lbs/day DAF (DMF)*

CONCENTRATION LIMITS mg/L

Parameter

Monthly Average

Weekly Average

Daily Maximum

Monthly Average

Weekly Average

Daily Maximum

Regulation

CBOD5** 250 (667) 500 (1334) 20 40 35 IAC 304.120 40 CFR 133.102

Suspended Solids** 313 (834) 563 (1501) 25 45 35 IAC 304.120 40 CFR 133.102

pH Shall be in the range of 6 to 9 Standard Units 35 IAC 304.125

Fecal Coliform

Daily Maximum shall not exceed 400 per 100 mL (May through October)

35 IAC 304.121

Chlorine Residual 0.35 0.70 35 IAC 302.208

Ammonia Nitrogen: March

19 (50)

48 (127)

64 (170)

1.5

3.8

5.1

35 IAC 355 and 35 IAC 302

April-October 19 (50) 48 (127) 63 (167) 1.5 3.8 5.0

Nov.-Feb. 50 (133) 71 (190) 4.0 5.7

Total Phosphorus (as P) Monitor only 35 IAC 309.146

Total Nitrogen Monitor only 35 IAC 309.146

Monthly Avg. not less than

Weekly Avg. not less than

Daily

Minimum

Dissolved Oxygen March-July

N/A

6.0

5.0

35 IAC 302.206

August-February 5.5 4.0 3.5

*Load Limits are calculated by using the formula: 8.34 x (Design Average and/or Maximum Flow in MGD) x (Applicable Concentration in mg/L) **BOD5 and Suspended Solids (85% removal required): In accordance with 40 CFR 133, the 30-day average percent removal shall not be less than 85 percent .

Public Notice/Fact Sheet -- Page 4 -- NPDES Permit No. IL0021814

The discharge(s) from the facility is (are) proposed to be monitored and limited at all times as follows: Discharge Number(s) and Name(s): 004 STP Outfall Load limits computed based on a design average flow (DAF) of 1.5 MGD (design maximum flow (DMF) of 4.0 MGD). The effluent of the above discharge(s) shall be monitored and limited at all times as follows:

LOAD LIMITS lbs/day DAF (DMF)*

CONCENTRATION LIMITS mg/L

Parameter

Monthly Average

Weekly Average

Daily Maximum

Monthly Average

Weekly Average

Daily Maximum

Regulation

CBOD5** 125 (334) 250 (667) 10 20 35 IAC 304.120 40 CFR 133.102

Suspended Solids** 150 (400) 300 (801) 12 24 35 IAC 304.120 40 CFR 133.102

pH Shall be in the range of 6 to 9 Standard Units 35 IAC 304.125

Fecal Coliform

Monitor only (May through October)

35 IAC 304.121

Chlorine Residual 0.05 35 IAC 302.208

Ammonia Nitrogen: March.

19 (50)

48 (127)

64 (170)

1.5

3.8

5.1

35 IAC 355 and 35 IAC 302

April-May/Sept.-Oct. 13 (33) 38 (100) 1.0 3.0

June-August 13 (33) 35 (93) 38 (100) 1.0 2.8 3.0

Nov.-Feb. 33 (87) 71 (190) 2.6 5.7

Total Phosphorus (as P) Monitor only 35 IAC 309.146

Total Nitrogen Monitor only 35 IAC 309.146

Monthly Avg. not less than

Weekly Avg. not less than

Daily

Minimum

Dissolved Oxygen March-July

N/A

6.0

5.0

35 IAC 302.206

August-February 5.5 4.0 3.5

*Load Limits are calculated by using the formula: 8.34 x (Design Average and/or Maximum Flow in MGD) x (Applicable Concentration in mg/L) **BOD5 and Suspended Solids (85% removal required): In accordance with 40 CFR 133, the 30-day average percent removal shall not be less than 85 percent.

Public Notice/Fact Sheet -- Page 5 -- NPDES Permit No. IL0021814

This Permit contains an authorization to treat and discharge excess flow as follows: Discharge Number(s) and Name(s): 005 Excess Flow Lagoon Outfall (Flows in excess of 2777 gpm) The effluent of the above discharge(s) shall be monitored and limited at all times a follows:

CONCENTRATION

LIMITS (mg/L)

Parameter Monthly Average Weekly Average Regulation

BOD5* 30 45 40 CFR 133.102

Suspended Solids* 30 45 40 CFR 133.102

Fecal Coliform Daily Maximum Shall Not Exceed 400 per 100 ML 35 IAC 304.121

pH Shall be in the range of 6 to 9 standard units 35 IAC 304.125

Chlorine Residual 0.75 35 IAC 302.208

Ammonia Nitrogen (as N) Monitor only 35 IAC 309.146

Total Phosphorus (as P) Monitor only 35 IAC 309.146

*The 30-day average percent removal shall not be less than 85 percent.

Public Notice/Fact Sheet -- Page 6 -- NPDES Permit No. IL0021814

This draft Permit also contains the following requirements as special conditions: 1. Reopening of this Permit to include different final effluent limitations. 2. Operation of the facility by or under the supervision of a certified operator. 3. Submission of the operational data in a specified form and at a required frequency at any time during the effective term of this

Permit. 4. More frequent monitoring requirement without Public Notice. 5. Prohibition against causing or contributing to violations of water quality standards. 6. Recording the monitoring results on Discharge Monitoring Report Forms using one such form for each outfall each month and

submitting the forms to IEPA each month. 7. The provisions of 40 CFR Section 122.41(m) & (n) are incorporated herein by reference. 8. Effluent sampling point location. 9. Controlling the sources of infiltration and inflow into the sewer system. 10. A requirement to monitor and a limit of 0.05 mg/L for residual chlorine when it is used. 11. Seasonal fecal coliform limits. 12. Monitoring for arsenic, barium, cadmium, hexavalent chromium, total chromium, copper, available cyanide, total cyanide,

fluoride, dissolved iron, total iron, lead, manganese, mercury, nickel, oil, phenols, selenium, silver and zinc is required to be conducted semi-annually beginning 3 months from the effective date.

13. Submission of annual fiscal data. 14. A requirement for biomonitoring of the effluent. 15. Submission of semi annual reports indicating the quantities of sludge generated and disposed. 16. Capacity, Management, Operations, and Maintenance (CMOM) plan. 17. Reopening of this Permit to include revised effluent limitations based on a Total Maximum Daily Load (TMDL) or other water

quality study. 18. Phosphorus Reduction Feasibility Plan 19. Phosphorus Removal Optimization Plan

NPDES Permit No. IL0021814

Illinois Environmental Protection Agency

Division of Water Pollution Control

1021 North Grand Avenue East

Post Office Box 19276

Springfield, Illinois 62794-9276

NATIONAL POLLUTANT DISCHARGE ELIMINATION SYSTEM

Reissued (NPDES) Permit

Expiration Date: Issue Date: Effective Date:

Name and Address of Permittee: Facility Name and Address:

City of Geneseo 115 South Oakwood Avenue Geneseo, Illinois 61254

City of Geneseo STP 207 North Stewart Street Geneseo, Illinois 61254 (Henry County)

Receiving Waters: Green River and Geneseo Creek In compliance with the provisions of the Illinois Environmental Protection Act, Title 35 of the Ill. Adm. Code, Subtitle C, Chapter I, and the Clean Water Act (CWA), the above-named Permittee is hereby authorized to discharge at the above location to the above-named receiving stream in accordance with the Effluent Limitations, Monitoring, and Reporting requirements; Special Conditions and Attachment H Standard Conditions attached herein. Permittee is not authorized to discharge after the above expiration date. In order to receive authorization to discharge beyond the expiration date, the Permittee shall submit the proper application as required by the Illinois Environmental Protection Agency (IEPA) not later than 180 days prior to the expiration date.

Alan Keller, P.E. Manager, Permit Section Division of Water Pollution Control

SAK:SKT:16040801.bah

Page 2

NPDES Permit No. IL0021814

Effluent Limitations, Monitoring, and Reporting

FINAL

Discharge Number(s) and Name(s): 001 STP Outfall Load limits computed based on a design average flow (DAF) of 1.5 MGD (design maximum flow (DMF) of 4.0 MGD). From the effective date of this Permit until the expiration date, the effluent of the above discharge(s) shall be monitored and limited at all times as follows:

LOAD LIMITS lbs/day DAF (DMF)*

CONCENTRATION LIMITS mg/L

Parameter

Monthly Average

Weekly Average

Daily Maximum

Monthly Average

Weekly Average

Daily Maximum

Sample Frequency

Sample Type

Flow (MGD) Continuous

CBOD5**,1

250 (667) 500 (1334) 20 40 3 Days/Week Composite

Suspended Solids1

313 (834) 563 (1501) 25 45 3 Days/Week Composite

pH Shall be in the range of 6 to 9 Standard Units 3 Days/Week Grab

Fecal Coliform***

Daily Maximum shall not exceed 400 per 100 mL (May through October)

3 Days/Week Grab

Chlorine Residual*** 0.35 0.70 3 Days/Week Grab

Ammonia Nitrogen: As (N)

March

19 (50)

48 (127)

64 (170)

1.5

3.8

5.1

3 Days/Week

Composite

April-October 19 (50) 48 (127) 63 (167) 1.5 3.8 5.0 3 Days/Week Composite

Nov.-Feb. 50 (133) 71 (190) 4.0 5.7 3 Days/Week Composite

Total Phosphorus (as P) Monitor only 1 Day/Month Composite

Total Nitrogen Monitor only 1 Day/Month Composite

Monthly Average not less

than

Weekly Average not less

than

Daily Minimum

Dissolved Oxygen March-July

N/A

6.0

5.0

3 Days/Week

Grab

August-February 5.5 4.0 3.5 3 Days/Week Grab

*Load limits based on design maximum flow shall apply only when flow exceeds design average flow. **Carbonaceous BOD5 (CBOD5) testing shall be in accordance with 40 CFR 136. ***See Special Condition 11. 1BOD5 and Suspended Solids (85% removal required): In accordance with 40 CFR 133, the 30-day average percent removal shall not

be less than 85 percent. The percent removal need not be reported to the IEPA on DMRs but influent and effluent data must be available, as required elsewhere in this Permit, for IEPA inspection and review. For measuring compliance with this requirement, 5 mg/L shall be added to the effluent CBOD5 concentration to determine the effluent BOD5 concentration. Percent removal is a percentage expression of the removal efficiency across a treatment plant for a given pollutant parameter, as determined from the 30-day average values of the raw wastewater influent concentrations to the facility and the 30-day average values of the effluent pollutant concentrations for a given time period. Flow shall be reported on the Discharge Monitoring Report (DMR) as monthly average and daily maximum. Fecal Coliform shall be reported on the DMR as a daily maximum value. pH shall be reported on the DMR as minimum and maximum value. Chlorine Residual shall be reported on DMR as daily maximum value. Dissolved oxygen shall be reported on the DMR as a minimum value. Total Phosphorus shall be reported on the DMR as a daily maximum value. Total Nitrogen shall be reported on the DMR as a daily maximum value.

Page 3

NPDES Permit No. IL0021814

Effluent Limitations, Monitoring, and Reporting

FINAL

Discharge Number(s) and Name(s): 004 STP Outfall Load limits computed based on a design average flow (DAF) of 1.5 MGD (design maximum flow (DMF) of 4.0 MGD). From the effective date of this Permit until the expiration date, the effluent of the above discharge(s) shall be monitored and limited at all times as follows:

LOAD LIMITS lbs/day DAF (DMF)*

CONCENTRATION LIMITS mg/L

Parameter

Monthly Average

Weekly Average

Daily Maximum

Monthly Average

Weekly Average

Daily Maximum

Sample Frequency

Sample Type

Flow (MGD) Continuous

CBOD5**,1

125 (334) 250 (667) 10 20 3 Days/Week Composite

Suspended Solids1

150 (400) 300 (801) 12 24 3 Days/Week Composite

pH Shall be in the range of 6 to 9 Standard Units 3 Days/Week Grab

Fecal Coliform Monitor only (May through October)

3 Days/Week Grab

Chlorine Residual 0.05 *** Grab

Ammonia Nitrogen: As (N)

March

19 (50)

48 (127)

64 (170)

1.5

3.8

5.1

3 Days/Week

Composite

April-May/Sept.-Oct. 13 (33) 38 (100) 1.0 3.0 3 Days/Week Composite

June-August 13 (33) 35 (93) 38 (100) 1.0 2.8 3.0 3 Days/Week Composite

Nov.-Feb. 33 (87) 71 (190) 2.6 5.7 3 Days/Week Composite

Total Phosphorus (as P) Monitor only 1 Day/Month Composite

Total Nitrogen Monitor only 1 Day/Month Composite

Monthly Average not less

than

Weekly Average not less

than

Daily Minimum

Dissolved Oxygen March-July

N/A

6.0

5.0

3 Days/Week

Grab

August-February 5.5 4.0 3.5 3 Days/Week Grab

*Load limits based on design maximum flow shall apply only when flow exceeds design average flow. **Carbonaceous BOD5 (CBOD5) testing shall be in accordance with 40 CFR 136. ***See Special Condition 10. 1BOD5 and Suspended Solids (85% removal required): In accordance with 40 CFR 133, the 30-day average percent removal shall not

be less than 85 percent. The percent removal need not be reported to the IEPA on DMRs but influent and effluent data must be available, as required elsewhere in this Permit, for IEPA inspection and review. For measuring compliance with this requirement, 5 mg/L shall be added to the effluent CBOD5 concentration to determine the effluent BOD5 concentration. Percent removal is a percentage expression of the removal efficiency across a treatment plant for a given pollutant parameter, as determined from the 30-day average values of the raw wastewater influent concentrations to the facility and the 30-day average values of the effluent pollutant concentrations for a given time period. Flow shall be reported on the Discharge Monitoring Report (DMR) as monthly average and daily maximum. Fecal Coliform shall be reported on the DMR as a daily maximum value. pH shall be reported on the DMR as minimum and maximum value. Chlorine Residual shall be reported on DMR as daily maximum value. Total Phosphorous shall be reported on the DMR as daily maximum value. Total Nitrogen shall be reported on the DMR as daily maximum value. Dissolved oxygen shall be reported on the DMR as a minimum value.

Page 4

NPDES Permit No. IL0021814

Effluent Limitations, Monitoring, and Reporting

FINAL

Discharge Number(s) and Names(s): 005 Excess Flow Lagoon Outfall (flows in excess of 2777 gpm and excess flow lagoon is full ) From the effective date of this Permit until the expiration date, the effluent of the above discharge(s) shall be monitored and limited at all time as follows:

CONCENTRATION LIMITS (mg/L)

Parameter Monthly Average Weekly Average Sample Frequency Sample

Type

Total Flow (MG) Daily When Discharging Continuous

BOD5* 30 45 Daily When Discharging Grab

Suspended Solids* 30 45 Daily When Discharging Grab

pH Shall be in the range of 6 to 9 Standard Units Daily When Discharging Grab

Fecal Coliform Daily Maximum Shall Not Exceed 400 per 100 mL Daily When Discharging Grab

Chlorine Residual 0.75 Daily When Discharging Grab

Ammonia Nitrogen (as N) Monitor only Daily When Discharging Grab

Total Phosphorus (as P) Monitor only Daily When Discharging Grab

* BOD5 and Suspended Solids (85% removal required) : In accordance with 40 CFR 133, the 30-day average percent removal shall not be less than 85 percent. The percent removal need not be reported to the IEPA on DMRs but influent and effluent data must be available, as required elsewhere in this Permit, for IEPA inspection and review. For measuring compliance with this requirement, 5 mg/L shall be added to the effluent CBOD5 concentration to determine the effluent BOD5 concentration. Percent removal is a percentage expression of the removal efficiency across a treatment plant for a given pollutant parameter, as determined from the 30-day average values of the raw wastewater influent concentrations to the facility and the 30-day average values of the effluent pollutant concentrations for a given time period. Total flow in million gallons shall be reported on the Discharge Monitoring Report (DMR) in the quantity maximum column. The main treatment facility flows at the time that 005 Excess Low Facilities are first utilized shall be reported in the comment section of the DMR in gallons per minute (gpm). Report the number of days of discharge in the comments section of the DMR. BOD5 and Suspended Solids shall be reported on the DMR as a monthly and weekly average concentration pH shall be reported on the DMR as a minimum and a maximum value. Fecal Coliform shall be reported on the DMR as a daily maximum value. Chlorine Residual shall be reported on the DMR as monthly average value. Ammonia Nitrogen shall be reported on the DMR as a maximum value. Total Phosphorus shall be reported on the DMR as a maximum value .

Page 5

NPDES Permit No. IL0021814

Influent Monitoring, and Reporting The influent to the plant shall be monitored as follows:

Parameter Sample Frequency Sample Type

Flow (MGD) Continuous

BOD5 3 Days/Week And daily when 005 is discharging

Composite

Suspended Solids 3 Days/Week And daily when 005 is discharging

Composite

Influent samples shall be taken at a point representative of the influent. Flow (MGD) shall be reported on the Discharge Monitoring Report (DMR) as monthly average and daily maximum. BOD5 and Suspended Solids shall be reported on the DMR as a monthly average concentration.

Page 6 NPDES Permit No. IL0021814

Special Conditions

SPECIAL CONDITION 1. This Permit may be modified to include different final effluent limitations or requirements which are consistent with applicable laws and regulations. The IEPA will public notice the permit modification. SPECIAL CONDITION 2. The use or operation of this facility shall be by or under the supervision of a Certified Class 1 operator. SPECIAL CONDITION 3. The IEPA may request in writing submittal of operational information in a specified form and at a required frequency at any time during the effective period of this Permit. SPECIAL CONDITION 4. The IEPA may request more frequent monitoring by permit modification pursuant to 40 CFR § 122.63 and Without Public Notice. SPECIAL CONDITION 5. The effluent, alone or in combination with other sources, shall not cause a violation of any applicable water quality standard outlined in 35 Ill. Adm. Code 302 and 303. SPECIAL CONDITION 6. The Permittee shall record monitoring results on Discharge Monitoring Report (DMR) Forms using one such form for each outfall each month. In the event that an outfall does not discharge during a monthly reporting period, the DMR Form shall be submitted with no discharge indicated. The Permittee will be required to submit electronic DMRs (NetDMRs) instead of mailing paper DMRs to the IEPA beginning December 21, 2016. More information, including registration information for the NetDMR program, can be obtained on the IEPA website, http://www.epa.state.il.us/water/net-dmr/index.html. The completed Discharge Monitoring Report forms shall be submitted to IEPA no later than the 25th day of the following month, unless otherwise specified by the permitting authority. Permittees not using NetDMRs during the interim period before December 21, 2016 shall mail Discharge Monitoring Reports with an original signature to the IEPA at the following address:

Illinois Environmental Protection Agency Division of Water Pollution Control Attention: Compliance Assurance Section, Mail Code # 19 1021 North Grand Avenue East Post Office Box 19276 Springfield, Illinois 62794-9276

SPECIAL CONDITION 7. The provisions of 40 CFR Section 122.41(m) & (n) are incorporated herein by reference. SPECIAL CONDITION 8. Samples taken in compliance with the effluent monitoring requirements shall be taken at a point representative of the discharge, but prior to entry into the receiving stream. SPECIAL CONDITION 9. Consistent with permit modification procedures in 40 CFR 122.62 and 63, this Permit may be modified to include requirements for the Permittee on a continuing basis to evaluate and detail its efforts to effectively control sources of infiltration and inflow into the sewer system and to submit reports to the IEPA if necessary.

SPECIAL CONDITION 10. For Discharge No. 004, any use of chlorine to control slime growths, odors or as an operational control, etc. shall not exceed the limit of 0.05 mg/L (daily maximum) total residual chlorine in the effluent. Sampling is required on a daily grab basis during the chlorination process. Reporting shall be submitted on the DMR’s on a monthly basis. SPECIAL CONDITION 11. Fecal Coliform limits for Discharge Number 001 are effective May thru October. Sampling of Fecal Coliform is only required during this time period. The total residual chlorine limit is applicable at all times. If the Permittee is chlorinating for any purpose during the months of November through April, sampling is required on a daily grab basis. Sampling frequency for the months of May through October shall be as indicated on effluent limitations, monitoring and reporting page of this Permit. SPECIAL CONDITION 12. The Permittee shall conduct semi-annual monitoring of the effluent and report concentrations (in mg/l) of the following listed parameters. Monitoring shall begin three (3) months from the effective date of this permit. The sample shall be a 24-hour effluent composite except as otherwise specifically provided below and the results shall be submitted on Discharge Monitoring Report Forms to IEPA unless otherwise specified by the IEPA. The parameters to be sampled and the minimum reporting limits to be attained are as follows:

Page 7 NPDES Permit No. IL0021814

Special Conditions