Warehouse floor coatings

-

Upload

david-ryan -

Category

Documents

-

view

236 -

download

2

description

Transcript of Warehouse floor coatings

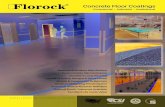

Warehouse Floor Warehouse Floor CoatingsCoatingsEP Floors Corp. provides knowledge and expertise in

warehouse and loading dock floors, using the latest high performance epoxy and polyurethanes. Industrial flooring systems range from thin mil epoxy coatings to 1/4″ towelled epoxy flooring, urethane resurfacers, and non slip systems. We have a system to fit your needs!

We provide Turn Key installation of warehouse epoxy floor coatings with our own crews, along with a solid, single-source warranty. Work may be done over weekends, holidays.

Fast turnaround is guaranteed !

“Perfect for warehouses that are in the corporate spotlight”

Loading Dock and Warehouse Floors

DO IT RIGHT, DO IT ONCE!

Warehouses and loading docks are tough environments for flooring. Bare concrete has cracks and joints, which combined with heavy traffic conditions, can cause concrete spalls and breakage, potholes, low spots, etc. This can wreak havoc on the wheels and suspensions on your material handling equipment; the repairs can run into the tens of thousands of dollars

The nature of the materials stored in the warehouse Corrosive liquids, solvents and specialty chemicals often demand a floor finish that can withstand potential spills, as well as the abuse dished out by the handling equipment typically used to maneuver containers that hold these kinds of materials (This type of area typically requires a towelled epoxy or urethane resurfacer).

The aesthetic expectations of the facilityA warehouse that is routinely part of corporate “dog and pony” shows must sparkle for every new visitor, and the floor finish must return to its initial luster upon regular cleaning. The coating must also be able to withstand the rigors of that frequent cleaning without chipping, undo wear, fading or discoloration.

Cleaning and MaintenanceThe floor coating must retain its essential properties in the face of routine maintenance. Cleaning and scrubbing, power-sweeping, automated buffing, and similar procedures designed to keep the operation in top shape can damage the floor finish unless it is specifically formulated to endure such treatment.

Epoxy/Polyurethane hybrid system – Thin Mil CoatingsEpoxy primer coat seals the concrete, and provides maximum adhesion and build thickness to the system. Polyurethane topcoat is applied for maximum cleanability, gloss retention, abrasion,chemical, and slip resistance.

1/8 to 1/4 inch Urethane Resurfacer system (trowelled or self leveling)This system is highly durable for heavy traffic conditions, and provides a permanent solution; it has the added benefit of restoring a heavily damaged concrete floor, to a smooth condition, and providing a vapor barrier for the concrete, which is needed in certain circumstances. An epoxy/urethane thin mil coating system is typically applied over this, for maximum cleanability, gloss retention, abrasion,chemical, and slip resistance.

Corporate Headquarters

4 Springfield StreetFifth FloorThree Rivers, MA 01080Phone: 413-283-5164Toll Free: 800-808-7773Email: [email protected]: 413-283-5347

Visit Our Website: http://www.epfloors.com

EP Floors Corp