Wall Chart for Hardness Testing

-

Upload

ali-clubist -

Category

Documents

-

view

67 -

download

2

description

Transcript of Wall Chart for Hardness Testing

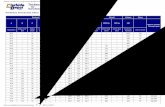

HRA HRB HRC HRD HR15N HR30N HR45N HV HB Rm 85.6 68.0 76.9 93.2 84.4 75.4 940.0 85.3 67.5 76.5 93.0 84.0 74.8 920.0 85.0 67.0 76.1 92.9 83.6 74.2 900.0 84.7 66.4 75.7 92.7 83.1 73.6 880.0 84.4 65.9 75.3 92.5 82.7 73.1 860.0 84.1 65.3 74.8 92.3 82.2 72.2 840.0 83.8 64.7 74.3 92.1 81.7 71.8 820.0 83.4 64.0 73.8 91.8 81.1 71.0 800.0 83.0 63.3 73.3 91.5 80.4 70.2 780.0 82.6 62.5 72.6 91.2 79.7 69.4 760.0 82.2 61.8 72.1 91.0 79.1 68.6 740.0 81.8 61.0 71.5 90.7 78.4 67.7 720.0 81.3 60.1 70.8 90.3 77.6 66.7 700.0 81.1 59.7 70.5 90.1 77.2 66.2 690.0 80.8 59.2 70.1 89.8 76.8 65.7 680.0 80.6 58.8 69.8 89.7 76.4 65.3 670.0 80.3 58.3 69.4 89.5 75.9 64.7 660.0 80.0 57.8 69.0 89.2 75.5 64.1 650.0 618.0 2180.0 79.8 57.3 68.7 89.0 75.1 63.5 640.0 608.0 2145.0 79.5 56.8 68.3 88.8 74.6 63.0 630.0 599.0 2105.0 79.2 56.3 67.9 88.5 74.2 62.4 620.0 589.0 2070.0 78.9 55.7 67.5 88.2 73.6 61.7 610.0 580.0 2030.0 78.6 55.2 67.0 88.0 73.2 61.2 600.0 570.0 1995.0 78.4 54.7 66.7 87.8 72.7 60.5 590.0 561.0 1955.0 78.0 54.1 66.2 87.5 72.1 59.9 580.0 551.0 1920.0 77.8 53.6 65.8 87.2 71.7 59.3 570.0 542.0 1880.0 77.4 53.0 65.4 86.9 71.2 58.6 560.0 532.0 1845.0 77.0 52.3 64.8 86.6 70.5 57.8 550.0 523.0 1810.0 76.7 51.7 64.4 86.3 70.0 57.0 540.0 513.0 1775.0 76.4 51.1 63.9 86.0 69.5 56.2 530.0 504.0 1740.0 76.1 50.5 63.5 85.7 69.0 55.6 520.0 494.0 1700.0 75.7 49.8 62.9 85.4 68.3 54.7 510.0 485.0 1665.0 75.3 49.1 62.2 85.0 67.7 53.9 500.0 475.0 1630.0 74.9 48.4 61.6 84.7 67.1 53.1 490.0 466.0 1595.0 74.5 47.7 61.3 84.3 66.4 52.2 480.0 456.0 1555.0 74.1 46.9 60.7 83.9 65.7 51.3 470.0 447.0 1520.0 73.6 46.1 60.1 83.6 64.9 50.4 460.0 437.0 1485.0 73.3 45.3 59.4 83.2 64.3 49.4 450.0 428.0 1455.0 73.0 44.5 58.8 82.8 63.5 48.4 440.0 418.0 1420.0 72.3 43.6 58.2 82.3 62.7 47.4 430.0 408.0 1385.0 71.8 42.7 57.5 81.8 61.9 46.4 420.0 399.0 1350.0 71.4 41.8 56.8 81.4 61.1 45.3 410.0 389.0 1320.0 70.8 40.8 56.0 80.8 60.2 44.1 400.0 380.0 1290.0 70.3 39.8 55.3 80.3 59.3 42.9 390.0 370.0 1255.0 69.8 38.8 54.4 79.8 58.4 41.7 380.0 361.0 1220.0 69.2 37.7 53.6 79.2 57.4 40.4 370.0 351.0 1190.0 68.7 36.6 52.8 78.6 56.4 39.1 360.0 342.0 1155.0 68.1 35.5 51.9 78.0 55.4 37.8 350.0 332.0 1125.0

HRA HRB HRC HRD HR15N HR30N HR45N HV HB Rm 67.6 34.4 51.1 77.4 54.4 36.5 340.0 323.0 1095.0 67.0 33.3 50.2 76.8 53.6 35.2 330.0 313.0 1060.0 66.4 32.2 49.4 76.2 52.3 33.9 320.0 304.0 1030.0 65.8 31.0 48.4 75.6 51.3 32.5 310.0 294.0 995.0 65.2 29.8 47.5 74.9 50.2 31.1 300.0 285.0 965.0 64.8 29.2 47.1 74.6 49.7 30.4 295.0 280.0 950.0 64.5 105.0 28.5 46.5 74.2 49.0 29.5 290.0 275.0 930.0 64.2 104.5 27.8 46.0 73.8 48.4 28.7 285.0 271.0 915.0 63.8 104.0 27.1 45.3 73.4 47.8 27.9 280.0 266.0 900.0 63.5 103.0 26.4 44.9 73.0 47.2 27.1 275.0 261.0 880.0 63.1 102.0 25.6 44.3 72.6 46.4 26.2 270.0 256.0 865.0 62.7 101.5 24.8 43.7 72.1 45.7 25.2 265.0 252.0 850.0

HRA HRB HRC HRD HR15T HR30T HR45T HV HB Rm 62.4 101.0 24.0 43.1 260.0 247.0 835.0 62.0 100.0 23.1 42.2 93.0 82.0 72.0 255.0 242.0 820.0 61.6 99.5 22.2 41.7 92.8 81.6 71.5 250.0 237.0 800.0 61.2 98.8 21.3 41.1 92.5 81.3 70.8 245.0 233.0 785.0 60.7 98.1 20.3 40.3 92.3 81.0 70.0 240.0 228.0 770.0

97.4 92.1 80.6 69.4 235.0 223.0 755.0 96.7 91.9 80.2 68.7 230.0 219.0 740.0 96.0 91.7 79.7 68.0 225.0 214.0 720.0 95.0 91.5 79.2 67.0 220.0 209.0 705.0 94.0 91.2 78.5 66.0 215.0 204.0 690.0 93.5 90.9 78.0 65.5 210.0 199.0 675.0 92.5 90.6 77.5 64.5 205.0 195.0 660.0 91.5 90.3 77.0 63.5 200.0 190.0 640.0 90.5 90.0 76.4 62.5 195.0 185.0 625.0 89.5 89.6 75.8 61.5 190.0 181.0 610.0 88.3 89.3 75.2 60.4 185.0 176.0 595.0 87.1 89.0 74.6 59.3 180.0 171.0 575.0 86.0 88.5 74.0 58.6 175.0 166.0 560.0 85.0 88.0 73.5 58.0 170.0 162.0 545.0 83.2 87.5 72.5 56.4 165.0 156.0 530.0 81.7 87.0 71.2 54.7 160.0 152.0 510.0 80.2 86.5 70.0 53.0 155.0 147.0 495.0 78.7 86.0 69.0 51.0 150.0 143.0 480.0 76.8 85.5 68.0 50.0 145.0 138.0 465.0 75.0 85.0 67.0 48.5 140.0 133.0 450.0 73.0 84.5 65.5 46.5 135.0 128.0 430.0 71.2 83.8 64.0 44.5 130.0 124.0 415.0 69.0 83.0 62.5 42.5 125.0 119.0 400.0 66.7 82.2 61.5 40.5 120.0 114.0 385.0 64.5 81.5 59.5 38.0 115.0 109.0 370.0 62.3 80.8 58.0 35.5 110.0 105.0 350.0 59.3 80.0 56.0 32.0 105.0 100.0 335.0 56.2 79.0 53.5 29.0 100.0 95.0 320.0 52.0 77.5 51.0 25.0 95.0 90.0 305.0 48.0 76.0 48.5 20.5 90.0 85.0 285.0 41.0 74.0 43.5 13.5 85.0 81.0 270.0

80.0 76.0 255.0

0 10 20 30 40 50 60 70 80 90 100 110 120 130

3.4

3.2

3.0

2.8

2.6

2.4

2.2

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0

D=1 D=2.5 D=5 D=10 d (mm)0.08 0.20.18 0.30.33 0.40.54 0.50.80 0.29 0.6

0.40 0.70.53 0.80.67 0.90.83 1.01.02 1.11.23 0.58 1.21.46 0.69 1.31.72 0.80 1.42.00 0.92 1.5

1.05 1.61.19 1.71.34 1.81.50 1.91.67 2.02.04 2.22.46 1.17 2.42.92 1.38 2.63.43 1.60 2.84.00 1.84 3.0

2.10 3.22.68 3.63.34 4.04.08 4.44.91 4.85.83 5.26.86 5.68.00 6.0

ZHV30/zwickiLine ZHU2.5/zwickiLine ZHU250

ZHR4150AK

ZHR8150SK

ZHV30-s ZHVμ

ZHV10

ZHU250CL ZHN2.0 Nanoindenter

h

≥ 8

h

≥ 3d≥ 2.5d

d

d

h≥

10

h

≥ 1

.5d

(d : h ≈ 7 : 1)

≥ 3d≥ 2.5d

≥ 6d≥ 3d

d

h

≥ 10h (cone)

≥ 1.5d (ball)

≥ 3 mm≥ 3 mm

≥ 6 mm≥ 1 or 2 mm

(HRC, D, A)

(HR...N/T)

ZHR valve testing

ZHV, ZHR handling system

MeasurementquantityRockwellhardnessHR.Theinden-tationdepthhismeasuredinmm.

DefinitionHR=N-h/SN...Numericalvalue(determinedforeachRockwellmethod)h...RemainingindentationdepthinmmS...ScalevalueinmmThisvalueisthechangeininden-tationdepthinmmthatcorres-pondstooneRockwellunit.

HRC,D,A = 100 - h/0.002 HRG,B,F,K,E,H = 130 - h/0.002

HR...N,T = 100 - h/0.001

MeasurementquantityBrinellhardnessHB.Twodiame-ters,atrightanglestooneanother,oftheremainingindentationinthespecimensurfacearemeasured.

DefinitionHB=0.102F/A=0.102·2F/(πD(D-√D²-d²))F...TestloadinNA...Indentationsurfaceinmm²D...ballindentordia.inmmd...arithmeticaveragefromtwomeasuredindentation

MeasurementquantityVickershardnessHV.Thelengthsofbothdiagonalsoftheremainingtestindentationaremeasured.

DefinitionHV=0.102F/A =0.1891F/d²F...TestloadinNA...Indentationsurfaceinmm²d...Arithmeticaveragevalueof

thediagonallengthsinmm

F

d1d2

MeasurementPosition

Loadingposition

Initialposition

Loadingposition

Measurementposition

hRefe

ren

ce leve

l F0 Fm F0 F

d1d2

Measurementposition

Loadingposition

minimumthickness:

Ref

eren

cele

vel

Initialposition

Loadingposition

Measurementposition

F0 Fm F0 F

Loadingposition

Measurementposition

minimumspecimenthickness:

indentationdistances:

Loadingposition

Measurementposition

minimumspecimenthickness:

indentationdistances:indentationdistances: F

token indenter pre-force [N] total-load [N] scale range

HRC diamond cone 98.07 1471 20…70 HRC

HRD diamond cone 98.07 980.7 40…77 HRD

HRA diamond cone 98.07 588.4 60…95 HRA

HRG 1/16" HM-ball 98.07 1471 30…94 HRG

HRB 1/16" HM-ball 98.07 980.7 10…100 HRB

HRF 1/16" HM-ball 98.07 588.4 60…100 HRF

HRK 1/8" HM-ball 98.07 1471 40…100 HRK

HRE 1/8" HM-ball 98.07 980.7 70…100 HRE

HRH 1/8" HM-ball 98.07 588.4 80…100 HRH

HR15N diamond cone 29.42 147.1 70…94 HR15N

HR30N diamond cone 29.42 294.2 42…86 HR30N

HR45N diamond cone 29.42 441.3 20…77 HR45N

HR15T 1/16" HM-ball 29.42 147.1 67…93 HR15T

HR30T 1/16" HM-ball 29.42 294.2 29…82 HR30T

HR45T 1/16" HM-ball 29.42 441.3 10…72 HR45T

(steel,copper) (lightmetal)

Hardness testing

IntelligentTesting

Rockwell ISO 6508 / ASTM E 18

Vickers ISO 6507 / ASTM E 384

Brinell and UniversalISO 6506 / ASTM E 10

No

resp

onsi

bilit

yis

take

nfo

rth

eco

rrec

tnes

sof

this

info

rmat

ion.

All

data

ata

mbi

entt

empe

ratu

re.A

llrig

hts

rese

rved

.Cop

yrig

htb

yZw

ick

2015

Indentec Hardness Testing Machines LimitedUnit 30 Navigation Drive, Hurst Business Park, Brierley Hill, West Midlands, DY5 1UTUKPhone +44 (0) 1384 484 070Fax +44 (0) 1384 481 074www.indentec.com [email protected]

ASMEC Advanced Surface Mechanics GmbHBautzner Landstrasse 45D-01454 RadebergGermanyPhone +49 (0) 351 2695 345Fax +49 (0) 351 2695 [email protected]

Zwick GmbH & Co. KGAugust-Nagel-Strasse 11D-89079 UlmGermanyPhone +49 (0) 73 05-10-0Fax +49 (0) 73 05-10-200www.zwick.com [email protected]

RockwellBallScales(HRB,HRF,etc.)RockwellDiamondScales(HRA,HRC,etc.)

HRNSuperficialRockwellScales

Hardness

Min

imum

Thic

kness

Theabovegraphsarebasedontheinternationallyacceptedrecommendationthatspecifiesaminimumthick-ness,notlessthantentimes(fifteentimes)thedepthindentationusingaconeindenter(ballindenter).Itisalsorecommendedthattheindentationcausesnovisiblemarkordeformationontheundersurfaceofthetestpiece.

MinimumThicknessRequirements average indentation diameter

minimum specimen thickness (mm)for Brinell

Conversion of hardness to hardness and hardness to tensile strenght for unalloyed and low-alloy steels and cast iron (extract of ISO 18265 table A.1)

HRTSuperficialRockwellScales