W380 Series MODEL W390 Series - WESCO International · are up to five times stronger than code ......

Transcript of W380 Series MODEL W390 Series - WESCO International · are up to five times stronger than code ......

MODEL: W380 Series MODEL W390 SeriesSTYLE: PINE STEPLADDER

LOAD CAPACITYOCf) Ifio Combined weigh!4b«JU IU9i of user and materials.Heavy Duty/Industrial UseTYPE I

ITriple riveted heavyduty plated steel earswith rail strap secure top

Internal Pinch-Proof"spreaders on 4' and6' models

Non-split topdrilled for tools

High qualityfinished rails

Grooved steps

Blind boreback legs

Rear doweibraced

Bottom step braced

Angle cut bottomsfor full ground contact

Internal Pinch-Proof" spreaders on 8' and external spreaders on 10' and 12'Additional bracing on 6' and above

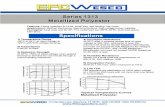

SPECIFICATIONS

ModelNo,

W384W386W388W3810W3812

Size4'6'8'

10 '1 2 '

Approx.Width

1 9 - 1 / 2 "22-1/2"25-1/2"28-1/2"3 1 - 1 / 2 "

Approx.Spread

29-1/2"4 1 - 1 / 2 "53-1/2"65-1/2"77-3/4"

Approx.Cu. Ft.

Per Unit3.35.37.7

10,31 3 , 1

Approx.ShippingWt. Lbs.

20.029.040.050.060.0

NOMINAL DIMENSIONSTop: 3 / 4 " x 7 - 1 / 2 " x 1 4 "

Front Rails: 3/4" x 3-1/2"Back Legs: 1"x 2-5/8"

Steps:Rear Dowels:

Rear Center Brace:

3/4" x 3-5/8"1 - 1 / 8 " Hickory(1 per foot)1" x 2-5/8" ( 1 0 ' & 12' )

STYLE PINE STEPLADDERLOAD CAPACITYOflfl I ||C Combined weightOvU lUwi ol user and materials.Extra Heavy Duty/Professional UseTYPE IA

Triple riveted extra heavyduty plated steel earswith rail strap secure top

Internal Pinch-Proofspreaderson 4' to 6' models

Non-split topdrilled for tools

High qualityfinished rails

Grooved steps

Blind boreback legs

Rear dowelbraced

Bottom step braced

Angle cut bottomsfor full ground contact

External Pinch-Proof" spreaders on 8' and external spreaders on 10' to 16'

n

SPECIFICATIONS

ModelNo,

W394W396W398W3910W3912W3914W3916**

Size41

6'8'

1 0 '12'1 4 '1 6 '

Approx.Width

19 -1 /2 "22-1/2"25-1/2"28-1/2"31-1 /2"34-1/2"37-1/2"

Approx,Spread

29-1/8"41 -1 /2 "53-1/2"65-3/4"77-3/4"

90"102 -1 /4 "

Approx,Cu, Ft,

Per Unit3,45.58,0

10,613,616.920.5

Approx.ShippingWt. Lbs.

21,032,044.056.070.093.0109.0

NOMINAL DIMENSIONSTop: 3/4" x 7-1 /2" x 14-3/4"

Front Rails: 1 " x 3 - 1 / 2 "Back Legs: 1"x 2-5/8"

Steps: 1" x 3-1/2"Rear Dowels: 1 - 1 / 8 " Hickory

(1 per foot)Rear Center Brace: 1 " x 2-5/8" (1 0' to 1 6')

o

d distributor of climbing equipment

AluminumWe start by melting commercially pure aluminum and add otherselect elements to cast our own unique aluminum alloys whichare specifically formulated for climbing products. This aluminumis then extruded to create aluminum sections that are fabricatedinto side rails, steps, rungs and other components.

WoodWe manufacture wood ladders using select grades of clearsouthern yellow pine boards and hardwoods, Modern, computeraided design and manufacturing techniques are used to createconsistently high quality products. Attention to design elementssuch as eased edges and rodded steps provide a superiorquality wood ladder.

History of TechnologicalDevelopmentFor over 75 years, the Werner name has stood for high qualityand superior customer service, With over 130 worldwidepatents, as well as ISO 9002 certification, the Company'screativity, vision and innovation are world renown, Our innovationhas led to a number of key developments in the ladder category.

While all Werner ladders contain unique features designed toenhance your productivity, one reason professionals prefer

Werner ladders over any other brand is ourexclusive ALFLO® 3 piece Twist-Proof®

rung joint, This revolutionary developmentis used to create extension ladders thatare up to five times stronger than code

requirements, Heat hardened seamlessextruded rungs are mechanically locked to

the rails using a unique aluminum connector,This feature adds rigidity and means Twist-Proof® performancefor all Werner extension ladders.

Pro's know Werner,use Wernerand prefer Werner!Werner is the professionals' ladder of choice and the brandthat consumers know and want.

BrandAwarenessProfessionals haveextremely strongtop of mindawareness ofthe Werner brand.

Werner

BrandPreferenceProfessionals preferWerner ladders2 to 1 over otherladder brands

Werner

ProductPerformanceWerner performswell on productattributes that areimportant toprofessionals

100%-

80% -

60% -

40% -

20% -

I Level of Importance to End Useri Performance of Werner

Overall Durability AvailabilityQuality

Source: Caney Research 1997

We are committed to delighting customers by exceeding theirexpectations, We are dedicated to designing, manufacturing anddistributing quality products utilizing technical capabilities andproviding superior customer service, Customer trust andconfidence in Werner products and services are a top priority.

WERNER,

ProductCertificationsANSI

MANUFACTURER CERTIFIESCONFORMANT TO

STANDARDS

AMERICAN NATIONALSTANDARDS INSTITUTE

PRODUCT LINES MEET OR EXCEED ANSI CODEFiberglass Ladders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A14.5 (1992)Aluminum Ladders . . . . , , . , . . . , . . . . . . , . , , . . . , . . . . . . . . A14.2 (1990)Wood Ladders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A 1 4 . 1 (1994)Ladder Jacks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A10.8 (1988)Extension Planks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A 1 0 . 8 (1988)

OCCUPATIONAL SAFETY ANDHEALTH ADMINISTRATION CODE

All Type II, I and IA fiberglass, aluminum and wood ladders, ladder jacks andextension planks meet or exceed code. OSHA CODE applies to ladders used inthe workplace. Werner Ladder Co. recommends Type II or heavier duty ratedladders for these applications.

UNDERWRITERSLABORATORY CODE

SERIES COMPLY WITH U.L. STANDARDS AS NOTED:Aluminum Ladders...............................................................................................AII SeriesLadder Jacks.............,,,....,,..,.,.................,.,,,..,,..........,..................,,,,.,.,..............All SeriesAluminum Extension Planks...............................................................................All SeriesFiberglass Ladders................................................................,........NO U.L. STANDARDS

NOTE: No ANSI, OSHA or U.L Standards have been written for atticladders for overhead access.

SAFETY//SWIART•$^._S £ w

**MtAV*

All Werner fiberglass ladders have electricallynon-conductive rails. This is a great benefitfor those working near electricity. Fiberglassrails also maintain a smooth surface evenafter weathering,

Werner ladders areproudly made in U.S.A.

CORPORATE HEADQUARTERSWerner Ladder Co.93 Werner RoadGreenville, PA 16125-9499Tel. (724)588-8600 • FAX (724) 588-0315

How to Placean OrderCall our Customer Service Department at (724) 588-8600from 8:00 AM to 5:00 PM (EST), Monday through Fridayor FAX your order to (724) 588-0315.

Note: All Special Order items are designated with a double asterisk(Example: 7516-2**\"^ i

Table of ContentsSeries

Fiberglass Stepladders5900 / 5900S Series . . , , , . . , , , .P5900 Series (Platform Ladders) ...6002 Model (Step Stool) , , , . . . . . .6000 / 6000S Series . . . , . . , . . , ,T6000 Series (Twin Stepladders) .,,PT6000-4C Series (Stockr's Ladders8

T6202 Model (Step Stool) , . . , , , . .6200 Series , , . . . , . . . . , . . , , , . .7200 Series , . . , , , . . , , , . . , . . . ,7400 Series , . . , , , . . , , , . , , , . , ,PT7400-4C Series (Stockr's Ladders8

Page No.

.1

.1

.2,2,3.3.4.4.5,5,6

T7200 Series [Twin Stepladders) , , . , , . . , , , . . , , .6T7400 Series (Twin Stepladders) . . . . . . . . . . . . . . . 7P7400 Series (Platform Ladders) . . . . . . . . . . . . . . . 7Comparison Chart , . . , , . . , . , , , , . . , , , . . , , . . , . 8E7400 Series (Trestle Ladders) , , , . . , , . . . , . . . , .97800 Series (Step/Extension Ladders) . . . . . , . , , , .9

Fiberglass Extension LaddersD5900-2 Series . , , . . , , . . . , , . . , , , . . , . . . , . . 1 0D6000-2 Series , , . . , , , . . , . . . . . . , . , . . , , , . , 1 0D6200-1 / D6200-2 Series . . , , , . . . . . . . . . , , ,117100-1 / 7100-2 Series , . . . , , . . . , . . . , . . , , , 1 1D7100-2 Series . , , , . . , , . . . , . . . , . . , , , . . , , . 1 2D7500-2 Series , , . . , , . . . , , . . , , , . . , , . . , . . , 1 2Comparison Chart . . , , , . . , . . . . , . . . , . . . . , . . , 1 3