VT - VTR - VTRR · VT - VTR - VTRR GENERAL FEATURES USAGE Buffer tank for heating systems with...

Transcript of VT - VTR - VTRR · VT - VTR - VTRR GENERAL FEATURES USAGE Buffer tank for heating systems with...

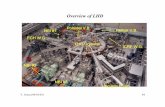

VT VT -- VTR VTR -- VTRRVTRR

GENERAL FEATURES GENERAL FEATURES

USAGE Buffer tank for heating systems with strong insulation to avoid heat loss. One or two fixed spiral coils (according to the version) for bioenergy systems, solar energy and integration to external sources

COSTRUCTION High quality steel type S235JR EN10025, assembled and welded with automatic systems in a controlled environment. Fixed spiral coil heat exchanger with steel tubes type S235JR EN10025 welded on the tank. VT: buffer tank without fixed heat exchanger. VTR: buffer tank with one fixed heat exchanger. VTRR: buffer tank with two fixed heat exchangers.

ANTI CORROSION TREATMENT External coating against rust.

INSULATION AND EXTERNAL FINISH

Rigid polyurethane for mod. 200 and 500 and flexible polyurethane for the remaing models , PVC external finish with zip fastener and themo-formed cover.

WARRANTY 5 years against corrosion

CERTIFICATION Conformity to Dir. 97/23/CE - Art. 3 - Par. 3

VTVT VTRRVTRR

VTRVTR

Buffer tanks “PUFFER” (storage only)

VT VT -- VTR VTR -- VTRRVTRR

Buffer tanks “PUFFER” (storage only)

Model 200 300 500 800 1000 1500 2000 2500 3000 4000 5000

Real storage capacity liters 185 295 500 780 900 1435 1980 2605 2910 3710 4945

d Diameter without insulation mm 450 550 650 790 790 950 1100 1250 1250 1400 1600

D Diameter with insulation mm 550 650 750 990 990 1150 1300 1450 1450 1600 1800

HT Total height mm

1350 1400 1680 1740 2040 2350 2400 2450 2740 2840 2850

Heating area for spiral coil on mod. PSR m2 - 1.50 2.40 2.70 3.10 4.20 4.50 4.75 5.00 6.00 7.00

Heating area for spiral coil on mod. PSRR m2 - 1.00 2.00 2.70 3.10 4.20 4.50 4.75 5.00 6.00 7.00

Tare weight mod. PS kg 70 75 115 140 150 230 265 310 335 490 580

Tare weight mod. PSR kg - 90 139 167 181 272 310 358 385 550 650

Tare weight mod. PSRR kg - 100 159 194 212 314 355 405 135 610 720

Connections

A Usage connections G1”½ G1”½ G1”½ G1”½ G1”½ G1”½ G1”½ G1”½ G1”½ G1”½ G1”½

B Usage connections G1”½ G1”½ G1”½ G1”½ G1”½ G1”½ G1”½ G1”½ G1”½ G1”½ G1”½

S Probes G½” G½” G½” G½” G½” G½” G½” G½” G½” G½” G½”

S1-S2 Spiral coil connections PSR - PSRR - G1” G1” G1” G1” G1”¼ G1”¼ G1”¼ G1”¼ G1”¼ G1”¼

Sf Air escape connections G1”¼ G1”¼ G1”¼ G1”¼ G1”¼ G1”¼ G1”¼ G1”¼ G1”¼ G1”¼ G1”¼

Technical data

PE Max. working pressure for buffer tank bar 6 6 6 6 6 6 6 6 6 6 6

PC Testing pressure for buffer tank bar 9 9 9 9 9 9 9 9 9 9 9

TE Max. working temperature °C 100 100 100 100 100 100 100 100 100 100 100

PS Max. working pressure for fixed spiral coil bar - 9 9 9 9 9 9 9 9 9 9

PCS Testing pressure for fixed spiral coil bar - 14 14 14 14 14 14 14 14 14 14

VT VTR VTRR

B

Sf

A

Sf Sf

A A B

B

S1-S4 S1-S2