VSD ACS 1000 Technical Catalogue

description

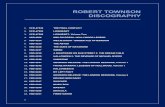

Transcript of VSD ACS 1000 Technical Catalogue

-

ACS 1000Medium Voltage AC Drives

for speed and torque control of315 to 5000 kW / 400 to 6700 hp

squirrel cage induction motors

Technical Catalog

Effective: October 23, 2000 ABB Industrie AG. All Rights Reserved.

-

We reserve all rights to this document, also in the event of patent issue orregistration of any other industrial property protection right. Misuse and inparticular duplication and forwarding to third parties are not permitted.This document has been checked with care. However, should the user findany errors, they should please be reported to ABB Industrie AG.The data stated in this manual is for product description purposes anddoes not represent assured characteristics. As we aim to keep our prod-ucts up to the most modern standard, differences may occur betweenentries in this technical catalog and the actual product.2 ACS 1000 Technical Catalog

-

Table of Contents

Chapter 1 - Overview 7

1.1 Introduction 71.2 The Standard Solution 71.3 Key Technology 71.4 Technical Benefits 81.5 ACS 1000 Types 9

Chapter 2 - Main Features 11

2.1 IGCT Power Semiconductors 112.2 Fuseless Design 112.3 Direct Torque Control 122.4 Input Stage 132.5 Output Stage 132.6 Elementary Diagram 14

Chapter 3 - Hardware Description 17

3.1 Electromagnetic Compatibility 173.2 ACS 1000 Cabinet Layout 173.2.1 Air-cooled Type 173.2.2 Water-cooled Type 193.2.3 Power Terminals 203.3 Control Equipment 213.4 Door Locks 223.5 IP Ratings 233.6 Lifting Arrangements 233.7 Standard Color 233.8 Additional Cabinets 23

Chapter 4 - User Interfaces 25

4.1 Overview 254.2 CDP 312 Control Panel 254.3 Standard I/Os 264.4 Fieldbus Adapter Modules 314.5 PC Tools 31ACS 1000 Technical Catalog 3

-

Chapter 5 - Parameters and Application Macros 33

5.1 Overview 335.2 Suitable Applications for Different Macros 335.3 Macro I/O interfaces 36

Chapter 6 - Standard Functions 39

6.1 General 396.2 Standard Control Functions 396.2.1 General Functions 396.2.2 Main Circuit Breaker Control 426.2.3 Local and Remote Control 426.2.4 Diagnostics 436.2.5 Programmable Digital and Analog Outputs 436.2.6 Scalable Analog Inputs 446.2.7 Input Signal Source Selections and

Signal Processing 446.3 Standard Protection Functions 456.3.1 Programmable Fault Functions 456.3.2 Pre-programmed Protection Functions 476.3.3 Other Protection Functions 496.4 Other Functions 496.4.1 Customer Specific Options 50

Chapter 7 - Options 51

7.1 Environmental Conditions 517.2 Converter Enclosure 517.3 Input Section 527.4 Motor Side 537.5 Converter Cooling 567.6 Converter Isolators and Bypass 597.7 Auxiliary & Control Interfaces 617.8 PC Tools 61

Chapter 8 - Selecting the Drive System 63

8.1 Overview 638.2 Main Circuit Breaker 638.2.1 Main Circuit Breaker Control 638.2.2 Tripping Loop 648.2.3 Main Circuit Breaker Features 658.3 Converter Input Transformer Selection 684 ACS 1000 Technical Catalog

-

8.4 Selection of the ACS 1000 Converter 698.4.1 ACS 1000 Output Filter 698.4.2 Non Quadratic Load Applications 698.4.3 ACS 1000 Selection Tables 708.5 Motor Selection 738.5.1 Load Capacity Curves 738.5.2 Selection Criteria 748.5.3 Retrofit 748.5.4 Torsional Excitation 75

Appendix A - Installation Guidelines 77

Ambient Conditions 77Mounting 77Power Equipment Installation 80

General 80Transformer Primary Cables 81Transformer Secondary Cables 81Motor Cables 82Power Cable Dimensions 82Equipment Grounding 82Auxiliary Power Cables 82Control Cables 83Cable Routing 83ACS 1000 Cable Entry and Termination 84Transformer Connection Diagram for12-pulse ACS 1000 85Transformer Connection Diagram for24-pulse ACS 1000 85Motor Connection Diagram for12 / 24-pulse ACS 1000 86

Appendix B - Technical Data 87

Transformer Connection / Converter Input 87Converter Output / Motor Connection 88Auxiliary Supply 88Environmental Aspects 89Derating of Drive Power 90

Air-cooled Converters 90Water-cooled Converters 91

Transportation and Storage 91Cooling 92

Air-cooled Converters 92Water-cooled Converters 92ACS 1000 Technical Catalog 5

-

Protection Functions 93Analog Inputs 94Analog Outputs 94Digital Inputs 95Digital Outputs 95Auxiliary Power Output 95Reference Voltage Output 96DDCS Fiber Optical Link 96Enclosures 96

Appendix C - Dimensions and Weights 97

Appendix D - Applicable Codes and Standards 101

CE Marking 101Low Voltage Directive 101Machinery Directive 101EMC Directive 102Emissions 102Immunity 102

UL Marking 103Applicable Codes and Standards 103

Appendix E - ACS 1000 Type Code 1056 ACS 1000 Technical Catalog

-

Chapter 1 - Overview

This Technical Catalog describes the main electrical, mechanical andenvironmental features of the ACS 1000 ABBs contribution to new solu-tions of medium-voltage AC drives. In addition, the Catalog looks at thevarious options available for the drive and offers advice on selecting amotor and drive combination. It also provides useful installation tips.

The ACS 1000 is a standard, medium-voltage AC drive, rated from 315 to5000 kW (400 to 6700 hp) for motor voltages of 2.3, 3.3 and 4.0 kV.The drive has been designed as a standard product rather than an engi-neered drive. It is, therefore, a core product of ABB, forming part of thecompanys ACS family. As such, the drive uses standard components,software tools and design principles as employed in the low voltage ACSrange. This vastly increases the reliability of the drive and offers users aconsistent addition to the extensive ACS product range.As a standard solution the ACS 1000 has many of the benefits associatedwith engineered drives already included. This meets the most commonsystem specifications with minimal engineering. In addition, because thedrive is pre-engineered, shorter delivery times to end-users are possible.About 85% of all medium-voltage drives are applied in standard applica-tions such as fans, pumps, conveyors and compressors, where thecustomized engineering content is minimal. The ACS 1000 is ideally suit-able for retrofit applications, where only a small portion of the worldsmotors are fitted with drives.Industries, which can benefit from this approach, include oil and gas,mining, water, pulp & paper, cement and power generation.

Two main technology features distinguish the ACS 1000 from other typeson the market: The motor control platform is based on Direct Torque Control (DTC)

which achieves the ultimate torque and speed performance.DTC allows the speed of any standard squirrel cage induction motorto be controlled without the need for expensive and fragile encodersor tachogenerator feedback devices.

1.1 Introduction

1.2 The Standard Solution

1.3 Key TechnologyACS 1000 Technical Catalog 7

-

Chapter 1 - Overview For the first time in any AC drive, a new power semiconductor switch-ing device is utilized. Known as IGCT (Integrated Gate CommutatedThyristor), the device provides an intrinsically less complex, more ef-ficient and reliable drive. This is achieved by fast switching and inher-ently low losses which mean less cooling equipment is needed.IGCTs do not require snubber circuits and allow power bridge imple-mentation with fewer power devices than conventional medium-voltage drives. While reliability is improved, the physical size of theACS 1000 is compact.

The technology described above brings many more practical benefits tothe ACS 1000, as described within this Catalog.For instance, the use of IGCTs together with active feedback control bymeans of an LC filter results in a sinusoidal output voltage. This provesuseful in retrofit applications, as the drive is compatible with existingsquirrel cage motors without the need to derate it. There are no unduevoltage rises stressing the motor insulation and voltage reflections areeliminated on long cable runs.Furthermore, DTC avoids any torque pulsations, which can be damagingto loads and their associated mechanical connections.The ACS 1000 is available for use with a separately mounted input isola-tion transformer (standard) or alternatively with an integrated dry-typetransformer. This provides installation flexibility and allows for the use of oilfilled transformers which are typically mounted outdoors.The ACS 1000 meets all common standards including IEC and EN. Inorder to meet the requirements of the North American market, theACS 1000 is also UL and Canadian UL listed. In addition, ABB has under-taken much development work to ensure that the converter adequatelymeets the requirements of the worlds harmonics standards, such asIEEE 519-1992.For details please refer to Appendix D - Applicable Codes and Standards.The ACS 1000 features a selection of pre-programmed and standardizedapplication macros for the configuration of inputs, outputs, signalprocessing and other parameters.

1.4 Technical Benefits8 ACS 1000 Technical Catalog

-

Chapter 1 - OverviewThe ACS 1000 is available as air-cooled and water-cooled types. The air-cooled ACS 1000 covers rated power outputs from 400 HP to 2250 HP(315 kW to 1600 kW). For higher power output ratings ranging from2500 HP to 6700 HP (1800 kW to 5000 kW), the converters are water-cooled.The ACS 1000 converter is available for 3 different medium voltage levels.These are the standard motor voltages of 2.3 kV, 3.3 kV and 4.0 kV. Forinformation on solutions for retrofit applications with motor voltages of upto 7.2 kV please contact your ABB representative.The table below provides an overview of the rated output power range,covering air and water-cooled converters for all three medium voltagelevels.For further details, refer to Chapter 8 - Selecting the Drive System.Table 1-1 Standard power ranges for ACS 1000 converters

** The power ratings apply to typical 4 pole motors. For those motors thefrequency converter has a built-in overloadability of 10%. When selectingthe frequency converter it should be observed that the rated current of theACS 1000 must be higher than or equal to the rated motor current in orderto achieve the rated motor power given in the table.Note: For air-cooled units (with enclosure class IP21) the load capacity(current and power) depends on the altitude and the ambient temperatureat the installation site. In case of water-cooled units the load capacitydepends on the cooling water temperature at the installation site. Fordetails on the derating factors, see Appendix B - Technical Data.

1.5 ACS 1000 Types

MotorVoltage

(kV)

Type ofCooling

Rated MotorPower Range**

HP

Max. cont.Power ofACS 1000

(kVA)Frame Size

2.3 Air 400 - 2250 400 - 2000 A1 - A3

2.3 Water 2500 - 4000 2300 - 3600 W1 - W2

3.3 Air 450 - 2250 400 - 2150 A1 - A3

3.3 Water 2500 - 6700 2400 - 5950 W1 - W3

4.0 Air 400 - 2250 400 - 2000 A1 - A3

4.0 Water 2500 - 6700 2300 - 5800 W1 - W3ACS 1000 Technical Catalog 9

-

Chapter 1 - Overview10 ACS 1000 Technical Catalog

-

Chapter 2 - Main Features

ABB researched and designed the Integrated Gate Commutated Thyristor(IGCT) specifically for the medium voltage market. IGCTs provide highspeed switching like IGBTs (Insulated Gate Bipolar Transistors) and at thesame time provide high voltage blocking and low loss conduction likeGTOs (Gate Turn-Off Thyristors). The result is a fast, low loss device thatcan be used at medium voltage levels without resorting to series topolo-gies. It transcends both of the older technologies from which it evolved.IGCTs also provide other benefits: Freewheeling diode is integrated into the same package Snubber circuits are not required Gating circuitry is packaged with the power device High reliability (low total parts count) High power density (combination of low total parts count and low

power losses) Self-protecting against destructive failures.All these features combined provide a medium voltage power switchingdevice with the best combination of performance, reliability, efficiency, andspace effectiveness available in the market today.

The ACS 1000 features a fuseless protected medium voltage drive.The patented design uses the new power semiconductor switching device,IGCT, for circuit protection.The IGCT, which is placed between the DC-link and the rectifier, can,unlike conventional fuses, directly isolate the inverter of the drive systemfrom the power supply side. This is achieved within 25 microseconds,which is 1000 times faster than the operational performance of fuses.Using the IGCT as an integrated protection device leads to a lower partscount within the drive system making the ACS 1000 a drive withoutstanding reliability.The reason why IGCTs are capable of performing a protection function,unlike other power semiconductor devices, lies in their low onstate lossesand their ability to turn off at high speed at medium voltage levels.

2.1 IGCT Power Semiconductors

2.2 Fuseless DesignACS 1000 Technical Catalog 11

-

Chapter 2 - Main FeaturesDirect Torque Control (DTC) is a unique motor control method for ACdrives. The inverter switching is directly controlled according to the motorcore variables flux and torque.The measured motor current and DC-link voltage are inputs to an adaptivemotor model which produces exact actual values of torque and flux every25 microseconds. Motor torque and flux comparators compare actualvalues to the reference values produced by the torque and flux referencecontrollers. Depending on the outputs from the hysteresis controllers, thepulse selector directly determines the optimum inverter switch positions.

Figure 2-1 DTC block diagram

2.3 Direct Torque Control

Switchpositions

Torquereference

Speedreference

Rectifier

=

~

Inverter

Torquecomparator

Fluxcomparator

Adaptivemotormodel

Torquereference controller

PID

FluxreferencecontrollerU

fU

fT

f

Speed controller+ acceleration compensator

Actual speed

Internal fluxreference

Actual torqueActual flux

Inverter currentDC bus voltage

DC bus

Fluxstatus

Torquestatus

Controlsignals

ASIC

Switch positioncommands

Mains

Internal torquereference

Optimumpulseselector

Filter current

Outputfilter

(3 measurements)

(4 measurements)

M3~12 ACS 1000 Technical Catalog

-

Chapter 2 - Main FeaturesHow does DTC differfrom PWM Flux Vector

Drives?

In DTC, each switching instance is determined separately based on thevalues of flux and torque, rather than switching in a predetermined patternas in conventional PWM flux vector drives.Table 2-1 DTC versus PWM Flux Vector controlled drives

For more information on DTC, please refer to the Technical GuideNo. 1 Direct Torque Control (3AFY 58056685 R0025).

The ACS 1000 features a 12-pulse diode rectifier input stage. This isadequate for most networks and normally meets the harmonic require-ments demanded by standards such as IEEE 519.For networks that are more demanding, the ACS 1000 can be suppliedoptionally with a 24-pulse configuration for water-cooled and for air-cooledtypes.

As a standard the ACS 1000 is equipped with a low pass LC sine filter inits output stage. Current feedback is used to actively control filter opera-tion. The low pass frequency is designed to be well below the lowestswitching frequency used by the inverter output stage. This greatlyenhances the purity of both the voltage and current waveforms applied tothe motor. This in turn provides many important benefits: Harmonic heating is virtually eliminated. The drive may be used to

supply standard medium voltage motors (existing or new) without ap-plying thermal derating factors.

DTC Flux Vector

Switching based on core motorvariables Flux and Torque

Switching based on separate control ofmagnetising and torque producingcomponents of current

Shaft speed and position not required Mechanical speed is essential. Requiresshaft speed and position(either measured or estimated)

Each inverter switching is determinedseparately (every 25 s).

Inverter switching based on averagereferences to a PWM modulator. Thisresults in delays in response and wastedswitchings.

Torque Step Rise Time (open loop) isless than 10 msec.

Torque Step Rise TimeClosed Loop 10 to 20 msec.Sensorless 100 to 200 msec.

2.4 Input Stage

2.5 Output StageACS 1000 Technical Catalog 13

-

Chapter 2 - Main Features Voltage reflection and the associated occurrence of voltage doublingat the motor input terminals is no longer an issue (the causal high fre-quency content does not exist). Therefore, any standard medium volt-age winding insulation system (existing or new) is compatible with theACS 1000.

The maximum length of the motor cables is not limited by theACS 1000 (normal voltage drop restrictions as found in any electricalinstallation still apply).

Motor bearing failures attributable to capacitively coupled high fre-quency current are no longer a problem (the causal high frequencycommon mode voltage is eliminated).

Motor insulation is not subject to the common mode voltage typical forother drive topologies.

Figure 2-2 and Figure 2-3 show the elementary circuit diagram of the 12-pulse and the 24-pulse versions of the ACS 1000.The 3-phase AC line voltage is supplied to the rectifier bridges through the3-winding converter transformer. In order to obtain 12 or 24-pulse rectifi-cation, appropriate phase shift is necessary between the secondary wind-ings of the transformer.The two fuseless rectifier bridges in the 12-pulse scheme (Figure 2-2) areconnected in series, such that the DC voltages are added up. Therefore,the full DC bus current flows through both bridges. In the 24-pulsescheme, 2 such bridge arrangements are connected in parallel as shownin Figure 2-3.

Figure 2-2 Elementary diagram - ACS 1000, 12-pulse version

2.6 Elementary Diagram

Diode

Rectifier

Intermediate

DC Link

Three Level

Inverter

Output

Sine Filter

Squirrel Cage

Induction Motor

NP

M

Protection

IGCTs

3

Medium

Voltage

Swi tchgear

Main Circuit

Breaker

Converter

Transformer

(Option)14 ACS 1000 Technical Catalog

-

Chapter 2 - Main FeaturesFigure 2-3 Elementary diagram - ACS 1000, 24-pulse versionEach leg of the 3-phase inverter bridge consists of a combination of 2IGCTs for 3-level switching operation: with the IGCTs the output isswitched between positive DC voltage, neutral point (NP) and negative DCvoltage. Hence both the output voltage and the frequency can becontrolled continuously from zero to maximum, using Direct TorqueControl.At the converter output a LC filter is used for reducing the harmoniccontent of the output voltage. With this filter, the voltage waveform appliedto the motor is nearly sinusoidal (see Figure 2-4). Therefore, standardmotors can be used at their nominal ratings. The filter also eliminates allhigh dv/dt effects and thus voltage reflections in the motor cables andstresses to the motor insulation are totally eliminated.

Figure 2-4 Voltage and current waveforms at converter output

Diode

Rectifier

Intermediate

DC Link

Three Level

Inverter

Output

Sine Filter

Squirrel Cage

Induction Motor

NP

M

Protection

IGCTs

3

Medium

Voltage

Swi tchgear

Main Circuit

Breaker

Converter

Transformer

(Option)

ACS 1000ACS 1000 Output voltage: 4.16kVOutput frequency: 60HzACS 1000 Technical Catalog 15

-

Chapter 2 - Main Features16 ACS 1000 Technical Catalog

-

Chapter 3 - Hardware Description

The riveted and folded cabinet construction of the ACS 1000 ensures anextremely strong yet flexible and self-supporting framework which avoidsthe need for additional skeletal support. Compared with traditional boltedframes the cabinet provides extremely effective protection against electro-magnetic emissions.The design fulfils the requirements of international standards likeUL 347A. For details please refer to Appendix D - Applicable Codes andStandards.Electromagnetic Compatibility (EMC) has been achieved by applying acabinet design consisting of folded, galvanized sheet metal plates andminimizing the spacing between the rivets. The cabinets inside walls arenot painted, because paint tends to reduce the effectiveness of metallicbonding which is paramount to successful EMC.Accordingly, only the front of the ACS 1000 cabinet is painted while allother walls are galvanized. However, the cabinet can be ordered optionallywith the whole of the outside painted.EMC performance is further enhanced by the use of metal cable channels.

3.2.1 Air-cooled TypeThe air-cooled type of the ACS 1000 is designed with inverter stacks,output filter and DC-link capacitor in one section (see Figure 3-1). Thissection experiences maximum air flow which is advantageous for thetemperature sensitive capacitors. The construction of the inverter stacksallows easy exchange of IGCTs by means of a specially designed toolwhich is part of the supply.The middle section accommodates cooling fan, rectifier stack, protectionIGCTs and filter reactor. The construction is such that the fan can beexchanged easily.The air intake is provided with an air filter in order to prevent dust andparticles from entering into the converter. The air filter can be replacedfrom outside while the drive system is in operation.

3.1 Electromagnetic Compatibility

3.2 ACS 1000 Cabinet LayoutACS 1000 Technical Catalog 17

-

Chapter 3 - Hardware DescriptionFigure 3-1 The ACS 1000 air-cooled type (12 / 24-pulse)1 Control section with separate power cable connection section2 Grounding switch and filter reactor section (24-pulse version with

additional rectifier stack)3 Rectifier stack, protection IGCTs and cooling fan4 Inverter stacks, air intake, output filter and DC-link capacitors

2 3 4118 ACS 1000 Technical Catalog

-

Chapter 3 - Hardware Description3.2.2 Water-cooled Type

12-pulse Version The water-cooled type of the ACS 1000 (see Figure 3-2) is equipped witha closed circuit water cooling system. Part of the cooling system is a fanand an air-to-water heat exchanger to maintain cooling of all componentswhich cannot be cooled by water.As with the air-cooled type, the construction of the inverter stacks allowseasy exchange of IGCTs by means of a specially designed tool which ispart of the supply.

Figure 3-2 The ACS 1000 water-cooled type (12-pulse)1 Control section with separate power cable connection section2 Filter and DC components section (grounding switch, filter reactor

and filter capacitors, DC-link capacitors, common mode choke)3 see item 24 Converter section (rectifier stack, protection IGCTs, inverter stacks)5 Cooling unit

1 2 3 4 5ACS 1000 Technical Catalog 19

-

Chapter 3 - Hardware Description24-pulse Version The cabinet layout of the water-cooled 24-pulse version of the ACS 1000is identical to the 12-pulse version, with the exception that there is an addi-tional cabinet on the left hand side of the control section, containing theextra rectifier stacks for 24-pulse operation.

3.2.3 Power TerminalsThe leftmost section (Figure 3-1 and Figure 3-2) contains the swing framewith the control equipment (see Section Control Equipment, page 21).Behind this swing frame and a protective separation door is the drivespower terminal section with busbars for mains and motor cables. Toprovide optimum access to the power terminals, the swing frame can beopened more than 120.Please refer to Appendix A - Installation Guidelines for further details oncable entry and connection.20 ACS 1000 Technical Catalog

-

Chapter 3 - Hardware DescriptionThe layout of the control cabinet is identical for all converter types.The control hardware (processor and communication boards) aremounted on the swing frame. Details can be seen in Figure 3-3.The customer I/Os are located behind the swing frame on the right sidewall (see Figure 3-4). Terminals for customer control and protectionsignals as well as for auxiliary power supply are also located there.

Figure 3-3 Control section with open front door

3.3 Control Equipment

Swing frame

Electronic powersupply board (EPS)

AMC3 control board

Interface board

IOEC1 board

p-transmitters(air- cooled

converters only)

Motor starters andcircuit breakers

Aux. supplytransformer

Batteries

Pulse encoder

Fieldbus interfaceACS 1000 Technical Catalog 21

-

Chapter 3 - Hardware DescriptionFigure 3-4 Control section with swing frame removed

All doors are hinged and locked using carriage key locks.The doors of the power sections of the drive are electromechanically inter-locked with the safety grounding switch and with the main circuit breakerupstream of the converter transformer. This interlock system ensures thatnone of the power cabinets can be opened until the main source of poweris disconnected, the DC-link capacitors are discharged and the safetygrounding switch is closed. Additionally the same interlock system insuresthat power cannot be initialized to the drive unless the doors are closedand the safety grounding switch has been opened.

IOEC2 board(standard)

Access door to powercable connection

section

IOEC3 board (stan-dard for water-cooled

converters)

IOEC4 board(optional)

Terminals for aux.voltages, control sig-

nals and tripping loop

3.4 Door Locks22 ACS 1000 Technical Catalog

-

Chapter 3 - Hardware DescriptionThe doors of the control section and of the cooling section (water-cooledtype) are not linked to the interlocking system. They can be opened at anytime. The high voltage busbar section is located behind the control swingframe and separated from the control section by a bolted protective shield.The power section doors of all additional cabinets (e.g. additional rectifiercabinet, braking chopper cabinet) are monitored by separate doorswitches since they are not included in the electromechanical interlocksystem. These door monitoring switches are wired to the drives trippingloop. If any of the doors are opened during operation, the MCB will betripped immediately.

The standard ACS 1000 cabinet is rated IP21 for air-cooled and IP 31 forwater-cooled types. Higher IP ratings are available as options. SeeChapter 7 - Options for further details.

The cabinets are fitted with lifting lugs as standard.

The standard color is RAL 7035 (light grey). Other colors are available onrequest.

The ACS 1000 cabinet system provides the flexibility to add furthersections to the converter at any time. Sections can be added in width of600, 800 and 1000 mm (24, 32 and 39 inches).

3.5 IP Ratings

3.6 Lifting Arrangements

3.7 Standard Color

3.8 Additional CabinetsACS 1000 Technical Catalog 23

-

Chapter 3 - Hardware Description24 ACS 1000 Technical Catalog

-

Chapter 4 - User Interfaces

The ACS 1000 can be controlled from several control locations: The detachable CDP 312 control panel mounted on the ACS 1000

front door of the control section External control devices, e.g. a supervisory control system,

connected to the analog and digital I/O terminals on the standard I/OBoards (IOEC)

Fieldbus adapter modules PC Tools (DriveWindow and DriveSupport) hooked up via a PC

adapter to the ACS 1000 control board.

The CDP 312 Control Panel is the basic user interface for monitoring,adjusting parameters and controlling the ACS 1000 converter operation.

Figure 4-1 CDP 312 Control Panel

4.1 Overview

4.2 CDP 312 Control Panel

ACT PAR FUNC DRIVE

ENTER

LOC

REM

RESET REF

1 L -> 1242rpm I

SPEEDCURRENT

TORQUE

76.00 A1242.0rpm86.00 %

Enclosure class IP54 when attached tothe Control Panel Mounting Platform

Multilingual Alphanumeric Display(4 lines x 20 characters)Plain text messages available inseveral languages

Control Panel Mode Selection keys

Double Up Arrow, Up ArrowEnterDouble Down Arrow, Down Arrow

Local/Remote, Reset, Reference andStart keys

Forward, Reverse and Stop keys

ControlPanelDisplay

ControlPanelKeypadACS 1000 Technical Catalog 25

-

Chapter 4 - User InterfacesUsing the CDP 312 panel it is possible to enter start-up data into the drive set a reference signal and give Start, Stop and Direction commands display actual values (three values can be read simultaneously) display and adjust parameters display information on the most recent forty fault events.

The standard I/O-boards offer a number of pre-programmed analog anddigital I/Os which are sufficient for most applications. For a wider range ofsignal interfaces optional I/O-boards can be ordered for water and air-cooled ACS 1000 to provide extended protection for transformer andmotor, external cooling equipment (e.g. fans, chillers), on-linesynchronization logic and other customer requirements.The air-cooled ACS 1000 is equipped with two I/O-boards (IOEC1 andIOEC2) as a standard with the option of two additional I/O-boards (IOEC3and IOEC4). The water-cooled ACS 1000 is equipped with three I/O-boards (IOEC1, IOEC2, IOEC3) with the option of one aditional I/O-board(IOEC4).All I/O-boards are identical in design with the same number of I/Os. Theanalog and digital I/Os are floating and galvanically isolated with ratingsas indicated in Table 4-1.While the function of digital and analog inputs are fixed and cannot bealtered, the signals allocated to digital and analog outputs can be changedby setting the corresponding parameters accordingly.

4.3 Standard I/Os

Table 4-1 I/O Board configuration with number and type of I/O

Number Signal Type Ratings

4 AnalogInputs

(AI) 0...20 mA / 4...20 mA or 0...10 V / 2...10 Vscalable by parameter setting

2 AnalogOutputs

(AO) 0...20 mA / 4...20 mAscalable by parameter setting

14 DigitalInputs

(DI) Opto-coupled, rated for 22...250 VAC or22...150 VDC

6 DigitalOutputs

(DO) With switch-over contact (SPDT),rated for 250 VAC, 2 A26 ACS 1000 Technical Catalog

-

Chapter 4 - User InterfacesStandard I/Os are marked in the following tables with a dot ( ). The letter(W) indicates that these I/Os are standard for the water-cooled ACS 1000.A signal name beginning with a slash (/) indicates a signal which is truewhen its status is low.i

Table 4-2 I/O Signals: remote control interface

Type Signal Name Remarks Standard

DI STANDARD INPUT 1 Macro specific I/O *

DI STANDARD INPUT 2 Macro specific I/O *

DI STANDARD INPUT 3 Macro specific I/O *

DI STANDARD INPUT 4 Macro specific I/O *

DI STANDARD INPUT 5 Macro specific I/O *

DI STANDARD INPUT 6 Macro specific I/O *

DI DISABLE LOCAL Remote input to disable thepossibility for a local/remoteswitch-over from the CDP 312control panel

DI REM ORD MCB CLOSE Remote request for closingthe main circuit breaker

DI REM ORD MCB OPEN Remote request for openingthe main circuit breaker

DI REMOTE RESET Remote fault reset (someconverter related faultscannot be reset remotely)

DO DRIVE READY Status output Drive Ready(i.e. MCB closed, DC-linkcharged, no lockout active)

DO DRIVE RUNNING Status output Drive Running

DO DRIVE ALARM Status output Drive Alarm

DO DRIVE TRIP Status output Drive Tripped

DO LOCAL MODE Local mode operation statusindication

AI REF VALUE 1 Macro specific I/OACS 1000 Technical Catalog 27

-

Chapter 4 - User Interfaces* see Chapter 6 - Standard Functions

AI REF VALUE 2 Macro specific I/O

AO SHAFT SPEED ACT VAL Actual speed monitoringoutput

AO MOT CURRENT ACT VAL /MOT TORQUE ACT VAL

Actual current / torquemonitoring output(programmable)

Table 4-3 I/O Signals: main circuit breaker

Type Signal Name Remarks Standard

DI MCB IS CLOSED Status feedback from themain circuit breaker

DI MCB IS OPEN Status feedback from themain circuit breaker

DI MCB IS AVAILABLE Status feedback from themain circuit breaker, showingthat the breaker is faulty,drawn-out or in test position

DO MCB ORD CLOSE Drive command to close themain circuit breaker (pulsesignal or maintained)

DO /MCB ORD OPEN Drive command to open themain circuit breaker (pulsesignal or maintained)

DO /MCB ORD TRIP Hardware tripping loop to themain circuit breaker (signalactive when low)

Table 4-4 I/O Signals: transformer

Type Signal Name Remarks Standard

DI /EXT TRAFO PROT TRIP Initiates a main circuit breakertrip (included in hardwiredtripping loop)

DI OIL LEVEL ALARM Transformer oil level alarmindication

W

Table 4-2 I/O Signals: remote control interface (continued)Type Signal Name Remarks Standard28 ACS 1000 Technical Catalog

-

Chapter 4 - User InterfacesDI OIL TEMP ALARM, or

TRAFO WDG TEMP ALARM

Transformer oil temperaturealarm indication

Transformer windingtemperature alarm indication

W

DI /OIL TEMP TRIP, or

/TRAFO WDG TEMP TRIP

Transformer oil temperaturetrip indicationTransformer windingtemperature trip indication

W

DI BUCHHOLZ ALARM Transformer alarm indicationfrom Buchholz relay

W

DI /BUCHHOLZ TRIP Transformer trip indicationfrom Buchholz relay

W

AI OIL TEMP, or

TRAFO WDG TEMP

Temperature measurement oftransformer oilTemperature measurement oftransformer winding

W

Table 4-5 I/O Signals: motor

Type Signal Name Remarks Standard

DI /EXT MOT PROT TRIP Initiates a main circuit breakertrip (included in hardwiredtripping loop)

DI EXT MOT PROT ALARM (External) motor protectionalarm indication

W

DI MOT COOLING ALARM (External) motor coolingalarm indication

W

DI /MOT COOLING TRIP (External) motor cooling tripindication

W

DI VIBRATION SV ALARM Motor vibration alarmindication

W

DI /VIBRATION SV TRIP Motor vibration trip indication W

DI /OVERSPEED TRIP Motor overspeed trip(included in hardwiredtripping loop)

W

AI MOT WDG TEMP PH U Motor winding temperature

AI MOT WDG TEMP PH V Motor winding temperature

AI MOT WDG TEMP PH W Motor winding temperature

Table 4-4 I/O Signals: transformer (continued)Type Signal Name Remarks StandardACS 1000 Technical Catalog 29

-

Chapter 4 - User InterfacesAI BRG TEMP DE Motor bearing temperature ofdriven end

W

AI BRG TEMP NDE Motor bearing temperature ofnon-driven end

W

Table 4-6 I/O Signals: process

Type Signal Name Remarks Standard

DI /PROCESS STOP Remote process stop input tostop the drive (signal activewhen low)

DI /INT/EXT EMERGENCY OFF Emergency OFF (signalactive when low) fromprocess side to trip the maincircuit breakerinstantaneously(included in hardwiredtripping loop)

Table 4-7 I/O Signals: Others

Type Signal Name Remarks Standard

DI /SUPPL VOLT UNBALANCE Trip from external voltageunbalance relay (signal activewhen low)

DI EXT WTR COOLING ALARM Alarm indication from externalwater cooling unit

DI /EXT WTR COOLING TRIP Trip (active when low) fromexternal water cooling unit

DI BRAKE CHOP FAN ALARM Alarm signal from brakingchopper

DI BRAKE CHOP TEMP TRIP Trip signal from brakingchopper

DI INPUT ISOLATOR OPEN Status input

DI INPUT ISOLATOR CLOSED Status input

DI OUTPUT ISOLATOR OPEN Status input

DI OUTPUT ISOLATORCLOSED

Status input

AI OUTSIDE AIR TEMP Temperature measurement ofoutside air

Table 4-5 I/O Signals: motor (continued)Type Signal Name Remarks Standard30 ACS 1000 Technical Catalog

-

Chapter 4 - User InterfacesA fieldbus module may be used for controlling and monitoring theACS 1000 instead of using the conventional hard-wired I/Os. There areseveral fieldbus adapter modules available for the ACS 1000.For further details, see Chapter 7 - Options.

DriveWindow offers several functions for commissioning and monitoringABB products. All the functions are available from the Menubar or theToolbar of the program. In DriveWindow the user has the choice betweentwo special displays and six different tools.For further details, see Chapter 7.8 PC Tools.

4.4 Fieldbus Adapter Modules

4.5 PC ToolsACS 1000 Technical Catalog 31

-

Chapter 4 - User Interfaces32 ACS 1000 Technical Catalog

-

Chapter 5 - Parameters and Application Macros

Parameters allow the user specific configuration of the ACS 1000. Theycan be set using the CDP 312 control panel.The application macros consist of pre-programmed parameter sets thatare adapted for a specific application. They offer pre-set signal interfacesfor opening/closing the main circuit breaker, starting/stopping the drivesystem and setting reference values.Depending on the process, the appropriate macro can be selected, thusenabling a quick and easy start-up of the ACS 1000.Using an application macro has the advantage that the number ofindividual parameters to be set during start-up is minimized. All para-meters have factory-set default values. Leaving them unchanged, a goodsystem performance is achieved in typical situations. These default valuescan be left unchanged or they can be set individually according to theneeds of the customer.The ACS 1000 can be operated with one of the following standard macros: Factory Speed Control Hand/Auto PID Control Torque Control Sequential Control Master/Follower User 1 User 2

Factory The Factory Macro is the default-set macro. It covers most of the commonapplications, such as: Pump, fan and other industrial processes with a square torque char-

acteristic Conveyors and other industrial drives requiring constant torque.

5.1 Overview

5.2 Suitable Applications for Different MacrosACS 1000 Technical Catalog 33

-

Chapter 5 - Parameters and Application MacrosSpeed Control The Speed Control Macro is essentially the same as the Factory Macro.The only difference to the Factory Macro is that a loading of the SpeedControl Macro will not affect the currently set motor control parameters(when loading the Factory Macro all parameters will be reset to theirdefault value).

Hand/Auto The Hand/Auto Macro is suitable for applications where the speed has tobe controlled automatically by a process control system and manually byan external control panel. The active control location is selected via adigital input.The macro is also recommended when the drive has to be controlled fromtwo external control stations. The active control station for starting /stop-ping and setting of the reference value is selected via a digital input.

PID Control The PID Macro is intended for the use with closed loop control systemssuch as pressure control, level control and flow control. For example: Booster pumps of municipal water supply systems Booster pumps of district heating systems Automatic level control of water reservoirs Speed control of different types of material handling systems where

the material flow has to be regulated.The PID-controller is incorporated into the ACS 1000 software. It is acti-vated by selecting the PID Macro.A process reference value is set via an analog input or by using the controlpanel of the ACS 1000. The actual process value is connected to a dedi-cated analog input.The internal PID-controller of the ACS 1000 eliminates the need of a sepa-rate PID-controller (no additional installation and wiring required).

Figure 5-1 Example of an application with PID control loop

Actual Value

Reference

LevelTrans-ducer

Pump

ACS 1000 converter34 ACS 1000 Technical Catalog

-

Chapter 5 - Parameters and Application MacrosTorque Control The macro is intended for processes requiring torque control, e.g. mixersand slave drives. The torque reference comes from a process automationsystem or a control panel.

Sequential Control The Sequential Control Macro is aimed for processes where differentconstant speed settings and/or different acceleration/deceleration rampsare required in addition to an adjustable speed reference value. Thedifferent settings can be selected automatically by a process controlsystem or they can be activated manually by selector switches which areconnected to the corresponding digital inputs.

Master/Follower The Master/Follower Macro is designed for applications with severalACS 1000 where the motor shafts are coupled to each other by gearing,chain, belt etc. Thanks to the Master/Follower macro the load can beevenly distributed between the drives or depending on the process atsome other ratio.

User 1 / User 2 The User Macro 1 and 2 allows to save a complete set of customizedparameters and to recall it at a later instant or to download it to anotherACS 1000.ACS 1000 Technical Catalog 35

-

Chapter 5 - Parameters and Application MacrosThe following tables give an overview of the pre-set digital and analoginputs and outputs, regarding opening/closing the main circuit breaker,starting/stopping the drive system, setting reference values and statusfeedback signals. All other customer interface signals are the same foreach application macro, see Chapter 4 - User Interfaces.All macro specific I/Os are available on the standard IOEC boards. Onlythe PID macro requires IOEC 4 board.

5.3 Macro I/O interfaces

Table 5-1 Macro specific digital and analog inputs

Macro I/Os I/O functions

FactorySpeed

DI MCB open/close commandsStart/ stop commandsSelection of directionSelection of 2 accel/decel rampsSelection of 2 const. speedsProcess stop or run enable

AI 2 speed reference values

Hand/Auto DI Selection of hand/auto modeMCB open/close commands in hand modeMCB open/close commnands in auto modeStart/ stop commands in hand modeStart/stop commands in auto modeSelection of 1 const. speedProcess stop or run enable

AI Speed reference value in hand modeSpeed reference value in auto mode

PID DI MCB open/close commandsStart/stop commandsSelection of directionSelection of reference valueSelection of 2 accel/decel rampsSelection of 3 const. speedsProcess stop or run enable

AI Reference valueActual value, process feedbackActual value process feedback

Torque DI MCB open/close commandsStart/stop commandsSelection of speed/torque controlSelection of 2 accel/decel rampsSelection of 1 constant speedProcess stop or run enable

AI Speed reference valueTorque reference value36 ACS 1000 Technical Catalog

-

Chapter 5 - Parameters and Application MacrosThe pre-set digital and analog outputs available for external use are thesame for each macro.Table 5-2 Macro specific digital and analog outputs

Sequential DI MCB open/close commandsStart/stop commandsSelection of 2 accel/decel rampsSelection of 7 const. speedsProcess stop or run enable

AI Reference value

Master Follower DI MCB open/close commandStart/stop commandSelection of 1 accel/decel rampSelection of 3 const. speedsProcess stop or run enable

AI Speed reference value

User 1 / User 2 Depends on application

Table 5-1 Macro specific digital and analog inputs (continued)Macro I/Os I/O functions

Macro I/Os I/O functions

FactorySpeedPIDTorqueSequentialMaster/Follower

DO Drive readyDrive runningDrive alarmDrive trip

AO Motor frequencyMotor torqueMotor speedMotor torque filteredACS 1000 Technical Catalog 37

-

Chapter 5 - Parameters and Application Macros38 ACS 1000 Technical Catalog

-

Chapter 6 - Standard Functions

The ACS 1000 is configured and customized by means of applicationparameters. These parameters can be altered by the user, either bymeans of the integrated CDP 312 control panel or by using a PC and theDriveWindow software package, as described in Chapter 7 - Options.Control and monitoring functions of the ACS 1000 can be activated bysetting parameters one by one or by invoking an Application Macro (seeChapter 5 - Parameters and Application Macros) which is optimized for aparticular application. Therefore some of the functions described in thischapter will be configured automatically if an application macro isselected.This chapter provides information about the standard control, monitoringand protection functions for the ACS 1000. A description of the basic I/Odevices and the application macros of the ACS 1000 can be found inChapter 4 - User Interfaces and Chapter 5 - Parameters and ApplicationMacros.

6.2.1 General Functions

Motor ID Calculation Based on the nameplate data all ACS 1000 internal motor controlparameters will be automatically calculated. This procedure is usuallyperformed once during commissioning. However, the procedure can berepeated whenever required (e.g. when the ACS 1000 will be hooked upto another motor).

Full Torque at ZeroSpeed

A motor fed by the ACS 1000 can develop short-term motor nominaltorque at start-up without any pulse encoder or tachogenerator feedback.This feature is essential for constant torque applications. However, ifpermanent operation at zero speed is required, a pulse encoder has to beused.

Enhanced Flying Start This feature allows a rotating motor (e.g. a turbo-pump or a fan) to betaken over by the ACS 1000. By means of the flying start function thefrequency of the motor is detected and the motor is started-up again by theACS 1000.

6.1 General

6.2 Standard Control FunctionsACS 1000 Technical Catalog 39

-

Chapter 6 - Standard FunctionsFlux Optimization Flux optimization of the ACS 1000 reduces the total energy consumptionand motor noise level when the drive operates below the nominal load.The total efficiency (ACS 1000 and motor) can be improved by 1...10%,depending on the load torque and speed. This function is activated byparameters.

Power Loss Ride-Through

If the incoming supply voltage is cut off the ACS 1000 will continue tooperate in an active but non-torque producing mode by utilizing the kineticenergy of the rotating motor and load. The ACS 1000 will be fully active aslong as the motor rotates and generates energy to the ACS 1000. Powerloss ride through can be enabled by parameters.

Auxiliary Ride Through The auxiliary ride through function guarantees correct fault indication andproper trip sequencing, in the event that the auxiliary power source feedingthe drive is lost. The function is activated by a parameter. During ridethrough the power for the control circuits of the ACS 1000 is supplied byinternal batteries. The ride through time is limited to 1 sec.

Acceleration andDeceleration Ramps

ACS 1000 provides two user-selectable acceleration and decelerationramps. It is possible to adjust the acceleration/deceleration times(0...1800 s) and select the ramp shape. Switching between the two rampscan be controlled via a digital input.The available ramp shape alternatives are:Linear: Suitable for drives requiring long acceleration/deceleration whereS-curve ramping is not required.S1: Suit. for short acc./dec. times.S2: Suit. for medium acc./dec. timesS3: Suit. for long acc./dec. times.S-curve ramps are ideal for conveyorscarrying fragile loads, or other applica-tions where a smooth transition isrequired when changing from onespeed to another.

Critical Speed There is a Critical Speed function available for applications where it isnecessary to avoid certain motor speeds or speed bands, for example dueto mechanical resonance problems. The ACS 1000 makes it possible toset up five different speed settings or speed bands which will be avoidedduring operation.

Linear

1 t (s)

Motor

1.25 2

S1

S2

S3

speed40 ACS 1000 Technical Catalog

-

Chapter 6 - Standard FunctionsEach critical speed setting allows theuser to define a low and a high speedlimit. If the speed reference signalrequires the ACS 1000 to operatewithin this speed range the CriticalSpeeds function will keep theACS 1000 operating at the low (orhigh) limit until the reference is out ofthe critical speed range. The motor isaccelerated/decelerated through thecritical speed band according to theacceleration or deceleration ramp.

Constant Speeds Up to 15 constant speeds can be programmed and selected by digitalinputs. If activated the external speed reference is overwritten. If theSequential Control Macro is used a standard set of parameter values isselected automatically.

Accurate SpeedControl

The static speed control error is typically +0.1% (10 % of nominal slip) ofthe motor nominal speed, which satisfies most industrial applications.

Accurate TorqueControl without Speed

Feedback

The ACS 1000 can perform precisetorque control without any speed feed-back from the motor shaft. With torquerise time less than 10 ms at 100%torque reference step compared toover 100 milliseconds in frequencyconverters using sensorless fluxvector control, the ACS 1000 isunbeatable.By applying a torque reference insteadof a speed reference, the ACS 1000will maintain a specific motor torquevalue; the speed will be adjusted auto-matically to maintain the requiredtorque.

Table 6-1 Typical performance figures for torque control, when DirectTorque Control is used

* When operated around zero frequency, the error may be bigger.

s 1 Lows1 High s2 Low s2 High

Speed

540 690 1380 1560

(rpm)

540690

1380

1560

(rpm)Motorspeed

reference

Torque Control ACS 1000no Pulse Encoder

ACS 1000with Pulse Encoder

Linearity error + 4 %* + 3 %

Torque rise time < 10 ms < 10 ms

100

t(s)

TTN

< 10 ms

90

10

(%)

Tref

Tact

TN = rated motor torqueTref = torque referenceTact = actual torqueACS 1000 Technical Catalog 41

-

Chapter 6 - Standard Functions

6.2.2 Main Circuit Breaker Control

All functions regarding the control of the main circuit breaker (opening,closing, tripping, monitoring) are included in the ACS 1000.For detailed information see Chapter 8 - Selecting the Drive System, MainCircuit Breaker, page 63.

6.2.3 Local and Remote ControlOperation of the ACS 1000 is possible either in local or remote controlmode.Local/remote control is selected directly on the CDP 312 control panel bypushing the LOC/REM push-button. A capital L on the display indicateslocal control:.

Remote control is indicated with a blank:

Local Control If the converter is in local control, local operation using the push-buttonson the converter front door and the CDP 312 control panel is possible. Inlocal operation mode no remote control command will be accepted.

Remote Control If remote control is selected, local operation from the push-buttons on theconverter front door and from the CDP 312 control panel is not possible.Instead all commands for closing and opening the main circuit breaker orstarting and stopping the drive are received via digital inputs from a remotecontrol station. The speed reference value is given as an analog inputsignal.Alternatively all remote control signals can be exchanged via an optionalfieldbus interface.Changing the control mode from local to remote and vice versa can bedisabled by setting digital input DISABLE LOCAL (see also Table 4-2).

LOC

REM MotSpeed 0.00 rpmPower 0.0 %

1 L -> 0.0 rpm 0Status RdyForMCBOn

LOC

REM MotSpeed 0.00 rpmPower 0.0 %

1 -> 0.0 rpm 0Status RdyForMCBOn42 ACS 1000 Technical Catalog

-

Chapter 6 - Standard Functions6.2.4 Diagnostics

Actual SignalMonitoring

Three signals can be displayedsimultaneously on the controlpanel.Actual signals to be displayedcan be selected in parametergroup 1 to 5, Actual Signals.For example: ACS 1000 output frequency, current, voltage and power Motor speed and torque DC Link voltage Active control location (Local / External 1 / External 2) Reference values ACS 1000 inverter air temperature Cooling water temperature, pressure and conductivity Operating time counter (h), kWh counter Digital I/O and analog I/O status PID controller actual values (if the PID Control Macro is selected)

Fault History The Fault History contains information on the forty most recent faultsdetected by the ACS 1000. Faults are displayed in alphanumeric charac-ters.

6.2.5 Programmable Digital and Analog Outputs

Programmable DigitalOutputs

Four digital outputs on the IOEC 2 board can be programmed individually.Each output has floating change-over contacts and can be allocated to aninternal binary control or status signal via parameter setting.Examples are: ready, running, fault, warning, motor stall, motor temperature alarm /

trip, ACS 1000 temperature alarm / trip, reverse rotation selected,external control selected, preset speed limits, intermediate circuitvoltage limits, preset motor current limit, reference limits, loss ofreference signal, motor operating at reference speed, process PIDcontroller actual value limits (low, high) etc.

If optional boards IOEC 3 and/or IOEC 4 are installed, a maximum of 12additional digital outputs (6 on each board) are available.

1 L -> 600.0 rpm 1Status RunningMotSpeed 600.00 rpmPower 75.0 %ACS 1000 Technical Catalog 43

-

Chapter 6 - Standard FunctionsProgrammable AnalogOutputs

Two programmable analog outputs on each IOEC board are at the usersdisposal.Depending on the setting of the corresponding parameters, the analogoutput signals can represent for example: motor speed, process speed (scaled motor speed), output frequency,

output current, motor torque, motor power, DC bus voltage, outputvoltage, application block output (process PID controller output),active reference, reference deviation (difference between thereference and the actual value of the process PID controller).

The selected analog output signals can be inverted and filtered. Theminimum signal level can be set to 0 mA, 4 mA or 10 mA.

6.2.6 Scalable Analog Inputs

Each analog input can be adapted individually to the type and range of theconnected input signal: signal type: voltage or current (selectable by DIP switches) signal inversion: if a signal is inverted, the maximum input level cor-

responds to the minimum signal value and vice versa minimum level: 0 mA (0 V), 4 mA (2 V) or by input tuning function (ac-

tual input value is read and set as minimum) maximum level: 20 mA (10 V) or by input tuning function (actual input

value is read and set as maximum) signal filtering time constant: adjustable between 0.01..10 s.The offset of the analog inputs can be calibrated automatically ormanually.

6.2.7 Input Signal Source Selections and Signal Processing

Two ProgrammableControl Locations

The ACS 1000 can receive the Start/Stop/Direction commands and thereference value from the integrated control panel and the Closing/Openingcommands for the main circuit breaker from the push buttons on thecontrol section door.Alternatively it is possible to predefine two separate external control loca-tions (EXT1 and EXT2) for these signals. The active external control loca-tion can be changed via the control panel or via a digital input.The control panel always overrides the other control signal sources whenswitched to local mode.Optionally, the converter can be equipped with a fieldbus adapter module,see Chapter 7 - Options.

Reference SignalProcessing

The ACS 1000 can handle a variety of speed reference schemes inaddition to the conventional analog input signal and control panel signals. The ACS 1000 reference can be given using two digital inputs:44 ACS 1000 Technical Catalog

-

Chapter 6 - Standard Functionsone digital input increases the speed, the other decreases it. The ac-tive reference is memorized by the control software.

The ACS 1000 can form a reference out of two analog input signalsby using mathematical functions: addition, subtraction, multiplication,minimum selection, and maximum selection.

It is possible to override the actual speed reference with predefinedconstant speeds (see Constant Speeds, page 41).It is possible to scale the external reference so that the signal minimumand maximum values correspond to a speed other than the nominalminimum and maximum speed limits.

The ACS 1000 offers several programmable fault functions and other non-user adjustable pre-programmed protection functions.

6.3.1 Programmable Fault Functions

Motor WindingTemperature

The motor can be protected from overheating by activating the motorwinding temperature monitoring function.The ACS 1000 standard solution offers three analog inputs for measuringand monitoring the motor winding temperature.Values for alarm and trip levels can be set.

Motor Stall The ACS 1000 protects the motor if a stall condition is detected. The moni-toring limits for stall frequency (speed) and stall time can be set by theuser. The user can also select whether the stall function is enabled andwhether the drive responds with an alarm or a trip when a stall is detected.The protection is activated if all the following conditions are fulfilledsimultaneuously:

1 The output frequency is below the setstall frequency.

2 The drive is in torque limit. The torquelimit level is a basic setup parameterthat sets maximum drive output torque.Although it indirectly effects operation ofthe motor stall protection, it should notbe considered a motor stall parameter.

3 The frequency and torque levels fromconditions 1 and 2 have been presentfor a period longer than the set stalltime.

Figure 6-1 Stall region of the motor

6.3 Standard Protection Functions

Stall region

Tm.a

Stall

Torque

Frequencyf (Hz)ACS 1000 Technical Catalog 45

-

Chapter 6 - Standard FunctionsUnderload Loss of motor load may indicate a process malfunction. The ACS 1000provides an underload function to protect the machinery and the processin such a serious fault condition. This monitoring function checks if themotor load is above the specified load curve. 5 different load curves canbe selected by the customer.Monitoring limits: underload curve and underload time can be chosen aswell as the drive response to the underload condition (alarm / trip indica-tion and stop the drive / no reaction).

Figure 6-2 Load curves for underload functionThe protection is activated if all the following conditions are fulfilled simul-taneously:1 The motor load is below the underload curve selected by the user

(see Figure 6-2).2 The motor load has been below the selected underload curve longer

than the time set by the user (Underload time).Overspeed The motor speed as determined by DTC is monitored. If the motor speed

exceeds the maximum permitted motor speed (user adjustable) a trip isinitiated. In addition, an input for connection of an external motor over-speed trip is available. A converter trip is also initiated, if the externalmotor overspeed trip is activated (signal active when low).

Undervoltage In order to detect a loss of the mains power supply, the positive andnegative DC link voltage levels are monitored. If these voltage levels dropbelow 70% of their nominal levels an undervoltage alarm is initiated andpower loss ride through is activated (provided it is selected). If the DC linkvoltage levels drop below 65% of their nominal values an undervoltage tripis initiated.

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

110%

120%

130%

140%

curve 1curve 2curve 3curve 4curve 5

Torque

Speed46 ACS 1000 Technical Catalog

-

Chapter 6 - Standard Functions6.3.2 Pre-programmed Protection Functions

Motor Phase Loss The phase loss function monitors the status of the motor cableconnections. The function is useful especially during motor starting:the ACS 1000 detects if any of the motor phases are not connected andrefuses to start.The phase loss function also monitors the motor connection status duringnormal operation. The motor operating frequency must be above aminimum level in order for this feature to function. Should a motor phaseloss be detected a trip is initiated.

Motor Overload The 3-phase RMS value of the motor current is monitored and comparedwith three adjustable thresholds. A pickup delay for each threshold canalso be set. In case an overload is detected an alarm message will bedisplayed and the converter will be shut down.

Overvoltage The levels of the positive and negative DC link voltage are monitored todetect whether an improper overvoltage condition develops. If thesevoltage levels rise above 130% of their nominal levels an overvoltage tripis initiated. On rare occasions, a combination of conditions can result inthe motor entering a self excitation mode that can cause the DC linkvoltage to continue to rise, despite the fact that a trip has been initiated. Ifthis condition occurs and if the DC link voltage levels rise above 135% oftheir nominal levels, a second overvoltage trip is initiated that causes theinner 6 IGCTs to be gated simultaneously such, that the motor windingsare effectively shunted together. This eliminates the self excitation voltagethat is causing the DC link voltage levels to rise. To provide ultimatereliability the second overvoltage trip is implemented both in software andredundantly in hardware (140%).

Short Circuit in theRectifier Bridge

A short circuit in the rectifier bridge is detected by monitoring the DC linkvoltage. If a short circuit is detected, a trip is initiated and the drive isdisconnected from the supply voltage.

Charging Fault The intermediate DC link voltage is monitored while the DC link is ener-gized. If the voltage does not reach a certain level after a preset time, atrip is initiated.

Supply Phase Loss If the voltage ripple in the intermediate DC link rises above a preset level,a trip is initiated because a supply phase may be lost.

Overcurrent The overcurrent trip limit for the ACS 1000 is 2.2 x IN RMS of the nominalinverter current. If this level is exceeded, a trip is initiated.

Inverter Temperature In order to insure that the inverter section does not exceed the tempera-ture limits, the current is monitored and limited to the maximum permittedlevel.

Cooling Circuit The operating condition of the cooling circuit is monitored. If any of themonitored signals such as water temperature, water pressure or conduc-tivity exceed a preset limit, a trip is initiated. In addition, the status of theACS 1000 Technical Catalog 47

-

Chapter 6 - Standard Functions

cooling water pumps, the water level in the expansion vessel and the

auxiliary fan are monitored.

Short Circuit of theInverter

The inverter is monitored to ensure that a short circuit condition does notexist. If a short circuit is detected a trip is initiated.

Ground Fault The current in the output filter ground leg is monitored and compared withtwo thresholds. The first threshold is set to a fixed percentage of the peakvalue of the nominal inverter current. The second threshold is adjustableand compared with the RMS value of the ground current. If the groundcurrent exceeds one of the thresholds a corresponding alarm messagewill be displayed and the drive will be shut down.Ground faults will be detected in the area between the ACS 1000 trans-former secondary side and the motor.

Operating System The operating system of the microprocessor board monitores differentfunctions within the control software and will initiate a trip if a malfunctionis detected. Such faults are displayed as Control SW fault. Should oneof these faults be detected during operation, the drive should be restarted.

Communication Fault Except for the measurement boards all communication links are realizedby DDCS (Distributed Drive Control System). If one of these links fails atrip is initiated.

Measurement Loss On the ADCVI board (analog digital conversion for voltage and current)analog signals are converted into digital signals. The digital signals arethen transmitted via PPCC (fiber-optic bus system) to the interface boardwhich is the main interface to the converter control system.In order to guarantee proper operation of the protection functions includedin the converter, the status of the communication is monitored on the inter-face board. If a fault is detected a trip is initiated.

Battery Test The back-up batteries are checked periodically by applying a known loadand by measuring the resulting voltage drop. If the charge of the batteriesis deficient, a fault message is displayed and either a normal stop or analarm is initiated.

ID-Run Fault During commissioning an identification run has to be carried out. Thenominal data for identification of the system parameters has to be entered.If incorrect values are used and therefore the system parameters cannotbe determined, a trip is initiated. In this case the identification run has tobe repeated after the correct data has been entered.48 ACS 1000 Technical Catalog

-

Chapter 6 - Standard Functions6.3.3 Other Protection Functions

External MotorProtection Trip

If the customer uses an external motor protection relay, it can beconnected to a pre-defined protection input of the ACS 1000. The motorprotection input is integrated into the tripping loop by a normally closed(NC) contact.

External TransformerProtection Trip

If the customer uses an external transformer protection relay, it can beconnected to a pre-defined protection input of the ACS 1000. The trans-former protection input is integrated into the tripping loop by a normallyclosed (NC) contact.

Line UnbalanceProtection Relay

An optional signal input is available to connect a line unbalance protectionrelay for initiation of a converter trip.

Process Stop A process stop button or relay can be connected to a pre-defined input ofthe ACS 1000. The actual process stop input must be closed duringnormal operation. If the digital input opens, the drive control initiates a stopcommand. The stop mode (ramp stop, stop at torque limit, or coast stop)can be selected by a parameter. When the drive is stopped the main circuitbreaker is opened.

External EmergencyOff

The normally closed (NC) contacts of external emergency-off buttons canbe wired into the tripping loop.For further details see Chapter 4 - User Interfaces.

Automatic Restart The ACS 1000 can automatically reset itself after an undervoltage hasoccurred. This function is activated by two parameters one to enable theautomatic restart function and one to select the undervoltage waiting time(adjustable between 0 and 600 s).If the automatic restart feature is activated and an undervoltage isdetected in the DC-link, the waiting time is started. If the voltage recoverswithin the selected time, the fault will be reset automatically and theconverter resumes normal operation. If the waiting time has elapsed andthe voltage has not recovered the converter is tripped and the MCB isopened.

Monitoring of LimitValues

The values of several user selectable signals can be monitored for adjust-able low and high limits.Adjustable limits can be set for: two speed values, a current value, twotorque values, two reference values and two actual values of the PIDcontroller. The digital status of the active limit appears on the control paneldisplay and can also be allocated to digital output.

ACS 1000 Information The software version and the serial number of the ACS 1000 can bedisplayed on the CDP 312 control panel.

6.4 Other FunctionsACS 1000 Technical Catalog 49

-

Chapter 6 - Standard FunctionsParameter Lock The user can prevent unwanted parameter changes by activating theParameter Lock.

6.4.1 Customer Specific OptionsInformation on additional user specific options that can be implemented inthe ACS 1000 is given in Chapter 7 - Options.50 ACS 1000 Technical Catalog

-

Chapter 7 - Options

Extended AmbientTemperature: 50 C

Above 40 C the converter output power must be derated by 1.5% per 1 Cand filter capacitors, suitable for high operating temperatures, aresupplied.

Corrosion ProtectedBus Bars

For certain environmental conditions (e.g. salty air in combination withincreased ambient temperature and high humidity) corrosion protectedbus bars can be chosen instead of the standard type. This choice is rele-vant for all power and grounding bus bars of the converter.

Coated PCBs For certain environmental conditions (e.g. salty air in combination withincreased ambient temperature and high humidity) the printed circuitboards (PCBs) can be ordered with a special varnish.

Converter Enclosure The standard IP classes of the converter enclosures are given in AppendixA - Installation Guidelines.The following IP ratings are optional: IP22, IP31, IP32 and IP42 (for air-cooled converters) IP54 (for water-cooled converters)

Door Interlocking The ACS 1000 is equipped with an electromechanical door interlockingsystem as standard.Alternative optional interlocking: Kirk key interlockingIf this option is required, contact your ABB representative.

Cabinet Color The standard color for the ACS 1000 converter is RAL 7035, Light Grey.Other RAL colors are available optionally and must be specified explicitlywhen ordered.

Cabinet Paint Finish The standard converter has painted front doors. Optionally, the entirecabinet exterior is available with painted surfaces (see also CabinetColor).

Split Cabinet The water-cooled ACS 1000 can be delivered with a shipping split for easytransportation. All materials necessary for joining the two parts aresupplied with the drive.

7.1 Environmental Conditions

7.2 Converter EnclosureACS 1000 Technical Catalog 51

-

Chapter 7 - OptionsExtended GroundingBusbar

The standard grounding busbar which is located in the power cabletermination section of the ACS 1000 can be an extended throughout themedium voltage sections of the ACS 1000.

Input Bridges The following input rectifier bridges are available: 12-pulse diode rectifier (standard)

This type is sufficient for most network conditions to fulfill the networkharmonic requirements according to IEEE 519-1992.It is the ideal solution for a small converter footprint and if an outdoortransformer can be used.

24-pulse diode rectifier with integrated or external transformerconfigurationThis type is recommended if superior network behavior is required.The 24-pulse diode rectifier is applicable if outdoor transformers arenot required. In this case there is no need for an oil pit and no addi-tional cabling between transformer and converter is needed whichcan substantially reduce construction and installation costs.

Motor and TransformerProtection

Refer to Sections Extended Motor Monitoring Interface, page 53 andExtended Transformer Monitoring Interface, page 52.

Extended TransformerMonitoring Interface

In addition to the standard signal Transformer Protection Trip (wired intotripping loop) the signals according to Table 7-1 can be included optionallyin the signal interface between the transformer and the ACS 1000.Note: This option requires the IOEC 3 board. The option is standard forwater-cooled converters (see Chapter 4 - User Interfaces, I/O Signals:transformer, page 28).

7.3 Input Section

Table 7-1 I/O signals for extended transformer monitoring

Type Signal Name Remarks

DI OIL LEVEL ALARM Transformer oil level alarmindication

DI OIL TEMP ALARM, or

TRAFO WDG TEMP ALARM

Transformer oil temperature alarmindication

Transformer winding temperaturealarm indication

DI /OIL TEMP TRIP, or

/TRAFO WDG TEMP TRIP

Transformer oil temperature tripindicationTransformer winding temperaturetrip indication52 ACS 1000 Technical Catalog

-

Chapter 7 - OptionsThe analog input "Oil Temperature" is suitable for an actual value in therange of 0..20 mA / 4..20 mA (or 0..10 V / 2..10 V) and can be usedinstead of the digital temperature alarm and trip inputs. The analog signalis monitored by the ACS 1000 for alarm or trip levels.

Line UnbalanceProtection Relay

A signal from a line unbalance protection relay can be monitored by wiringit into the tripping loop of the ACS 1000. If the signal is low the main circuitbreaker is tripped immediately.

Common Mode Choke This option is needed if the cable length between the converter trans-former and the ACS 1000 exceeds the following limits: 30 m (98 ft) for ACS 1000, 12-pulse versions and 20 m (66 ft) for ACS 1000, 24-pulse versions.If the cables are longer than the limits below, the ABB representativeshould be contacted: 200 m (656 ft) for ACS 1000, 12-pulse versions and 150 m (492 ft) for ACS 1000, 24-pulse versions.The DC link common mode choke functions like a transformer. Togetherwith the common mode damping resistor it provides damping of thecommon mode voltages and limits the common mode currents experi-enced by the main power transformer and transformer secondary cables.

Extended MotorMonitoring Interface

In addition to the standard signal Motor Protection Trip (wired into trip-ping loop) the signals according to Table 7-2 can be included optionally inthe signal interface between the motor and the ACS 1000.Note: This option requires the IOEC 3 board. The option is standard forwater-cooled converters (see Chapter 4 - User Interfaces, I/O Signals:motor, page 29),

DI BUCHHOLZ ALARM Transformer alarm indication fromBuchholz relay

DI /BUCHHOLZ TRIP Transformer trip indication fromBuchholz relay

AI OIL TEMP, or

TRAFO WDG TEMP

Temperature measurement oftransformer oilTemperature measurement oftransformer winding

Table 7-1 I/O signals for extended transformer monitoring (continued)Type Signal Name Remarks

7.4 Motor SideACS 1000 Technical Catalog 53

-

Chapter 7 - OptionsThe analog inputs are suitable for actual values in the range of 0..20 mA /4..20 mA (or 0..10 V / 2..10 V) and are monitored by the ACS 1000 foralarm and trip levels.

Ex-Zone SignalInterface for Motor

Measurements (ZenerBarriers)

For motor installations in hazardous areas (Ex-Zone) all interface signalsfrom the motor have to be connected to Zener Barriers mounted in theconverter. This applies to the winding temperature and bearingtemperature measurements as well as to all digital signals e.g. externalmotor protection alarm and trip and external overspeed trip.If this option is required, contact your ABB representative.

Pulse EncoderInterface Module

The Module allows a pulse encoder to be connected to the ACS 1000. Apulse encoder is advantageous in applications where the flying startfunction is used. The actual frequency of a rotating motor can be detectedfaster and rapid start-up by the converter can be achieved. It is alsorecommended if a highly accurate read-out of the speed is required.Another application for a pulse encoder would be for motors running atspeeds below 5 Hz for longer periods.The requirements for a pulse encoder are as follows: Supply voltage 12 VDC or 24 VDC (supplied by the module) Single ended or differential connection can be used Available signal channels: A, A inverted, B (90 electr. phase shift to

A), B inverted (Z (zero channel), Z inverted - optional)

Table 7-2 I/O signals for extended motor monitoring

Type Signal Name Remarks

DI EXT MOT PROT ALARM (External) motor protection alarmindication

DI MOT COOLING ALARM (External) motor cooling alarmindication

DI /MOT COOLING TRIP (External) motor cooling tripindication

DI VIBRATION SV ALARM Motor vibration alarm indication

DI /VIBRATION SV TRIP Motor vibration trip indication

DI /OVERSPEED TRIP Motor overspeed trip (included inhardwired tripping loop)

AI BRG TEMP DE Motor bearing temperature ofdriven end

AI BRG TEMP NDE Motor bearing temperature of non-driven end54 ACS 1000 Technical Catalog

-

Chapter 7 - Options

n

The encoder should provide 2 pulses/revolution. The recommended

pulse train is 2048 pulses/revolution. Maximum signal frequencyshould not exceed 100 kHz.

The module is fed from the ACS 1000 internal control power supply.

Increased OutputFrequency

The ACS 1000 can be ordered with an increased output frequency of82.5 Hz as a maximum. This option requires an optimized sine filterconfiguration.

Braking Chopper Effective motor braking and short deceleration times can be achieved byusing resistor braking. For resistor braking, the ACS 1000 converter mustbe equipped with a braking chopper and a braking resistor.Braking choppers are available for all ACS 1000 types. The choppers canbe ordered factory-installed or as add-on kits.The operation of the braking chopper is controlled by the ACS 1000control system. The braking chopper hardware is located in an additionalcabinet.The input currents of the braking chopper are monitored for overcurrentand unbalance in order to detect any defective component in the circuit. Incase a short circuit or an unsymmetry in the braking chopper is detecteda converter trip is initiated.Braking chopper and braking resistors are each monitored forovertemperature by means of thermal models. Alarm and trip levels aredetermined and set during commissioning.For more information about braking chopper and braking resistor, see theresistor specification or contact your ABB representative.

Braking Resistor The braking resistor has to be specified individually for eachproject by ABB Industrie AG. For further information contact your ABBrepresentative.

Circuit Breaker forMotor Space Heater

A motor space heater can be connected directly to a single-phase auxiliarypower circuit breaker, installed in the converter cabinet. Based on thepower rating of the heater, one of the circuit breaker sizes as indicated inTable 7-3 can be used.ACS 1000 Technical Catalog 55

-

Chapter 7 - OptionsMotor Starter for MotorCooling Fan / Pump

A motor cooling fan or pump can also be connected directly to an auxiliarymotor starter installed in the converter. Based on the power rating of thecooling fan or pump, one of the following motor starter sizes can bechosen:

Redundant CoolingFan (Air-cooled

ACS 1000)