Vol II Pipeline Engineering Part 1

-

Upload

arown-sebastian -

Category

Documents

-

view

2.563 -

download

15

Transcript of Vol II Pipeline Engineering Part 1

VOLUME – II

PIPELINE ENGINEERING

LPG PIPELINE CONNECTIVITY TO HPCLBOTTLING PLANT - RAJAHMUNDRY

0 08.06.2009

DESIGN BASIS/JOB SPECIFICATION/ STANDARD

SPECIFICATION/STANDARDS/ DRAWINGS/DATASHEET

REV. DATE

GAIL (INDIA) LTD.

LPG PIPELINE CONNECTIVITY TO HPCL BOTTLING PLANTRAJAHMUNDRY

BIDDING DOCUMENT FOR LAYING OF PIPELINE AND ASSOCIATED FACILITIES

MASTER INDEX

VOLUME IA - COMMERCIAL

VOLUME IB - SCHEDULE OF PRICE

VOLUME IC - SCOPE OF WORK

VOLUME II - PIPELINE ENGINEERING – DESIGN BASIS/JOB SPECIFICATION/ STANDARD SPECIFICATION/STANDARDS/ DRAWINGS/DATASHEET

VOLUME III - ELECTRICAL& CP SYSTEM – DESIGN BASIS/ JOB SPECIFICATION/ STANDARD SPECIFICATION/ STANDARDS/DRAWING/ DATASHEETS

VOLUME IV - INSTRUMENTATION, TELECOM & SCADA – STANDARD SPECIFICATION/STANDARDS/ DRAWINGS/ DATASHEETS

VOLUME V - CIVIL & STRUCTURE – DESIGN BASIS/ JOB SPECIFICATION/ STANDARD SPECIFICATION/STANDARDS/DRAWINGS/ DATASHEETS

VOLUME VI - PROCESS PACKAGE – PROCESS DESIGN BASIS/ STANDARD SPECIFICATION/FLOW DIAGRAM/ P&ID/DATASHEETS

VOLUME VII - ROUTE MAP, ALIGNMENT SHEET, CROSSING DETAIL, SURVEYREPORTS, SURVEY DATA (ALL IN SOFT COPY)

(BIDDING DOCUMENT NO.: 8000001260)

Page 1 of 6

INDEXVolume – II

PIPELINE ENGINEERING

S. NO.

TITLE REV. SPEC. No. of Pages

JOB SPECIFICATION

1 Engineering Design Basis 0 0002-04-04-03-001 142 Piping Material Specification 0 0002-04-05-02-001 543 Welding Specification for

Mainline for Transportation of LPG

0 0002-04-04-02-001 47

4 Welding Specification Chart 0 0002-04-04-02-001-WSC1 045 Specification for Geo Textile

bags for Anti-Buoyancy0 0002-04-04-02-002 06

6 Technical Specification for Pre-Commissioning and Commissioning

STANDARD SPECIFICATION – PIPELINES

1 Specification for Seamless Pipe 0 S-04-02-003 062 Specification of ERW pipe 0 S-04-02-004 343 Specification of External coating

– 3L PE Coating0 S-04-02-005 34

4 Specification of Internal Epoxycoating

0 S-04-02-006 31

5 Specification of Ball Valve 0 S-04-02-007 176 Specification of Plug Valve 0 S-04-02-008 147 Specification for Seamless

fittings & Flanges, Size up to DN 400 mm (16”)

0 S-04-02-013 07

8 Specification for Long Radius Bends for Onshore Pipelines

0 S-04-02-015 10

9 Specification for Insulating Joints for Onshore Pipelines

1 S-04-02-019 9

10 Specification for Casing Insulator and End Seals

0 S-04-02-020 08

11 Specification for Field Joint 0 S-04-02-021 15

0 0002-04-04-02-003 14

(BIDDING DOCUMENT NO. – 8000001260)

Page 2 of 6

Coating (Onshore Pipeline)12 Specification for Concrete

Weight Coating of Onshore Pipelines

0 S-04-02-022 15

13 Specification for Repair of Polyethylene Coating

0 S-04-02-023 06

14 Specification for Pipeline rivercrossing using directional drilling method

0 S-04-02-025 15

15 Construction of pipelines crossing Roads, Rail Roads and Minor Water Crossings

0 S-04-02-026 11

16 Major Water Crossing -Conventional Trenching

0 S-04-02-027 15

17 Specification for Pipeline Construction (Onshore)

0 S-04-02-028 43

18 Specification for Hydrostatic Testing of Onshore Pipelines

0 S-04-02-029 22

19 Specification for Pipeline Markers

0 S-04-02-030 05

20 Specification for Documentation for Pipeline Construction

0 S-04-02-031 09

21 Specification for Blasting 0 S-04-02-032 1122 Specification for Detailed

Pipeline Route Survey (Onshore)0 S-04-02-033 17

23 Welding Specification for Fabrication of Piping

0 S-04-02-034 32

24 Spec. for Instructions to Vendor for Quality Data Requirement

0 S-04-02-035 10

25 Specification for basket Filters 0 S-04-02-038 08

STANDARD SPECIFICATION – PIPING

1 Technical Notes for Pipes 0 S-05-02-001 092 Technical Notes for Valves 0 S-05-02-002 173 Technical Notes for

Butt Welded, Socket Welded and Screwed Fittings

0 S-05-02-003 07

4 Technical Notes for Flanges, Spectacle Blinds and Drip legs

0 S-05-02-004 05

5 Technical Notes for Bolts and Nuts

0 S-05-02-005 03

6 Technical Notes forGaskets

0 S-05-02-006 03

7 Standard Specification for Fabrication and Erection of

0 S-05-02-011 16

Page 3 of 6

Piping8 Standard Specification of "Non-

Destructive Examination of Piping"

0 S-05-02-012 16

9 Specification for Inspection, Flushing and Testing of Piping System

0 S-05-02-013 10

10 Specification for Shop and Field Painting

0 S-05-02-014 49

11 Inspection and Test Plan for Gaskets

0 S-05-06-001 04

12 Standard specification of PMI at Vendor's works.

0 S-14-02-001 07

STANDARD DRAWING – PIPELINES

1 Typical Right of Way for Pipelines

0 S-04-01-001 02

2 Typical Trench Dimensions for Pipelines

1 S-04-01-002 01

3 Pipeline Symbols 0 S-04-01-003 014 Topographical Symbols 0 S-04-01-004 015 Existing pipeline on sleeper

crossing0 S-04-01-005 02

6 Pipeline Road/ Highway Uneased Crossing

0 S-04-01-006 01

7 Details of casing vent and drain 0 S-04-01-007 018 Casing pipe details 0 S-04-01-008 019 Existing Under Ground Pipe

Crossing (Type-I)0 S-04-01-009 02

10 Existing Under Ground Pipe Crossing (Type-II)

0 S-04-01-010 02

11 Under Ground Cable Crossing 0 S-04-01-011 0212 Over Head Power Line Crossing S-04-01-012 0213 Typical trench dimension for two

or more pipelines in common trench

0 S-04-01-013 01

14 K.M. Post 0 S-04-01-014 0315 Typical ROU boundary marker 0 S-04-01-015 0216 Aerial marker 0 S-04-01-016 0317 Direction marker 0 S-04-01-017 0318 Pipeline Warning Sign 0 S-04-01-018 0319 Navigable Waterway Pipeline

Crossing Warning Sign0 S-04-01-019 02

20 Pipeline Road/Highway Cased Crossing

0 S-04-01-020 02

Page 4 of 6

21 Typical Stream Crossings 0 S-04-01-021 0222 Typical Slope Breakers Details 0 S-04-01-022 0323 Bank Protection Details for

water crossings0 S-04-01-023 03

24 Select Backfill for Station Approach

0 S-04-01-026 02

25 Slope stabilization in ghat/ hill areas

0 S-04-01-027 02

26 Soil stabilization in hilly areas 0 S-04-01-028 0327 Typical lined canal cased

crossing detail0 S-04-01-029 02

28 Typical lined canal crossings(Uncased)

0 S-04-01-030 01

29 Typical Cross section for ROU preparation in Hilly areas

0 S-04-01-031 01

STANDARD DRAWING – PIPING

1 Jack Screw for Spectacle Blind 0 S-05-01-001 012 Jack Screw for Spacer & Blind 0 S-05-01-002 013 Vents & Drains on Lines 1-1/2”

& Below0 S-05-01-003 01

4 Vents & Drains on Lines 2” & Above

0 S-05-01-004 01

5 Wells Installations 1-1/2” Diameter Traps

0 S-05-01-005 02

6 Pressure Tappings – PG, PT, PI, PA, PC etc

0 S-05-01-006 01

7 Handle Projections for Spacers and Blinds

0 S-05-01-007 01

8 T-Strainer Type-1 2"-4" (150# RF, 300# RF and RTJ, 600# RF and RTJ)

0 S-05-01-008 01

9 Orientation of Orifice Traps 0 S-05-01-010 0110 Stub-in Standard 0 S-05-01-011 0211 Welding of pipe with different

thickness0 S-05-01-012 01

12 Fillet weld details 0 S-05-01-013 0113 Welding details for branch

connections0 S-05-01-014 01

14 Method of cutting and dimensions of field manufactured concentric reducers

0 S-05-01-015 01

15 Tolerances for fabrication 0 S-05-01-016 0116 Pipe shoe for slope line pipesize 0 S-05-01-020 02

Page 5 of 6

2" thru 6" type-S9A/9B/9C17 Low support sliding for bare and

insulated pipe size 2" thru 36" type-L1 & L1A

0 S-05-01-021 02

18 Low support fixed for bare & insulated pipe size 2" thru 36" type-L3 & L3A.

0 S-05-01-022 01

19 Low support sliding for bare pipe size 3/4" thru’ 36" type-L5 & L5A.

0 S-05-01-023 01

20 Low support sliding for bare and insulated pipe size 2” thru 36” Type-L6

0 S-05-01-024 02

21 Low support Fixed/Restrained for bare and insulated pipe size 2" thru 36", type-L7 & L7A

0 S-05-01-025 03

22 Restrained Low support for bare and insulated pipe size 2" thru 36", type-L8 & L8A

0 S-05-01-026 01

23 Adjustable low support sliding for pipe size 2" thru 6" type-L10 & L10A

0 S-05-01-027 01

24 Low support sliding & fixed for pipe size 3/4" thru 11/2"type-L15.

0 S-05-01-028 02

25 Low support stanchion for bare & insulated CS/AS/SS pipe type – L16 and L16A

0 S-05-01-029 01

26 Adjustable low support with 4 bolts for pipe size 8" thru 24" type-L17 & L17A.

0 S-05-01-030 02

27 Adjustable low support for bare and insulated pipe size 2" thru 24". type-L18 & L18A

0 S-05-01-031 01

28 Adjustable low support with guide & cross guide for bare and insulated pipe size 2" thru 24" type-L19 & L19A.

0 S-05-01-032 02

29 Pipe clamp for bare pipe size 1/2" thru 24” Type C-1

0 S-05-01-033 01

30 U-bolt for bare pipe size 1/2" thru 24" type-C4

0 S-05-01-034 01

31 Dummy pipe support for bare pipe size 2" thru 24" type B-39

0 S-05-01-035 02

32 Dummy pipe support for insulated pipe size 2" thru 24"

0 S-05-01-036 02

Page 6 of 6

type-B4033 Pipe support brackets type-B42 0 S-05-01-037 0134 Guide support for bare size 1/2"

thru 24" type-G10 S-05-01-038 01

35 Guide support for bare size 1/2" thru 24" type-G2 & G2A

0 S-05-01-039 02

36 Cross guide for bare pipe size 2" thru 24" type-G3

0 S-05-01-040 02

37 Cross guide for bare pipe size 2" thru 24" type-G4.

0 S-05-01-041 02

38 Anchor for bare pipe size 2" thru 24" type-G5.

0 S-05-01-042 02

39 Supporting arrangement for angle & relief valves type-SP2.

0 S-05-01-043 01

40 Typical anti vibration support for control valve-SP3.

1 S-05-01-044 01

DATA SHEETS – LINEPIPE / PIPING

1 Data sheet of Ball Valve 0 0002-04-04-04-BV-001 022 Data sheet of IJ 0 0002-04-04-04-IJ-001 013 Data sheet of Basket Filter 0 0002-04-04-04-FS-001 024 Data sheet of Temperature

Safety Valve (class 600# lines) 0 0002-04-04-04-TSV-001 02

5 Data sheet of Temperature Safety Valve (class 300# lines)

0 0002-04-04-04-TSV-002 02

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

ENGINEERING DESIGN BASIS - PIPELINE ENGINEERING

0002-04-04-03-001 Page 1 of 14

Copyright GAIL – All rights reserved

ENGINEERING DESIGN BASIS (PIPELINE ENGINEERING)

LPG PIPELINE CONNECTIVITY TOHPCL BOTTLING PLANT, RAJAHMUNDRY

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

ENGINEERING DESIGN BASIS - PIPELINE ENGINEERING

0002-04-04-03-001 Page 2 of 14

Copyright GAIL – All rights reserved

TABLE OF CONTENTS

1.0 INTRODUCTION

2.0 SCOPE

3.0 DESIGN CODES AND STANDARDS

4.0 DESCRIPTION OF FACILITIES

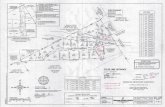

5.0 PIPELINE ROUTE

6.0 DESIGN DATA

7.0 PIPELINE AND ASSOCIATED FACILITIES DESIGN

8.0 OTHER TECHNICAL REQUIREMENTS

ANNEXURE-A LIST OF CODES AND STANDARDS

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

ENGINEERING DESIGN BASIS - PIPELINE ENGINEERING

0002-04-04-03-001 Page 3 of 14

Copyright GAIL – All rights reserved

1.0 INTRODUCTION

M/s GAIL (India) Ltd. proposes to lay Liquefied petroleum gas (LPG) pipe line for transportation of LPG from IP-1 station (VSPL) to HPCL Bottling Plant, Rajahmundry. The proposed LPG pipeline shall be of 114.3 mm (4”) OD, approximately 3.3 km long as mentioned below:-

2.0 SCOPE

This document establishes minimum design parameters and basis for design and detailed engineering of the Pipeline and Associated facilities covered under this project as defined briefly herein below.

3.0 DESIGN CODES AND STANDARDS

Pipelines and terminal facilities envisaged shall be designed and engineered primarily in accordance with the provisions of the latest edition of Code ASME B31.4 (Transportation systems for Liquid Hydrocarbons, LPG, Anhydrous Ammonia and Alcohol and OISD 141 (Design and construction requirements for cross country Hydrocarbon pipelines). In addition, requirements, as applicable to LPG service of following codes/standards shall be complied with:

OISD Std. 138 : Inspection of Cross Country Pipelines-Onshore

ASME B 31.3 : Chemical Plant & Petroleum Refinery Piping

API Std. 1102 : Steel Pipeline Crossing Railways & Highways

API Std. 1104 : Standard for Welding Pipelines and Related Facilities

API Std. 1105 : Bulletin of construction practices for oil and product pipelines

API RP 1109 : Marking liquid petroleum pipeline facilities

API RP 1110 : Recommended practice for the pressure testing of liquid petroleum pipelines

OISD 214 : Cross country LPG pipelines

Petroleum : Part V, Transport by pipelinesRules, 1976

American federal : Part-195, Minimum federal safety standards for liquid Safety regulations pipelines

In case of conflict between the requirements of ASME B31.4 / OISD 141 / OISD 214and other codes/Standards referred above, requirement of ASME B 31.4/OISD 141 / OISD 214 shall govern. In case of conflict between requirements of B31.4/OISD 141 / OISD 214 and this document, requirements of this document shall govern.

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

ENGINEERING DESIGN BASIS - PIPELINE ENGINEERING

0002-04-04-03-001 Page 4 of 14

Copyright GAIL – All rights reserved

4.0 DESCRIPTION OF FACILITIES

Details of facilities shall be as per P&IDs, process design basis, data sheets, line schedule etc covered in the process package. The pipeline facilities envisaged as a part of this project are described briefly herein below.

4.1 IP-1 station End:

Facilities at IP-1 station end include hook up with 12” spare TOP available).

4.2 HPCL Bottling Plant End:

Facilities at HPCL Bottling plant end include Filters, Pressure reduction unit and Metering (Mass flow Meters).

4.3 Main Pipeline

4” x 3.3 km cross country pipeline from IP-1 station (VSPL) to Metering station in the premises of HPCL Bottling plant. (ref. PFD)

5.0 PIPELINE ROUTE

5.1 Pipeline Route

Salient features of the surveyed pipeline route (as per Industrial Location maps and survey reports) are tabulated herein below:

Size, OD 4” (114.3 mm)Length (Km) 3.3Highest elevation above MSL (m) Refer alignment sheetsLowest elevation above MSL (m) Refer alignment sheetsNo. of River Crossing , Width > 100 m NilNo. of Road Crossing (NH/SH) Nil / 1No. of Railway Crossing NilNo. of Canal Crossing 3

5.2 Terrain Details

For Terrain details and Land use pattern refer Alignment sheets attached elsewhere in the bid document.

6.0 DESIGN DATA

6.1 Main pipeline shall be designed for conditions as follows:

PIPELINE DESIGN PARAMETERDescription Value

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

ENGINEERING DESIGN BASIS - PIPELINE ENGINEERING

0002-04-04-03-001 Page 5 of 14

Copyright GAIL – All rights reserved

Customer connectivity from VSPL 114.3 mm (4”) ODProduct LPGDesign Pressure (Kg/ Cm2g) 99.93Operating Pressure (Kg/ Cm2g) 57.5 - 63Maximum Design Temperature (0C)i. Above Ground Sectionii. Under Ground Section

-20 to 65.0 0 to 45.0

Economic Design Life (Years) 35Corrosion Allowance (mm) 0.5

All terminal facilities (equipment and associated piping) shall be designed for design and operating conditions given in the process package.

7.0 PIPELINE AND ASSOCIATED FACILITIES DESIGN

7.1 General

Pipeline and pipeline stations to be installed as a part of this project shall be designed and engineered in accordance with the standards/codes referred in section 3.0 of this document.

7.2 Pipeline

7.2.1 Pipeline shall be designed in accordance with requirements of ASME B 31.4 and OISD 141 / OISD 214. The pipeline shall withstand all installation, testing and operating condition/ loads. All necessary calculations shall be carried out to verify structural integrity and stability of the pipeline for the combined effect of pressure, temperature, bending (elastic), soil/pipe interaction, external loads and other environmental parameters as applicable during all phases of work from installation to operation. Such calculations shall include, but are not limited to following:

- Buoyancy control and stability analysis for pipeline section to be installed in areas subjected to flooding/submergence. Unless specified, specific gravity of installation in such area shall be at least 1.2.

- Stress analysis at canal, road crossings etc.

- Pipeline expansion and its effect on station piping (above ground/below ground).

7.2.2 Pipeline shall also be checked for adequacy against anticipated earthquake loading and any special measures such as increase in wall thickness/ grade/ select backfill etc. as required to ensure safety and integrity of the pipeline system shall be implemented.

7.2.3 Pipeline and its associated facilities shall be designed using the applicable design code and as modified below.

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

ENGINEERING DESIGN BASIS - PIPELINE ENGINEERING

0002-04-04-03-001 Page 6 of 14

Copyright GAIL – All rights reserved

7.3 Station Piping

7.3.1 Station piping to be provided at Customer metering stations be designed in accordance with ASME B 31.4 / OISD 141 and utility piping to be provided at these locations shall be designed in accordance with the provisions of ASME B 31.3.

7.3.2 All piping shall be designed for combined effects of pressure, weight and temperature during operating conditions without over stressing the piping, valves or equipment. All piping shall be adequately supported, guided or anchored so as to prevent undue vibration, deflection or loads on connected equipment such as filters, meters etc.

7.4 Materials Pipeline and its appurtenances shall be provided with carbon steel materials suitable for the intended service, as detailed in subsequent paragraphs

7.4.1 Line pipe:

Line pipe shall conform to API 5L and Company specifications. Type of line pipe to be used shall be SEAMLESS/EW.

Sr. No.

LINE SIZE GRADE Thickness

1 4” (114.3 mm) API 5L Gr. B, PSL-2 6.4 mm

7.4.2 Other Materials

All other materials and equipments including insulating joints, ball valves, flanges and fittings etc. shall be carbon steel suitable for the service conditions and shall be compatible with the line pipe material. Material shall have maximum hardness of 248 HV10 and shall have requisite notch toughness.

7.5 External/ Internal corrosion coating

7.5.1 Pipeline to be installed below ground shall be protected against external corrosion by a combination of high integrity externally applied coatings and permanent impressed Cathodic protection system. Externally applied coating shall be three layer side extruded polyethylene coating. Minimum thickness of coating shall be as per coating specification.

7.5.2 All above ground piping and structures shall be painted to prevent atmospheric corrosion. Painting of above ground piping and structures shall be as per specifications. Painting shall be suitable for normal corrosive environment / corrosive environment, as applicable, as defined in Painting Specification, No. S-05-02-014, for all stations.

7.6 Insulating joints Insulating joints shall be provided to electrically isolate the buried pipeline from above ground pipeline. Insulating joints shall be monolithic type and shall allow smooth passage of pigs. Insulating joints shall be installed in above ground portion of the

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

ENGINEERING DESIGN BASIS - PIPELINE ENGINEERING

0002-04-04-03-001 Page 7 of 14

Copyright GAIL – All rights reserved

pipeline, immediately after the buried/aboveground transition at the stations.

Wherever pressure/ temperature transmitters are used on cathodically protective pipeline the same shall be electrically isolated by providing insulating joints/ flanges.

7.7 Pipeline Burial

The pipeline shall be buried normally at a depth of 1.0 meter below natural ground level except in areas likely to have an increased risk of impact damage or third party interference where the pipeline shall be buried with a minimum depth of cover as mentioned below:

S. No. Location Minimum Cover

(m)

1.0 Industrial, commercial and residential area

1.2

2.0 Rocky terrain 1.0

3.0 Minor water crossing/ canal/ drain/ nala/ waterways

1.5

4.0 HDD crossing of canals (below bed) 2.5

5.0 River crossings for which scour depth is defined (below scour)

1.5

6.0 Other River crossings (Bank width >50m) (Below Bed) 2.5 (For normal soil)

1.5 (For rocky strata)

7.0 Other River crossings (Bank width < 50m) (Below Bed)

1.5

8.0 Cased/uncased road crossing 1.2

9.0 Cased railway crossing 1.7

10.0 Drainage, ditches at roads/railway crossings

1.2

11.0 Marshy land/Creek area 2.0

Additional soil cover other than specified above shall be provided based on the safety and risk analysis. In case, any private dwelling, industrial building or place of public assembly falls within 15 m of pipeline, additional cover of minimum 300 mm shall be provided over and above the cover indicated in the above table.

7.8 Marshy Areas / Areas Prone to Flooding

Wherever marshy areas/areas prone to flooding are encountered along the pipeline route, pipeline shall be provided with anti buoyancy measures viz. continuous concretecoating/ Geotextile gravel filled bags. Unless specified otherwise in AFC drawings,

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

ENGINEERING DESIGN BASIS - PIPELINE ENGINEERING

0002-04-04-03-001 Page 8 of 14

Copyright GAIL – All rights reserved

specific gravity of installation in such areas shall be at least 1.2.

7.9 Pipeline in common ROW

The location of new underground pipeline, when running parallel to an existing underground pipeline in same ROU/ROW shall be laid at minimum clear distance of 5.0 m from the existing underground pipeline. This distance may be reduced to 3.0 m after assessment of construction methodology which do not result in unsafe conditions during construction.

7.10 Backfilling

In normal cross-country areas, the pipeline trench shall be backfilled with excavated soil. Select rockfill/ slope breakers shall be provided in the trench in steep areas (slope generally 10% and more) to prevent erosion. In case of rivers/water bodies prone to scour and erosion, the safety cover shall be provided below the predicted scour level. In addition to the cover, anti buoyancy measures (concrete coating) shall be provided at river crossings.

Contractor shall keep top 150 mm of excavated top soft soil (free of gravels) aside, which shall be back filled in the end as top layer.

Select backfill shall be provided at approaches to terminal up to transition point (below ground/above ground) inside terminal.

Select back fill shall also be provided as applicable for areas prone to seismic activity. Recommendation of Seismic Analysis Report should be considered for such special backfill.

Pipeline route shall be examined to establish any drainage requirement in hilly terrain. In case required, the drainage shall be designed to prevent trench flooding during construction and protect the integrity of the installed pipeline following completion of all construction activities.

In rocky areas, the trench bottom shall have sand/soft soil padding of 150 mm. After laying of pipeline, sand/soft soil padding shall be placed around and on top of the pipe so that thickness of compacted padding on top of pipe corrosion coating shall be at least 150 mm.

Disposal of debris and surplus material to designated disposal areas or designated place(s), as the case may be and as directed by Engineer-in-charge shall be carried out.

8.0 OTHER TECHNICAL REQUIREMENTS

8.1 Valves

All valves installed shall be gas actuated/ hand operated and with butt welding ends.

The provisions of remote operated feature shall be as per the operation and control philosophy to be adopted for the project.

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

ENGINEERING DESIGN BASIS - PIPELINE ENGINEERING

0002-04-04-03-001 Page 9 of 14

Copyright GAIL – All rights reserved

8.2 Piping

8.2.1 General

This section describes the design requirements of piping applicable for Customer metering stations.

All piping and equipment shall be designed as per ASME B 31.4. All piping materials shall be as per Piping Material Specification (PMS).

Utility piping to be provided shall be designed in accordance with the provisions ofASME B 31.3.

Design shall provide consideration for all loadings like weight, temperature etc., significantly affecting the pipe material stresses in addition to fluid pressure.

8.2.2 Piping flexibility/stress analysis

All piping shall be designed for thermal expansion under start up, operating and shut down conditions without over stressing the piping, valves or equipment. Provisions for expansion shall normally be made with bends and offsets.

All piping shall be adequately supported, guided or anchored so as to prevent undue vibration, deflection or loads on connected equipments. Equipments/ valves requiring periodical maintenance shall be supported in such a way that the valves and equipment can be removed with minimum temporary pipe supports.

8.2.3 Piping layout

Piping will be located above-ground wherever possible within the terminals.

Piping shall be designed considering skin temperature of piping material under empty conditions as 650C or design temperature of pipeline whichever is higher.

Piping stress analysis shall be carried out to determine allowable pipe movement and support requirements wherever felt necessary.

Buried piping inside the terminal area will have a minimum depth of cover of 1.2m.

Where buried pipes come out of the ground, the underground coating on the pipe will continue for a distance of 500 mm above ground.

Platforms, crossovers shall be provided for ease of operation and maintenance, if required.

Platform for filters shall be provided for maintenance/ operational access, if

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

ENGINEERING DESIGN BASIS - PIPELINE ENGINEERING

0002-04-04-03-001 Page 10 of 14

Copyright GAIL – All rights reserved

required. Painting above ground piping and structures shall be as per specifications

enclosed in the Bid package.

8.3 Welding

Welding shall be carried out in accordance with API 1104, specification for welding and welding charts. Butt welds shall be 100 % radiographed / UT for welding, as applicable for all pipelines.

For gas service all butt welds for process piping shall be 100% radiographed and for utility piping NDT requirements shall be as per specification no. S-05-02-12.

8.4 Hydrostatic Testing

After installation, the entire pipeline system shall be hydro tested with inhibited water. The water shall be tested, as applicable prior to using for hydro testing. The minimum hydrostatic pressure in any section shall be as per ASME B 31.4 for liquid hydrocarbon pipelines. The maximum hydrostatic test pressure at any location of the pipeline shall not exceed the pressure required to produce a hoop stress equal to 90% of SMYS of the pipe material based on minimum wall thickness in the test section. The test duration shall be minimum 24 hours. Hydrostatic testing of terminals shall be carried out separately. Terminals as well as other intermediate facilities shall be tested at 1.4 times the design pressure. The test duration shall be 6 hours.

8.5 Dewatering and swabbing

Dewatering, swabbing and pre-commissioning operations shall be carried out after hydro testing and prior to commissioning of the pipeline as per Project specifications. After swabbing operation the pipeline sections shall be dried as per relevant specification enclosed with the tender.

8.6 Crossings

8.6.1 Water Crossings

All water crossing (drains etc.) shall be installed by open cut unless specified otherwise.In case the job is carried out through HDD, the same is to be carried out as per the relevant specifications enclosed with the bidding document. The agency carrying out HDD shall have relevant experience.

Wherever there is an evidence of bank erosion, the banks shall be protected by using gravel and boulders filled embankment mattresses of galvanized iron wire to be laid over the backfilled, compacted and graded banks.

8.6.2 Road Crossing

Road crossings shall comply with the requirements of API 1102 and the requirements of the concerned road authorities. Unless otherwise required by concerned Authorities,

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

ENGINEERING DESIGN BASIS - PIPELINE ENGINEERING

0002-04-04-03-001 Page 11 of 14

Copyright GAIL – All rights reserved

casing pipe shall not be used. Provision of casing at locations other than national highways shall be decided based on type of road crossing and as per requirements of local authorities if necessary. The casing pipe shall be three nominal pipe sizes larger than the carrier pipe. The crossing angle shall be as close to 90º as possible. Casing insulators and end seals shall be provided to ensure electrical isolation of carrier pipe and casing pipe.

8.6.4 Existing Pipeline Crossing

The specific requirements of Owner/operator of existing pipeline shall generally be followed. The minimum clearance between the lines shall be 300 mm unless specified otherwise.

8.7 Valves

8.7.1 Application of various types of valves shall be as follows:

Valve type Typical application

Globe Throttling

Ball On/off, Isolation (on main line)

Plug On/off, Isolation (in the terminals)

Check Uni-directional flow

All pipeline valves shall comply with the requirements of API 6D/ relevant PMS. Ball valves shall have primary metal seated design. In order to minimize potential leak sources, valves used in mainline shall be with butt-weld ends. Valve installed within the terminal to isolate the mainline/ pipeline shall also be provided with butt welding ends. However terminal valves shall be flanged ends. Flanges may be used where frequent access or removal of equipment is required.

Wherever underground valves are provided, valves shall be provided with a stem extension in such a way that the centre line of the rim of the hand wheel on a horizontal shaft or centre of power actuator as approximately 1.0 m above the finished ground level.

Minimum size of any tapping from the underground pipeline shall be 2" NB and shall be provided with an isolation ball valve located at a minimum distance from the pipeline.

8.8 Branch Connections

All branch connections or side tap shall be as per PMS.

8.9 Pipeline Bends

In order to accommodate changes in vertical and horizontal alignment, pre-fabricatedbends shall be used. Miter bends shall not be used for change in direction.

8.10 Specifications All procurement of materials shall be as per Piping Material Specification (PMS) and specifications indicated in PMS.

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

ENGINEERING DESIGN BASIS - PIPELINE ENGINEERING

0002-04-04-03-001 Page 12 of 14

Copyright GAIL – All rights reserved

ANNEXURE - A (LIST OF CODES AND STANDARDS)

In addition to the codes/standards mentioned in para 3.0, the latest edition of the below listed equivalent codes and standards shall also be used for design of proposed pipeline. The listing includes, but is not limited to, the following:

1. Line Pipes API 5L Specification for Line pipe API 5L1 Recommended Practice for Railroad Transportation

of Line pipe API 5LW Recommended Practice for Transportation of Line

pipe on Barges & Marine Vessels 2. Valves

API 6D Specification for pipeline valves (Steel Gate, Plug, Ball and Check Valves)

API 602 Compact Steel Gate Valves-Flanged, Threaded, Welding & Extended Body ends.

ASTM A694 Forgings, Carbon & Alloy steel for Pipe Flanges, Fittings, Valves & parts for High Pressure Transmission Service.

MSS-SP-6 Finishes for Contact Faces of connecting End Flanges of Ferrous Valves and Fittings.

MSS-SP-25 Standard Marking System for Valves, Fittings & Unions

BS 5351 Steel Ball Valves for the Petroleum, Petrochemical and Allied Industries

3. Flanges & Fittings MSS-SP-44 Steel Pipeline Flanges

ANSI B16.5 Pipe Flanges and Flanged Fittings

ANSI 16.20 Ring-joint Gaskets & Grooves for Steel Pipe Flanges

ASTM A105 Forgings, Carbon Steel for Piping Components ASTM A193 Carbon & Alloy Steel Bolts & Studs for High

Temperature Service API 601 Standard for Metallic Gaskets for Raised-Face Pipe

Flanges & Flanged Connections

ANSI B16.9 Factory Made Wrought Steel Butt Welding Fittings

ANSI B16.11 Forged Fittings, Socket Welded & Threaded

ANSI B16.26 Butt Welding Ends ASTM A234 Piping Fittings of Wrought Carbon Steel and Alloy

Steel for Moderate and Elevated Temperatures

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

ENGINEERING DESIGN BASIS - PIPELINE ENGINEERING

0002-04-04-03-001 Page 13 of 14

Copyright GAIL – All rights reserved

ASTM A694 Forgings, Carbon & Alloy Steel for Pipe Flanges, Fittings, Valves & Parts for High Pressure Transmission Service.

MSS-SP-75 Specification for High Test Wrought Butt Welding Fittings

MSS-SP-97 Integrally Reinforced Forced Branch Outlet Fittings – Socket Welding, Threaded and Butt Welding Ends.

PFI-ES-24 Pipe Bending Methods, Tolerances, Processes & Material Requirements

4. Testing & Welding ANSI/AWS D1.1 Structural Steel Welding

API 1104 Standard for Welding Pipelines and Related Facilities

AWS A3.0 Welding Terms and Definitions

AWS A5.1 Welding Electrodes AWS A5.5 Specification for Low Alloy Steel Covered Arc

Welding Electrodes

ASTM E165 Liquid Dye Penetrant Inspection of Pipeline Welds ASTM A370 Standard Methods and Definitions for Mechanical

Testing of Steel Products. ASTM E18 Standard Hardness Test for Metals

ASTM E23 Standard for Impact Test for Metals

ASTM E84 Standard Test Method for Micro-hardness of Metals ASTM E92 Standard Test Method for Vickers Hardness of

Metallic Materials ASTM E110 Standard Test Method Indentation Hardness for

Metallic Materials by Portable Hardness Testers

ASTM E709 Standard Guides for Magnetic Particle Examination MSS-SP-53 Quality Standard for Steel Casting & Forging-

Magnetic Particle Method MSS-SP-54 Quality Standard for Steel Casting & Forging-

Radiographic Examination MSS-SP-55 Quality Standard for Steel Castings & Forgings-

Visual Method. 5. Surface Preparation, Painting and Coating

SIS-05-59 Pictorial Surface Preparation Standards for Painting Steel Surfaces

SSPC-SP-01 Solvent Cleaning

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

ENGINEERING DESIGN BASIS - PIPELINE ENGINEERING

0002-04-04-03-001 Page 14 of 14

Copyright GAIL – All rights reserved

SSPC-SP-03 Power Tool Cleaning

SSPC-SP-05 Joint Surface Preparation Standard: White Metal Blast Cleaning

SSPC-SP10 Structural Steel Painting Council – Joint Surface

NACE No.2 Preparation Standard - Near-White Metal Blast

Cleaning

SSPC-PA-02 Measurement of Dry Paint Thickness and Magnetic Gauges

ASTM E12 Measurement of Pipeline Dry Film Coating Thickness

ASTM-G6 Abrasion Resistance of Pipeline Coating ASTM G8

Cathodic Disbonding of Pipeline CoatingsNACE-RP-0274 High Voltage Electrical Inspection of Pipeline

Coatings Prior to InstallationNACE-RP-0169 Recommended practice control of external

corrosion on underground or submerged metallic piping system

NACE-RP-0177Recommended practice mitigation of alternating current & lightening effects on metallic structures and corrosion control systems

6. Safety Systems

IP Model Code of Safe Practice in the Petroleum Industry parts 3, 6 and 9

7 Quality Systems

ISO – 8402 Quality vocabulary

ISO – 9000 Quality management and quality assurance standards guideline for selection and use

ISO – 9001 Quality system model for quality assurance in design / development production , installation and servicing

ISO – 9002 Quality system model for quality assurance in Production and installation

ISO – 9003 Quality system model for quality assurance in final inspection and test

SNT – TC – 1A Personnel qualification & certification in Non-destructive testing

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 1 of 54

PIPING MATERIAL SPECIFICATION

LPG PIPELINE CONNECTIVITY TO HPCL BOTTLING PLANTRAJAHMUNDRY

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 2 of 54

CONTENTS

SL NO. DESCRIPTION

1.0 SCOPE

2.0 CODES AND STANDARDS

3.0 MATERIAL SPECIFICATIONS

4.0 CLASS DESIGNATION CODES

5.0 PIPELINE

6.0 PIPING

7.0 FITTINGS

8.0 BENDS

9.0 FLANGES

10.0 GASKETS

11.0 BOLTING

12.0 THREAD SERALANT

13.0 VALVES

14.0 QUICK OPENING END CLOSURE

15.0 HYDROTESTING VENT AND DRAINS

TABLE - 1 PIPE WALL THICKNESS DETAILS FOR MAINLINE SPUR LINE

TABLE - 2 PRESSURE/TEMP & OTHERS DESIGN CONDITIONS FOR VARIOUS PIPING CLASSES

ANNEXURE-A,B,C,D,E

MATERIAL SPECIFICATIONS FOR PIPING CLASSES

ANNEXURE-1 LIST OF ATTACHMENTS

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 3 of 54

1.0 SCOPE

1.1 It is propose to install a Liquefied Petroleum Gas (LPG) pipeline system from VSPL tap-off point at IP-1 to HPCL Bottling Plant, Rajahmundry – A.P. to meet the LPG requirement of HPCL Bottling Plant. The proposed LPG pipeline shall be of 114.3 mm (4”) OD, approximately 3.5 km long.

The scope shall include piping and tap-off points at IP-1, PRS at IP-1 and Metering Skid at HPCL Bottling Plant.

This document covers minimum requirements for various piping materials necessary for the design of the piping/ pipeline and metering skid facilities coming under the project. This specification shall be read in conjunction with various Codes and Standards of latest edition, as applicable.

2.0 CODES AND STANDARDS

2.1 Pipeline and pipeline terminal facilities envisaged as part of this project shall be designed and engineered primarily in accordance with the provisions of the latest edition of the following codes:

(i) ASME B31.4 - Liquid Transportation Systems for Hydrocarbons, Liquid Petroleum Gas, Anhydrous Ammonia and Alcohohols.

(ii) ASME B31.3 - Chemical Plant and Petroleum Refinery Piping

(iii) OISD Standard 141 - Design and Construction Requirements for Cross CountryHydrocarbon Pipelines.

2.2 All codes, standards and specifications referred herein shall be the latest edition of such documents.

2.3 For sake of brevity the initials of the society to which the codes are referred may be omitted in the specifications, for example, B16.5 is a code referring to ASME; A106 is a code referring to ASTM.

2.4 In addition, GAIL specifications and standards for various piping and pipeline materials shall also be applicable.

3.0 MATERIAL SPECIFICATIONS

Individual piping class has been generally designed to cover a set of service operating within pressure-temperature consideration as per ASME B16.5/ B16.34 or part of it. Deviations of material from class specifications may occur due to specific design conditions and/ or availability. These deviations are permissible if they equal or better the individual class requirements and shall be subjected to approval on case-to-case basis.

All materials shall conform to detailed specifications / data sheets for items as applicable.

4.0 CLASS DESIGNATION CODE

The piping class designation shall generally consist of three digits made up of a letter, number, letter e.g. A1A, A3A, A4A, B1A, D1A, E1A, etc. as follows:

First letter indicates ASME Class rating e.g.

A – Class 150

B – Class 300

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 4 of 54

D – Class 600

E – Class 900

The middle number indicates differences in the specifications within the same class rating and material.

The last letter indicates type of material. e.g. A – Carbon steel.

5.0 PIPELINE

5.1 Line pipe material grade and wall thickness details are indicated in Table-I.

6.0 PIPING

6.1 Carbon steel pipe shall be made by open hearth, electric furnace or basic oxygen process only. The steel used shall be fully killed and made with fine grain structure. The grade and wall thickness of various sizes of pipes shall be as per piping material specification for the applicable class.

6.2 Pipe dimensions shall be in accordance with ASME B 36.10 for carbon steel ASTM standard pipes,API 5L for carbon steel API 5L grade pipes & ASME 36.19 for stainless steel pipe.

6.3 All pipe threads shall conform to American Standard taper as per ASME B1.20.1 NPT, unless otherwise specified.

6.4 For butt weld end, bevel shall be in accordance with API specification 5L or ASME B 16.25 as applicable.

7.0 FITTINGS

7.1 Fully killed carbon steel shall be used in the manufacture of fittings. The fitting shall have carbon equivalent not exceeding 0.45, based on check analysis.

7.2 Threaded joints, if used, shall conform to American Standard taper as per ASME B1.20.1 NPT.

7.3 Dimensions of socket welded/ screwed fittings shall conform to ASME B 16.11. Swage shall be as per BS 3799.

7.4 Dimensions of steel butt welded fittings shall be as per ASME B 16.9/ MSS-SP-75.

7.5 Bore of socket welded fittings shall suit outside diameter (OD) of pipe and its thickness.

7.6 Butt welding ends shall conform to API specification 5L or ASME B 16.25 as applicable. In case of difference in thickness of matching ends, requirements of ASME B 31.4/B 31.3 shall apply.

7.7 Integrally reinforced forged branch fittings such as Thredolet, Sockolet, Weldolet etc. shall be as per MSS-SP-97. Fittings not covered in ASME B16.9 and MSS-SP-97 shall conform to manufacturer’s standard.

7.8 Fittings thickness tolerances shall match pipe thickness tolerance.

8.0 BENDS

8.1 Unless otherwise specified for process piping, elbow of radius R = 1.5 D shall only be used.Minimum Bend Radius D = Specified Outside Diameter.

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 5 of 54

8.2 For main line, Cold field bends with radius R= 30D (where D is pipe OD) shall be used. Limited use of shop fabricated bends radius R = 6D bends (shop bends) may be permitted for reason of space constraints.

8.3 Bends with a bend radius of 3 times nominal pipe diameter can be used on fabricated lines up to and including 1 ½” pipe size for utility services if essentially required.

8.4 In order to accommodate changes in vertical and horizontal alignment in piggable section of pipeline, Elastic bends/ Cold field bends/ Hot formed long radius bends shall be used. Long Radius Bend shall be used only when indicated in the drawing.

8.5 Miters shall not be used.

9.0 FLANGES

9.1 Pressure Temperature rating of flanges shall conform to B16.5/ -SP-44/ B16.47 as applicable.

9.2 Dimensions of flanges shall be in accordance with B16.5/ MSS-5P44/ B16.47 as applicable.

9.3 Neck of weld neck (WN) flanges shall suit pipe bore and thickness.

9.4 Bore of socket welded (SW) flanges shall suit pipe O.D. and its thickness.

9.5 Threads for screwed flanges, if used, shall conform to American Standard taper as per ASME B 1.20.1 NPT.

9.6 Sizes for blind flanges shall be indicated by nominal pipe size.

9.7 Unless specified otherwise in Piping Material Specification the flange face finish shall be as per ASME B16.5/ ASME B 16.47 as applicable.

9.8 For RTJ Flange faces the gasket groove finish shall be smooth finish to 32-63 microinches AARH as per MSS-SP-6. Hardness of Gasket groove shall be minimum 140 BHN.

9.9 Butt welding ends of WN flanges shall conform to ASME B 16.25.

9.10 Spectacle blind/ spacer & blinds shall be in accordance with ASME B16.48/ manufacturer’sstandard.

9.11 Two jack screws, 1800 apart shall be provided in all RTJ flange assemblies and spectacle blind or spacer & blind assemblies as per GAIL standards.

10.0 GASKETS

10.1 Non metallic gaskets for flanged pipe joints shall conform to ASME B 16.21. Gasket material end thickness shall be as indicated in piping material specification for the applicable piping class.

10.2 Spiral wound metallic gasket with compressed asbestos filler shall conform to ASME B16.20/ API 601. All spiral wound gaskets shall be provided with stainless steel centering ring. Gasket thickness shall be as indicated in piping material specification for the applicable piping class.

10.3 Spiral wound gasket shall be self-aligning type.

10.4 For RTJ flanges, octagonal ring type gaskets of soft iron with maximum hardness of 90 BHN conforming to ASME B 16.20 shall be used.

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 6 of 54

11.0 BOLTING & THREADS

11.1 Nuts for stud bolts shall be American Standard Hexagon Heavy Series and double chamfered.

11.2 Dimension and tolerances for stud bolts and nuts shall be as per ASME B18.2.1 and 18.2.2 with full threading to ASME B 1.1 Class 2A thread for bolts and Class 2B for nuts. Diameter and length of stud bolts shall be as per ASME B 16.5/ ASME B16.47 with full threading.

11.3 Threads for nuts shall be as per ASME B 1.1

Nuts for stud bolts dia ¼“ to 1” : UNC-2B

Nuts for stud bolts dia 1⅛ %” to 3¼ : 8UN-2B

11.4 Threads for stud bolts shall be as per ASME B 1.1, as follows:

Stud bolts dia ¼“ to 1” : UNC-2A

Stud bolts dia 1⅛ %” to 3¼ : 8UN-2A

11.5 Heads of jack screws shall be heavy hexagonal type. Jack screw end shall be rounded. Stud bolts shall be fully threaded with two hexagonal nuts.

12.0 THREAD SEALANT

12.1 Threaded joints shall be made with 1” wide PTFE jointing tape.

13.0 VALVES

13.1 Valve ends shall be as per piping material specification for various piping class.

13.2 Sectionalizing valves (Block valves) and other isolation valves installed on the main pipeline shall have butt welding ends. All inline isolation valves on the mainline (pipeline) shall be full bore valves to allow smooth passage of cleaning as well as intelligent pigs.

13.3 All buried valves shall be provided with stem extension as per relevant specification/ data sheet.

13.4 Flange dimensions and face finish of flanged end valves shall conform to clause 9.0 of this specification.

13.5 Butt welding ends of Butt Welded valves shall conform to ASME B 16.25.

13.6 Face to face and end to end dimensions shall conform to applicable standards.

13.7 Valves shall conform to following standards unless specified otherwise in piping materialspecification for various piping class.

Flanged/ Socket Welded end valves (1½” and below)

Gate Valves : API 602 Globe Valves : BS 5352Check Valve : BS 5352Ball Valves : BS 5351 Plug Valves : BS 5353

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 7 of 54

Flanged/ Butt Welded end valves (2” and above)

For Process Lines For Utilities Line

Gate Valves : API 6D(*) API 600Globe Valves : BS 1873 BS 1873Check Valves : API 6D BS 1868Ball Valves : API 6D BS 5351Plug Valves : API 6D -

* Only conduit valves shall be used.

13.8 All manual operated valves shall be provided with wrench / hand wheel or gear operator as specified here in below.

13.8.1 Gate Valves

For ASME class 150 and 300 : Hand wheel operated for size ≤12” NB.Gear operated for size ≥14” NB.

For ASME class 600 : Hand wheel operated for size ≤ 10” NB.Gear operated for size ≥ 12” NB

For ASME class 900 : Hand wheel operated for size ≤ 6” NB.Gear operated for size ≥ 8” NB

13.8.2 Globe Valves

For ASME class 150, 300 and 600- Hand Wheel operated for all size

For ASME class 900 - Hand wheel operated for size ≤ 4” NB.Gear operated for size ≥ 6” NB

13.8.3 Ball valves & Plug Valves

For all ASME class : Wrench operated for size ≤ 4” NB. Gear operated for size ≥ 6” NB.

13.8.4 Power Actuated Valves

Power actuated valves shall have either electrical motor operator or hydraulic actuator as indicated in P&IDs. The actuator shall have provision for remote operation as per P&IDs.

14.0 QUICK OPENING END CLOSURE

Not Applicable

15.0 HYDROTESTING VENTS AND DRAINS

In terminal piping, high point vents and low point drains required for the purpose of hydro testingshall be of size 0.75”. These vents & drains shall consist of threadolet and plug. Plug shall be seal welded after hydrotesting.

TABLE -1

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 8 of 54

W.T

. (m

m)

6.4

ME

TH

OD

OF

MA

NU

FAC

TU

RE

SEA

ML

ESS

, EW

MA

TE

RIA

L

(API

5L

)

API

5L

Gr.

B

TPI

PE

DIA

(I

NC

H)

4

SEC

TIO

N

LIN

E P

IPE

VSP

L (

IP-1

) -

HPC

L B

OT

TL

ING

PL

AN

T

PIPE

LIN

E

Sl.

No.

1. Not

e: (

1)

Des

ign

Fact

or c

onsi

dere

d 0.

72.

(2)

Wal

l thi

ckne

ss in

clud

es 0

.5 m

m c

orro

sion

all

owan

ce.

(3)

Leg

end

: EW

– E

lect

ric

Wel

ded

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 9 of 54

TABLE – 2

Pressure/ Temp & Other Design Conditions for various piping Classes

Design ConditionClass ServicePressure

(Kg/cm2 g)Temp. (0 C)

C.A. (mm)

Pipe Material Design Code

D1A LPG 98.0 65 0.5 API 5L GR- B / ASTM A106 Gr.B as

applicable

ASME B 31.4 / OISD –141

D4A LPG 95.1 65 0.5 A 333 Gr. 6 ASME B 31.4 / OISD –141

B1A LPG 49.0 65 0.5 API 5L GR- B / Gr.X-42 / ASTM A106 Gr.B

as applicable

ASME B 31.4 / OISD –141

B4A LPG 47.4 65 0.5 A 333 Gr. 6 ASME B 31.4 / OISD –141

A1A FO (Diesel) 19.0 65 1.5 ASTM A106 Gr.B ASME B 31.3

A3A Utilities 10.5 65 1.5 ASTM A106 Gr.B ASME B 31.3

A4A LPG 18.1 65 0.5 A 333 Gr. 6 ASME B 31.4

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 10 of 54

ANNEXURE A

PIPING MATERIAL SPECIFICATION

(A1A - CLASS 150#)

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 11 of 54

PIPING CLASS : A1A, 150 #

BASE MATERIAL : CARBON STEEL

CORROSION ALLOWANCE : 1.5 MM

SPECIAL REQUIREMENT : NON IBR

TEMPERATURE (Deg. F) AND PRESSURE ( psig ) RATINGSTEMPERATURE 0F - 20 100 200 300 400 500

PRESSURE (psig) 285 285 260 230 200 170

SERVICE : DIESEL (FUEL OIL)

NOTES

1. PRESSURE – TEMPERATURE RATINGS INDICATED ARE APPLICABLE TO FLANGES AND FLANGED FITTINGS (AS PER ANSI B 16.5).

2. PROCUREMENT OF MATERIALS SHALL BE AS PER THE DETAILED SPECIFICATIONS/ DATA SHEETS AS APPLICABLE.

3. NDT OF WELDS SHALL BE AS PER GAIL SPECIFICATION S-05-02-012.

4. ALL VENTS AND DRAINS SHALL BE PROVIDED WITH GATE VALVE UNLESS OTHERWISE INDICATED IN P&ID.

5. SPECIAL NOTES

ITEM SIZE DESCRIPTION

MAINTENANCE JOINTS

ALLFLANGED TO BE KEPT MINIMUM

0.75” & BELOW SW COUPLING, 6000#

FOR 1.00” & 1.50” SW COUPLING, 3000#

PIPE JOINTS

2.0” & ABOVE BUTT WELDED

ON LINES ≤1.5” REFER GAIL STD.S-05-01-003DRAINS

ON LINES ≥2.0” AS PER P&ID OR 0.75”

ON LINES ≤1.5” REFER GAIL STD – S-05-01-003VENTS

ON LINES ≥2.0” AS PER P&ID OR 0.75”

TEMP. CONN 1.5” FLANGED, INSTALLATION AS PER GAIL STD –S-05-01-005 WITH SOCKOLET.

PRESS. CONN 0.75” SW SCH 160 NIPPLE WITH GATE VALVE INSTALLATION TO SPEC AS PER STD.S-05-01-006

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 12 of 54

72 7270 7068 6866 6664 6462 6260 6058 5856 5654 5452 5250 5048 4846 4644 4442 4240 4038 3836 3634 3432 3230 3028 2826 2624 2422 2220 2018 1816 1614 1412 1210 E 108.0 E E 8.06.0 E E E 6.05.0 5.04.0 E E E E 4.03.5 3.53.0 E E E E E 3.02.5 2.52.0 E E E E E E 2.01.5 T E S S S S S 1.51.25 1.251.0 T T S S S S S S 1.00.75 T T T S S S S S S 0.750.5 T T T T S S S S S S 0.5

BR

AN

CH

PIP

E (

SIZ

E I

N I

NC

HE

S)

0.50

0

0.75

0

1.00

0

1.25

0

1.50

0

2.00

0

2.50

0

3.00

0

3.50

0

4.00

0

5.00

0

6.00

0

8.00

0

10.0

0

BR

AN

CH

PIP

E (

SIZ

E I

N I

NC

HE

S)

RUN PIPE (SIZES IN INCH) – A1A

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 13 of 54

CODE DESCRIPTION

E TEE BW T TEES SWH H.COUPLING W WELDOLETSP PIPE TO PIPE D TEE WITH REDUCERR REINFORCED S SOCKOLETS

Item Type Lower Size (Inch)

Upper Size (Inch)

Sch./ Thk

Dim. STD

Material Description

PIPE GROUP (A1A)

PIPE 00.500 00.750 S160 B 36.10 ASTM A 106 GR.B PE, SEAMLESS

PIPE 01.000 01.500 S 80 B 36.10 ASTM A 106 GR.B PE, SEAMLESS

PIPE 02.000 02.000 S 80 B 36.10 ASTM A 106 GR.B BE, SEAMLESS

PIPE 03.000 04.000 S 40 B 36.10 ASTM A 106 GR.B BE, SEAMLESS

FLANGE GROUP (A1A)

FLNG.WN, RF, SMOOTH

00.500 04.000 M B-16.5 ASTM A 105

FITTING GROUP (A1A)

FITTINGS 00.500 00.750 B-16.11 ASTM A 105 SW, 6000

FITTINGS 01.000 01.500 B-16.11 ASTM A 105 SW, 3000

FITTINGS 02.000 04.000 M B-16.9 ASTM A 234,GR. WPB (USE ASTM A 105 FOR O-LETS)

BW, SEAMLESS

BLINDS (A1A)

BLINDS, RF 00.500 4.000 ASTM A 105

FIGURE-8/ SPACER & BLINDS (A1A)

FIGURE-8/ SPACER & BLINDS, FF

00.500 04.000 ASTM A 105 STD. NO. ASME B 16.48

BOLT GROUP (A1A)

BOLT.STUD 00.500 04.000 B18.2 BOLT: 193 GR.B7,NUT:

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 14 of 54

A194 GR. 2H

Gasket Group (A1A)

GASKET 00.500 04.000 B16.20-ANSI B 16.5

SP,WND, SS316+CAF AND SS 316 CENTERING RING 5.0 mm THK.

CAPS (A1A)

CAPS 00.500 0.750 A 105 SCREWED, 6000#

CAPS 01.000 01.500 A 105 SCREWED, 3000#

CAPS 02.000 04.000 A 234 Gr. WPB SEAMLESS, BW

PERMANENT STRAINER (A1A)

PERMANENT STRAINER

00.500 1.500 BODY A 105, INTERNALS SS 304 SW, 800#, TYPE –Y, MNF. STD.

PERMANENT STRAINER

02.000 4.000 BODY A 234 GR. WPB, INTERNALS SS 304

BW, THK. TO MATCH PIPE THK. TYPE – T, STD. S-05-01-008

VALVE GROUP (A1A)

00.500 01.500 BS 5351 BODY-ASTMA 105, TRIM-ASTM A 182 GR. F304

150#, RF, LONG PATTERN

VLV. BALL

02.000 04.000 API 6D BODY-ASTMA 216 GR. WCB/ A 234 GR. WPB/ A 516 GR. 70, BALL- A 216 GR. WCB/ A 234 GR. WPB/ A 395 + ENP

150#, RF, LONG PATTERN

00.500 01.500 BS-5352 BODY-ASTM A105,TRIM-ASTM A182 GR. F304

SW,800#, PISTON CHECK VALVE

VLV.CHECK

02.000 04.000 BS-1868 BODY-ASTMA 216 GR. WCB,TRIM-ASTMA 216 GR. WCB WITH 13% Cr. OVERLAY

RF ,150#

00.500 01.500 BS-5352 BODY-ASTM A 105,TRIM-ASTM A 182 GR. F304

SW,800#VLV.GLOBE

02.000 04.000 BS-1873 BODY-ASTM A 216 GR. WCB,TRIM-13% Cr. STEEL

RF, 150#

00.500 01.500 API-602 BODY-ASTM A 105, TRIM-A 182 , GR. F 304

SW,800#VLV.GATE

02.000 04.000 API-600 BODY-ASTM A 216 GR. WCB , TRIM-A 216, GR. WCB WITH 13% Cr. OVERLAY

RF, 150#

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 15 of 54

ANNEXURE B

PIPING MATERIAL SPECIFICATION

(A3A - CLASS 150#)

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 16 of 54

PIPING CLASS : A3A, 150 #

BASE MATERIAL : CARBON STEEL

CORROSION ALLOWANCE : 1.5 MM

SPECIAL REQUIREMENT : NON IBR

TEMPERATURE (Deg. F) AND PRESSURE ( psig ) RATINGSTEMPERATURE 0F - 20 100 200 300 400 500

PRESSURE (psig) 285 285 260 230 200 170

SERVICE (ABOVE GROUND) : IA, AP, WD, WS, IG

NOTES

1. PRESSURE – TEMPERATURE RATINGS INDICATED ARE APPLICABLE TO FLANGES AND FLANGED FITTINGS (AS PER ANSI B 16.5).

2. PROCUREMENT OF MATERIALS SHALL BE AS PER THE DETAILED SPECIFICATIONS/ DATA SHEETS AS APPLICABLE.

3. NDT OF WELDS SHALL BE AS PER GAIL SPECIFICATION S-05-02-012.

4. ALL VENTS AND DRAINS SHALL BE PROVIDED WITH GATE VALVE UNLESS OTHERWISE INDICATED IN P&ID.

SPECIAL NOTES

ITEM SIZE DESCRIPTION

MAINTENANCE JOINTS

ALLFLANGED TO BE KEPT MINIMUM

1.5” & BELOW SW COUPLING 3000 #PIPE JOINTS

2.0” & ABOVE BUTT WELDED

ON LINES ≤1.5” REFER GAIL STD.S-05-01-003DRAINS

ON LINES ≥2.0” AS PER P&ID OR 0.75”

ON LINES ≤1.5” REFER GAIL STD S-05-01-003VENTS

ON LINES ≥2.0” AS PER P&ID OR 0.75”

TEMP. CONN 1.5” FLANGED, INSTALLATION AS PER GAIL STD. S-05-01-005 WITH SOCKOLET

PRESS. CONN 0.75 SW SCH 80 NIPPLE WITH GATE VALVE INSTALLATION TO SPEC AS PER STD. S-05-01-006

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 17 of 54

72 7270 7068 6866 6664 6462 6260 6058 5856 5654 5452 5250 5048 4846 4644 4442 4240 4038 3836 3634 3432 3230 3028 2826 2624 2422 2220 2018 1816 1614 1412 1210 108.0 8.06.0 P 6.05.0 5.04.0 E P 4.03.5 3.53.0 E P P 3.02.5 2.52.0 E P P P 2.01.5 T E H H H 1.51.25 1.251.0 T T H H H H 1.00.75 T T T H H H H 0.750.5 T T T T H H H H 0.5

BR

AN

CH

PIP

E (

SIZ

E I

N I

NC

HE

S)

0.50

0

0.75

0

1.00

0

1.25

0

1.50

0

2.00

0

2.50

0

3.00

0

3.50

0

4.00

0

5.00

0

6.00

0

BR

AN

CH

PIP

E (

SIZ

E I

N I

NC

HE

S)

(A3A)

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 18 of 54

CODE DESCRIPTION

E TEE BW T TEES SWH H.COUPLING W WELDOLETSP PIPE TO PIPE D TEE WITH REDUCERR REINFORCED S SOCKOLETS

Item Type Lower Size (Inch)

Upper Size (Inch)

Sch./ Thk

Dim. STD

Material Description

PIPE GROUP (A3A)

PIPE 00.500 00.750 S160 B 36.10 ASTM A 106 GR.B PE, SEAMLESS

PIPE 01.000 01.500 S 80 B 36.10 ASTM A 106 GR.B PE, SEAMLESS

PIPE 02.000 02.000 S 80 B 36.10 ASTM A 106 GR.B BE, SEAMLESS

PIPE 03.000 04.000 S 40 B 36.10 ASTM A 106 GR.B BE, SEAMLESS

FLANGE GROUP (A3A)

FLNG.SW, RF, SMOOTH

00.500 01.500 M B-16.5 ASTM A 105

FLNG.WN, RF, SMOOTH

02.000 04.000 M B-16.5 ASTM A 105

FITTING GROUP (A3A)

FITTINGS 00.500 01.500 B-16.11 ASTM A 105 SEAMLESS, SW, 3000 #

FITTINGS 02.000 4.000 M B-16.9 ASTM A 234,GR. WPB BW, SEAMLESS

BLINDS (A3A)

BLINDS, RF 00.500 4.000 ASTM A 105

FIGURE-8/ SPACER & BLINDS (A3A)

FIGURE-8/ SPACER & BLINDS, FF

00.500 4.000 ASTM A 105 STD. NO. ASME B 16.48

BOLT GROUP (A3A)

BOLT.STUD 00.500 04.000 B-18.20 BOLT : A 193 GR. B7, BOLT : FULLY THREADED, NUT :

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 19 of 54

NUT A 194 GR. 2H HEAVY HEXAGONAL

GASKET GROUP (A3A)

GASKET 00.500 04.000 B-16.20 – ANSI B 16.5

COMPRESSED ASBESTOS, 2.0 mm thk., RING TYPE (IS 2712, Gr. W/3)

CAPS (A3A)

CAPS 00.500 01.500 ASTM A 105 SCREWED, 3000#

CAPS 02.000 04.000 ASTM A 234 GR. WPB SEAMLESS, BW

PERMANENT STRAINER (A3A)

PERMANENT STRAINER

00.500 1.500 BODY CS, INTERNALS SS 304

SW, 800#, TYPE – Y, MNF. STD.

PERMANENT STRAINER

02.000 4.000 BODY CS , INTERNALS SS 304

BW, THK. TO MATCH PIPE THK. TYPE – T, STD. S-05-01-008

VALVES GROUP (A3A)

00.500 01.500 BS 5351 BODY-ASTMA 105, TRIM- ASTM A 182 GR. F304

150#, RFVLV. BALL

02.000 04.000 BS 5351 BODY-ASTMA 216 GR. WCB, BALL- 13 % Cr.

150#, RF,

00.500 01.500 BS-5352 BODY-ASTMA105,TRIM-ASTM A182 GR. F304

SW,800#, PISTON CHECK VALVE

VLV.CHECK

02.000 04.000 BS-1868 BODY-ASTMA 216 GR. WCB,TRIM-ASTM A 216 GR. WCB WITH 13% Cr. OVERLAY

RF ,150#

00.500 01.500 BS-5352 BODY-ASTM A 105,TRIM-ASTM A 182 GR. F304

SW,800#VLV.GLOBE

02.000 04.000 BS-1873 BODY-ASTM A 216 GR. WCB,TRIM-13% Cr. STEEL

RF, 150#

00.500 01.500 API-602 BODY-ASTM A 105, TRIM-A 182 , GR. F 304

SW,800#VLV.GATE

02.000 04.000 API-600 BODY-ASTM A 216 GR. WCB , TRIM-A 216, GR. WCB WITH 13% Cr. OVERLAY

RF, 150#

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 20 of 54

ANNEXURE C

PIPING MATERIAL SPECIFICATION

(A4A - CLASS 150#)

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 21 of 54

PIPING CLASS : A4A, 150 #

BASE MATERIAL : CARBON STEEL

CORROSION ALLOWANCE : 0.5 MM

SPECIAL REQUIREMENT : NON IBR

TEMPERATURE (Deg. F) AND PRESSURE ( psig ) RATINGSTEMPERATURE 0F - 49 100 200 300 400 500

PRESSURE (psig) 265 265 250 230 200 170

SERVICE : LIQUID PETROLEUM GAS (LPG) FLARE/ BLOW DOWN

NOTES

1. PRESSURE – TEMPERATURE RATINGS INDICATED ARE APPLICABLE TO FLANGES AND FLANGED FITTINGS (AS PER ANSI B 16.5).

2. PROCUREMENT OF MATERIALS SHALL BE AS PER THE DETAILED SPECIFICATIONS/ DATA SHEETS AS APPLICABLE.

3. NDT OF WELDS SHALL BE AS PER GAIL SPECIFICATION S-05-02-012.

4. ALL VENTS AND DRAINS SHALL BE PROVIDED WITH GATE VALVE UNLESS OTHERWISE INDICATED IN P&ID.

5. SPECIAL NOTES

ITEM SIZE DESCRIPTION

MAINTENANCE JOINTS

ALLFLANGED TO BE KEPT MINIMUM

0.75” & BELOW SW COUPLING, 6000#

FOR 1.00” & 1.50” SW COUPLING, 3000#

PIPE JOINTS

2.0” & ABOVE BUTT WELDED

ON LINES ≤1.5” REFER GAIL STD.S-05-01-003DRAINS

ON LINES ≥2.0” AS PER P&ID OR 0.75”

ON LINES ≤1.5” REFER GAIL STD – S-05-01-003VENTS

ON LINES ≥2.0” AS PER P&ID OR 0.75”

TEMP. CONN 1.5” FLANGED, INSTALLATION AS PER GAIL STD –S-05-01-005 WITH SOCKOLET.

PRESS. CONN 0.75” SW SCH 160 NIPPLE WITH GLOBE VALVE INSTALLATION TO SPEC AS PER STD.S-05-01-006

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 22 of 54

72 7270 7068 6866 6664 6462 6260 6058 5856 5654 5452 5250 5048 4846 4644 4442 4240 4038 3836 3634 3432 3230 3028 2826 2624 2422 2220 2018 1816 1614 1412 1210 E 108.0 E E 8.06.0 E E E 6.05.0 5.04.0 E E E E 4.03.5 3.53.0 E E E E E 3.02.5 2.52.0 E E E E E E 2.01.5 T E S S S S S 1.51.25 1.251.0 T T S S S S S S 1.00.75 T T T S S S S S S 0.750.5 T T T T S S S S S S 0.5

BR

AN

CH

PIP

E (

SIZ

E I

N I

NC

HE

S)

0.50

0

0.75

0

1.00

0

1.25

0

1.50

0

2.00

0

2.50

0

3.00

0

3.50

0

4.00

0

5.00

0

6.00

0

8.00

0

10.0

0

BR

AN

CH

PIP

E (

SIZ

E I

N I

NC

HE

S)

RUN PIPE (SIZES IN INCH) – A4A

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 23 of 54

CODE DESCRIPTION

E TEE BW T TEES SWH H.COUPLING W WELDOLETSP PIPE TO PIPE D TEE WITH REDUCERR REINFORCED S SOCKOLETS

Item Type Lower Size (Inch)

Upper Size (Inch)

Sch./ Thk

Dim. STD

Material Description

PIPE GROUP (A4A)

PIPE 00.500 00.750 S160 B 36.10 ASTM A 333, Gr. 6 PE, SEAMLESS

PIPE 01.000 01.500 S 80 B 36.10 ASTM A 333, Gr. 6 PE, SEAMLESS

PIPE 02.000 02.000 S 80 B 36.10 ASTM A 333, Gr. 6 BE, SEAMLESS

PIPE 03.000 04.000 S 40 B 36.10 ASTM A 333, Gr. 6 BE, SEAMLESS

FLANGE GROUP (A4A)

FLNG.WN, RF, SMOOTH

00.500 04.000 M B-16.5 ASTM A 350 GR. LF2

FITTING GROUP (A4A)

FITTINGS 00.500 00.750 B-16.11 ASTM A 350, GR. LF2 SW, 6000

FITTINGS 01.000 01.500 B-16.11 ASTM A 350, GR. LF2 SW, 3000

FITTINGS 02.000 04.000 M B-16.9 ASTM A 420 GR. WPL 6 (USE ASTM A 350 GR. LF2 FOR O-LETS)

BW

BLINDS (A4A)

BLINDS, RF, SMOOTH

00.500 04.000 ASTM A 350 GR. LF2

FIGURE-8/ SPACER & BLINDS (A4A)

FIGURE-8/ SPACER & BLINDS, FF

00.500 04.000 ASTM A 350 GR. LF2 STD. NO. ASME B 16.48

BOLT GROUP (A4A)

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 24 of 54

BOLT.STUD 00.500 04.000 B18.2 BOLT: A 320 GR. L7, NUT: A194 GR. 4

Gasket Group (A4A)

GASKET 00.500 04.000 B16.20-ANSI B 16.5

SP,WND, SS316+CAF AND SS 316 CENTERING RING 5.0 mm THK.

CAPS (A4A)

CAPS 00.500 00.750 A 350 GR. LF2 SCREWED, 6000#

CAPS 01.000 01.500 A 350 GR. LF2 SCREWED, 3000#

CAPS 02.000 04.000 A 420 GR. WPL 6 SEAMLESS, BW

PERMANENT STRAINER (A4A)

PERMANENT STRAINER

00.50001.500

BODY A 350 LF2, INTERNALS SS 304

SW, 800#, TYPE –Y, MNF. STD.

PERMANENT STRAINER

02.00004.000

BODY A 420 WPL 6, INTERNALS SS 304

BW, THK. TO MATCH PIPE THK. TYPE – T, STD. S-05-01-008

VALVE GROUP (A4A)

00.500 01.500 BS 5351 BODY-ASTMA 350 GR. LF2, TRIM- 18/8 SS

150#, RF, LONG PATTERN

VLV. BALL

02.000 04.000 API 6D BODY-ASTMA 352 GR. LCB, TRIM – 18/8 SS

150#, RF, LONG PATTERN

00.500 01.500 BS-5352 BODY-ASTM A350 GR. LF2,TRIM- 18/8 SS

SW,800#, PISTON CHECK VALVE

VLV.CHECK

00.200 04.000 API 6D BODY-ASTM A 352 GR. LCB,TRIM-18/8 SS

RF ,150#

00.500 01.500 BS-5352 BODY-ASTM A 350 GR. LF2,TRIM- 18/8 SS

SW,800#VLV.GLOBE

02.000 04.000 BS-1873 BODY-ASTM A 352 GR. LCB, TRIM- 18/8 SS

RF, 150#

00.500 01.500 API-602 BODY-ASTM A 350 GR. LF2,TRIM- 18/8 SS

SW,800#VLV.GATE

02.000 04.000 API-6D BODY-ASTM A 352 GR. LCB, TRIM- 18/8 SS

RF, 150#

00.500 01.500 BS 5353 BODY-ASTM A 350 GR. LF2,TRIM- 18/8 SS

RF, 150#VLV. PLUG

02.000 04.000 API-6D BODY-ASTM A 352 GR. LCB, TRIM- 18/8 SS

RF, 150#

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 25 of 54

ANNEXURE D

PIPING MATERIAL SPECIFICATION

(B1A - CLASS 300#)

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 26 of 54

PIPING CLASS : B1A, 300 #

BASE MATERIAL : CARBON STEEL

CORROSION ALLOWANCE : 0.5 MM

SPECIAL REQUIREMENT : NON IBR

TEMPERATURE (Deg. F) AND PRESSURE ( psig ) RATINGSTEMPERATURE 0F - 20 100 200 300 400 500

PRESSURE (psig) 740 740 675 655 635 600

SERVICE: LIQUID PETROLEUM GAS (LPG)

NOTES

1. PRESSURE – TEMPERATURE RATINGS INDICATED ARE APPLICABLE TO FLANGES AND FLANGED FITTINGS (AS PER ANSI B 16.5).

2. PROCUREMENT OF MATERIALS SHALL BE AS PER THE DETAILED SPECIFICATIONS/ DATA SHEETS AS APPLICABLE.

3. NDT OF WELDS SHALL BE AS PER GAIL SPECIFICATION S-05-02-012.

4. ALL VENTS AND DRAINS SHALL BE PROVIDED WITH GLOBE VALVE UNLESS OTHERWISE INDICATED IN P&ID.

SPECIAL NOTES

ITEM SIZE DESCRIPTION

MAINTENANCE JOINTS

ALLFLANGED TO BE KEPT MINIMUM

0.75” & BELOW SW COUPLING 6000 #

FOR 1.00” & 1.50” SW COUPLING 3000 #

PIPE JOINTS

2.0” & ABOVE BUTT WELDED

ON LINES ≤1.5” REFER GAIL STD.S-05-01-003DRAINS

ON LINES ≥2.0” AS PER P&ID OR 0.75”

ON LINES ≤1.5” REFER GAIL STD S-05-01-003VENTS

ON LINES ≥2.0” AS PER P&ID OR 0.75”

TEMP. CONN 1.50” FLANGED, INSTALLATION AS PER GAIL STD. S-05-01-005 WITH SOCKOLET

PRESS. CONN 0.75” SW SCH 160 NIPPLE WITH GLOBE VALVE INSTALLATION TO SPEC AS PER STD. S-05-01-006

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 27 of 54

72 7270 7068 6866 6664 6462 6260 6058 5856 5654 5452 5250 5048 4846 4644 4442 4240 4038 3836 3634 3432 3230 3028 2826 2624 2422 2220 2018 1816 1614 1412 1210 108.0 8.06.0 E 6.05.0 5.04.0 E E 4.03.5 3.53.0 E E E 3.02.5 2.52.0 E E E W 2.01.5 T E S S S 1.51.25 1.251.0 T T S S S S 1.00.75 T T T S S S S 0.750.5 T T T T S S S S 0.5

BR

AN

CH

PIP

E (

SIZ

E I

N I

NC

HE

S)

0.50

0

0.75

0

1.00

0

1.25

0

1.50

0

2.00

0

2.50

0

3.00

0

3.50

0

4.00

0

5.00

0

6.00

0

BR

AN

CH

PIP

E (

SIZ

E I

N I

NC

HE

S)

(B1A)

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 28 of 54

CODE DESCRIPTION

E TEE BW T TEES SWH H.COUPLING W WELDOLETSP PIPE TO PIPE D TEE WITH REDUCERR REINFORCED S SOCKOLETS

Item Type Lower Size (Inch)

Upper Size (Inch)

Sch./ Thk

Dim. STD

Material Description

PIPE GROUP (B1A)

PIPE 00.500 00.750 S160 B 36.10 ASTM A 106 GR.B PE, SEAMLESS

PIPE 01.000 01.500 S 80 B 36.10 ASTM A 106 GR.B PE, SEAMLESS

PIPE 02.000 02.000 S 80 B 36.10 ASTM A 106 GR.B BE, SEAMLESS

PIPE 03.000 06.000 S 40 B 36.10 ASTM A 106 GR.B BE, SEAMLESS

PIPE 08.000 10.000 6.4 B 36.10 API 5L GR.B BE, SEAMLESS

FLANGE GROUP (B1A)

FLNG.SW, RF, SMOOTH

00.500 01.500 M B-16.5 ASTM A 105

FLNG.WN, RF, SMOOTH

02.000 10.000 M B-16.5 ASTM A 105

FITTING GROUP (B1A)

FITTINGS 00.500 00.750 B-16.11 ASTM A 105 SW, 6000 #

FITTINGS 01.000 01.500 B-16.11 ASTM A 105 SW, 3000 #

FITTINGS 02.000 10.000 M B-16.9 ASTM A 234,GR. WPB (USE ASTM A105 FOR O-LETS)

BW, SEAMLESS

BLINDS (B1A)

BLINDS, RF 00.500 10.000 ASTM A 105

FIGURE-8/ SPACER & BLINDS (B1A)

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 29 of 54

FIGURE-8/ SPACER & BLINDS, FF

00.500 10.000 ASTM A 105 STD. NO. ASME B 16.48

BOLT GROUP (B1A)

BOLT.STUD 00.500 10.000 B-18.20 BOLT : A 193 GR. B7, NUT A 194 GR. 2H

BOLT : FULLY THREADED, NUT : HEAVY HEXAGONAL

GASKET GROUP (B1A)

GASKET 00.500 10.000 B-16.20 – ANSI B 16.5

SS 316 SPIRAL WOUND WITH CAF FILLER AND SS 316 CENTERING RING 5.0 mm THK.

CAPS (B1A)

CAPS 00.500 00.750 ASTM A 105 SCREWED, 6000#

CAPS 01.000 01.500 ASTM A 105 SCREWED, 3000#

CAPS 02.000 04.000 ASTM A 234 GR. WPB SEAMLESS, BW

PERMANENT STRAINER (B1A)

PERMANENT STRAINER

00.500 1.500 BODY A 105, INTERNALS SS 304 SW, 800#, TYPE –Y, MNF. STD.

PERMANENT STRAINER

02.000 4.000 BODY A 234 GR. WPB , INTERNALS SS 304

BW, THK. TO MATCH PIPE THK. TYPE – T, STD. S-05-01-008

PERMANENT STRAINER

06.000 10.000 BODY A 234 GR. WPB, INTERNALS SS 304

BW, THK. TO MATCH PIPE THK. TYPE – T, STD. S-05-01-009

VALVES GROUP (B1A)

00.500 01.500 BS 5351 BODY-ASTMA 105, TRIM-ASTM A 182 GR. F304

300#, RF, LONG PATTERN

VLV. BALL

02.000 14.000 API 6D BODY-ASTMA 216 GR. WCB/ A 234 GR. WPB/ A 516 GR. 70, BALL- A 216 GR. WCB/ A 234 GR. WPB./ A 395 + ENP

300#, RF, STEM AISI 4140 + ENP

00.500 01.500 BS-5352 BODY-ASTM A105,TRIM-ASTM A182 GR. F304

SW,800#, PISTON CHECK VALVE

VLV.CHECK

02.000 14.000 API 6D BODY-ASTMA 216 GR.WCB,TRIM-ASTM A 216 GR. WCB WITH 13% Cr. OVERLAY

RF ,300#

00.500 01.500 BS-5352 BODY-ASTM A 105,TRIM-ASTM A 182 GR. F304

SW,800#VLV.GLOBE

02.000 14.000 BS-1873 BODY-ASTM A 216 GR. WCB,TRIM-13% Cr. STEEL

RF, 300#

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 30 of 54

00.500 01.500 API-602 BODY-ASTM A 105, TRIM-A 182 , GR. F 304

SW,800#VLV.GATE

02.000 14.000 API-6D BODY-ASTM A 216 GR. WCB ,TRIM-A 216, GR. WCB WITH 13% Cr. OVERLAY

RF, 300#

00.500 01.500 API-602 BODY-ASTM A 105, PLUG-A 182 , GR. F 304

SW,800#VLV.PLUG

02.000 14.000 API-6D BODY-ASTM A 216 GR. WCB/ A 234 GR. WPB/ A 516 GR. 70 ,PLUG-A 216, GR. WCB/ A 234 GR. WPB/ A 395 +ENP

RF, 300#

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 31 of 54

ANNEXURE E

PIPING MATERIAL SPECIFICATION

(B4A - CLASS 300#)

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 32 of 54

PIPING CLASS : B4A, 300 #

BASE MATERIAL : CARBON STEEL

CORROSION ALLOWANCE : 0.5 MM

SPECIAL REQUIREMENT : NON IBR

TEMPERATURE (Deg. F) AND PRESSURE ( psig ) RATINGSTEMPERATURE 0F - 49 100 200 300 400 500

PRESSURE (psig) 695 695 655 640 620 585

SERVICE: LIQUID PETROLEUM GAS (LPG) FLARE / BLOW DOWN

NOTES

1. PRESSURE – TEMPERATURE RATINGS INDICATED ARE APPLICABLE TO FLANGES AND FLANGED FITTINGS (AS PER ANSI B 16.5).

2. PROCUREMENT OF MATERIALS SHALL BE AS PER THE DETAILED SPECIFICATIONS/ DATA SHEETS AS APPLICABLE.

3. NDT OF WELDS SHALL BE AS PER GAIL SPECIFICATION S-05-02-012.

4. ALL VENTS AND DRAINS SHALL BE PROVIDED WITH GLOBE VALVE UNLESS OTHERWISE INDICATED IN P&ID.

SPECIAL NOTES

ITEM SIZE DESCRIPTION

MAINTENANCE JOINTS

ALLFLANGED TO BE KEPT MINIMUM

0.75” & BELOW SW COUPLING 6000 #

FOR 1.00” & 1.50” SW COUPLING 3000 #

PIPE JOINTS

2.0” & ABOVE BUTT WELDED

ON LINES ≤1.5” REFER GAIL STD.S-05-01-003DRAINS

ON LINES ≥2.0” AS PER P&ID OR 0.75”

ON LINES ≤1.5” REFER GAIL STD S-05-01-003VENTS

ON LINES ≥2.0” AS PER P&ID OR 0.75”

TEMP. CONN 1.5” FLANGED, INSTALLATION AS PER GAIL STD. S-05-01-005 WITH SOCKOLET

PRESS. CONN 0.75 SW SCH 160 NIPPLE WITH GLOBE VALVE INSTALLATION TO SPEC AS PER STD. S-05-01-006

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 33 of 54

72 7270 7068 6866 6664 6462 6260 6058 5856 5654 5452 5250 5048 4846 4644 4442 4240 4038 3836 3634 3432 3230 3028 2826 2624 2422 2220 2018 1816 1614 1412 1210 108.0 8.06.0 E 6.05.0 5.04.0 E E 4.03.5 3.53.0 E E E 3.02.5 2.52.0 E E E E 2.01.5 T E S S S 1.51.25 1.251.0 T T S S S S 1.00.75 T T T S S S S 0.750.5 T T T T S S S S 0.5

BR

AN

CH

PIP

E (

SIZ

E I

N I

NC

HE

S)

0.50

0

0.75

0

1.00

0

1.25

0

1.50

0

2.00

0

2.50

0

3.00

0

3.50

0

4.00

0

5.00

0

6.00

0

BR

AN

CH

PIP

E (

SIZ

E I

N I

NC

HE

S)

(B4A)

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION

0002-04-05-02-001Page 34 of 54

CODE DESCRIPTION

E TEE BW T TEES SWH H.COUPLING W WELDOLETSP PIPE TO PIPE D TEE WITH REDUCERR REINFORCED S SOCKOLETS

Item Type Lower Size (Inch)

Upper Size (Inch)

Sch./ Thk

Dim. STD

Material Description

PIPE GROUP (B4A)

PIPE 00.500 00.750 S160 B 36.10 ASTM A 333, Gr. 6 PE, SEAMLESS

PIPE 01.000 01.500 S 80 B 36.10 ASTM A 333, Gr. 6 PE, SEAMLESS

PIPE 02.000 02.000 S 80 B 36.10 ASTM A 333, Gr. 6 BE, SEAMLESS

PIPE 03.000 04.000 S 40 B 36.10 ASTM A 333, Gr. 6 BE, SEAMLESS

FLANGE GROUP (B4A)

FLNG.SW, RF 00.500 01.500 M B-16.5 ASTM A 350 GR. LF2

FLNG.WN, RF 02.000 04.000 M B-16.5 ASTM A 350 GR. LF2

FITTING GROUP (B4A)

FITTINGS 00.500 00.750 B-16.11 ASTM A 350 GR. LF2 SW, 6000 #

FITTINGS 01.000 01.500 B-16.11 ASTM A 350 GR. LF2 SW, 3000 #

FITTINGS 02.000 04.000 M B-16.9 ASTM A 420 GR. WPL 6 (USE A350 GR. LF2 FOR O-LETS)

BW, SEAMLESS

BLINDS (B4A)

BLINDS, RF 00.500 04.000 ASTM A 350 GR. LF2

FIGURE-8/ SPACER & BLINDS (B4A)

FIGURE-8/ SPACER & BLINDS, FF

00.500 04.000 ASTM A 350 GR. LF2 STD. NO. ASME B 16.48

BOLT GROUP (B4A)

BOLT.STUD 00.500 4.000 B-18.20 BOLT : A 320 GR. L7, NUT A 194 BOLT : FULLY THREADED,

SPECIFICATION REV-0 GAIL (INDIA) LTD NEW DELHI

PIPING MATERIAL SPECIFICATION