Vise clamping inserts - niederhauser.ch€¦ · 58451139 oml - vise power 130 52 90 25 - 12 14 11 -...

Transcript of Vise clamping inserts - niederhauser.ch€¦ · 58451139 oml - vise power 130 52 90 25 - 12 14 11 -...

05/2015

Vise clamping inserts

Contents:

Introduction / Product Overview SinterGrip ........................................................................4

The advantages of the system ..............................................................................................5

Technical features ...............................................................................................................6-7

Charts ......................................................................................................................................8

Jaws STANDARD ....................................................................................................................9

Jaws STARTER KIT ..............................................................................................................10

SinterGrip Inserts ................................................................................................................. 11

Accessoires .......................................................................................................................... 11

4 technical subject to change

Conventional method

SinterGrip method

Introduction / Product Overview SinterGripOur new product SinterGrip is born to satisfy the current need to clamp a workpiece for very few millimeters (with SinterGrip 3.5mm clamping surface)!

And this for the following reasons:

1. In order to machine the workpiece completely in a single operation. (especially for 5 axis machines)

2. In order to save money for the raw materials, especially when they have a big impact on the price (aluminium, titanium, etc.)

Indirectly to these reasons, and in order to improve the performance of the machine tool and the tools.

higher cutting speed + higher feed rate = bigger volume of metal removed = less time to machine the workpoce,

the market requires safe clamping, which could at the same time possibly avoid the deformations of the piece itself.

Only 3.5 mm clamping surface, no need of pre-machining the workpiece, clamping stability, higher cutting rate: SinterGrip brings only advantages compared to the traditional systems.

On the contrary, traditional systems need, for the clamping of the workpiece, a bigger clamping surface, with the result of waste of raw materials and greater possibility of deformation of the workpiece.

3.5 mm

30 mm

5technical subject to change

The advantages of the system

It doesn’t need to use a special machine or tool to realize the punching

It doesn’t need a pre-machining on the workpiece, (as dovetail or others)

- It doesn’t require to use a new vise or other

- Exceptional stability of the workpiece clamping

- No vibrations

- Nodeformations(byreducingtheclampingforceafterthefirstpunching)

- Minimum depth of the workpiece clamping: only 3.5 mm

- Huge savings in materials

- Possibility to machine the workpiece with very short tools (for 5 axis machines)

- Huge metal removal rate of = less time to machine the workpiece

- Geometric couplings without any clearance

- Different types of SinterGrip for different materials (aluminium, steel and hardned steel)

1

1

2

2

6 technical subject to change

Technical featuresSinterGrip are solid carbide serrated inserts type ISO P30:P35 and coated with method PVD

Coated cemented carbide currently represents 80 - 90 % of all cutting tool inserts. Its success as a tool material is due to its unique combination of wear resistance and toughness, and its ability to be formed in complex shapes.

Coated cemented carbide combines cemented carbide with a coating. Together they form a grade which is customized for its application.

The big advantage of SinterGrip is therefore the combination of this material together with its own teeth sharpening, the special tapered shape and the special triangular shape, coming from detailed studies by our technical department.

In a general sense, the insert with its own special section of pyramid shape and special teeth sharpening penetrates into the material of the workpiece and creates some coupling without any clearance, unloading the forces and the vibrations, becoming a sole body with the vise and the workpiece.

The special triangular shape creates a coupling without any clearance, in fact:- It divides the clamping forces;- It allows high coupling precision between the gripper (insert) and the jaw of the vise;- It absorbs the vibrations, allowing high stability.

The special tapered shape (5 degrees) of the inserts section:- Creates pull-down effect into the insert which is transferred to the workpiece, avoiding the lifting of the same.

The special teeth sharpening:- The lower angle is bigger than the upper one. This creates a pull-down effect on the workpiece;- Permits, after the engraving, to clamp the workpiece with a lower clamping force, avoiding any deformation of the same.

1

2

3

The combination of both elements (the tapered shape and the teeth sharpening) creates a double pull-down effect.

1 2

3

7technical subject to change

Technical featuresInsert SinterGrip for steel (STD) Insert SinterGrip for aluminium (ALU)

Insert SinterGrip for hard steel and titanium (until 50 - 54 HRC) Engraving in aluminium

Depth penetraiton stop surface

70º

40º 30º

0.41

0.19

3.18

2.8610.69

A

A

A-A

5º

70º

0.621.88

0.30

70º

40º 30º

0.36

0.3

0.3

3.18

0.59

1.710.81 70º

A

A

A-A

5º

70º

40º 30º

0.39

0.4

0.3

3.18

0.59

2.0510.81

A

A

A-A

5º

90º

0.30

8 technical subject to change

ChartsThe values indicate in the chart are those of the penetration of each tooth of the insert, in relation to the number of inserts used, the type of material and the clamping force.

The ratio between inserts and penetration depth is inversely proportional, that is, fewer inserts = more penetration.

Steelwithtensilestrength≈980N/mm2

5 Inserts/jaw - 10 Inserts totalclamping surface 3.5 mm

Steelwithtensilestrength≈980N/mm2

1 Inserts/jaw - 2 Inserts totalclamping surface 3.5 mm

Hardened steel HRC 50 - 545 Inserts/jaw - 10 Inserts totalclamping surface 3.5 mm

Steelwithtensilestrength≈980N/mm2

5 Inserts/jaw - 10 Inserts totalclamping surface 2 mm

Aluminium 5 Inserts/jaw - 10 Inserts totalclamping surface 3.5 mm

Example: Steelwithtensilestrength≈980N/mm2

5 Inserts/jaw - 10 Inserts totalclamping surface 3.5 mm

Pen

etra

tion

dept

h

Clamping force Clamping force

Clamping force Clamping force

Clamping force

Clamping force

Pen

etra

tion

dept

hP

enet

ratio

n de

pth

Pen

etra

tion

dept

hP

enet

ratio

n de

pth

Penetration depth

0,00

0,15

0,10

0,20

0,05

mm.

Kg.3000 4000

0,13

0,16

0,00

0,03

0,02

0,04

0,01

mm.

Kg.3000 4000

0,02

0,03

mm.

Kg.3000

0,33

2000

0,30

4000

0,370,400,350,300,250,200,150,100,050,00

0,50

0,40

0,30

0,20

0,10

0,00

mm.

Kg.3000

0,40

2000

0,39

1000

0,30

4000

0,43

mm.

Kg.3000 4000

0,16

0,280,30

0,25

0,20

0,15

0,10

0,05

0,00

0.16 mm

4000 kg

StahlSteelAcier

9technical subject to change

JawsSinterGrip can be used with all the mechanical, mechanical-hydraulic or hydraulic clamping systems. For all the other clamping systems, please check the compatibility of these systems with grippers.

Shape of the self-centring seat of the inserts with dovetail interlocking

Fixing holes to the vise

Made of steel with tensile strength ≈1080N/mm2+nitriding

1

2

3

STANDARD

Scope of delivery:- 1 x Set of Jaws- 1 x Set of Parallels (PP)- 1 x Wrench Torx T9- 1 Set Screws (10 pce.)

Check the dimensions of your jaw bofore purchasing.

Special jaws "Standard" upon request

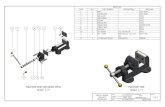

Order number Type A B C D D1 E F ø ø1 PP No.Inserts

58451119 ALLMATIC - T-REX / TITAN 124.4 39.5 88 12.3 18 12 14 7 11 36.5 958451129 GRESSEL / WNT / SCHUNK / FRESMAK 125 40 80 15 - 12 14 9 - 36.5 958451139 OML - VISE POWER 130 52 90 25 - 12 14 11 - 49 958451149 HILMA 125 45 80 14 - 12 14 9 - 42 958451219 OML - TC/MC 150 mm 148 50 110 28 - 12 15 9 - 47 958451229 KURT 6" 152 44.1 98.4 23.6 - 18.4 15.875 11 . 41 958451319 ALLMATIC - T-REX / TITAN 160 49.8 88 12.3 20 12 14 7 11 47 1158451329 GRESSEL / WNT / SCHUNK / FRESMAK 160 50 100 20 - 12 14 11 - 47 1158451339 OML - VISE POWER 160 55 90 25 - 12 14 11 - 52 1158451349 HILMA 160 54 100 17 - 12 14 11 - 51 1158451419 OML - TC/MC 200 mm 196 70 130 49 - 18 15 9 - 67 13

1

2 2

3

C

AF

D D

1

BØ

Ø1

E

10 technical subject to change

Scope of delivery:- 1 x Set of Jaws- 1 x Wrench Torx T9- 1 Set Screws (10 pce.)

Shape of the self-centring seat of the inserts with dovetail interlocking

Step 3.5 x 4 mm

Made of steel with tensile strength ≈980N/mm2+nitriding

1

2

3

STARTER KIT

... and how it works

Order number A B F No. Inserts

58453119 125 59 14 958453319 160 59 14 958453419 200 70 15 9

Take the necessary dimensions of your vise

Drill the jaws at the same height of the supports of the vise

Mill the jaws to the necessary height

Mount the kit onyour vise

1 2

3

A

F

B

3.5

164

1 3

2 4

11technical subject to change

SinterGrip Inserts

Accessories

Sintergrip insertsThe set includes 10 inserts

Order number Description

58450119 Set 10 SinterGrip - inserts STD for steel

Order number Description

58450129 Set 10 SinterGrip - inserts HRC for hardened steel / titanium until 50-54 HRC

Order number Description

58450139 Set 10 SinterGrip - inserts for ALU

Order number Description

58450219 Kit 10VTX30 x inserts SinterGrip

Order number Description

58450310 Screwdriver TORX T9

Order number Description

58450320 Wernch TORX T9

Order number Description

58450410 Special cutting tool D3

Order number Description

58450519 Kit 10 protection inserts in aluminium

FN NIEDERHAUSER AG

Allemd 39 CH - 6204 Horw

phone 0041 / (0)41 340 50 75 / fax 0041 / (0)41 340 50 74

[email protected] / www.niederhauser.ch

![Welcome [] · 2019-08-05 · OML 1 OML 2 OML 3 OML 4 OML 5 Technology Standards Standards not defined without goal to standardize. ... to last replication interval Virtual Machine](https://static.fdocuments.in/doc/165x107/5f330ca087e5a327623269bd/welcome-2019-08-05-oml-1-oml-2-oml-3-oml-4-oml-5-technology-standards-standards.jpg)