Viking Warm Roof also featuring Viking WarmSpan€¦ · 76mm Rigid Insulation Board Waterproofing...

Transcript of Viking Warm Roof also featuring Viking WarmSpan€¦ · 76mm Rigid Insulation Board Waterproofing...

Viking Warm Roof also featuring Viking WarmSpan

The most energy efficient roof insulation system

Clear Ceiling Cavity

76mm Rigid Insulation Board

Waterproofing Membrane

Substrate

Joists

Ceiling

Flush Downlight

Polyurethane Foam Adhesive

Vapour Barrier

Waterproofing Membrane

Roof Vent

Substrate

Traditional Insulation (eg Glass Wool)

Joists

Ceiling

Flush Downlight

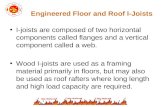

What is a Warm Roof?The most commonly accepted definition of a warm roof (for low slope roofs) is “a roof where the insulation is installed on top of the roof structure” i.e. insulated from the outside of the building. The Viking Warm Roof includes rigid polyisocyanurate (closed-cell foam) sheets on top of which the waterproofing membrane is adhered.

With a correctly designed warm roof:

n The dew point is on the outside of the building = no damp or rotten materials inside

n Thermal bridging is avoided

n The roof cavity is clear for wiring (not stuffed with insulation)

n The savings in air conditioning and heating costs hugely shorten the amortisation period of the initial warm roof cost

n The rigid insulation sheets add further structural integrity to the roof

n Significantly higher R-values are achieved (uniformly across the entire roof; not just in parts)

n Warm roof insulation systems can easily be retrofitted onto an existing building

n No ventilation of the ceiling cavity is required

What components make up a Viking Warm Roof?n Vapour barrier (for cool stores and regions with extreme climatic variances)

n Kingspan Polyiso insulation panel (including tapered)

n Any of Viking’s sheet membrane systems

The ‘Cold Roof’ MethodIn contrast to this technique, the mainstream method of insulating roofs in New Zealand is what’s commonly referred to as the “cold-roof” method where the insulation (usually glass wool), is stuffed between rafters/joists in the ceiling cavity i.e. on the inside of the building. But there are a number of shortfalls with this system.

With internal moisture levels in modern buildings higher than ever before, excess moisture rises up through gaps such as down-lights into the roof cavity. If the roof cavity is insufficiently vented, the moist air finds its dew point when it meets the underside of the roof substrate (the “cold deck”). This condensation can lead to rotting roof substrates, damp ceilings and wet insulation (which eventually renders it ineffective).

Even if the roof cavity is sufficiently vented a great deal of heat can be lost in the process. The maximum thickness of the wool insulation is restricted by the depth of the rafters/joists.

In 2007, the Department of Building and Housing introduced “H1” – the code requirement for building insulation; the aim of which was to decrease the amount of heating energy required by 30%, to achieve healthy indoor temperatures.

Despite approximately 300,000 homes still being inadequately insulated, New Zealanders are looking increasingly closer at energy efficiency. There has never been a better time to invest in a “warm roof”…

Cold Roof

Warm Roof

Appraisal No.826 [2014]

Why a Viking Warm Roof?n Polyiso board supplied by Kingspan Insulation (World leading rigid insulation manufacturer)

n F.A.S.T. adhesive to secure panels to substrate (Avoids mechanical fasteners and therefore some thermal bridging)

n Any Viking sheet membrane can be used on it

n Torchable surface for torch-on membrane option

n Thermal performance of the system helps towards achieving green star points for a building

n BRANZ appraised to ensure it meets New Zealand building code requirements

n Full System Warranty option* = peace of mind

n Tapered option = maximum watershed

n Highest R-Value = maximum ROI

n Rigid insulation sheets = dimensional stability

n Highest possible fire performance rating (Group 1-S) = peace of mind

n No CFCs in manufacture = environmentally friendly

n Perfect as an overlay option = avoids re-roofing

* Conditions apply

The Building Code The Building Code is performance based, meaning the architect has the freedom to use any method of insulating a building provided the minimum R-value performance specified for the building’s geographic zone will be met.

If the building does not meet the minimum requirements for each of its categories (roof, walls, floor etc), calculation or modelling methods can be used where some well insulated areas can compensate for low insulation in others to achieve an acceptable aggregate R-value for the building.

Due to its very high thermal efficiency, a Viking Warm Roof can assist in this way with architectural designs that have a disproportionate amount of glazing (thermally inefficient) to make the most of a view. For more information visit: www.dbh.govt/energy-efficiency

Insulation Efficiency Comparison (R-Value from new)

0

0.25

0.50

0.75

1.25

1.00

Paper Board

Gypsum

Plywood

Fibre Board

Fibreglass Batts

Extruded Polystyrene

Skellerup Polyiso

R-V

alue

per

25m

m

Kingspan Polyiso

Extruded Polystyrene

Fibreglass Batts

Fibre Board

Plywood

Gypsum

Paper Board

Trough opening Min Thickness

75mm or less 25mm

200mm or less 50mm

300mm or less 75mm

Polyiso Spanning Capabilities on Metal Roof Seams

Comprehensive Quality AssuranceA Viking Warm Roof is backed by a 20 year warranty and is eligible to apply for the Viking Full System Warranty.

20YEARS

•VI

KING PRODUCT

•

WA

R R A N

TY

Kingspan Polyiso Long Term R-Values*

*’Long Term Thermal Resistance’ which is the average R-Value over the life of the product

Thickness Panel Dimensions LTTR

25mm 1.2 x 2.4 0.95

50mm 1.2 x 2.27 1.90

75mm 1.2 x 2.27 2.85

The Overlay Option Thermal efficiency aside, a warm roof is a perfect, practical solution for overlaying over an existing low-slope roof with weather-tightness issues (of any substrate including metal).

This is especially useful for buildings with inhabitants and/or expensive items and/or critical activities taking place inside, that would normally require re-locating if the existing roof had to be removed and fully replaced eg: supermarkets; schools; hospitals; manufacturing facilities. The Warm Roof option negates the need for relocation of people and contents and avoids the expensive waste disposal of the existing roof and scaffolding/shrink wrap covering required to maintain weather tightness during replacement.

In the case of existing low-slope metal roofs, a warm roof overlay can avoid the expensive carpentry involved in re-pitching the roof plane up to the minimum three degree slope requirement.

What’s more, electricity savings from the building’s new energy efficiencies can amortise the entire re-roof cost as quickly as eight years after installation (depending on the thickness used and colour of membrane installed on top – Refer to Supermarket Case study).

Tapered ServiceUsing tapered polyiso panels can be a practical solution to promote watershed near to roof outlets, or for some projects, to slope a whole roof rather than re-pitch the flat substrate. Viking has two ways of providing tapered insulation:

Proprietary Tapered Sheets

Viking currently stocks two sizes of Kingspan tapered sheets; each with a one degree slope which can be cut to size and/or doubled-up to form a two degree slope if desired.

Code Description

VWT050Tapered Polyiso 1.2m x 1.2m

(50mm –30mm)

VWT070Tapered Polyiso 1.2m x 1.2m

(70mm –50mm)

Bespoke Tapered Service

Kingspan offers a premium service whereby a building’s plans can be supplied to their head office in the UK. With the specific slope specified along with the positioning of the hips and valleys, the tapered insulation can be priced as a custom tapered roof that is supplied as a numbered ‘jigsaw’ that can be fitted for that roof substrate on site. A minimum lead-time of 14 weeks will be required after the price has been accepted.

Kingspan Insulation Represented in 70 countries (in 59 of which their insulation manufacturing facilities are located), Kingspan is one of the world’s leading suppliers of panel-based insulation systems. With the provision of energy efficient systems as their reason-for-being, they are also leaders in the harnessing of solar and wind energy.

More importantly, Kingspan Insulation has a sales office in Auckland, New Zealand, from where their NZ Manager (mostly on a technical capacity) works in partnership alongside Viking Roofspec to assist all project key stakeholders from the architect, builder and roofing contractor, through to the council and end-user in the appropriate specification and use of their world-class products. For more information on Kingspan visit www.kingspaninsulation.co.nz

Property

Compressive Strength1.5kPa @ 10%

compression (BS EN 826)

Water Vapour Resistance>300MN s/g-m

(BS EN 12086)

Fire Performance Rating Group 1-S (ISO9705)

Kingspan Physical Properties

CHALLENGE: THE COUNTDOWN SUPERMARKET IN CARLYLE STREET, NAPIER, HAS A STEEL ROOF WHICH HAD BEEN BENT AND SPLIT DUE TO FOOT TRAFFIC. AS A RESULT THE ROOF HAD BEEN LEAKING INTO THE SUPERMARKET. THE BUILDING IS OWNED BY THE OYSTER GROUP, WHICH IS A SPECIALIST PROPERTY COMPANY, OPERATING THROUGHOUT NEW ZEALAND.

SolutionIn order to protect the building; Countdown’s stock; and its customers, a new roof was required. Representatives from Viking Roofspec met with The Oyster Group to discuss three options:

1. Replacement with a heavier gauge steel roof 2. Replacing the roof with ply and membrane 3. Overlaying the steel with a Warm Roof System.

Viking recommended the installation of the Viking Warm Roof. This is an overlay system where rigid sheets of polyurethane foam insulation called Polyiso, are installed on top of the steel. Polyiso renders the best R-value (energy-saving capacity per inch) of any insulation in the market. Viking Enviroclad membrane is then adhered on top to provide the waterproofing layer. The advantages of the Viking Warm Roof System are:

n Eliminating damage by foot traffic creating water ingress

n Adding structural integrity due to the adhered rigid insulation layer

n As the warm roof is an overlay system, the old roof didn’t need to be removed. Otherwise there would have been costly downtime from evacuating the building during the re-roofing process

n No costs associated with disposing of the current steel roof – (both labour and steel disposal costs)

n No need to uplift the existing air-conditioning and plant units

n Vital Energy Savings - The Warm Roof offers the benefit of insulating the building during the changing New Zealand seasons. Extra insulation leads to vital energy savings. Additionally, the white Enviroclad membrane reflects 92% of the sun’s radiation, so during the hot Hawkes Bay summers, the reflective roof will bring further energy savings

n The roof will deliver ongoing financial contributions to the building, eventually rendering itself as a “free” roof to The Oyster Group

n For peace of mind, Viking only has licenced applicators installing its materials, which gives them the confidence to provide a 20 year product warranty of substance.

ResultThe Oyster Group purchased the Viking Warm Roof System to protect the building; offer security and peace of mind to its customers and to avoid having to close the store down while the roof was replaced. It also provides the added benefit of significant energy savings, which will eventually pay for the roof and contribute financially to the building.

INNOVATIVE RE-ROOF SOLUTION – COUNTDOWN SUPERMARKET, NAPIER

ADDED BENEFIT OF SIGNIFICANT ENERGY SAVINGS WHICH WILL EVENTUALLY PAY FOR THE ROOF.

Case Study: Viking Warm Roof

Auckland Office80 Alexander Crescent, OtaraPO Box 14-541, PanmureAuckland 1741, New Zealand

Christchurch Office2 Nazareth Avenue, MiddletonPO Box 9117, Tower JunctionChristchurch 8149, New Zealand

T. 0800 729 799F. 0800 729 [email protected]

Warm roofs need not be complex. Viking Roofspec has developed the country’s simplest, yet most energy-efficient and cost-effective warm roof-on-steel system – Viking WarmSpan.

What is Viking WarmSpan?It is a proprietary warm roof-on-steel-tray system. This is made up of a wide-spanning steel tray roof deck, which also forms the vapour barrier with its flashing system. Kingspan Polyisocyanurate (PIR) rigid insulation panels are adhered on top and the system is completed with any of Viking Roofspec’s sheet waterproofing membrane systems.

How does Viking ‘WarmSpan’ differ from ‘Warm Roof’?Viking WarmSpan is a Warm roof, but to date, Viking’s Warm roofs have comprised of our polyiso panels and membranes installed on concrete, ply or steel substrates already in-situ (new or old), whereas the Viking WarmSpan system includes the substrate supplied by Viking as well – in this instance, a steel tray that has been specifically engineered and tested for New Zealand’s Building Code and conditions.

What is the number one benefit of Viking WarmSpan?Viking WarmSpan significantly reduces a building’s overall structural costs without compromising the integrity of the building. With a spanning ability between purlins of up to 3.6m (versus the 400mm centred joists required under a heavy 17mm plywood substrate), WarmSpan is not just a roofing system, it’s a tool that facilitates a smarter method of overall building construction.

What are the other benefits of WarmSpan?n Simplicity – avoids using unnecessary components;

n Cost – the most cost-effective in the market;

n Spanning ability – up to 3.6m between purlins;

n Less weight than a traditional warm roof –eg: loading on building reduced by 2/3 over timber;

n No thermal bridging – no mechanical fasteners thanks to F.A.S.T. adhesive technology;

n Highest possible fire rating – Group 1S

n Integrated vapour barrier – one less layer than other systems.

n Wind uplift resistance - F.A.S.T. Adhesive System rivals uplift of any mechanical fastener.

What testing has been completed with Viking WarmSpan?Nationally-recognised engineers – Holmes Solutions, completed point-load and uniform-distributed-load of the system over a range of purlin spans. WarmSpan is the only NZ engineering-certified warm-roof-on-steel system that has been developed and tested to meet the wind and snow load loadings specified for the building code. (See engineering report on our website: www.vikingroofspec.co.nz)

Appraisal No.826 [2014]

What components will Viking Roofspec supply?Viking Roofspec will supply the entire WarmSpan system, including the steel. One system – one warranty. This is in-keeping with Viking Roofspec’s ethos of providing a complete, tested system.

Vapour BarrierViking WarmSpan’s steel-tray with its air-tight flashing system, forms the integral vapour barrier in contrast to other systems that have a separate peel-and-stick membrane which is punctured with thousands of mechanical fasteners.

Cover Board?There is nothing preventing a cover board being specified with Viking WarmSpan, however it is simply not necessary from a point-load resistance perspective. Even Kingspan’s thinnest polyiso (25mm), exceeds the minimum code requirements for an ‘unrestricted access’ roof in terms of durability (1.5kPa). Additionally, most roofs have little foot traffic except for maintenance staff. But if you’re still concerned about insulation damage, weldable walkway matting is a cost-effective, tough and sensible option, as it covers only a small percentage of the roof area, in the form of a ‘path’, yet it directs all foot traffic where you want it to go.

In Conclusion:Viking WarmSpan provides assistance to building owners and architects with the supply of a fully-engineered; energy-efficient low-slope roof system that reduces the total construction costs of the roof and the building significantly, while delivering increased performance and greater durability.

A Warm Roof should be simple, flexible, cost-effective and energy efficient. Furthermore, it’s one system which comes with one – all encompassing warranty. Don’t be wooed by the unnecessary complexity that other highly-tricked, yet “less effective systems offer.”

“WarmSpan is not just a roofing system, it’s a tool that facilitates a smarter method of overall building construction.”

Comprehensive Quality AssuranceViking WarmSpan is backed by a 20 year warranty and is eligible to apply for the Viking Full System Warranty.

20YEARS

•VI

KING PRODUCT

•

WA

R R A N

TY

CHALLENGE: THE ICONIC CHRISTCHURCH BOTANICAL GARDENS VISITOR CENTRE HAS A COMPLEX ROOF

– a 1000m2 saw tooth design with termination points featuring glass. As the self-proclaimed ‘Garden City’, it was important to create a comfortable environment for both the plants and the 1.4 million visitors per annum; particularly during the colder months.

The new building was designed by award winning Auckland Architect Pattersons, with design and installation of the roof taking 4 years from start to finish due to the interruption of earthquakes.

SolutionIn an attempt to meet the comfort requirements, Viking Roofspec recommended installation of a Warm Roof due to its ability to insulate the building and work into the design of the saw tooth roof. The Warm Roof system comprised of a white Enviroclad membrane at 1.5mm thick adhered over polyiso insulation panels of 75mm thickness, and a vapour barrier. The Enviroclad seams are always heat welded for the ultimate in waterproofing protection.

White Enviroclad was used as it provides 92% solar reflectivity, (which provides numerous energy savings benefits). The R-Value (measure of thermal resistance) of the Warm Roof system is the highest in the construction industry and is pivotal to creating a comfortable internal environment throughout the seasons at the visitors centre.

There were a number of challenges that came to Viking’s attention during the project:

n Multiple redesigns from the glass manufacturers required changes to the roof design at the termination points

n Winter weather

n Substandard plywood had to be replaced before Viking’s Warm Roof solution could be installed

n Coordination of contractor and sub-trades to deliver the project on time

These were all challenges overcome by the architect, Viking and the Viking Approved Applicator, through a professional and focused approach utilising great teamwork and collaboration across the key stakeholders.

It was all about taking care of the detail to ensure a watertight finish.

ResultWith the Viking Warm Roof System installed, the Christchurch Botanical Gardens visitors centre was able to acquire a great looking roof incorporated into the overall aesthetics of the building. More importantly, a watertight roof finish was achieved that protects the building and its inhabitants from the elements.

Christchurch Botanical Gardens also achieved the ultimate in quality assurance with the acquisition of a Viking Full System Warranty. This allows for greater risk minimisation as the warranty covers both the product and the installation under one process.

CONTROLLING THE CLIMATE FOR VISITORS AND PLANTS – CHRISTCHURCH BOTANICAL GARDENS

A WATERTIGHT ROOF FINISH THAT PROTECTS THE BUILDING AND ITS INHABITANTS FROM THE ELEMENTS.

Case Study: Viking Warm Roof

Auckland Office80 Alexander Crescent, OtaraPO Box 14-541, PanmureAuckland 1741, New Zealand

Christchurch Office2 Nazareth Avenue, MiddletonPO Box 9117, Tower JunctionChristchurch 8149, New Zealand

T. 0800 729 799F. 0800 729 [email protected]