spiral.imperial.ac.uk · Web viewThe flour used was purchased from Wessex Mill in Oxford, UK. A...

Transcript of spiral.imperial.ac.uk · Web viewThe flour used was purchased from Wessex Mill in Oxford, UK. A...

Extrusion of Unleavened Bread Dough: Experiments and Simulations

M.A.P. Mohammeda,b, L. Wanigasooriyaa , S. Chakrabarti-Bellc, and M.N. Charalambidesa,*

aDepartment of Mechanical Engineering, Imperial College London, SW7 2AZ London, United

Kingdom

bDepartment of Process and Food Engineering, Faculty of Engineering, Universiti Putra Malaysia,

43400 UPM, Serdang, Selangor, Malaysia

cDepartment of Food Science and Nutrition, University of Minnesota, 1334 Eckles Ave., St. Paul, MN

55108, USA

*corresponding author email: [email protected]

ABSTRACT

An experimental and numerical study on ram extrusion of bread dough was conducted in order to develop

predictive models for the pressures involved, as well as the deformation of the extruded dough. Such studies are

needed as high pressures can potentially lead to significant degassing, tearing and shearing of the dough and

hence poor bread quality; the latter limits the use of extrusion processes which would otherwise be a cost –

effective forming process. A laboratory extrusion rig was designed, with dies of varying angles and exit radii.

Rate dependent behaviour was observed from tests conducted at different extrusion speeds, and higher extrusion

pressure was reported for dies with smaller exit radius or larger die angle. A simulation of extrusion was

performed to predict the extrusion pressure as well as the extrudate swell, as a function of die geometry and

extrusion rate. A continuum approach was taken in the constitutive model of dough which is a starch filled

system in a protein matrix. A nonlinear viscoelastic model combined for the first time with the Mullins model

for filled rubbers is found to capture the continuum behaviour well. A Coulomb friction law combined with a

maximum shear stress limit was used to describe the contact definition between the extrusion barrel and the

dough. Higher die angles and higher extrusion speeds require higher shear stress limit values for the model and

the experiments to agree. A possible reason for this is that the shear stress limit depends on maximum strain as

well as strain rate imposed during the extrusion process. Static zones were observed both experimentally and

numerically. The onset of the static zones was predicted well but quantifying the geometry of the latter needs

further studies.

1

Keywords: Bread dough; adaptive meshing; extrusion pressure; critical shear stress limit; extrudate swell;

rheology

1. Introduction

The most common forming method of bread dough is sheeting or rolling and as a result several publications

have focussed on this process [1, 2, 3, 4]. Extrusion on the other hand is not commonly used in processing bread

doughs because of the high pressures involved which tend to densify, tear and shear the dough, leading to poor

quality. As a result, not many studies have been reported so far on extrusion of bread like dough. However,

extrusion could offer an efficient and cost-effective approach for the formation of both cooked and uncooked

products; therefore models need to be developed which can determine the effect of the extrusion parameters (die

geometry, extrusion speed) on the involved pressures and deformations in the extruded dough. Only then, can

extrusion processes be designed accurately such that they do not compromise the dough quality. This study

offers novel tools which can be used towards potentially solving the problems associated with the extrusion

process.

Studies on ram extrusion so far have been performed for paste-like materials, such as cellulose paste [5, 6, 7],

talc-based paste [8], plasticine clay [9] and mozzarella cheese [10]. The shape of the dough after extrusion, also

known as the extrudate, depends on the geometry of the extruder as well as the mechanical behaviour of dough.

The die geometry can be varied in terms of the exit radius and the entry angle such that the effect on the

extrusion pressure and extrudate swell can be investigated. In addition, bread dough has been shown to behave

as a rubberlike, viscoelastic and/or viscoplastic material, as reported by various authors [11, 12, 13, 14]. The

complex mechanical behaviour of dough combined with the abrupt geometry change in the die-exit, makes

testing and modelling of dough ram extrusion a challenging task. For example, in the pasta extrusion process,

Pena et al. [15] reported that different formulations (using different Semolina and wheat flour weight

percentages) influenced the apparent viscosity of the pasta during extrusion tests, which behaved like a shear-

thinning material. Likewise, Sarghini et al. [16] proposed a non-Newtonian power-law temperature dependent

model to simulate extrusion of pasta with different moisture content and at varying temperature. Lucisano et al.

[17] showed that different types of materials used for the extrusion die (i.e. Teflon and bronze) influenced the

quality of the pasta produced (i.e. mechanical strength, porosity and microstructure of pasta). Dhanasekharan

and Kokini [18, 19] reported numerical simulations of screw extrusion of wheat flour dough, which showed the

2

complexity of the process arising from the screw geometric variables such as the helix angle, the screw length to

screw diameter ratio, and the clearance between the screw and the barrel.

Due to the fact that only limited studies have been reported on dough extrusion and specifically on modelling of

this important process, a need arises for a study which can quantify and predict (through a model) the effect of

the extrusion parameters, such as pressure, speed, die opening and die angle on the extrudate geometry and

extrusion pressure. Ideally a large scale extrusion system is needed to conduct such an investigation, but this is

prohibitively expensive to implement due to high tooling cost, as well as inherent complexity of such a large

system. An alternative to this is to perform a capillary extrusion experimental study, similar to other reported

investigations on food doughs using capillary rheometers [15, 16, 20, 21]. The rheometers enable measurements

of wall shear rate (from the rheometer piston speed) and wall shear stress (from the rheometer pressure drop) to

obtain the shear viscosity of the material extruded though if the material exhibits wall slip, the analysis is not

straight forward and extensive effort is needed to estimate the slip velocity [22]. Wall slip occurs when a thin

layer of inviscid fluid forms at the wall of the tube, which can occur in food suspensions like fruits and

vegetable purees. In addition, due to the small capillary size and complexity of the rheometer, an investigation

of the extrusion parameters like extrudate dimensions (especially due to swelling) and different die dimensions

(e.g. die entry angle and die exit radius) is difficult to conduct.

In this study, in order to investigate the behaviour of dough during extrusion, a laboratory ram extrusion rig was

designed and manufactured. Experimental extrusion pressures and extrudate swell were then compared to

numerical model predictions. Details of the experimental work are given in section 2. This is then followed with

the rheological model used for dough and the numerical model that aims to predict the behaviour of dough

during extrusion. Solutions to common issues such as the severe mesh distortion encountered in the model and

the complex contact behaviour between the dough surface and the extrusion die wall are presented.

2. Experimental

A simple mixture of wheat flour, salt and water was used to prepare bread dough. The flour used was purchased

from Wessex Mill in Oxford, UK. A mixture of 198.5g of wheat flour, 120g of distilled water and 1.5g of salt

was mixed for three minutes using an instrumented laboratory 6-pin mixer at a constant speed in ambient

conditions. The three minutes mixing time was found to be the “optimum” mixing time, with the mixing torque

reaching a maximum at this time. Following mixing, the dough was separated into smaller portions and wrapped

using cling film. Paraffin oil was applied on the surface of the sample to maintain its moisture level. Note that

3

the dough recipe used in this work contains no leavening agent; it is assumed that dough processing such as the

extrusion studied here, takes place before the leavening starts to alter the dough’s consistency and its mechanical

behaviour.

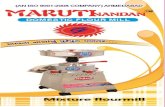

The extrusion rig used is shown in Figure 1, consisting of a 25 mm diameter poly (methyl methacrylate)

(PMMA) barrel in which the internal bore was polished. The barrel was split in two halves to facilitate filling

and to avoid air bubbles. Each half was filled with dough and the two halves were then clamped together. A

steel piston with a PTFE plug was used with an Instron 5543 testing machine to give extrusion speeds of 50

mm/min, 200 mm/min and 500 mm/min. The loads were measured using 5 kN and 100 N load cells. The dies

were mounted on the base of the barrel and then placed on a frame to allow the extrudate to flow out freely.

8

1 Bottom base2 Top base3 Die4 Ram5 Half section of barrel unit6 PTFE plug7 Circular recess8 Cut out section

8

1 Bottom base2 Top base3 Die4 Ram5 Half section of barrel unit6 PTFE plug7 Circular recess8 Cut out section

Figure 1. Extrusion rig set up.

Dies with different arbitrary angles but close to industrial practice were used for the experiments, as shown in

Figure 2. The entry radius was set to be the same (12.5 mm) for all the dies tested. In Figure 2, the dies are

arranged in rows from the smallest entry angle, 26°, to the largest, 108°. The exit radius was arbitrarily varied

from the widest, 9 mm, to the smallest, 5.5 mm. In the first row of Figure 2, the dies have the same entry angle,

26°, but a different exit radius, 9 mm, 7 mm and 5.5 mm, and are called Die 26°a, Die 26°b and Die 26°c

respectively. The dies in the second row on the other hand have the same exit radius, 5.5 mm, but different entry

4

angles, namely 44°, 72° and 108°. All die exits were rounded with a filet radius, R of 2 mm as shown in Figure

2, in order to avoid sharp corners and imperfections in the extruded dough. Multiplying the cross section of the

barrel unit (radius of 12.5 mm) by the extrusion speeds of 50, 200 and 500 mm/min gives the volumetric flow

rates as 0.41, 1.63 and 4.09 cm3/s respectively. The apparent shear rate for fluid flow can therefore be

determined from these volumetric flow rates and barrel radius [22] as 0.27, 1.07 and 2.67 /s for the speeds of 50,

200 and 500 mm/min respectively.

The experiments were performed at 22 °C and 50 % relative humidity. Since the extrusion rig was set up

vertically, steady state extrusion pressures were achieved by extruding the dough into glycerol (density of 1.25

g/ml) to counteract the effect of gravity on the experimental results, as demonstrated by Wanigasooriya [23].

18

25 25 25

25 25 25

026

Die 260 a

14

026

Die 260 b

11

026

Die 260 c

044

Die 440

072

Die 720

0108

Die 1080

R=2 R=2 R=2

R=2 R=2 R=2 11 11 11

Figure 2. Dies used for wheat flour dough extrusion. All dimensions shown are in mm.

Experimental results using dies with a 26° angle and different exit radii (Die 26°a, Die 26°b and Die 26°c) are

shown in Figure 3. Rate dependent behaviour is observed with higher pressure recorded as speed increased. The

extrusion pressures reached steady state conditions after approximately 40 mm ram displacement for all the 26°

5

dies. Note that the initial rise in extrusion pressure is due to the dough being compressed by the ram until it is

consolidated into the barrel and die, with a steady state reached thereafter. Decreasing the exit radius of the dies

resulted in higher extrusion pressures.

6

(a)

(b)

(c)

0

5

10

15

20

25

30

35

0 20 40 60 80 100

Extr

usio

n pr

essu

re (k

Pa)

Ram displacement (mm)

500 mm/min

50 mm/min

Die 260c

0

2

4

6

8

10

12

14

16

18

0 20 40 60 80 100

Extr

usio

n pr

essu

re (k

Pa)

Ram displacement (mm)

500 mm/min

50 mm/min

Die 260 b

0

2

4

6

8

10

12

0 20 40 60 80 100

Exru

sion

pres

sure

(kPa

)

Ram displacement (mm)

500 mm/min

50 mm/min

Die 260 a

Figure 3. Experimental results for dies with 26° entry angle and different exit radii, namely 9 mm, 7 mm and

5.5 mm for Die 26°a, Die 26°b and Die 26°c respectively. For each speed, four different traces are shown

7

obtained from replicate experiments. Dotted vertical line marks the approximate position of the onset of the

steady state conditions.

An interesting phenomenon in the extrusion process is the formation of static zones. Static zones at the walls of

the die are defined as stationary material which does not move into the die-exit. This has been observed by

Benbow and Bridgwater [24] who investigated the presence of static zones during extrusion using square entry

die angles (i.e. 180°) and large diameter reductions typically seen in industrial extrusion of pastes.

An investigation of the formation of the static zones was performed in this study through deformation

visualisation experiments using coloured (Supercook food colouring) markers on the dough. These colours were

obtained by brushing different food paints onto the barrel wall before dough was moulded into the barrel (see

Figure 4). No static zones were observed at the die wall for the dies with a 26° angle. This is illustrated with the

example shown in Figure 4 for Die 26°c, where the various colours along the barrel wall move sequentially into

the die exit.

Figure 4. Image sequence obtained from the visualisation experiments using die 26°c, highlighting the absence

of static zones [23].

Experimental results for dies with entry angle of 44°, 72° and 108° with the same entrance and exit radii are

shown in Figure 5. Similar to the earlier results, the extrusion pressure is higher at larger speeds and steady state

conditions are achieved in all cases. A larger steady state pressure is observed as the entry angle is increased

from 26° (Die 26°c in Figure 3) to 108º as expected. The maximum point exhibited in the transient stages of the

extrusion pressure plots in Figure 3 is less evident in Figure 5 due to the larger steady state extrusion pressures

required for these steeper dies and smaller die exit radius.

8

(a)

(b)

(c)

0

5

10

15

20

25

30

35

40

45

0 20 40 60 80

Extr

usio

n pr

essu

re (k

Pa)

Ram displacement (mm)

200 mm/min

50 mm/min

Die 440

0

10

20

30

40

50

60

70

80

90

0 20 40 60 80 100

Extr

usio

n pr

essu

re (k

Pa)

Ram displacement (mm)

200 mm/min

50 mm/min

Die 720

0

20

40

60

80

100

120

0 20 40 60 80 100

Extr

usio

n pr

essu

re (k

Pa)

Ram displacement (mm)

200 mm/min

50 mm/min

Die 1080

Figure 5. Experimental results for Die 44°, Die 72° and Die 108° with the same entrance and exit radii, 12.5

mm and 5.5 mm respectively. For each speed, three different traces are shown obtained from replicate

experiments. Dotted vertical line marks the approximate position of the onset of the steady state conditions.

9

No static zones were observed for Die 44°. However, for Die 72° static zones occurred at both speeds of 50

mm/min and 200 mm/min. This is visualised in Figure 6 for the test at 200 mm/min, where the various colours

along the barrel wall do not move into the die exit, indicating the occurrence of static zones. Similar static zones

were also reported for die 108° at both speeds of 50 mm/min and 200 mm/min. It is worth noting here that,

using the paint markers in the video recordings for dies that did not display these static zones, it was found that

the slip velocities in the cylindrical part of the barrel were very close (within a ±5% difference) to the

experimental ram speeds, signifying plug flow.

10s 12s 14s 16s

18s 20s 22s 24s

h

Figure 6. Image sequence of extrusion at 200 mm/min using die 72° demonstrating the formation of a static

zone.

An illustration of the static zone and natural angle formed, , is provided in Figure 7. As already mentioned,

during the formation of static zones, a pile up of colours can be seen with a static zone of height, h, being

developed (an example is shown in Figure 6 at t=18s). The static dough was seen to pile up at the onset of

extrusion and remain at the height h throughout the extrusion tests. A value of i can be assigned based on the die

geometry (Figure 7), and the natural angle, can then be calculated from . The natural angles

obtained from die 72° and die 108° under 50 mm/min and 200 mm/min are listed in Figure 7. The extrusion

10

angle which is double the natural angle is therefore in the range of 28° - 36° for both die 72° and die 108°. This

would explain why the steady state pressure seems to level off as the die entry angle increases from 72° to 108°

(see Table I for average steady state extrusion pressures); extrusion is occurring at the same angle of

approximately 28° - 36°. Finally, the rise in extrusion pressure for die 72° and die 108° as compared to the

pressure seen in die 44° is due to the extra shearing taking place at the interface of the formed natural angle.

Note that the above calculations for the natural angle imply a 3D conical shaped static zone as shown by the

shape of the black regions in Figure 7. This assumption cannot be verified here as no accurate flow visualisation

data were available. Therefore, in the absence of experimental evidence, it was felt that this is the simplest way

of quantifying the available observations. Note that Cheyne et al. [25] and Bryan et al. [26] have reported curved

boundaries, as opposed to the straight boundaries of the conical assumption, based on extrusion studies on

potato starch and cellulose-based pastes respectively. On the other hand Perrot et al. [27] reported straight

boundaries from a study on extrusion of kaolin paste and also suggested that the roughness of the extruder walls

largely controls the length and geometry of the dead zones. Finally, Mitsoulis and Hatzikiriakos [28] reported

that the shape and size of the static zone (in their paper this is referred to as vortex flow and size) was influenced

by the elongational viscosity of the branched polypropylene melt undergoing extrusion flow.

Con

ical

sta

tic z

one

dough

h

i

n

(a) (b)nNatural angle,Die

72ᵒ (50 mm/min)

108ᵒ (50 mm/min)

72ᵒ (200 mm/min)

108ᵒ (200 mm/min)

18ᵒ

14ᵒ

17ᵒ

18ᵒ

nNatural angle,

24ᵒ

24ᵒ

25ᵒ

26ᵒ

(Test) (Model)

Figure 7. Illustration of natural angle, , and natural angles obtained from experiments and finite element

models using dies 72° and 108°.

Table I. Steady state extrusion pressure data from various dies.

Die 26°a 26°b 26°c 44° 72° 108°Steady state pressure (kPa)

0.90 ± 0.19 3.64 ± 0.18 9.72 ± 0.78 16.64 ± 1.11 35.07 ± 1.02 39.20 ± 2.43

11

50 mm/minSteady state pressure (kPa)1200 mm/min2500 mm/min

2.13 ± 0.441 5.93 ± 0.261 18.82 ± 1.071 32.23 ± 3.012 69.91 ± 4.912 84.49 ± 2.542

3. Numerical Work

3.1 Constitutive material model

For simplicity, even though dough is a two phase starch/gluten particulate composite [14], a continuum material

model is assumed when simulating the ram extrusion process. For this, the visco-hyperelastic model combined

with the Mullins effect was used, where the former model is based on the work by Charalambides et al. [29],

and the latter model is added here to simulate stress softening occurring as evidenced from cyclic loading data

involving large strains. The Mullins model was initially suggested for modelling damage in the form of particle

debonding during loading-reloading cycles of filled rubbers [30, 31]; it is hypothesised here that dough can be

treated as a filled ‘rubber’ too as the gluten matrix has previously been found to behave very much like a rubber

[14].

The viscoelastic part of the model assumes a separable time and strain dependent material behaviour [32]. T he

relaxation stress under a small step strain loading history is defined as a function of time, , and strain,

through , where the former is represented by the Prony series:

(1)

in which t and are time and relaxation time constants respectively, and and are dimensionless

constants. The stress under an arbitrary loading history can be obtained using the Leaderman form of the

convolution integral [33] evaluated at time, t:

(2)

12

The nominal stress, , in Equation (2) is obtained using the van der Waals hyperelastic potential, where the

stress is given as a function of via , with being the hyperelastic potential. The stress under

uniaxial tension and compression can be derived as:

(3)

where is the instantaneous initial shear modulus, is the locking stretch constant, and a is the global

interaction parameter. The parameter is the stretch ratio, that is , with and being the

deformed and original length of the sample respectively, tested under uniaxial tension and compression modes

[29]. Note that the model described above is slightly different to earlier published work by the authors [32]

where the term was in effect inside the convolution integral of Equation (2), with the true stress replacing

nominal stress in the time derivative. This change was introduced recently in Abaqus in order to accurately

describe the finite element viscoelastic model at large strain, as demonstrated and discussed in detail by

Ciambella et al. [34]. The difference in the calculated stress data resulting from this change is only slight

(maximum 3.7% at strain of 1) [35]. Equation (1) and Equation (3) are substituted in Equation (2) which is then

solved using the numerical algorithm of finite time increments [32, 35] to yield an expression suitable for

parameter calibration through a least squares optimisation tool. The calibrated model was checked against that

predicted from a finite element analysis of a single-element model loaded uni-axially and the stress-strain results

were found to coincide.

As already mentioned, the Mullins model [30] is intended to simulate stress softening in filled rubbers under

cyclic loading using a damage variable, , which scales the deviatoric stress of the primary (undamaged)

hyperelastic behaviour and varies with the deformation [36, 37]:

(4)

where is the deviatoric part of the potential U of the hyperelastic model, and is the maximum

value of at a material point during its deformation history. The other parameters, r, m and are

13

material parameters, and erf(x) is the error function. Note that erf(x) reaches an asymptotic value of 1.0 for x

bigger than approximately 2. Equation (4) implies that no damage occurs when is equal to and the

value of reaches its maximum possible value which is 1.0. For values of less than , reduces

monotonically and damage takes place. The following restriction applies to the parameters of the Mullins

model: , and . These parameters, r, and m control the amount of damage (stress

softening). A lower damage occurs when the magnitudes of these parameters are increased.

The model (Equations 2 and 4) was calibrated using the dough test data under different loading conditions,

namely uniaxial compression, uniaxial tension, cyclic-compression and relaxation-compression, as depicted in

Figure 8. Details on the experimental procedures used to conduct the tests on dough are provided in [14] and

[29]. The uniaxial tension test was performed by clamping both ends of a sample and by pulling in opposite

directions at a fixed rate using a universal testing machine (Instron 5543 with 1kN load cell). For uniaxial

compression tests, the load direction is opposite to the load direction of the uniaxial tension test. Cyclic

compression tests were conducted by loading and unloading a sample under compression mode at the same

strain rate. The re-loading of the sample was activated once the stress in the unloading part becomes zero.

Finally, stress relaxation was conducted under compression mode, where the specimen was compressed at a rate

of 5 /min to a strain of 1 which was then held fixed for 1000 s while the force decay was recorded. All

compression experiments were conducted under lubricated conditions [38].

The calibration was performed simultaneously using a least squares method [32]. A constraint was defined

during the calibration procedure where the time dependent constants, are set to be non-negative values. The

Mullins model (Equation 4), which influenced the unloading part of the cyclic test was then employed to

improve the unloading-reloading response through a single element model simulation in the finite element

model. The constant m was set to zero, which implies a significant amount of damage even at low strain levels

[37]; a more detailed discussion on this is provided later in this section. The calibrated parameters are shown in

Table II whereas the model fit is compared to the experimental data in Figure 8. The chosen Mullins parameters

also lead to the minimum value of being equal to approximately 0.1 [37]. Note that the values in Table II are

unique, since the model was calibrated using multiple modes of deformation. The value of which is the initial

shear modulus can be compared with that found for gluten and solid cheese which were approximately 3.3 kPa

[14] and in the range of 100-200 kPa depending on the cheese type [32], respectively. For the Mullins

14

parameters, Gracia et al. [39] reported the following values for industrial rubber (r=1.001, =2.35-3.15, m=0),

whereas Bose and Dorfmann [40] modelled soft-bodied arthropod muscle (r=1.05, =0.5, m=0.0038).

Table II. Material parameters of bread dough.

Material constants Value (kPa) 4.6

7

0.4

(at = 0.1, 1, 10, 100, 1000, and s)0.6, 0.22, 0.12, 0.05, 0.009, 0.001

1.10.30.0

(a) (b)

(c) (d)

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

0 0.2 0.4 0.6 0.8 1

True

stre

ss (k

Pa)

True strain

Test

Model5/min

0.5/min

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

0 0.2 0.4 0.6 0.8 1

True

stre

ss (k

Pa) [

-]

True strain [-]

Test

Model50/min

5/min

0

0.5

1

1.5

2

2.5

0 0.2 0.4 0.6 0.8 1

True

stre

ss (k

Pa) [

-]

True strain [-]

Test

Model 5/min

0

0.4

0.8

1.2

1.6

2

0.01 0.1 1 10 100 1000

True

stre

ss (k

Pa) [

-]

Time (s)

Test

Model 5/min

15

Figure 8. Calibration of material model with bread dough experimental results: (a) uniaxial tension; (b) uniaxial

compression; (c) cyclic-compression; and (d) relaxation-compression from a strain of 1. The [-] sign in the

vertical axis title in (b) to (d) implies negative values (under compression mode).

Figure 8 shows that the material model agrees reasonably well with the experimental results. To the authors’

knowledge, this is the first time that a good model agreement is observed with relaxation and cyclic loading data

from such large strains as the ones shown in Figures 8(c) and 8(d). To highlight the effectiveness of the Mullins

model in capturing the unloading-reloading curves of a cyclic test, Figure 9(a) shows a comparison between the

models with and without the Mullins effect. The material constants in Table II were applied to the former

model, whereas no Mullins function was employed for the latter model. A distinct difference is observed when

the Mullins effect was introduced, capturing the experimental cyclic unloading-reloading curves shown in

Figure 8(c) more accurately.

16

(a)

(b)

(c)

0

0.5

1

1.5

2

2.5

0 0.2 0.4 0.6 0.8 1

True

stre

ss (k

Pa) [

-]

True strain [-]

Model (with Mullins effect)

Model (without Mullins effect)

0

0.5

1

1.5

2

2.5

0 0.2 0.4 0.6 0.8 1

True

stre

ss (k

Pa) [

-]

True strain [-]

=1.1, =0.3

=1.1, =0.6

=1.1, =2

β

β

β

r

r

r

0

0.5

1

1.5

2

2.5

0 0.2 0.4 0.6 0.8 1

True

stre

ss (k

Pa) [

-]

True strain [-]

=1.1, =0.3

=2, =0.3

=4, =0.3

ββ

β

r

r

r

Figure 9. (a) Comparison between model with and without Mullins. Parametric study of the Mullins effect by

varying: (b) the constant, r, and (c) the constant, β. In all cases, the constant, m is set to be equal to zero.

17

Furthermore, a parametric study was conducted to investigate the effect of the Mullins model constants r and

on the cyclic test results. The Mullins constants were first set to the values shown in Table II. The constant, r,

was kept constant while the other constant, , was varied (see Figure 9(b)). In another case (Figure 9(c)), the

constant was kept constant while varying r. Note that in all cases, the constant m is set to zero. Values for

the constant lower than 0.3 were also attempted, but this caused the simulation to terminate prematurely due

to numerical convergence problems. It can be seen that increasing the parameters r and leads to a smaller

amount of stress softening in the unloading-reloading curves.

The material parameters shown in Table II are next used in the numerical study of the ram extrusion process as

discussed below.

3.2 Extrusion model development

A finite element simulation of extrusion was performed in Abaqus/Explicit [37] using axisymmetric elements.

An explicit integration scheme was selected due to its ability to solve highly nonlinear systems involving

complex contacts whilst not requiring as much disk space as an implicit integration scheme [37]. A schematic of

the model is shown in Figure 10(a). The billet represents dough being forced through the barrel with dies at

different angles and exit radii as shown in Figure 2. The material parameters in Table II are assigned to the billet

and the boundary conditions used in the model are as shown in Figure 10. At the top of the billet, a constant

velocity equal to the experimental crosshead speed, S, was applied as shown. Linear, 4 node, axisymmetric

quadrilateral, reduced integration elements were used. Both frictionless conditions and a Coulomb frictional

contact were defined at the dough and die wall interface in order to study the effect of friction on the extrusion.

The latter is discussed further below.

18

Die

Barrel

Rig

id s

urfa

ce

Bill

et (w

orkp

iece

)

Force from ram

Rig

id s

urfa

ce

x

y

(a) (b)

0x

y S

Figure 10. (a) Schematic of dough extrusion simulation; and (b) mesh and boundary conditions ( signifying

displacement in the two directions x and y).

Wanigasooriya [23] simulated extrusion using Abaqus/Explicit and included axisymmetric elements with a

frictionless contact between the billet and the die. He highlighted the issue of severe mesh distortion where the

elements penetrate the corner near the entry to the die and the mesh boundary is no longer closely following the

profile of the die. This unrealistic severe mesh distortion worsens as the analysis proceeds until a point is

reached where the analysis prematurely terminates. Here, in an attempt to avoid this problem, the mesh shown

in Figure 10(b) was introduced. The mesh is refined near the die wall and the sharp end of the billet next to the

die wall is smoothed in an effort to reduce the mesh distortion problem. In addition, the adaptive meshing

technique was used. The latter enables a high-quality mesh throughout the analysis, even when large

deformations occur, by allowing the mesh to move independently to the material. This is possible due to the fact

that the adaptive meshing technique combines the features of pure Lagrangian analysis (in which the mesh

follows the material) and Eulerian analysis (in which the mesh is fixed spatially and the material flows through

19

the mesh). This type of adaptive meshing is often referred to as Arbitrary Lagrangian-Eulerian (ALE) [37]. To

clarify further, adaptive meshing allows the mesh to move independently of the material whilst leaving the

topology (elements and connectivity) of the mesh unchanged. The following parameters are required to use the

ALE option in Abaqus: frequency and remeshing sweep per increment. A default value of frequency = 10 and a

remeshing sweep per increment = 1 as suggested for Abaqus/Explicit were used [37].

A mesh sensitivity study was performed by varying the number of elements in the extrusion model until the

extrusion steady state pressure converged within a tolerance of 1-5 %. At least 1000-1500 elements were needed

to perform the extrusion simulation for Dies 26°a, 26°b and 26°c, whereas at least 2000-3000 elements are

needed for Dies 44°, 72° and 108°.

3.3 Extrusion simulation results

The numerical simulation results will be compared with the experimental data in this section. Note that only the

steady state region is examined; the initial, transient regions where the pressure rises before it reaches its steady

state value is largely dependent on the amount of pressure that is applied on the dough whilst filling the barrel

before the experiment starts. In addition, in the numerical model, the die is not completely filled before the ram

is displaced downwards (see Figure 10) which will also affect the transient stage.

The model fit to the extrusion test data at different rates using the frictionless condition is shown in Figures 11

and 12. Frictionless condition here refers to a zero coefficient of friction, , between the billet and the die. It is

observed that the model underestimates the extrusion test data for all dies and extrusion speeds. In addition, in

some cases (i.e. Die 108° at both speeds) convergence or steady state was not obtained due to severe distortion

of some elements; the simulation terminated prematurely. This is thought to be due to the extremely large strain

at these extrusion geometries; at such high constriction ratios, static zones as discussed in section 2, would start

forming and the numerical method is not able to simulate this behaviour.

20

(a) (b)

(c) (d)

(e) (f)

0

0.5

1

1.5

2

2.5

3

3.5

0 20 40 60 80 100

Exru

sion

pres

sure

(kPa

)

Ram displacement (mm)

Test 50 mm/min =0.09 =0.09, slip = 0.5 kPa =0.09, slip = 0.3 kPa =0.09, slip = 0.1 kPa =0 (frictionless)

Die 260 aµµµµµ

0

2

4

6

8

10

12

0 20 40 60 80 100

Extr

usio

n pr

essu

re (k

Pa)

Ram displacement (mm)

Test 50 mm/min

=0.09

=0.09, slip=0.5 kPa

=0.09 slip=0.3 kPa

=0.09, slip=0.1 kPa

=0 (frictionless)

Die 260 bµ

µµ

µ

µ

0

10

20

30

0 20 40 60 80 100

Extr

usio

n pr

essu

re (k

Pa)

Ram displacement (mm)

Test 50 mm/min =0.09 =0.09, slip=0.5 kPa =0.09, slip=0.3 kPa =0.09, slip=0.1 kPa =0 (frictionless)

Die 260 c

µµµµµ

0

10

20

30

0 20 40 60 80 100

Extr

usio

n pr

essu

re (k

Pa)

Ram displacement (mm)

Test 50 mm/min =0.09 =0.09, slip=1 kPa =0.09, slip=0.5 kPa =0.09, slip=0.3 kPa =0 (frictionless)

Die 440

µµµµµ

0

10

20

30

40

50

60

70

80

90

0 20 40 60 80 100

Extr

usio

n pr

essu

re (k

Pa)

Ram displacement (mm)

Test 50 mm/min =0.09 =0.09, slip=3 kPa =0.09, slip=1 kPa =0.09, slip=0.5 kPa =0 (frictionless)

Die 1080

µµµµµ

0

20

40

60

80

0 20 40 60 80 100

Extr

usio

n pr

essu

re (k

Pa)

Ram displacement (mm)

Test 50 mm/min =0.09 =0.09, slip=3 kPa =0.09, slip=2 kPa =0.09, slip=1 kPa =0 (frictionless)

Die 720

µµµµµ

Figure 11. Comparison between experimental data and extrusion model at 50 mm/min.

21

(a) (b)

(c) (d)

(e) (f)

0

2

4

6

8

10

12

0 20 40 60 80 100

Exru

sion

pres

sure

(kPa

)

Ram displacement (mm)

Test 500 mm/min =0.09 =0.09, slip = 0.5 kPa =0.09, slip = 0.3 kPa =0.09, slip = 0.1 kPa =0 (frictionless)

Die 260 aµµ

µ

µ

µ

0

10

20

30

40

0 20 40 60 80 100

Extr

usio

n pr

essu

re (k

Pa)

Ram displacement (mm)

Test 500 mm/min =0.09 =0.09, slip=1 kPa =0.09, slip=0.7 kPa =0.09, slip=0.5 kPa =0 (frictionless)

Die 260 cµµµµµ

0

5

10

15

20

25

0 20 40 60 80 100

Extr

usio

n pr

essu

re (k

Pa)

Ram displacement (mm)

Test 500 mm/min =0.09 =0.09, slip = 1 kPa =0.09, slip = 0.5 kPa =0.09, slip = 0.3 kPa =0 (frictionless)

Die 260bµµµµµ

0

10

20

30

40

50

60

0 20 40 60 80 100

Extr

usio

n pr

essu

re (k

Pa)

Ram displacement (mm)

Test 200 mm/min =0.09 =0.09, slip=3 kPa =0.09, slip=2 kPa =0.09, slip=1 kPa =0 (frictionless)

Die 440

µµµµµ

0

20

40

60

80

100

0 20 40 60 80 100

Extr

usio

n pr

essu

re (k

Pa)

Ram displacement (mm)

Test 200 mm/min =0.09 =0.09, slip=7 kPa =0.09, slip=5 kPa =0.09, slip=3 kPa =0 (frictionless)

Die 720

µµµµµ

0

20

40

60

80

100

120

0 20 40 60 80 100

Extr

usio

n pr

essu

re (k

Pa)

Ram displacement (mm)

Test 200 mm/min =0.09 =0.09, slip=7 kPa =0.09, slip=5 kPa =0.09, slip=3 kPa =0 (frictionless)

Die 1080

µµµµµ

Figure 12. Comparison between experimental data and extrusion model at 500 mm/min and 200 mm/min.

Next, the effect of a non-zero coefficient of friction assigned between the die wall and the billet surface on the

model results was investigated. An independent measurement of the friction during extrusion was obtained by

22

Wanigasooriya [23] by placing a known mass of dough on to one half of the lubricated (paraffin oil) extrusion

unit. The extrusion unit was then attached onto a combination reversing protractor (see Figure 13(a)). The

kinetic coefficient of friction was determined by allowing the dough sample to slide and subsequently altering

the angle until no sliding occurred. The value of was calculated from , where θ is the angle at

which the dough sample stopped sliding, as shown in Figure 13(b). Several dough samples of mass varying

from 3 to 30 grams were used for the experiment, giving an average resting angle of ~5º and a coefficient of

friction of =0.09.

The comparison between the model and the extrusion test data at different rates corresponding to a coefficient of

friction of =0.09 is shown in Figures 11 and 12 (curve =0.09). It is observed that except for Die 26°a, the

model fit extremely overestimates the response and fails to converge for all other dies.

This is believed to be caused by a critical shear stress limit being reached when the contact pressure stress

becomes very large. By allowing sliding to occur if the magnitude of the shear stress reaches the critical shear

stress limit, regardless of the magnitude of the contact pressure stress, sliding of the dough on the barrel surface

takes place and therefore the extrusion pressure drops. Therefore an alternative contact definition was employed,

consisting of a critical shear stress limit, τmax, combined with the coefficient of friction, as mentioned

above. This model is illustrated in Figure 13(c). The Coulomb friction model defines the equivalent shear stress,

, at which sliding of the surfaces starts as a function of the contact pressure, p, and coefficient of friction, ,

through:

(5)

Note that the equivalent shear stress, , (shown in the vertical axis of the graph in Figure 13c) is generally

defined as: , where and refer to the components of shear stress [37] for a three dimensional

simulation. In the case presented here, the simulation is only a 2D axisymmetric case therefore the equivalent

shear stress is simply the shear stress at the die wall and dough interface. With the introduction of the critical

shear stress limit, τmax, contacting surfaces can carry shear stresses only up to this limit across their interface

before relative tangential motion can begin [37]. As the value of this parameter τmax is not known, a parametric

study was conducted where the finite element model was run with varying values of τmax, keeping all other input

parameters constant.

23

Dough

N sin θ = µN cos θ µ = tan θFor sliding:

(b)

f = µN cos θ

N sin θ N cos θN = mgθ

(Coefficient of friction)

(critical shear stress with limit)max

Equivalent Shear stress,

, (kPa)

ContactPressure (kPa)

max

(a)

(c)

µ

Figure 13. (a) Experimental measurements of the kinetic coefficient of friction [23]; (b) free body diagram of

friction on an inclined plane; and (c) slip regions for the friction model with a limit on the critical shear stress.

The results of the parametric study are shown in Figures 11 and 12 (curves with different τmax values)

for the low and high extrusion speeds respectively. The value of τmax which leads to agreement between the

experimental and numerically predicted values can be obtained from these Figures and these values are

displayed in Table III for the various dies. As already mentioned, only steady state extrusion pressures are

24

compared in Figures 11 and 12 as the initial loading stage of the curve will vary depending on the exact initial

dough shape and barrel fill. Also shown in Table III are values of the imposed values of the maximum principal

strain rate and maximum principal strain at the area around the die exit as obtained from contour plots such as

the one shown in Figure 14 (a). Although it is difficult to conclude a trend in the τmax value when both strain and

strain rate are varying simultaneously, it is apparent that τmax increases as strain or strain rate increase. A value of

τmax = 0.3 kPa however would lead to reasonable agreement between the experimental and numerical data for

most of the dies studied whereas values of τmax = 1.0-7.0 kPa would be needed for the higher entry angle dies

and higher extrusion speeds. Such values seem reasonable in terms of their magnitude but experimental

validation through testing of the dough/die wall interface is needed.

Table III. The maximum shear stress limit, τmax, and maximum principal strain and rate for different dies.

Die Extrusion

rate

(mm/min)

Maximum

principal strain

rate (Numerical)

(1/s)

Analytical

average strain

rate (Equation

6) (1/s)

Maximum

principal

strain

(Numerical)

Analytical

strain

(Equation 7)

τmax

(kPa)

26°a 50 0.031 0.048 0.79 0.66 0.1-0.3

26°b 50 0.062 0.0651.33 1.16

0.1-0.3

26°c 50 0.102 0.0831.65 1.64

0.1-0.3

44° 50 0.19 0.151.69 1.64

0.3-0.5

72° 50 0.23 0.261.77 1.64

2.0

108° 50 NA 0.49NA 1.64

NA

26°a 500 0.44 0.48 0.76 0.66 0.5

26°b 500 0.75 0.645 1.22 1.16 0.3-0.5

26°c 500 1.25 0.83 1.52 1.64 0.7-1.0

44° 200 0.91 0.581.65 1.64

1.0-2.0

72° 200 1.49 1.041.70 1.64

5.0-7.0

108° 200 NA 1.97NA 1.64

NA

25

The numerical values of maximum principal strain and strain rate in Table III are next compared with analytical

approximations of these quantities. Wanigasooriya [23] suggested an average strain rate, , for the extrusion

tests using the following analytical equation:

(6)

where S is the extrusion speed , Db and Da are the entry and exit diameter of the die, respectively and α is half of

the entry angle. The remaining parameter, R, is equal to the extrusion ratio given by: R= Ab/Aa , where Ab is the

cross-sectional area of the billet and Aa is the area of the extrudate at die exit. In addition, the extrusion tensile

strain experienced by the dough as it travels down the die is calculated using the following:

(7)

Details for the derivation of Equations (6) and (7) are provided in Dieter [41]. The average strain rate and strain

calculated using Equations (6) and (7) for all dies at different extrusion speeds is shown in Table III. The

analytical and numerical results are close, apart from the strain rates at high entry angles (44º and 72°) at the

higher speed, giving confidence in the reported data.

Pressure peaks were observed in the simulation results for Dies 26°c, 44°, 72° and 108° in Figures 11 and 12, as

highlighted for example in Figure 11 (f). This is due to the significant volume of material being forced through

the die opening in a short time period, as highlighted in Figure 14 (b). This however is confined to the initial

transient response and does not affect the steady state results discussed above.

26

(a) (b)

Figure 14. (a) Contours of maximum principal strain for Die at 500 mm/min. (b) Contours of Mises

stress (Pa) for die 72º at 200 mm/min; a significant volume of material (highlighted in dotted circle) is forced

through the die. The contour variable ‘LE, max. principal’ in (a) represents the maximum principal strain,

whereas the contour variable ‘S, Mises’ in (b) is the equivalent von Mises stress.

The effect of the critical stress on the results is significant, as shown in Figure 11 and Figure 12. Indeed it was

observed that at steady state, the critical shear stress was activated for the vast majority of the elements along

the barrel and die wall contact area; therefore slip conditions prevail.

The numerical model was then used in an attempt to predict the onset of static zones. Figure 15 shows the

contour plots for the magnitude of the total displacement vector for dies 44º and 72º. As can be seen in the

figure, die 44º does not show a static zone whereas die 72º shows a region where the flow is very restricted. By

comparing such plots for all dies it was found that dies 26° a, 26° b, 26° c, and 44° did not show any static

zones, in contrast to dies 72° and 108° at both extrusion speeds. This is in agreement with the experimental

observations discussed above. A similar calculation was performed as for the experimental study (Figure 7) in

order to calculate the numerically predicted natural angles. The results are shown in the Table of Figure 7(b).

The model predicts an average value of 25° as opposed to the average value of 17° from the experiments.

Bearing in mind the uncertainties in the definition of this static zone geometry and the arbitrariness chosen in

27

the static zone definition, the two quoted values are not too dissimilar. However further studies are needed to

improve such predictions.

h

i

1tan ih

(a) (b)

Figure 15. Contour plots for the magnitude of the total displacement vector for: (a) dies 44º and (b) 72º. Scale

shown in meters (m).

Finally, experimental and numerical results for the extrudate swell (using numerical results from the upper limit

of τmax in Table III) are shown in Figure 16. The extrudate diameter plotted on the vertical axis of Figure 16 was

measured from video recordings of the tests at 10 mm from the die exit. Swelling of the extrudates (both in tests

and models) is observed when compared to the die exit diameters (taken from Figure 2) which are also plotted

on the same graph. This indicates partial recovery of the dough after deformation, as also evidenced in the cyclic

compression tests (Figure 8c). The results for die 108° are not shown because no steady state numerical results

were obtained for either of the two speeds. A good agreement between the numerical and the experimental

values is observed. There is further evidence that the friction model (Figure 13) used to model the contact

behaviour at the dough and barrel interface is appropriate and leads to realistic predictions for both the extrusion

pressure experienced by the dough as well as the deformation of the latter as it exits the die.

28

(a)

(b)

0

5

10

15

20

25

0 1 2 3 4 5 6

Extr

udat

e di

amet

er (m

m)

Die

TestModelDie exit diameter

260a 260b 260c 440 720

50 mm/min

0

5

10

15

20

25

0 1 2 3 4 5 6

Extr

udat

e di

amet

er (m

m)

Die

TestModelDie exit diameter

260a 260b 260c 440 720

200 mm/min &500 mm/min

Figure 16. Extrudate swell as obtained from simulation results and experimental measurements.

4. Conclusions

Experiments with dies of different entry angles and exit radii were conducted. The dough used in the extrusion

experiments was first characterised through mechanical tests including uniaxial tension and lubricated

compression, stress relaxation and cyclic loading tests. A non-linear viscoelastic model was calibrated using

these mechanical data consisting of a hyperelastic model combined with the Prony series as well as, for the first

time, including the Mullins model. The latter captures damage in the filled (starch) system as evidenced from

cyclic loading test data at large strains. Numerical simulations of the extrusion were then performed, where an

adaptive meshing technique was chosen. The occurrence of static zones at higher die entry angles is discussed.

Simulations performed using a frictionless contact between the billet and die wall showed that the model

underestimates the response at high entry angles. Therefore a frictional contact between the die wall and the

billet surface was defined, where the kinetic coefficient of friction, µ, of 0.09 was obtained from the

experimental study by [23]. When this value of µ was used in the model, the response was overestimated, i.e.

29

the extrusion pressure was much higher than the experimentally measured values. This prompted the use of a

critical shear stress limit, τmax, in the model. The results show that higher die angles require higher τmax values for

the model and experiments to agree. This indicates a complex contact behaviour between die wall and dough,

which needs to be investigated further in the future. The models developed in the study are relatively simple and

can be used as a powerful tool in the industrial design of common extrusion processes in soft solids foods. The

specific problems usually associated with the high extrusion pressures such as shearing, tearing and

densification in extruded doughs can then be predicted and avoided. The latter would pave the way for novel,

cost-effective extrusion processes to be employed in bread making.

Acknowledgement

The authors would like to thank Q.W.L. Lim and P.J. Tow, both undergraduate students in Mechanical

Engineering at Imperial College London, for conducting part of the experimental and numerical work of the

study. Financial support for this study was provided by the Malaysian Ministry of Education and Universiti

Putra Malaysia. Lastly, the anonymous reviewers are acknowledged for their useful comments and suggestions,

References

[1] Xiao, W., M. N. Charalambides, and J. G. Williams, “Sheeting of wheat flour dough,” Inter. J. Food Sci.

Tech. 42, 699-707 (2007).

[2] Chakrabarti-Bell, S., J. S. Bergstrom, E. Linskog, and T. Sridhar, “Computational modelling of dough

sheeting and physical interpretation of the non-linear rheological behaviour of wheat flour dough,” J. Food Eng.

100, 278-288 (2010).

[3] Patel, M. J., and S. Chakrabarti, “Flour quality and dough elasticity: dough sheetability,” J. Food Eng. 115,

371-383.

[4] Bousquieres, J., C. Deligny, A. Riaublanc, and T. Lucas, “CLSM study of layers in laminated dough: roll out

of layers and elastic recoil,” J. Cereal Sci. 60, 82-91.

[5] Rough, S. L., J. Bridgwater, and D. I. Wilson, “Effects of liquid phase migration on extrusion of

microcrystalline cellulose pastes,” Inter. J. Pharmaceutics 204, 117-126 (2000).

30

[6] Mascia, S., M. J. Patel, S. L. Rough, P. J. Martin, and D. I. Wilson, “Liquid phase migration in the extrusion

and squeezing of microcrystalline cellulose pastes,” Europe. J. Pharma. Sci. 29, 22-34 (2006).

[7] Patel, M. J., S. Blackburn, and D. I. Wilson, “Modelling of paste flows subject to liquid phase migration,”

Inter. J. Num. Methods Eng. 72, 1157-1180 (2007).

[8] Martin, P. J., D. I. Wilson, and P. E. Bonnett, “Rheological study of a talc-based paste for extrusion-

granulation,” J. Europ. Ceramic Soc. 24, 3155-3168 (2004).

[9] Aydin, I., F. R. Biglari, B. J. Briscoe, C. J. Lawrence, and M. J. Adams, “Physical and numerical modelling

of ram extrusion of paste materials: conical die entry case,” Comput. Mater. Sci. 18, 141-155 (2000).

[10] Muliawan, E. B., and S. G. Hatzikiriakos, “Rheology of mozzarella cheese: extrusion and rolling,” Inter.

Dairy J. 18(6), 615-623 (2008).

[11] Ng, T. S. K., and G. H. McKinley, “Power law gels at finite strains: the nonlinear rheology of gluten gels,”

J. Rheol. 52(2), 419-449 (2008).

[12] Tanner, R. I., S. C. Dai, and F. Qi, “Bread dough rheology and recoil: 1. rheology,” J. Non-Newton. Fluid

Mech. 148, 33-40 (2008).

[13] Sofou, S., E. B. Muliawan, S. G. Hatzikiriakos, and E. Mitsoulis, “Rheological characterization and

constitutive modelling of bread dough,” Rheol. Acta 47(4), 369-381 (2008).

[14] Mohammed, M. A. P., E. Tarleton, M. N. Charalambides, and J. G. Williams, “Mechanical characterization

and micromechanical modeling of bread dough,” J. Rheol. 57(1), 249-272 (2013).

[15] Pena, E. D. L., F. A. Manthey, B. K. Patel, and O. H. Campanella, “Rheological properties of pasta dough

during pasta extrusion: effect of moisture and dough formulation,” J. Cereal Sci. 60, 346-351 (2014).

[16] Sarghini, F., A. Romano, and P. Masi, “Experimental analysis and numerical simulation of pasta dough

extrusion process,” J. Food Eng. 176, 56-70 (2016).

[17] Lucisano, M., M. A. Pagani, M. Mariotti, and D. P. Locatelli, “Influence of die material on pasta

characteristics,” Food Res. Inter. 41(6), 646-652 (2008).

[18] Dhanasekharan, K. M., and J. L. Kokini, “Viscoelastic flow modelling in the extrusion of a dough-like

fluid” J. Food Process Eng. 23, 237-247 (2000).

31

[19] Dhanasekharan, K. M., and J. L. Kokini, “Design and scaling of wheat dough extrusion by numerical

simulation of flow and heat transfer,” J. Food Eng. 60(4), 421-430 (2003).

[20] Bagley, E. B., F. R. Dintzis, and S. Chakrabarti, “Experimental and conceptual problems in the rheological

characterization of wheat flour doughs,” Rheol. Acta 37, 556-565.

[21] Hicks, C. I., and H. See, “The rheological characterisation of bread dough using capillary rheometer,”

Rheol. Acta 49, 719-732 (2010).

[22] Steffe, J. F. Rheological methods in food process engineering. (Freeman Press, Michigan, 1996).

[23] Wanigasooriya, L., Mechanical Characterisation and Ram Extrusion of Wheat Flour Dough, PhD Thesis,

Mechanical Engineering Department, Imperial College London, UK (2006).

[24] Benbow, J., and J. Bridgwater. Paste Flow and Extrusion. (Clarendon Press, Oxford, 1993).

[25] Cheyne, A., J. Barnes, and D. I. Wilson, “Extrusion behaviour of cohesive potato starch pastes: I.

Rheological characterisation,” J. Food Eng. 66(1), 1-12 (2005).

[26] Bryan, M. P., S. L. Rough, and D. I. Wilson, “Investigation of static zones and wall slip through sequential

ram extrusion of contrasting micro-crystalline cellulose-based pastes,” J. non-Newton. Fluid Mech. 220, 57-68

(2015).

[27] Perrot, A., Y. Melinge, D. Rangeard, F. Micaelli, P. Estelle, and C. Lanos, “Use of ram extruder as a

combined rheo-tribometer to study the behaviour of high yield stress fluids at low strain rate,” Rheol. Acta 51,

743-754 (2012).

[28] Mitsoulis, E., and S. G. Hatzikiriakos, “Bagley correction: the effect of contraction angle and its

prediction,” Rheol. Acta 42, 309-320 (2003).

[29] Charalambides, M. N., L. Wanigasooriya, J. G. Williams, S. M. Goh, and S. Chakrabarti, “Large

deformation extensional rheology of bread dough,” Rheol. Acta 46, 239–248 (2006).

[30] Mullins, L., “Effect of stretching on properties of rubber,” J. Rubber Res. 16, 275-289 (1947).

[31] Mullins, L., and N. R. Tobbin, “Theoretical model for the elastic behaviour of filler-reinforced vulcanized

rubbers,” Rubbers Chemistry Tech. 30(2), 555-571 (1957).

32

[32] Goh, S. M., M. N. Charalambides, and J. G. Williams, “Determination of the constitutive constant of non-

linear viscoelastic materials,” Mech. Time-Depend. Mater. 8, 255-268 (2004).

[33] Williams, J. G., Stress Analysis of Polymers (John Wiley, London, 1980).

[34] Ciambella, J., M. Destrade, and R. W. Ogden. “On the ABAQUS FEA model of finite viscoelasticity,”

Rubber Chem. Tech. 82(2), 184-193 (2009).

[35] Mohammed, M. A. P., Mechanical Characterisation, Processing and Microstructure of Wheat Flour Dough.

PhD Thesis, Mechanical Engineering Department, Imperial College London, UK (2012).

[36] Ogden, R. W., and D. G. Roxburgh, “A pseudo-elastic model for the Mullins effect in filled rubber,”

Proceed. Royal Soc. London, Ser. A 455, 2861-2877 (1999).

[37] Abaqus, User Manual ver 6.14. (Hibbit Karlsson and Sorensen, Providence, 2014).

[38] Charalambides, M. N., S. M. Goh, L. Wanigasooriya, J. G. Williams, and W. Xiao, “Effect of friction on

uniaxial compression of bread dough,” J. Mater. Sci. 40, 3375- 3381 (2005).

[39] Gracia, L. A., E. Pena, J. M. Royo, J. L. Pelegay, and B. Calvo, “A comparison between pseudo-elastic and

damage models for modelling the Mullins effect in industrial rubber components,” Mech. Res. Comm. 36, 769-

776 (2009).

[40] Bose, K., and A. Dorfmann, “Computational aspects of a pseudo-elastic constitutive model for muscle

properties in a soft-bodied antropod,” Inter. J. Non-Linear Mech. 44, 42-50 (2009).

[41] Dieter, G. E., Mechanical Metallurgy, (McGraw-Hill, Tokyo, 1988) SI Metric Ed.

33