VI: The Unsymmetrical Laminate · VI: The Unsymmetrical Laminate If the laminate is symmetric,...

Transcript of VI: The Unsymmetrical Laminate · VI: The Unsymmetrical Laminate If the laminate is symmetric,...

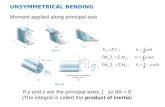

VI: The Unsymmetrical Laminate If the laminate is symmetric, there is no coupling between mid‐plane strains and laminate curvatures, as illustrated by Equation (1) of Section V‐A. However, if the laminate is unsymmetric, coupling does exist as shown in Equation (1) below:

The objective here is to derive the elements of the matrix that relates the in‐plane and bending stress resultants to the mid‐plane strains and laminate curvatures. We are especially interested in the “B” matrix of Equation (1).

Before we proceed with this derivation, recall the equations for the strains in the kth lamina, Equation (2) of Section V‐A:

[ε126]k = [εo126] + z [K126]

We obtain the expression for the strains in the kth lamina by substituting Equation (3) into Equation (9) of Section II‐D:

[σ126]k = [Q126]k [ε126]k[σ126]k = [Q126]k [εo126] + z [Q126]k [K126]

The expression for N1 is determined as follows:

Substitution of the expression for σ1 from Equation (4) into equation (5) yields:

After integration, Equation (6) becomes:

where n is the number of layers in the laminate and k refers to a particular layer.Similarly:

The expression for M1 is:

If we obtain the expression for σ1 from Equation (4) and follow the procedure presented in Section IV‐A, we have

Similarly,

If we combine Equations (8), (9) and (10), we have

If we combine Equations (12), (13) and (14), we have

We now combine Equation (16) and (18) and the derivation is complete:

Where Aij = (Qij)k (bk – ak) Bij = (Qij) k

Dij = (Qij) k

If the laminate is symmetric w. r. t. the mid‐plane, we see that Bij = 0, and the in‐plane quantities become uncoupled from the flexural quantities. Otherwise, there is coupling because of the existence of the “B” matrix. That is, in‐plane loads cause bending and twisting as well as in‐plane strains. Also, flexural loads cause in‐plane strains as well as bending and twisting.

2

22kk ab

3

33kk ab

Summary: Laminate Analysis

Problems (Chapter VI)

A laminate consists of Graphite/Epoxy, T300/5208, layers as follows: [0, 45, 90]. The applied stress resultants are N1 = 100 lb/in, N2 = N6 = M1 = M2 = M6 = 0. Determine the stresses (σx, σy, σz) in the middle of the 90° lamina.

Now let’s combine Equations (1), (2) and (3):

or [εxys] = [Sxys] [δxys] + ΔT [αxy] + C [βxy]

The quantities α and β are the thermal expansion coefficient and the swelling coefficient respectively. The constant C is the moisture concentration, and ΔT is the temperature change. The equilibrium moisture concentration in humid air is related to relative humidity by a power law:

The quantities αx, αy, βx, βy, a and b are determined experimentally. Typical values for Gr/EP AS/3501 are as follows:αx = −0.3E−6 m/m°K αy = 28.1E−6 m/m°Kβx = 0 βy= 0.44 m/m a = 0.018 b = 1

Laminate equations including the effects of temperature and moisture are developed as follows:Stress‐Strain, Local Coordinates:

[εxys] = [Sxys] [σxys] + ΔT [αxy] + C [βxy]Where [Sxys] is given in Section II‐A

[Sxys] −1 [εxys] = [σxys] + ΔT [Sxys] −1 [αxy] + C [Sxys] −1 [βxy] [Qxys] [εxys] = [σxys] + ΔT [Qxys] [αxy] + C [Qxys] [βxy] [σxys] = [Qxys] [εxys] − ΔT [Qxys] [αxy] − C [Qxys] [βxy]where [Qxys] = [Sxys] −1 is given in Section II‐A

Transformation of Stress:[σxys] = [T] [σ126]

Or [σ126] = [T] −1 [σxys]Where [T] is given in Section II‐C

Transformation of Strain:[εxys] = [Ť] [ε126]where [Ť] is given in Section II‐C.

Stress‐Strain, Global Coordinates:

[σxys] = [Qxys] [εxys] − ΔT [Qxys] [αxy] − C [Qxys] [βxy]

[T] [σ126] = [Qxys] [Ť] [ε126]− ΔT [Qxys] [αxy] − C [Qxys] [βxy]

[σ126] = [T] −1 [Qxys] [Ť] [ε126]− ΔT [T] −1 [Qxys] [αxy] − C [T] −1 [Qxys] [βxy]

[σ126] = [Q126] [ε126]− ΔT [Ǭ 126] [αxy] − C [Ǭ 126] [βxy]

where [Q126] is given in Section II‐Da

and [Ǭ 126] = [T] −1 [Qxys]

[Q126] −1 [σ126] = [ε126] − ΔT [Q 126] −1 [Ǭ 126] [αxy] − C [Q126] −1 [Ǭ 126] [βxy]

[S126] [σ126] = [ε126] − ΔT [S126] [Ǭ 126] [αxy] − C [S126] [Ǭ 126] [βxy]

[ε126] = [S126] [σ126] + ΔT [S126] [Ǭ 126] [αxy] + C [S126] [Ǭ 126] [βxy]

where [S126] is defined in Section II‐D.

Strain Curvature:[ε126] = [ε o

126] + z [K126] from Section V‐A

Stress, Strain and Curvature:[σ126] = [Q 126] [ε126] − ΔT [Ǭ 126] [αxy] − C [Ǭ 126] [βxy] [σ126] = [Q 126] [εo126] + z [Q 126] [K126] − ΔT [Ǭ 126] [αxy] − C [Ǭ 126] [βxy]

Stress Resultants:If we use the procedure presented in Section IV‐A, we can easily develop the expressions for N1, N2, N6 and M1, M2, M6:

whereH1 = (Ǭ 11 αx + Ǭ 12 αy)k (bk – ak)H2 = (Ǭ 21 αx + Ǭ 22 αy)k (bk – ak) H6 = (Ǭ 16 αx + Ǭ 26 αy)k (bk – ak)J1 = (Ǭ 11 αx + Ǭ 12 αy)kJ2 = (Ǭ 21 αx + Ǭ 22 αy)kJ6 = (Ǭ 16 αx + Ǭ 26 αy)k

H*1 = (Ǭ 11 βx + Ǭ 12 βy)k (bk – ak)

H*2 = (Ǭ 21 βx + Ǭ 22 βy)k (bk – ak)

H*6 = (Ǭ 16 βx + Ǭ 62 βy)k (bk – ak)

J*1 = (Ǭ 11 βx + Ǭ 12 βy)kJ*2 = (Ǭ 21 βx + Ǭ 22 βy)kJ*6 = (Ǭ 16 βx + Ǭ 26 βy)k

If the laminate is symmetric, J1 = J2 = J6 = 0 Bij = 0 J*1 = J*2 = J*6 = 0

n

k 1

n

k 1

n

k 1

n

k 1

n

k 1

n

k 1

n

k 1

n

k 1

n

k 1

n

k 1

n

k 1

n

k 1

2

22kk ab

2

22kk ab

2

22kk ab

Summary: Laminate Analysis

Problems (Chapter VII)A [0,90] laminate of AS/3501 Gr‐Ep, unidirectional tape is cured on a flat tool at 350°F. Determine the shape (curvatures and twists) of the panel after it has been cured and taken from the tool.

The matrix for this laminate is (metric):

Verify the values for A11, B11 and D11

DBBA

2924.001962.002352.01962.007177.004101.008185.0004101.006676.08185.0

EEEE

EEE

EEE

VIII: Strength and Failure

A. Lamina Failure Assumption

Maximum Stress TheoryThis theory assumes that yielding will occur when one of the principal stresses becomes equal to the yield stress in simple tension or the yield stress in compression.

Maximum Strain TheoryThis theory assumes that yielding will occur when the value of the principal strain equals the value of the yield strain in simple tension or compression.

Maximum Shear TheoryThis theory assumes that yielding will occur when the maximum shear stress reaches the value of the maximum shear stress occurring in simple tension.

Maximum Strain Energy TheoryThis theory assumes that yielding will occur when the total strain energy per unit volume equals the strain energy per unit volume at yielding in uniaxial tension or compression.

Distortion Energy TheoryThe total energy absorbed by a body may be divided into two p[arts, one part associated with the change in volume (change in size) and the other associated with the distortion (change in shape) of the body. This theory assumes that yielding begins when the distortion energy equals the distortion energy at yield in uniaxial tension. This theory usually fits (but not always) the experimental data better than the other theories. It is expressed mathematically as follows:

σx2 – σxσy + σy2 + 3τxy2 = σys2

‐ + + =1

The quantities σx, σy and τxy are the state of stress at a point and σys is the yield stress of the material in simple tension. Yielding will occur when the left hand side of Equation (2) reaches the value of 1. For composite materials, we need a failure criteria for individual plies. The strength of a composite laminate is based on the strength of the individual plies within the laminate. As the load is applied to the laminate, there will be a first ply failure followed by other ply failures until the last ply fails, which would be the ultimate failure.

2

2

ys

x

2ys

yx

2

2

ys

y

2

23ys

xy

Unidirectional composite laminae have highly directionally dependent strengths. Furthermore, the longitudinal strength can be twenty times the transverse and shear strengths. For ant state of applied stress, we cannot say which component of stress is responsible for failure. In fact, all components contribute to failure. Thus we shall use a failure criterion that includes interaction among all the stress or strain components, the failure criterion used here for orthotropic materials is one that is analogous to the distortion energy theory for isotropic materials. Without derivation, it is expressed mathematically as follows:

where X = Longitudinal Tensile StrengthX' = Longitudinal Compressive StrengthY = Transverse Tensile StrengthY' = Transverse Compressive StrengthS = Shear Strength associated with x,y coordinate system

Yield will occur when the left hand side of Equation (3) reaches a value of 1. For simplicity, we can write Equation (3) as follows:

Fxx σx2 + 2Fxy σx σy + Fyy σy2 + Fss σs2 + Fx σx + Fy σy = 1Where

We can also write Equation (4) in terms of Strain as follows:

Gxx εx2 + 2Gxy εx εy + Gyy εy2 + Gss εs2 + Gx εx + Gy εy = 1where

Gxx = Fxx Qxx2 + 2Fxy Qxx Qxy + Fyy Qxy

2

Gyy = Fxx Qxy2 + 2Fxy Qxy Qyy + Fyy Qyy

2

Gxy = Fxx Qxx Qxy + Fxy [Qxx Qyy + Qxy2] + Fyy Qxy Qyy

Gss = Fss Qss2

Gx = Fx Qxx + Fy Qxy

Gy = Fx Qxy + Fy Qyy

B. Strength Ratio The strength ratio for a lamina is defined as the ratio of the allowable strain to actual strain or allowable stress to actual stress:

When the left hand sides of Equation (4) and (6) are less than 1, the stresses and strains are defined as actual stresses and strains. When the left hand sides are equal to 1, the stresses and strains are defined as allowable values. Since εx = Rε and σa = Rσ, we write Equations (4) and (6) as follows:

Fxx σxa2 + 2Fxy σxa σya + Fyy σya2 + Fss σsa2 + Fx σxa + Fy σya = 1or Fxx σx2 R2 + 2Fxy σxR σyR + Fyy σy2R2 + Fss σs2R2 + Fx σxR + Fy σyR = 1or [Fxx σx2 + 2Fxy σx σy + Fyy σy2 + Fss σs2]R2 + [Fx σx + Fy σy ]R = 1 (10)and [Gxx εx2 + 2Gxy εx εy + Gyy εy2 + Gss εs2]R2 + [Gx εx + Gy εy]R = 1 (11)

We solve either Equation (10) or (11) for the two roots of R. one root is the Strength Ratio corresponding to a particular set of stresses, while the other root corresponds to the same set of stresses but reversed in sign.

C. Laminate Strength The strength of laminate is determined by examining the strength ratios of each ply. The ply with the lowest strength ratio will fail first and it is assumed to fail when it reaches a value of 1. The state of stress resultant when this ply failure occurs is called the first‐ply‐failure state. The plies with higher strength ratios will fail later, when the externally applied load is increased. This successive ply failure progresses until the last ply or ultimate failure occurs.

To determine the allowable stress resultants, proceed as follows:

Allow the stress resultants to increase until the strength ratio for one of the plies is reduced to 1. This ply is assumed to fail. Eliminate the failed ply by reducing its elastic constants to small values, but allowing it to remain in the laminate in its original position. Allow the stress resultants to increase further until the strength ratio of another ply is reduced to 1, then eliminate it the same way. Repeat this process until ultimate failure occurs.

• Example Problem A laminate of [0/45/–45/90]s is subjected to the stress resultants shown. The 0° and 90° plies are Glass/Epoxy 1002 and the 45° and –45° plies are Graphite/Epoxy T300/5208. The thickness per ply is 0.000125m. Determine the strength ratio of the 45° lamina. N1 = 100x106(8)(0.000125) = 100,000 N/mN2 = 0N6 = 40x106(8)(0.000125) = 40,000 N/mFrom Section III‐D, Figure 1b, we see how to obtain σx, σy, σs, from N1, N2, N6. Then from Figure 2, Section VIII‐B, we see how to obtain R:From Equation 8, Section III‐A, we have

and ε1 = 3.59x10–3 , ε2 = –1.99x10–3 , ε6 = 1.576x10–3

From equation (9), Section II‐D, we have

and σ1 = 186.5 MPa , σ2 = 106.9 MPa, σ6 = 142.0 Mpa

From equation (4), Section II‐C, we have

and σx = 288.7 MPa , σy = 4.68 MPa, σs = –39.84 MPa

From Table 7, Section II‐B, we have X = 1500 MPa X' = 1500 MPaY = 40 MPa Y' = 240 MPaS = 68 Mpa

From Equations (5), Section VIII‐B, we have Fxx = 0.444x10–18 Fyy = 0.444x10–18

Fxy = 0.444x10–18 Fss = 0.444x10–18

Fx = 0.444x10–18 Fy = 0.444x10–18

From Equation 10, Section VIII‐B, we have[0.444(288.7)2x10–6 + 2(–3.36)(288.7)(4.68)x10–6 + 101.6(4.68)2 x10–6 + 216.2 (–39.84) 2 x 106 ] R2 + [0 (288.7) x 10–3 + 20.93 (4.68) x10–3] R–1 = 00.3733R2 + 0.0980 R –1 = 0R = 1.51, –1.77If we reverse the stress resultants, we obtain R = 1.77, –1.51. The answer to our problem is R = 1.51.

Problem (Chapter VIII)1. A laminate consists of Graphite/Epoxy, T300/5208, layers as follows: [0, 45, –45, 90]s. The applied stress resultants are M1 = 25 in‐lb/in, M2 = 0, M6= 0, N1 = 1500 lb/in, N2 = 0, N6 = 0. Strength ratios for the upper and lower surfaces of each lamina are shown in the figure.Verify the value of R = 0.610 for the upper surface of layer number 7. What does this value imply? Based on the values of the strength ratios for this laminate, what action(s) would you suggest?