Version 21.04.2014 Retail Excellence - IGA Tasmania Ops/Manuals... · Gondola ends feature value...

Transcript of Version 21.04.2014 Retail Excellence - IGA Tasmania Ops/Manuals... · Gondola ends feature value...

Version 21.04.2014 Retail Excellence

Page 2

Introduction .................................................................................................................... 4

Housekeeping ................................................................................................................. 5

External Store Entrance ................................................................................................. 6

Internal Store Entrance ................................................................................................... 7

Front End ........................................................................................................................ 8

Store Ambience .............................................................................................................. 10

Point of Sale .................................................................................................................... 11

Ticketing Standards ......................................................................................................... 12

Manager’s Checklists ...................................................................................................... 14

Food Safety ..................................................................................................................... 15

Customer Service ............................................................................................................ 17

Compelling Fresh Offer ................................................................................................... 18

Key Fresh Cues ............................................................................................................... 20

Receiving and Storage ..................................................................................................... 22

Page 3 Version 21.04.2014 Retail Excellence

Produce .......................................................................................................................... 24

Meat ............................................................................................................................... 26

Delicatessen .................................................................................................................... 30

Bakery ............................................................................................................................. 32

Long Life Retail Excellence .............................................................................................. 35

Grocery ........................................................................................................................... 36

Dairy ............................................................................................................................... 38

Freezer ............................................................................................................................ 39

Dairy Coolrooms ............................................................................................................. 40

Freezer Rooms ................................................................................................................ 41

Back Dock ....................................................................................................................... 42

Administration ................................................................................................................ 43

Page 4

They happen because there is a robust process in place that provides customers with a clean and safe environment to shop in, provides them with new, well merchandised and high quality stock at a competitive price.

This, together with exceptional service, gives your customers an experience that makes them want to come back!

That’s how the locals like it!

The Key Value Drivers Pocket Book has been developed for Store Managers and Retail Owners to use as a quick reference guide, to assist you in the day-to-day management of your store.

Outstanding customer experiences in supermarkets do not happen by chance.

Intr

od

ucti

on

Page 5

Each team member should be constantly aware of general housekeeping ensuring that:

Shop floor is spotlessly clean and free of dirt build-up.

Fixtures are clean and damaged stripping is replaced.

Under gondolas are clean and free of stock.

Spills are cleaned immediately and ‘Caution Wet Floor’ signs are used.

Cleaning rosters are in place in all departments.

Cleaning equipment is readily available, clean and maintained in good condition.

All customer service areas are neat, clean and tidy.

Great housekeeping practices are vital and show your customers that you care about the environment they shop in.

Ho

use

kee

pin

g

Page 6

Carpark is clean, in good repair and clear of rubbish.

Gardens are tidy, clean and clear of rubbish and weeds.

Outside lighting is working and brand logo/s are not obstructed.

External walls should be clean and free of any grime, graffiti and cobwebs.

All signage must be tidy and comply IGA Standards.

Windows should be clean and largely free of posters and collateral so shoppers can see through into a tidy, well presented store.

Trading hours are clearly visible.

Special posters are visible and well presented.

The front of store is the first and last view the customer sees during every visit. Is your external store area clean and tidy?

Exte

rnal

Sto

re E

ntr

ance

Page 7

Trolley bay area clean and tidy, not blocking the

entrance.

Trolleys are available.

Trolleys are clean and in good condition.

Baby capsules are clean and in good condition.

Baskets are available and in good condition.

Store entrance is clean and tidy.

Any floral displays are fresh, watered and ticketed.

Community Notice Board is clearly visible.

Promotional material and hanging posters do not interfere with shopper visibility, gondola end messages and directional signage across the store.

Catalogues are available near the entrance area.

The entrance is the first and last impression the customer has during their visit. Is your store front entrance clean and tidy?

Inte

rnal

Sto

re E

ntr

ance

Page 8

Team members trained in customer service standards.

Checkout team members have been briefed on new product lines throughout the store as well as current promotions and sales activity.

Should be aware of the PLUs for all new produce lines.

Customer service is always maintained in a friendly, courteous and professional manner.

Enough checkouts are open during peak trading periods.

Refer to your Hourly Sales Report to maximise rosters with peak trading.

Fro

nt

End

Is your ‘Customer Service’ your store’s ‘Point of Difference’? Do your team members engage with your customers?

Page 9

Team members are wearing correct uniform and

name badge.

Impulse stands are clean, well stocked and ticketed.

Drink fridges are clean, full and well ticketed.

Magazine stands clean and full of current magazines.

Cigarette cabinets are clean and displayed according to your State Tobacco Legislation.

Visitor sign-in book available.

All checkouts are clean.

All checkout scales are clean and scale checks actioned and recorded.

All Workplace, Health & Safety (WHS) practices are followed.

Customer service counter clean.

The checkout area of the store is the last point of contact with customers and often what they remember most.

Fro

nt

End

Page 10

All store lights are working and lighting is effective, clear and bright.

High level and navigational signage is clearly visible so shoppers can easily identify aisle contents and departments.

Radio is operating and volume set to be played at a background level.

Aisles are uncluttered and it is easy to move around the store.

Customers can easily access all aisles and areas with a trolley.

Ensure air conditioning temperature is set to provide a comfortable shopping environment.

Your store should be inviting, clean and easily accessible for all customers. Would a new customer who had never visited your store find the store inviting?

Sto

re A

mb

ien

ce

Page 11

Make sure you feature the optimal amount of POS for

your store. Too much POS creates extra clutter and makes stores feel cramped and look messy.

Check that all POS is correctly installed.

Remove damaged, old and dirty POS.

Take down campaign POS as soon as activity ends.

Make sure special tickets are tidy and hanging straight.

Expired special tickets are removed.

Damaged, ripped and dirty special tickets should be replaced.

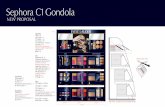

Gondola ends feature value messaging and price communications, and should tie in with the stronger catalogue offers.

Tidy, well presented POS can improve and lift a customer’s overall shopping experience. A pleasant shopping experience will encourage repeat visits.

Po

int

of

Sale

Page 12

The following principles of display and merchandising must be adhered too. The customer must be able to:

See the price of the product.

Touch and feel the product.

Self-select the product.

Access the product safely.

And do all of this in the shortest possible time.

Shelf Labels

Every product on shelves must have a shelf label.

Shelf labels are located to the left side of the first facing of each product.

Labels must be current and in good condition.

‘Marked for Delete’ labels with zero stock-on-hand must be removed.

Is value messaging clear throughout your store?

Tick

etin

g St

and

ard

s

Page 13

Shelf Tickets

Shelf tickets are applied using shelf / ticket clips.

Special tickets are placed over the existing shelf label.

All shelf tickets are in good condition.

All shelf tickets are current.

Damaged / missing shelf tickets are replaced.

Special Posters

All bulk off-location displays are ticketed with special poster.

All special posters are in good condition.

All special posters are current.

Damaged / missing special posters replaced.

Tick

etin

g St

and

ard

s

Large display — large ticket. Shelf display — shelf ticket.

Page 14

Run Store Manager’s Checklist twice a day ensuring the following points are maintained at high standards:

Retail Area Appearance and Staff Appearance.

Safety and Security.

Cleaning Programs are implemented, Cleaning Schedules are actioned and all departments are compliant to Food Safety Standards.

Run Store Manager’s Key Metrics a minimum of once a day to review:

Sales and GP.

Rosters and Wages.

Promotional and Advertised Lines.

Wastage / Shrinkage.

The store should be inviting, clean and easily accessible for all customers. Does your store invite customers to shop?

Man

age

r’s

Ch

eck

lists

Page 15

Temperature Checks must be recorded 2 times a day,

minimum / maximum temperatures are:

–18oC frozen foods.

+4oC for chilled and refrigerated foods.

+60oC for hot foods.

Temperatures need to be checked for all refrigeration and freezer displays and storage units.

Temperature Checks are actioned and recorded daily in each department including:

Produce.

Delicatessen / Seafood.

Meat.

Bakery.

Back Dock / Storeroom.

Australian Food Standards legislation requires strict compliance of storing, selling, handling & preparation of ALL fresh and perishable products. These MUST be adhered to.

Foo

d S

afet

y

Page 16

Foo

d S

afet

y Date-code rules applies across the store:

All items that have exceeded their date-code must be recorded and removed from show.

Use the First In First Out (F.I.F.O) method of stock rotation.

Items marked with use-by-dates must be sorted on shelves with oldest dates in front.

Scale Checks must be actioned and recorded daily in:

Checkouts.

Produce.

Delicatessen / Seafood.

Meat.

Bakery.

Back Dock / Storeroom.

Customers need to be able to clearly see the date-code on items.

Page 17

Customer Service

All transactions should ensure that team members:

Greet the customer.

Engage the customer.

Process the sale.

Farewell the customer.

Product Knowledge

All team members should know the location of products and when asked they:

Should take the customer to the product.

Should not just point to where the product is.

Should be aware of new produce lines that have been ranged to the store.

Customer service is a personal engagement between customers and team members. Do your team members excel in customer service?

Cu

sto

me

r Se

rvic

e

Page 18

Co

mp

elli

ng

Fre

sh O

ffe

r Key Value Drivers are the critical elements that need to be delivered in every department, every day to ensure that customers can shop in your store with confidence.

The following pages outline the Key Value Drivers for each Fresh Department.

By ensuring these actions are followed up on a daily basis, you will be setting the standards in your store that will provide your customers with a consistently great compelling fresh offer!

You must conduct a ‘Would I Buy It’ check in every fresh department at least twice a day.

Page 19

Each morning engage each of your Department Managers and their teams. These daily Department Tours must cover basic trading plans and daily reporting, and include:

A discussion on the previous day’s achievements in sales and profit performance.

A discussion regarding performance in relation to budgets.

Department Tours should be actioned at the beginning of each Managers’ shift, and should include the following:

A review of the opportunities and plans for today’s trade.

A review the key drivers for each department.

Give your customers a fresh experience that keeps them coming back and one that they are happy to tell their family and friends about.

Co

mp

elli

ng

Fre

sh O

ffe

r

Page 20

Key

Fre

sh C

ue

s Would I buy it checks are completed a minimum of twice a day. The key indicators for the freshness of your fresh departments are as follows:

Bananas — there must be bananas on show that are ripe and ready to eat.

Potatoes — there are absolutely no green potatoes on show.

Tomatoes — there are no over ripe tomatoes on display, they must be firm and of good colour.

Middle Bacon — is pink in colour and there are no dry or dark edges.

Roast Chickens — have wings attached are moist and not dried out.

Salads — are turned frequently and not dried out.

Customers will judge your ability as a proud shopkeeper by the quality of stock on display.

Page 21

Sliced Meats — are regularly culled and dried pieces

of meat are removed from show.

Mince — is bright red in colour and discoloured mince is removed from show.

Prawns — are bright in colour and there is no dark discolouration around the head.

Markdowns are actioned in a timely manner always.

Pre-packed stock — be marked down two days prior to the used-by-date.

Markdowns — be made early in the morning to allow the greatest opportunity to sell through on the first day.

Make your first markdown your best markdown as stock is more likely to sell whilst it is still as fresh as possible!

Key

Fre

sh C

ue

s

Page 22

Re

ceiv

ing

and

Sto

rage

The correct stock receiving and storage practices in your fresh food departments are critical in maximising your sales and profit.

When receiving your fresh food and chilled deliveries, it is vital that you adhere to the following procedures:

All stock is checked when received to ensure that you have been charged appropriately. This includes checks by weight (if applicable) and by the number of cartons / units.

Great receiving processes provide safe, quality merchandise for your customers that in turn, maximise sales and profits.

Page 23

All fresh and chilled stock is temperature checked

with a correctly calibrated temperature gun or probe.

All fresh and chilled stock must be received at between 0oC and 5oC temperature.

All stock is transferred to refrigerated storage within 20 minutes of delivery.

All stock is rotated and date coded when placing into cool rooms.

All stock is rotated when placed on fixtures.

Any credits or claims are processed immediately.

All direct vendor and bread returns are personally checked every day prior to the driver leaving the store.

Do not overload trolleys and fixtures; too much weight will damage fresh perishable stock!

Re

ceiv

ing

and

Sto

rage

Page 24

Pro

du

ce

To maximise Produce Department trading ensure that:

Stock on show is of stunning quality.

Promotional lines are featured towards the front of the department.

All lines are correctly ticketed with promotional and standard point of sale.

All Country of Origin claims are accurate.

Correct department flows are implemented.

Stock weight reflects customer shopping patterns and requirements.

Stock on hand counts are completed before all orders are entered.

All price changes have been actioned, as required.

All fresh areas should reflect season and or event (Christmas, Easter, Summer, Winter etc.)

You must conduct ‘Would I Buy It’ checks throughout the course of the trading day.

Page 25

All stock has been rotated in the cool room.

Outstanding levels of housekeeping are maintained on the shop floor and back of house.

Team members’ are using the correct personal protective equipment (PPE).

Team members personal presentation is of a high standard.

Date-code checks are completed daily on all packaged products.

Front End file integrity is accurate.

Front End team members have been made aware of any new lines.

Cabinet, bin and fridge cleaning rosters are in place and actioned.

Aim to fill less, more often and then increase your stock weight for your peak trading times.

Pro

du

ce

Page 26

Me

at

Fresh quality stock on show:

Meat must have good bloom and dark meat should be reduced in price or removed from show.

Promotional lines are prominently featured and aggressively ticketed.

Conduct a ‘Would I Buy It’ check every time you walk past your meat case!

Correct meat department flows are implemented and reflect the below table.

Where different grades of species are on show always start with premium cuts and end with economy cuts.

Mince Beef Lamb

Pork Veal Small Goods

Page 27

Where possible Pet Food should be located in a

separate location.

Where this is not possible use a divider to separate the offer.

Stock weight reflects customer shopping patterns and requirements.

Know your market and have the right range available in the right tray sizes.

Aim to cut less, more often.

Stock on hand counts are completed before all orders are placed.

Cutting sheets are used to control stock weight on show.

Me

at

Page 28

Me

at

All stock in the cool room is date coded and rotated using First in First Out (F.I.F.O.) principles.

Packing standards reflect the standards outlined in the IGA Packing Standards Chart.

Outstanding levels of housekeeping are maintained on the shop floor and back of house.

No stock is to be stored on the cool room floor.

Cabinet cleaning roster is in place and data stripping is clean and free of dried blood and old ticket residue.

Meat wells and shelves should be spotlessly clean with no evidence of dried blood.

Great housekeeping standards are critical. Show your customers you care about the cleanliness of your department!

Page 29

Remember: The first markdown is the best markdown!

Markdowns actioned in a timely manner.

First markdowns should be taken 2 days prior to use-by date.

Daily department pack-up and deep-clean is conducted to an outstanding standard every day.

All documentation for legislative compliance is completed, filed and maintained correctly.

Team members’ are using the correct Personal Protective Equipment (PPE).

Team members personal presentation is of a high standard.

Team members are removing aprons and coats when they are leaving the preparation area.

No jewellery, watches or nail polish are worn by team members.

Me

at

Page 30

De

licat

ess

en

All of the core range available.

All products ticketed.

Salads are turned frequently to avoid drying out.

No discolouring of meats.

Bain Marie at correct operating temperature greater than +60oC.

Hot Chickens are always available.

Promotions are fully merchandised, with highlighted ticketing.

All products are correctly ticketed.

All windows and glass is clean and streak free.

All bowls and tickets are clean.

Relevant meal solution offer displayed for time of day.

All Country of Origin / ingredients claims are accurate.

Hot chickens are your opportunity to generate a $10 unit sale. Is your Hot Box and Grab ‘N’ Go unit full when it needs to be?

Page 31

Date-code check is completed daily and actioned.

No foreign objects and personal food stuffs are in the preparation area.

Reserve stock is stacked within safety guidelines.

Stock control is in use for product ordering.

Sufficient stock weight of promotions and displays are replenished as required.

Increase your display stock levels in line with your customer demand to drive sales and reduce shrinkage.

All documentation for legislative compliance is completed, filed and maintained correctly.

Team members are dressed as per Food Safety Standards.

Clean aprons, hats and name badges are worn by team members (aprons are not worn on shop floor).

No jewellery, watches or nail polish worn by team members.

De

licat

ess

en

Page 32

Bak

ery

Coverage of in-store baked products are available at start of the day’s trade.

Bread crumbs are removed from merchandising units.

Tongs and bags are clean and readily accessible.

Promotional locations are full and ready for the day’s trade.

Sliced white bread — is always available and on show.

Walk the department reviewing all fixtures, freshness, quality and eye appeal of product.

Review in-stock position, ensuring:

All of the core range is available.

Out of stocks reviewed and filled where possible.

Loose roll fixture is full and ready for trade.

In-store baked product is amongst the highest GP contribution range in your store. Are you maximising your opportunity?

Page 33

All baked-in store products are within quality

guidelines*, removing products that:

Do not pass the ‘Would I Buy It?’ check.

Remove fresh bread products that are yesterdays’ production.

Out-of-code checks conducted and actioned.

*refer to Metcash approved suppliers benchmark sheets.

Ensure all of your kilojoule reference statement are located prominently!

All ingredients are stored in air tight containers, date-coded and stored correctly.

Stock control is in use for product ordering.

Production schedule is in use and correctly filled out.

All documentation for legislative compliance is completed, filed and maintained correctly.

Cabinet, bin and fridge cleaning rosters are in place and actioned.

Bak

ery

Page 34

Bak

ery

All products are ticketed.

All promotions are merchandised and ticketed correctly.

No foreign objects and personal food stuffs are in preparation areas or cool rooms.

All Country of Origin and ingredients claims are accurate.

Good fresh food practices are vital in giving your customers the safest and highest quality stock available.

All team members dressed as per required standards.

Clean aprons, hat and name badges are worn by all team members (note that aprons are not worn on shop floor).

No jewellery, watches or nail polish are worn by team members.

Page 35

When implemented, the following Key Value Drivers will provide your customers with a positive long life offer due to product availability, excellent displays and merchandising, and a friendly and convenient shopping experience.

Always view your store through a customer’s eyes, ensuring that the shopping environment is clean and safe and that your full range is available for self-selection.

Lon

g Li

fe R

etai

l Exc

elle

nce

If a customer looks lost, offer your assistance and take them to the product they are looking for.

Page 36

Shelves are clean and dust free.

Shelves and fixtures are in good condition.

All clip strips are full, ticketed and relate (cross merchandise) to the aisle.

Deleted lines have been actioned and new lines ready to replace them.

Damaged / out-of-code stock is removed and actioned.

Gro

cery

Catalogue lines are available (check against

catalogue).

All promotions are merchandised and ticketed correctly.

All shelves are well-stocked and product is available to purchase.

Stock on shelves has correct shelf tickets and is pulled-forward and faced-up (labels facing the front).

Well-stocked shelves invite customers to stay in your store and shop. Are your shelves well-stocked and inviting?

Page 37

Ends and Displays are:

Well-stocked.

Cross merchandised and well ticketed.

As per promotional planner.

Neat, tidy and clean (looks inviting).

Free of damaged stock.

Stock is rotated using F.I.F.O. practices.

Week numbers are printed on capping stock, to support F.I.F.O., practices and capping is not over stocked.

Night fill carton rate productivity is completed daily.

All team members are dressed as per required store standards.

Workplace Health & Safety (WHS) practices are followed.

Empty shelves gives the impression your stock is poorly managed. Are your shelves, ends and displays full and inviting for customers to purchase?

Gro

cery

Page 38

Catalogue lines are available (check against catalogue).

All promotions are merchandised and ticketed correctly.

All shelves are well-stocked and product is available to purchase.

Stock on shelves has correct shelf tickets and is pulled-forward and faced-up (labels facing the front).

Dairy cabinets — clean, dust free, in good condition.

Deleted lines have been actioned and new lines ready to replace them.

Date-code checks have been actioned and recorded.

Temperature is not greater than; +4oC for chilled / refrigeration checks actioned and recorded.

Markdowns are actioned and recorded.

Good presentation is visually appealing — ‘eye appeal is buy appeal’

Are your shelves well stocked and inviting?

Dai

ry

Page 39

Freezers — clean, dust free and in good condition.

Deleted lines have been actioned and new lines ready to replace deleted lines.

Date-code checks have been actioned and recorded.

Temperature no greater than; -18oC for freezers and checks are actioned and recorded.

Markdowns actioned and recorded.

Catalogue lines are available (check against catalogue).

All promotions are merchandised and ticketed effectively.

All shelves are well-stocked and product is available to purchase.

Stock on shelves has correct shelf tickets and is pulled-forward and faced-up (labels facing the front).

Fre

eze

r

Empty shelves give the impression stock is poorly managed. Are your shelves, ends and displays full and inviting for customers to purchase?

Page 40

Stock that is out of date-code has been actioned and recorded correctly.

Stock-on-hand and order level quantities are reviewed.

Temperatures are checked and actioned for all dairy and chiller product lines upon delivery.

All deliveries are checked against the invoice or delivery docket.

Reduce wastage by making the first markdown the best markdown.

Temperature is not greater than; +4oC for coolrooms checks actioned and recorded.

Coolrooms clean to Food Safety Standards

Excess stock stored correctly and date-codes recorded on carton using F.I.F.O. practices.

Stock that is to be returned for credits are actioned.

Daily milk order is reviewed and submitted.

Dai

ry C

oo

lro

om

s

Page 41

Temperature is not greater than; -18oC for freezer

rooms checks actioned and recorded.

Freezer rooms clean to Food Safety Standards

Excess stock stored correctly and date-codes recorded on carton using F.I.F.O. practices.

Stock that is to be returned for credits are actioned.

Workplace Health & Safety practices are followed.

Stock-on-hand and order level quantities reviewed.

Temperatures are checked and actioned for all freezer product lines upon delivery.

All deliveries are checked against the invoice or delivery docket.

Team members wear appropriate personal protection equipment (PPE clothing) when working in Freezer Rooms.

Ensure coolroom doors are kept closed at all times.

Fre

eze

r R

oo

ms

Page 42

Cigarettes stored securely immediately after delivery.

All equipment working correctly.

Safety signs available, fire exists clear and fire equipment accessible.

All Personal Protection Equipment (PPE) available.

Workplace Health & Safety practices are followed.

Back dock door closed when not receiving deliveries.

Back Dock / Storeroom is clean, free of clutter.

Delivery area cleared to be able to receive deliveries.

Excess stock stacked neatly on pallets. Do not use shopping trolleys.

All shrinkage has been actioned and recorded.

All refrigeration and freezer deliveries have been temperature checked and recorded.

Bac

k D

ock

Good receiving processes provide a safe environment to receive deliveries and to store stock. Does your receiving processes maximise quality stock control?

Page 43

All deliveries are checked against the invoice

(or delivery docket) immediately.

All invoices are signed (or stamped) after the check has been completed and stored securely.

All credits actioned immediately.

All stock transfers actioned to the correct department.

All logbooks reviewed to ensure processes have been actioned:

Wastage and Shrinkage logbook.

Temperature Check logbook.

Markdown logbook.

Scale Check logbook.

Staff rosters reviewed.

Administration processes identify overcharges and quantities under or non-delivered which impacts your store’s GP and shrinkage. Check deliveries against the invoice!

Ad

min

istr

atio

n