Ventilated Facades Brochure LoRes2

-

Upload

stroescu-silviu -

Category

Documents

-

view

58 -

download

4

Transcript of Ventilated Facades Brochure LoRes2

Well Insulated

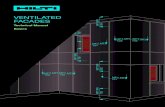

Ventilated Façades

Building InsulationSeptember 2004

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

2

ContentsWell Insulated Ventilated Façades .......... 3

The Design of a GoodFunctional Ventilated Wall ..................... 4

Why Choose Paroc Stone Wool ............. 6

Energy Efficient Building ........................ 8

Applications ........................................ 10

•Nordic Wall with Cladding ................ 10

•Nordic Wall with Brick Lining ............ 11

•Cross-Laid Frame with Cladding ...... 12

•Frame with Cladding ........................ 14

•Frame with Brick Lining .................... 15

• Industrial Wall Structure No I ............ 16

• Industrial Wall Structure No II ........... 17

•Glass Curtain Façade ....................... 18

•Steel Cassette Façade No I ............... 19

•Steel Cassette Façade No II .............. 20

•Concrete with Brick Lining No I ......... 22

•Concrete with Brick Lining No II ........ 23

•Curtain wall with Façade Panel No I . 24

•Curtain wall with Façade Panel No II 26

Product Information ............................ 28

General Instructions forInsulation Work ................................... 30

3

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

fire. It should also be able to allowinternal moisture to be conveyedthrough it to the outside. In addition,especially in colder climates, theinsulation should be able to minimiseor even eliminate, the effect of coldbridges caused by components, such asconcrete, steel or wooden studs, thatpass through the various layers of thewall structure.

Effective solutions through theuse of Paroc stone wool thermalinsulationParoc stone wool thermal insulation isan effective solution to the challengesof layered external walls. With a broadrange of products and structuralconfigurations, the right insulation forany climate or building can be easilyfound.

The range comprises differentinsulation of varying size and rigidityand with different coatings and wind-proofing specifications. Paroc stonewool is a versatile and durable highquality thermal insulation. It is hasgood elasticity and compressivestrength, is non-combustible and doesnot absorb moisture. Furthermore,Paroc stone wool offers effective soundinsulation and is environmentallyfriendly throughout its lifecycle.

The applications which Parocthermal insulation products can beapplied to and combined with offer asimilar degree of versatility.Depending on the climate andbuilding type Paroc offers a number ofsolutions that combine differentinsulation products with different wallstructures. Whatever your insulationneeds, Paroc has the answer.

Well InsulatedVentilated Façades

The advantages of wellinsulated ventilated facadesThe use of layered external wallstructures fitted with a separate,ventilated, façade creates an effectiveand durable climate shield whencombined with the right thermalinsulation solution.

Various types of ventilated wallstructures are available, each designedwith different requirements in mind.A structure that fulfils the needs ofone building or climate might notnecessarily function so well in another.

It is, however, possible to identifyseveral common requirements that allexternal wall structures should be ableto meet. Cold, wind, precipitation,sound and fire should all be preventedfrom penetrating through the wallstructure into the building. With theright choice of thermal insulation,these are requirements that can be metby any external wall.

In addition, the use of the correctthermal insulation can generatesignificant financial andenvironmental benefits. With well-insulated external walls the amount ofenergy needed to heat a building isreduced, thereby saving money onenergy bills and contributing towardsa reduction in emissions at the energygeneration level. Of course the moretangible environmental benefits of awarm, dry, draft-free and quietbuilding will be felt and appreciatedby everybody throughout the entirelifetime of the structure.

The challenges of this type ofstructureWhen layered external walls are used,a ventilation air gap is almost alwaysrecommended between the insulationlayer and the external façade. Thistype of structure demands highperformance, reliable and durablethermal insulation.

The thermal insulation should beimpervious to external moisture, windand sound and be highly resistant to

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

4

External Walls ProvideProtection Against the Elements

The external walls of a buildingfunction as a climate shield andshould protect against cold,precipitation, strong winds, noise andfire. A good external wall structure,with the right insulation solution, is aprerequisite for a healthy and pleasantindoor climate.

Wind protection requirementsNational building codes seldom giveany requirements for wind protection.In such cases our recommendationsbelow could be followed. Ifrequirements are given in nationalbuilding codes, and exceed theserecommendations, the nationalrequirements should be followed. Therecommendations below are based onscientific investigations, carried out inFinland and Lithuania by externalresearch institutes, and long-termexperience in the Nordic countries.

Protecting your thermalinsulationVentilated facades can be designed inmany different ways, but all systemsshould prevent deterioration of theinner shell due to moisture. If thethermal insulation has an openstructure, like universal slabs, thisneeds to be shielded by a wind barrierso that the thermal performance of theinsulation is preserved. The airventilation openings in the facadelayer, and the gap thickness,determine the wind protectionneeded. The construction examplesshown below create a foundation for adurable and functioning building.

Air tightnessTo avoid air flowing through thestructure and causing negative effects,an air infiltration barrier needs to beplaced on the inside of the buildingenvelope. The requirements of airtightness set for the barrier are often

The Design of a Good Functional Ventilated Wall

given in the building codes for eachmarket area, but the general trend istowards improved air tightness, inparticular after the adoption of theEnergy Performance Directive inEurope.

In practice, sufficient air tightnessis achieved by the use of massivestructures such as concrete ormasonry, but in the case of (light)frame constructions, an air infiltrationbarrier such as a plastic foil isnecessary. The air tightness of thebuilding envelope could be measuredin accordance with the standardizedpressure test EN 13829, by subjectingthe building to a 50 Pa overpressureand evaluating the air exchange rate ofthe building. The air exchange rateshould not exceed 1 per hour.

The importance of air gapsIn a ventilated exterior wall, an air gapis placed behind the facade. Thepurpose of the gap is to remove excessmoisture from the structure by theflow of air, and keep it dry to ensureproper functioning. The air flow inthe gap is normally upwards.Openings are designed at the bottomto allow the air to enter the gap. In thegap the air warms, picking upmoisture, and flows up until releasedthrough the openings at the top of thewall.

Preventing cold air intrusionA wind barrier is used to stop thewind from blowing through or aroundthe universal (light density) thermalinsulation and causing “forced’’convection in the insulation. Thiswould have a negative impact on thethermal performance of the universalinsulation. The wind protectionshould also have relevant moisturevapor transfer capability in order totransfer moisture vapor into theventilated air gap.

The surface material of the windprotection should also be chosen tocomply with the fire safety

moisturebarrier

windbarrier

requirements in each market area. Thefire safety requirements are usuallyonly imposed for high-rise buildings.The wind protection can either be afaced or non faced stone wool boardor slab, structural board, or a foil.Corners are often a critical point inventilated wall constructions so specialcare must be taken in order to avoidair intrusion. See examples ofsolutions in the installation guidelines.

Fire ProtectionBoth external and internal walls needto offer protection against fire. Whenselecting insulation for external walls,two issues should be considered – howthe material reacts in a fire and towhat extent it can resist fire. Whilealmost all types of mineral wool areclassified as non-combustible material,Paroc stone wool boasts anexceptionally high meltingtemperature of around 1000 °Cproviding longer protection.Therefore, rather than adding to thefire load, Paroc stone wool offers aneffective fire resistant thermalinsulation solution.

5

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

To design the insulation of ventilatedexternal walls, see also the “Designand Installation Guidelines” duringdimensioning and installation inwww.paroc.com.

Minimizing Cold BridgesMassive beams that run through thewall construction create cold bridges.Cold bridges are among the mostproblematic structural components interms of structural functionality. Heatloss via cold bridges occurs at a fargreater rate than via surroundingstructural components. In addition,the moisture condensation that occursat cold bridges increases theaccumulation of moisture in thefaçade structure. Cold bridges can,however, be minimized through theuse of a wall construction with a fully-covering insulation layer and bykeeping to a minimum the size andquantity of fastenings and othercomponents that pass through thethermal insulation layer.

Sound InsulationAs traffic noise and other lowfrequency sounds have increased,requirements for effective soundinsulation in walls have becomestricter. By using stone wool wallinsulation, noise reduction can beimproved significantly.

Additional InsulationThe question of additional thermalinsulation is most commonly raisedduring renovation. Additional thermalinsulation is usually chosen in order toincrease living standards, improveenergy efficiency or as part of façaderepair and maintenance. Additionalinsulation can be installed eitherexternally or internally, thoughexternal insulation is most efficient as

it provides the building with a fully-covering insulation layer without coldbridges and does not reduce the insideroom area. External insulation alsoprevents moisture related problemsbetter than internal insulation.

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

6

Stone Wool is Versatile Non-combustible Thermal InsulationParoc stone wool is the most versatileand commonly used thermalinsulation material in many Europeancountries.

Paroc stone wool uniquelycombines excellent thermal and soundinsulation properties with a highly fireretardant material. In addition toconstruction, stone wool is used inconditions that impose extremelydemanding and versatile requirementson insulation such as the shippingindustry and nuclear power plants.

Excellent Fire ResistanceProperties in ConstructionsParoc stone wool is made of stone andcan therefore be used as thermalinsulation in applications with highlydemanding fire specifications. Almostall types of mineral wool are classifiedas non-combustible material, butParoc stone wool has high meltingtemperature of around 1000 °C

providing long protection. Therefore,rather than adding to the fire load,Paroc stone wool offers an effectivefire resistant thermal insulationsolution. Most non-coated Paroc stonewool products are classified asEuroclass A1.

Because of its unique fireproperties Paroc stone wool can beutilized as fire insulation and asstructural protective cladding. Instructures insulated with Paroc stonewool, the spreading of any fire isretarded or prevented altogether.

Life-long Insulation MaterialParoc stone wool retains its thermalinsulation properties for the entirelifetime of a building. Paroc stonewool is a chemically robust materialwith a strong resistance to organic oilsand solvents.

Retains Its FormParoc stone wool does not expand orshrink, even as a result of dramaticchanges in temperature or humidity.Therefore no cracks will form at thejoints of the slabs and there isconsequently no risk of heat leakage ormoisture condensation.

Does Not Absorb or AccumulateMoistureParoc stone wool does not absorb oraccumulate moisture in a capillaryway, because it ensures rapidevaporation of temporary occuringmoisture. A building insulated withParoc stone wool stays dry ensuringhealthy internal air quality and thelongevity of the building. Extensiveresearch carried out in Finland byTampere University of Technology andTurku University confirms that Parocstone wool is a poor environment formicrobe growth.

Good Elasticity and CompressionStrengthThe various types of Paroc stone woolinsulation products are developed for

different purposes. Flexible stone woolis elastic and easy to cut to the rightsize and install tightly in structures.Rigid stone wool is capable of bearingcompression loads of up to 80 kPa.

Efficient Sound InsulationDue to its porous fiber structure andsuitable density, Paroc stone woolprovides excellent insulation againstexternal noise through walls and roofsas well as internal noise throughpartitions, intermediate floors andacoustic ceilings.

Environmentally FriendlyParoc stone wool is environmentallyfriendly throughout its lifecycle,causing no harm to nature during orafter use. Stone wool does not containany ingredients or chemicals thatprevent or impede recycling.

Paroc Stone Wool and IndoorAir QualityParoc stone wool is an extremely cleanmaterial and as such has been selectedas the insulation material for housesbuilt for people with allergies andrespiratory illnesses. The FinnishBuilding Information Foundation andthe Indoor Air Association bothclassify Paroc stone wool as the bestM1 grade in the emissionclassifications as it does not polluteindoor air.

Paroc — an Expert in InsulationAs one of the leading thermalinsulation manufacturers, Paroc,together with the top researchers andinstitutions in the field, has developedconsiderable expertise in the thermalinsulation sector.

Why Choose Paroc Stone Wool

Paroc stone wool withstands very hightemperatures. The image shows a testsample of the PAROC UNS product beforeand after an EN ISO 1182 non-combustion test where the test sample isburned at a temperature of 750 °C.

7

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

����������

��

���

���

��

���

��

�� �� � �� � �� ��

���

����

����

����

�

�������������������������� �!����

"#�����������#����#�

$�������������#���%����

&#�������������#����#�

&�����������'��#������������������������������(����(���)

�)���*����#+������*��������(��,��#������������������&-.���/��

�� �

The behavior of certain construction materials in a “standard”fire. A “standard fire” simulates the development oftemperature of a fire in normal room space.

Stone wool does not melt even in a fire. Thus a structure canwithstand a fire considerably longer, which can criticallyimprove the chance of rescue and limit damage.

Due to a “breathing”, air-permeable structure, moistureevaporates quickly in correctly realized constructions.

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

8

Energy Efficient Building

������(�����#�����

+�����%�������(��*�����#���%

����0��

1���%0�����

!�*��������

2��#���%������

One of the biggest threats to theglobal environment is the climatechange caused by the greenhouse gasesin the atmosphere. The mostimportant cause of this threat is theuse of fossil fuels. Buildings consumealmost 40 % of the primary energyused in Europe. That is more thantwice the energy consumption oftraffic and consequently contributes toa major part of the CO

2 emissions.

The construction sector faces amajor challenge in slowing down thisdevelopment, because a sizablepercentage of the energy used inbuildings could be saved by relativelyminor investments in energy efficientsolutions. A VTT study (VTT 1589,Energy Consumption and Profitability

Costs Savings in FacadesFacades play a profound role in theenergy efficiency of buildings.Depending on the building type andstructures, approximately one fifthof the energy losses of buildings takeplace through the external walls,excluding the effect of windows anddoors.

Insulation U-value Energy Heating SavingsThickness loss/m2/year costsmm W/m2K kWh/m2/year € /m2/year € /m2/year

0 1.49 196.9 11.82 0150 0.22 28.7 1.72 10.1

Helsinki climatic zoneEnergy price 0.06 € / kWh

The calculation is based on the average Finnish energy price of0.06 €/kWh and using the Helsinki climate conditions. Theclimate conditions in Helsinki are about the same as in Estonia,Latvia and part of Lithuania, as can be seen from the map.

The total costs of the building during itslifetime

As the simple calculation belowshows, up to 10€ in heating costsevery year per each square meter ofexternal wall can be saved by adding150 mm of stone wool compared toa non-insulated wall. Consider thetotal savings during the lifetime ofthe building!

of Energy-Saving Measures in a Low-Energy House, Espoo 1994) showsthat 50 % savings in heating energyconsumption, compared to an averageconsumption level, can easily bereached with normal buildingtechnology. The pay back time forsuch an investment is 5 - 6 years.

The average cost of insulation istypically 2 - 5 % of the building costs.An investment in insulation easilyresults in substantial savings in heatingcosts during the lifetime of thebuilding.

The EU has ratified a directive onEnergy Performance of Buildings,which requires every EU country toestablish legislation to certify buildingsaccording to their energy efficiency.

These energy loss calculations are carried out with DOF Thermalsoftware, which can be used to calculate the U-values, energylosses and moisture distribution in all kind of structures based onthe EN standards.

DOF Thermal software is available at www.doftech.fi

9

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

WAS 50 WAS 25t or WAS 35tt or WPS3n

50 mm 70 mm 30 mm 50 mm

100 mm 0.25 0.22 0.30 0.25

125 mm 0.22 0.20 0.25 0.22

150 mm 0.20 0.18 0.22 0.20

175 mm 0.18 0.16 0.20 0.18

200 mm 0.16 0.15 0.18 0.16

Recommended InsulationThicknessesTo help to design economicalinsulation solutions we have calculatedU-values for each application on thefollowing pages. The U-values markedwith blue color fulfill the Finnishthermal insulation requirements TheU-values marked with red colorrepresent energy efficient, economicallow-energy insulation thicknesses. TheParoc low-energy concept represents abuilding that consumes half theheating energy compared to anaverage building.

The U-values have been calculatedusing Lambda-design values. For stonewool lambda-design = lambda-declared. National Building Codesand EN 6946 may require anadditional delta-U correction in orderto take into consideration air gaps,convection, incorrect installation,fasteners etc. In these calculations wehave taken into account only the effectof possible fasteners.

The U-values marked withblue color fulfill the Finnish

thermal insulationrequirements The U-values

marked with red colorrepresent energy efficient,

economical low-energyinsulation thicknesses.

U-value = Thermal transmittancethrought theconstruction per m2,W/m2K

Lamda-declared = Thermal conductivityof a materialdeclared by themanufactor

Lamda-design = Thermal conductivityof a material used indetermining the U-value

UNS 37,thickness (mm)

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

10

" Internal facing

" Air and vapor barrier

" Wooden stud 50 mm x thickness,

c 600, and PAROC UNS 37

" PAROC WAS 25t ≥ 30 mm or

PAROC WAS 35tt ≥ 30 mm

" Nail batten + ventilation gap ≥ 20mm

" Wooden panel

Nordic Wall with Cladding

Fully-covering wall insulation on topof the studs significantly reduces coldbridges and the amount of moistureon the wooden studs. We call thisconstruction a Nordic Wall - ournumber one recommendation for awooden structure. In a Nordic Wallthe desired U-value can be achievedwith a thinner structure compared toother wooden structures.

A wooden panel allows high airmovements in the ventilation gap.Therefore we recommend the use oflow air permeability products, such asPAROC WAS 25t or PAROC WAS35tt on top of the studs.

The role of the internal air andvapor barrier is essential in thisstructure: together with the windbarrier it is the only air tight structurallayer.

123

4

56

1

2

3

4

5

6Alternative solution:PAROC WPS 3nas a wind barrier

U-values according to EN-standards (W/m2K)

WAS 25t or WAS 35tt or WPS 3n

30 mm 50 mm

100 mm 0.30 0.25

125 mm 0.25 0.22

150 mm 0.22 0.20

175 mm 0.20 0.18

200 mm 0.18 0.16

These U-values have been calculated using λdesign -values. For stone wool the λdesign value is equal to λdeclared value calculated according to EN standards. The surface resistances and

U-value corrections used in this calculation are stated below. These corrections may be different in each country; the correct values are declared in national building codes.

Rsi = 0.13 m2K/W

Rse = 0.13 m2K/W

∆U” = 0 W/ m2K

∆Uf = 0 W/ m2K

The internal facing and the wooden panel are not included in the U-value.

UNS 37

11

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

Nordic Wall with Brick Lining

The Nordic Wall with brick liningprovides an excellent solution for theextreme condition requirements of theNordic winter. Fully-covering wallinsulation on top of the studssignificantly reduces cold bridges andthe amount of moisture on thewooden studs.

A brick façade keeps the airmovements in the ventilation channelat a lower level compared to a woodenpanel. A brick wall absorbs a lot ofwater – the water may even penetratethrough the whole brick lining. Toprevent the water from leaking intothe insulation a proper ventilation gapmust be designed. The gap must besolid, open and finless. To ensureproper ventilation of the structure,every third vertical seam of the secondlowest layer of bricks should be leftopen.

The wall must also be designed sothat water can run out of thestructure.

" Internal facing

" Air and vapor barrier

" Wooden stud 50 mm x thickness,

c 600, and PAROC UNS 37

" PAROC WAS 35 ≥ 30mm or

PAROC WAS 50 ≥ 50mm

" Ventilation gap ≥ 20mm

" Façade stone

56

123

4

5 6

1

2

3

4

Alternative solution:PAROC WPS 3nas a wind barrier

UNS 37,thickness (mm)

U-values according to EN-standards (W/m2K)

WAS 50 WAS 25t or WAS 35tt or WPS3n

50 mm 70 mm 30 mm 50 mm

100 mm 0.25 0.22 0.30 0.25

125 mm 0.22 0.20 0.25 0.22

150 mm 0.20 0.18 0.22 0.20

175 mm 0.18 0.16 0.20 0.18

200 mm 0.16 0.15 0.18 0.16

These U-values have been calculated using λdesign -values. For stone wool the λdesign value is equal to λdeclared value calculated according to EN standards. The surface resistances and

U-value corrections used in this calculation are stated below. These corrections may be different in each country; the correct values are declared in national building codes.

Rsi = 0.13 m2K/W

Rse = 0.13 m2K/W

∆U” = 0 W/ m2K

∆Uf = 0 W/ m2K

The internal facing and the façade stone are not included in the U-value.

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

12

" Internal facing

" Air and vapor barrier

" Primary stud(s) 50 mm thickness,

c 600 + PAROC UNS 37

" Secondary stud 50 mm thickness,

c 600 + PAROC UNS 37

" Wind protection (structural board, foil)

" Nail batten + Ventilation gap ≥ 20mm

" Wooden panel

Cross-Laid Frame with Cladding

A cross-laid stud frame wall is therecommended structure when a singleframe is not enough. However aNordic Wall is often a moreeconomical solution and gives betterthermal resistance.

The horizontal cross laidsecondary studs can also be mountedon the inside*. The vapor barrier isthen installed between the woodenframe and the secondary frame. Thisstructure allows electricity cables to bedrawn inside the vapor barrier.Therefore there is no need to breakthe vapor barrier which means there isless leakage.

5

6

7

1

2

3

4

567

123

4

U-values according to EN-standards (W/m2K)

Secondary stud & UNS 37

50 mm 75 mm

100 mm 0.26 0.23

125 mm 0.23 0.20

100+50 mm* 0.20 0.18

125+50 mm* 0.18 0.16

150+50 mm* 0.16 0.15

*) + 50 mm means a horisontal stud mounted horisontal on the inside.

These U-values have been calculated using λdesign -values. For stone wool the λdesign value is equal to λdeclared value calculated according to EN standards. The surface resistances and

U-value corrections used in this calculation are stated below. These corrections may be different in each country; the correct values are declared in national building codes.

Rsi = 0.13 m2K/W

Rse = 0.13 m2K/W

∆U” = 0 W/ m2K

∆Uf = 0 W/ m2K

The internal facing and the wooden panel are not included in the U-value.

A 9 mm wind protection plaster board is included.

Primary stud(s)& UNS 37

13

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

14

Frame with Cladding

This type of wall contains the mostimportant components of an insulatedwall structure. However meeting highlevel thermal requirements results in athick and uneconomical wooden studsize. Often it is a better solution to usea Nordic Wall application, which ismore economical and gives muchbetter thermal resistance.

• Internal facing

" Air and vapor barrier

" Wooden stud 50 mm x thickness,

c 600, + PAROC UNS 37

" Wind protection (structural board, foil)

" Nail batten + ventilation gap

" Wooden panel

U-values according to EN-standards (W/m2K)

UNS 37

125 mm 150 mm 175 mm 200 mm 225 mm

0.34 0.29 0.25 0.22 0.20

These U-values have been calculated using λdesign -values. For stone wool the λdesign value is equal to λdeclared value calculated according to EN standards. The surface resistances and

U-value corrections used in this calculation are stated below. These corrections may be different in each country; the correct values are declared in national building codes.

Rsi = 0.13 m2K/W

Rse = 0.13 m2K/W

∆U” = 0.01 W/ m2K

∆Uf = 0 W/ m2K

The internal facing and the wooden panel are not included in the U-value.

A 9 mm wind protection plaster board is included.

5

6

1

2

3

4

56

123

4

15

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

Frame with Brick Lining

This type of wall contains the mostimportant components of an insulatedwall structure. However meeting highlevel thermal requirements results in athick and uneconomical wooden studsize. Often it is a better solution to usea Nordic Wall application, which ismore economical and gives muchbetter thermal resistance.

A brick façade keeps the airmovements in the ventilation channelat a lower level compared to a woodenpanel. A brick wall absorbs a lot ofwater – the water may even penetratethrough the whole brick lining. Toprevent the water from leaking intothe insulation a proper ventilation gapmust be designed. The gap must besolid, open and finless. To ensureproper ventilation of the structure,every third vertical seam of the secondlowest layer-of-bricks should be leftopen.

• Internal facing

• Air and vapor barrier

• Wooden stud + PAROC UNS 37

• Wind protection (structural board, foil)

• Ventilation gap ≥ 20 mm

• Façade stone5

6

1

2

3

4

56

1234

U-values according to EN-standards (W/m2K)

UNS 37

125 mm 150 mm 175 mm 200 mm 225 mm

0.34 0.29 0.25 0.22 0.20

These U-values have been calculated using λdesign -values. For stone wool the λdesign value is equal to λdeclared value calculated according to EN standards. The surface resistances and

U-value corrections used in this calculation are stated below. These corrections may be different in each country; the correct values are declared in national building codes.

Rsi = 0.13 m2K/W

Rse = 0.13 m2K/W

∆U” = 0.01 W/ m2K

∆Uf = 0 W/ m2K

The internal facing and the wooden panel are not included in the U-value.

A 9 mm wind protection plaster board is included.

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

16

Industrial Wall Structure No I

This is a typical solution for semiheated industrial buildings andwarehouses.

The metal frame sets specificthermal insulation requirements. Thethermal conductivity of stainless steelis about 400-times higher than that oftimber and over 1000-times higherthan that of stone wool! However, thethermal resistance of the structure canbe significantly improved by addingfully-covering wall insulation on topof the steel studs. An insulation layerbreaks down the cold bridgeseffectively.

In buildings where the indoor airconditions are demanding; for examplehigh humidity and/or temperature, itis especially important to design aproper, solid moisture barrier andadequate ventilation of the façade.

The fire performance of the finalwall structure is strongly affected bythe fire properties of the insulation.All Paroc stone wool productspresented here belong to Euroclass A1- stone wool tolerates high temperaturesof up to 1000 °C, protecting the steelstructures from fire.

• Sheet metal

• Air and vapor barrier

• Steel frames + PAROC UNS 37

• PAROC WAB 10t, 20 mm

• Air ventilation gap

Sheet metal

51

2

3

4

5

1234

6

6

U-values according to EN-standards (W/m2K)

1) Steel frames 0.7 c 600, steel screw diameter 4 mm c 3002) Steel frames 0.7 mm c 1200, steel screw diameter 4 mm c 3003) Steel frames 1.5 mm c 600, steel screw diameter 4 mm c 3004) Steel frames 1.5 mm c 1200, steel screw diameter 4 mm c 300

WAB 10t

20 mm 20 mm 20 mm 20 mm1) 2) 3) 4)

100 mm 0.45 0.37 0.47 0.38

125 mm 0.40 0.32 0.42 0.33

150 mm 0.36 0.28 0.38 0.30

175 mm 0.33 0.26 0.35 0.27

200 mm 0.31 0.23 0.33 0.25

These U-values have been calculated using λdesign -values. For stone wool the λdesign value is equal to λdeclared value calculated according to EN standards. The additional ∆U-value

used in this calculation is stated below. The ∆U-value may be different in each country; the correct value is declared in national building codes.

Rsi = 0.13 m2K/W

Rse = 0.04 m2K/W

∆U” = 0 W/ m2K

The internal and the external sheet metals are not included in the U-value.

These recommendations are based on half-warm buildings requirements.

UNS 37

17

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

Industrial Wall Structure No II

This kind of structural solution iscommonly used in semi heatedindustrial buildings and warehouses,although we recommend that itshould be applied only to buildingswith a low indoor temperature. Thesteel frame forms cold bridges throughthe insulation; the effect of the coldbridges is greater the higher thetemperature difference over the wall is.The cold bridges should be eliminatedby a layer of fully covering insulation.See the application on the previouspage.

The fire performance of the finalwall structure is strongly affected bythe fire properties of the insulation.All Paroc stone wool productspresented here belong to Euroclass A1- stone wool tolerates high temperaturesof up to 1000 °C, protecting the steelstructures from fire.

• Sheet metal

" Air and vapor barrier

" Steel frames + PAROC UNS 37

" Wind protection (structural board, foil)

" Air ventilation gap

Sheet metal5

12

3

4

5

1234

U-values according to EN-standards (W/m2K)

UNS 37

100 mm 125 mm 150 mm 175 mm 200 mm

1.5 mm, c 600 0.89 0.78 0.69 0.62 0.57

1.0 mm, c 600 0.78 0.67 0.59 0.53 0.48

0.7 mm, c 600 0.69 0.59 0.52 0.46 0.42

1.5 mm, c 1200 0.62 0.53 0.46 0.41 0.37

1.0 mm, c 1200 0.57 0.48 0.41 0.37 0.33

0.7 mm, c 1200 0.52 0.44 0.38 0.33 0.30

These U-values have been calculated using λdesign -values. For stone wool the λdesign value is equal to λdeclared value calculated according to EN standards. The additional ∆U-value

used in this calculation is stated below. The ∆U-value may be different in each country; the correct value is declared in national building codes.

Rsi = 0.13 m2K/W

Rse = 0.04 m2K/W

∆U” = 0 W/ m2K

The internal facing and the external sheet metal are not included in the U-value.

These recommendations are based on semi-warm buildings requirements.

Steelframe

6

6

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

18

is fitted due to the risk of colorchanges in the surface.

The fire performance of the finalwall structure is strongly affected bythe fire properties of the insulation.All Paroc stone wool productspresented here belong to Euroclass A1- stone wool tolerates high temperaturesof up to 1000 °C, protecting the steelstructures from fire.

Glass curtain facade

Glass curtain facades are very commonlyused in office buildings all over Europe.There are many different kinds ofglass facade systems available and allmay have specific requirements on theinsulation application. This applicationshows only one principal solution.

As with industrial walls, the metalframe sets specific thermal insulationrequirements. The thermal conductivityof stainless steel is about 400-timeshigher than that of timber and over1000-times higher than that of stonewool. The thermal resistance of thestructure can be significantly improvedby adding fully-covering wall insulationon top of the steel studs. An insulationlayer breaks down the cold bridgeseffectively.

Well thought-out structural designis especially important in glass facades,because any mistakes often causevisual harm and are therefore easy todetect through the glass. For example,cold bridges often cause moisturecondensation, which may result incolor changes on the surface. Forphysical as well as visual reasons it isimportant to install a proper, solid

moisture barrier to prevent the internalmoist air from leaking through thewall structure and condensing on theglass. Effective ventilation is alsoneeded to prevent condensation.

A wall insulation slab with blacktissue forms an elegant background tothe glass façade. It’s not recommendedto have the black tissue coveredinsulation unprotected before the glass

• Internal facing

• Air and vapor barrier

• Steel frames + PAROC UNS 37

• PAROC WAS 25tb or

PAROC WAS 35tb or

PAROC WAS 50tb

• Air ventilation gap

• Glass façade

5

1234

6

1 2

3 4

5

6

U-values according to EN-standards (W/m2K)

WAS 25tb or WAS 35tb WAS 50tb

30 mm 50 mm 50 mm 70 mm

100 mm 0.34 0.30 0.31 0.28

125 mm 0.29 0.27 0.27 0.25

150 mm 0.26 0.24 0.24 0.22

175 mm 0.23 0.21 0.21 0.20

200 mm 0.21 0.19 0.19 0.18

These U-values have been calculated using λdesign -values. For stone wool the λdesign value is equal to λdeclared value calculated according to EN standards. The additional ∆U-value

used in this calculation is stated below. The ∆U-value may be different in each country; the correct value is declared in national building codes.

Rsi = 0.13 m2K/W

Rse = 0.13 m2K/W

∆U” = 0 W/ m2K

∆Uf = 0.016 W/ m2K

The internal facing and the glass facade are not included in the U-value.

NOTE: The values in the table only indicate the relation between different insulation thicknesses. The steel frames and the construction details influence the values and shall beaccounted for.

UNS 37

19

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

Steel Cassette facade No I

A steel cassette façade has become apopular application in office buildingsand other commercial buildings. Inaddition to block walls it can beapplied on concrete walls, brick wallsand of course on steel frames as well.The insulation application is basicallythe same. When designing a steelcassette façade on steel frame walls, seethe special instructions about moistureand air tightness described on page16: Industrial Wall no I.

The lightweight blocks themselveshave good thermal properties.However it is often more economicalto use thinner blocks and cover thethermal insulation requirements byinsulation – if it is possible in terms ofthe mechanical requirements. The useof fully-covering insulation betweenthe steel cassettes and the supportingframe breaks down cold bridgeseffectively.

Profiles and the steel façade systemare mounted in accordance with thesystem providers’ instructions. Thefastening system should be designedso that it leads water outsidethe wall.

All Paroc stone wool productspresented here belong to the EuroclassA1 and fulfill the highest fire demands.

• Light weight blocks, concrete,

brick or steel frame

• Steel frames + PAROC UNS 37

• PAROC WAS 25t ≥ 30mm

• Air ventilation gap

• Façade cassette5

1

234

1

2

3

45

U-values according to EN-standards (W/m2K)

1) Steel frames 1.5 mm c 6002) Steel frames 0.7 mm c 6003) Steel frames 1.5 mm c 12004) Steel frames 0.7 mm c 1200

WAS 25t

30 mm 30 mm 30 mm 30 mm1) 2) 3) 4)

75 mm 0.50 0.48 0.42 0.41

100 mm 0.46 0.43 0.37 0.36

125 mm 0.43 0.40 0.33 0.32

150 mm 0.41 0.38 0.31 0.30

175 mm 0.39 0.36 0.29 0.28

200 mm 0.38 0.35 0.28 0.26

These U-values have been calculated using λdesign -values. For stone wool the λdesign value is equal to λdeclared value calculated according to EN standards. The additional ∆U-value

used in this calculation is stated below. The ∆U-value may be different in each country; the correct value is declared in national building codes.

∆U” = 0.04 W/ m2K

Rsi = 0.13 m2K/W

Rse = 0.04 m2K/W

An 80 mm internal concrete slab is included, but not the ventilation gap.

NOTE: The values in the table only indicate the relation between different insulation thicknesses. The steel frames and the construction details influence the values and shall beaccounted for.

UNS 37

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

20

• Concrete brick or other stone

based frame

" Steel frames + PAROC UNS 37

" Wind protection (foil, structured

board)

" Air ventilation gap

" Façade cassette

Steel Cassette facade No II

This insulation application is a moreeconomical version of the applicationpresented on the previous page. Inaddition to block walls it can beapplied on concrete walls, brick wallsand of course on steel frames as well.

The lightweight blocks themselveshave good thermal properties.However it is often more economicalto use thinner blocks and cover thethermal insulation requirements byinsulation – if it is possible in terms ofthe mechanical requirements.

Profiles and the steel façade systemare mounted in accordance with thesystem providers’ instructions. Thefastening system should be designed sothat it leads water outside of the wall.

All Paroc stone wool productspresented here belong to the EuroclassA1 and fulfill the highest firedemands.

5

1

23

4

1

2

3

4 5

U-values according to EN-standards (W/m2K)

UNS 37

100 mm 125 mm 150 mm 175 mm 200 mm

1.5 mm, c 600 0.60 0.53 0.48 0.44 0.42

1.0 mm, c 600 0.56 0.48 0.43 0.40 0.37

0.7 mm, c 600 0.52 0.44 0.40 0.36 0.34

1.5 mm, c 1200 0.49 0.42 0.37 0.34 0.31

1.0 mm, c 1200 0.46 0.40 0.35 0.31 0.29

0.7 mm, c 1200 0.45 0.38 0.33 0.30 0.27

These U-values have been calculated using λdesign -values. For stone wool the λdesign value is equal to λdeclared value calculated according to EN standards. The additional ∆U-value

used in this calculation is stated below. The ∆U-value may be different in each country; the correct value is declared in national building codes.

∆U” = 0.04 W/ m2K

Rsi = 0.13 m2K/W

Rse = 0.04 m2K/W

An 80 mm internal concrete slab is included, but not the wind protection or ventilation gap.

NOTE: The values in the table only indicate the relation between different insulation thicknesses. The steel frames and the construction details influence the values and shall beaccounted for.

Steelframe

21

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

22

Concrete with Brick Lining No I

A brick façade provides a beautiful,traditional appearance to a building.

When designing brick walls thefollowing criteria must be taken intoconsideration. Brick walls absorb a lotof water – the water may evenpenetrate through the whole bricklining. To prevent the water fromleaking into the insulation a properventilation gap must be designed. Thegap must be solid, open and finless. Toensure proper ventilation of thestructure, every third vertical seam ofthe second lowest layer of bricksshould be left open.

The wall must also be designed sothat water can run out of thestructure.

All Paroc stone wool productspresented here belong to the EuroclassA1 and fulfill the highest firedemands.

• Stone based frame:

Concrete slab (C), brick (B) light weight

concrete (LW) or aerated concrete (AC)

" PAROC WAS 50

" Air ventilation gap ≥ 20mm

" Façade stone

1

234

1

34

2

U-values according to EN-standards (W/m2K)

Frame

C 150 mm B 130 mm LW 150 mm AC 150 mm

50 mm 0,62 0,58 0,48 0,41

80 mm 0,43 0,41 0,36 0,32

100 mm 0,36 0,35 0,31 0,28

120 mm 0,31 0,30 0,28 0,25

150 mm 0,26 0,26 0,24 0,22

These U-values have been calculated using λdesign -values. For stone wool the λdesign value is equal to λdeclared value calculated according to EN standards. The additional ∆U-value

used in this calculation is stated below. The ∆U-value may be different in each country; the correct value is declared in national building codes.

Rsi = 0.13 m2K/W

Rse = 0.13 m2K/W

∆U” = 0.04 W/m2K

∆Uf = 0.005 W/m2K

∆U = 0,04 (including fasteners)

The internal concrete and the façade stone are not included the U-value.

WAS 50

23

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

Concrete with Brick Lining No II

A brick façade provides a beautiful,traditional appearance to a building.

When designing brick walls thefollowing criteria must be taken intoconsideration. Brick walls absorb a lotof water – the water may evenpenetrate through the whole bricklining. To prevent the water fromleaking into the insulation a properventilation gap must be designed. Thegap must be solid, open and finless. Toensure proper ventilation of thestructure, every third vertical seam ofthe second lowest layer of bricksshould be left open.

The wall must also be designed sothat water can run out of thestructure.

All Paroc stone wool productspresented here belong to the EuroclassA1 and fulfill the highest firedemands.

• Concrete block, brick or other stone

based frame

" PAROC UNS 37 and

" PAROC WAS 25t ≥ 30mm

or PAROC WPS 3n

" Air ventilation gap ≥ 20mm

" Façade stone5

1

23

4

1

3

4

5

U-values according to EN-standards (W/m2K)

WAS 25t or WPS 3n

30 mm 50 mm

75 mm 0.32 0.27

100 mm 0.27 0.23

125 mm 0.23 0.20

150 mm 0.20 0.18

175 mm 0.18 0.16

200 mm 0.16 0.15

These U-values have been calculated using λdesign -values. For stone wool the λdesign value is equal to λdeclared value calculated according to EN standards. The additional ∆U-value

used in this calculation is stated below. The ∆U-value may be different in each country; the correct value is declared in national building codes.

Rsi = 0.13 m2K/W

Rse = 0.13 m2K/W

∆U” = 0.04 W/ m2K

∆Uf = 0.005 W/ m2K

The internal concrete and the façade stone are not included the U-value.

2

UNS 37

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

24

Curtain wall with Façade Panel No I

• Concrete, brick or other stone based

frame

" Steel frame + PAROC UNS 37 and

" PAROC WAS 25t ≥ 30 mm or

PAROC WAB 10t 20 mm or

PAROC WAB 5t 13 mm

" Air ventilation gap

" Façade panel5

1

23

4

1

3

4

5

2

This insulation application is basicallythe same as for Steel Cassette Facades.It can be applied on concrete walls,light weight block walls, brick wallsand of course on steel frames as well.

There are many of different FaçadePanel systems around Europe; theseinsulation recommendations, withsmall variations, can be fitted to all ofthem. The façade system is designedaccording to the system providers'instructions. The fastening systemshould be designed so that it leadswater outside the wall.

The supporting concrete wallprovides an air-tight basis for theinsulation solution. The moisturefrom newly laid concrete is able to dryout through stone wool insulation -due to its porous fiber structure andhigh water vapor permeability. Aproper air flow in the ventilation gapneeds to be ensured in order toprevent condensation. The bestsolution is to have a constant ventilationgap from the bottom to the top of thefaçade. In high rise buildings it isadvisable to divide the ventilation gapinto 3 - 4 storey high segments.

All Paroc stone wool productspresented here belong to the EuroclassA1 and fulfill the highest firedemands.

U-values according to EN-standards (W/m2K)

Wind protection and insulation board

WAB 5t WAB 10t WAS 25t13 mm 20 mm 30 mm 50 mm

75 mm 0,52 0,49 0,42 0,34

100 mm 0,44 0,41 0,36 0,31

125 mm 0,38 0,36 0,32 0,28

150 mm 0,33 0,32 0,29 0,25

175 mm 0,30 0,29 0,27 0,24

200 mm 0,27 0,26 0,24 0,23

These U-values have been calculated using λdesign -values. For stone wool the λdesign value is equal to λdeclared value calculated according to EN standards. The additional ∆U-value

used in this calculation is stated below. The ∆U-value may be different in each country; the correct value is declared in national building codes.

∆U” = 0.04 W/ m2K

∆U = 0,02- 0,04 (including fasteners)

Rsi = 0.13 m2K/W

Rse = 0.13 m2K/W

An 80 mm internal concrete slab is included, but not ventilation gap or the façade panel

NOTE: The values in the table only indicate the relation between different insulation thicknesses. The steel frames and the construction details influence the values and shall beaccounted for.

To get appropriate values it is necessary to calculate the overall energy loss trough curtain walling systems using finite element software or to follow the detailed procedures inISO/FDIS 15099, EN ISO 10211-2 or prEN ISO 10077-2.

UNS 37

25

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

26

Curtain wall with Façade Panel No II

This insulation application is analternative version of the applicationpresented on the previous page. It canbe applied on concrete walls, lightweight block walls, brick walls and ofcourse on steel frames as well.

There are plenty of differentFaçade Panel systems around Europe;these insulation recommendations,with small variations, can be fitted toall of them. The façade system isdesigned according the systemproviders’ instructions. The fasteningsystem should be designed so that itleads the water outside the wall.

The supporting concrete wallprovides an air tight basis for theinsulation solution. The moisturefrom newly laid concrete is able to dryout through stone wool insulation -due to its porous fiber structure andhigh water vapor permeability. Aproper air flow in the ventilation gapneeds to be ensured in order toprevent condensation. The bestsolution is to have a constantventilation gap from the bottom to thetop of the façade. In high risebuildings it is advisable to divide the

ventilation gap into 3 - 4 storey highsegments.

All Paroc stone wool productspresented here belong to the EuroclassA1 and fulfill the highest firedemands.

• Concrete brick or other stone based

frame

" Steel frame + PAROC UNS 37

" Wind protection (foil, structural board)

" Air ventilation gap

" Façade panel5

1

23

4

1

3

4

5

2

U-values according to EN-standards (W/m2K)

UNS 37

100 mm 125 mm 150 mm 175 mm 200 mm

0.51 0.43 0.38 0.34 0.31

These U-values have been calculated using λdesign -values. For stone wool the λdesign value is equal to λdeclared value calculated according to EN standards. The additional ∆U-value

used in this calculation is stated below. The ∆U-value may be different in each country; the correct value is declared in national building codes

∆U” = 0.04 W/ m2K

Rsi = 0.13 m2K/W

Rse = 0.13 m2K/W

An 80 mm internal concrete slab is included, but not ventilation gap or the façade panel.

NOTE: The values in the table only indicate the relation between different insulation thicknesses. The steel frames and the construction details influence the values and shall beaccounted for.

To get appropriate values it is necessary to calculate the overall energy loss trough curtain walling systems using finite element software or to follow the detailed procedures inISO/FDIS 15099, EN ISO 10211-2 or prEN ISO 10077-2.

27

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

28

Product Information

PAROC WAS 25 (t) (tb)

Semi-rigid fire-safe stone wool slab with excellent thermalinsulation properties. To facilitate easier handling the productin large-size comes with one (t) surface of the slabs facedwith glass tissue. Also available with black glass tissue,PAROC WAS 25tb.

ApplicationPAROC WAS 25t is high-quality thermal insulation for insulating the outsides of flexibleinsulations in certain ventilated wooden structures. The insulation slabs are attached tothe supporting frame without supporting rails, creating a continuous thermal insulationlayer.

Width x Length Thickness600 x 1200 mm 30 - 150 mm1200 x 1800 mm 30 - 100 mm

Other sizes can be supplied on request.

Package TypePlastic package or packages on a pallet.

Lambda, declared, λD 0.034 W/mKIn accordance with EN 13162

Air permeability, l⊥⊥⊥⊥⊥ 25 10-6 m2/sPaIn accordance with EN 29053

Reaction to Fire A1, -,-In accordance with EN 13501-1

Water absorption (short term), declared, WS ≤1 kg/m2

Water absorption (long term), declared, WL (P) ≤3 kg/m2

Appr. weight/m3 90 kg/m3 ± 10%

PAROC WAS 35 (t) (tt) (tb)

Semi-rigid fire-safe stone wool slab with excellent thermalinsulation properties. To facilitate easier handling, the productin large-size comes with either one (t) or two (tt) surfaces ofthe slab faced with glass tissue. Also available with blackglass tissue, PAROC WAS 35tb.

ApplicationPAROC WAS 35t (t) is a large-size high-quality thermal insulation product for insulatingthe outsides of flexible insulations in certain ventilated structures. The insulation slabsare attached to the supporting frame without supporting rails, creating a continuousthermal insulation layer.

Width x Length Thickness600 x 1200 mm 30 - 150 mm1200 x 1800 mm 30 - 100 mm

Other sizes can be supplied on request.

Package TypeLoose product on a wooden pallet with plastic wrapping.

Lambda, Declared, λD 0.034 W/mKIn accordance with EN 13162

Air permeability, l⊥⊥⊥⊥⊥ 35 10 -6 m2/sPaIn accordance with EN 29053

Reaction to Fire A1, -,-In accordance with EN 13501-1

Water absorption (short term), declared, WS ≤1 kg/m2

Water absorption (long term), declared, WL (P) ≤3 kg/m2

Appr. weight/m3 70 kg/m3 ± 10%

PAROC UNS 37

Flexible fire-safe stone wool with excellent thermal insulationproperties. Its resiliance makes it easy to handle and install.

ApplicationPAROC UNS 37 is a multi-purpose general insulation for the thermal insulation of exter-nal walls. A wide range of measurements ensures suitability for different structures andapplications. Examples can be seen below.

Width x Length Thicknesswooden frames 565 x 1220 mm 50 - 150 mmwooden frames 565 x 1320 mm 50 - 150 mmSteel frames 610 x 1220 mm 42 - 150 mm

Other sizes can be supplied on request.

PackagingPlastic package or packages on a pallet.

Lambda, declared, λD 0.037 W/mKIn accordance with EN 13162

Reaction to Fire A1, -,-In accordance with EN 13501-1

Water absorption (short term), declared, WS ≤1 kg/m2

Water absorption (long term), declared, WL (P) ≤3 kg/m2

Appr. weight/m3 30 kg/m3 ± 10%

PAROC WAS 50 (t) (tb)

Semi-rigid fire-safe stone wool slab with good thermalinsulation properties. Also available with black glass tissue,PAROC WAS 50tb.

ApplicationPAROC WAS 50 is an thermal insulation for insulating external stone cavity walls.

Width x Length Thickness600 x 1200 mm 30 - 200 mm

Other sizes can be supplied on request.

Package TypePlastic package or packages on a pallet.

Lambda, Declared, λD 0.035 W/mKIn accordance with EN 13162

Air permeability, l⊥⊥⊥⊥⊥ 50 10-6 m2/sPaIn accordance with EN 29053

Reaction to Fire A1, -,-In accordance with EN 13501-1

Water absorption (short term), declared, WS ≤1 kg/m2

Water absorption (long term), declared, WL (P) ≤3 kg/m2

Appr. weight/m3 45 kg/m3 ± 10%

29

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

More information on our web pages www.paroc.com.

PAROC Metal WasherA metal washer for PAROC WAS products to be used in struc-tures with fire demands.

PAROC Plastic WasherA plastic washer for PAROC WAS products.

PAROC SpacerA spacer for PAROC WAS products.

PAROC WPS SpacerA special spacer for PAROC WPS products. Because of thetightness of the facing a normal spacer can not be used.

PAROC WPS TapeA special tape for sealing the joints of PAROC WPS products

PAROC KnifeA special knife for cutting PAROC stone wool products.

Accessories

PAROC WAB 5t

Thin, rigid stone wool board with glass tissue facing.

ApplicationSpecial product developed for steel construction, which when attached to the outside offlexible insulations, protects the insulation layer from harmful airflow. Also well suited forbreaking up cold bridges.

Width x Length Thickness1200 x 1800 mm 13 mm

Other sizes can be supplied on request.

Package TypePlastic package, plastic packages on a pallet or loose product on a pallet.

Lambda, Declared, λD 0.039 W/mKIn accordance with EN 13162

Air permeability, l⊥⊥⊥⊥⊥ 5 10-6 m2/sPaIn accordance with EN 29053

Reaction to Fire A1, -,-In accordance with EN 13501-1

Water absorption (short term), declared, WS ≤1 kg/m2

Water absorption (long term), declared, WL (P) ≤3 kg/m2

Appr. weight/m3 200 kg/m3 ± 10%

PAROC WPS 3n

Semi-rigid fire-safe stone wool insulation slab with excellentthermal insulation properties. One side of the slab is facedwith tough windproof Tyvek special facing and the other withglass tissue.

ApplicationPAROC WPS 3n is an excellent windproof thermal insulation. Its facing does not preventmoisture from evaporating into outside air but it protects from wind and, duríng installa-tion, from rain and spray. The thermal insulation properties can be further enhanced bytaping up the seams of the slab with special seaming tape.

Width x Length Thickness3000 x 1200 mm 30 - 70 mm1800 x 1200 mm 30 - 70 mmOther sizes can be supplied on request.

Package TypePlastic package or packages on a pallet or loose product on a pallet.

Lambda, Declared, λD 0.034 W/mKIn accordance with EN 13162

Reaction to Fire F, -,-In accordance with EN 13501-1

Air Permeability for Coating, l⊥⊥⊥⊥⊥ 10 10-6 m3/m2 sPaIn accordance with EN 29053

Water absorption (short term), declared, WS ≤1 kg/m2

Water absorption (long term), declared, WL (P) ≤3 kg/m2

Water vapor resistance for coating, declared Zi 0.06 m2 hPa/mg

Appr. weight/m3 80 kg/m3 ± 10%

PAROC WAB 10t

Thin, rigid stone wool board with glass tissue facing.

ApplicationSpecial product developed for steel construction, which when attached to the outside offlexible insulations, protects the insulation layer from harmful airflow. Also well suited forbreaking up cold bridges.

Width x Length Thickness1200 x 2400 mm 20 mmOther sizes can be supplied on request.

Package TypePlastic package, plastic packages on a pallet or loose product on a pallet.

Lambda, Declared, λD 0.037 W/mKIn accordance with EN 13162

Air Permeability, l⊥⊥⊥⊥⊥ 10 10-6 m2/sPaIn accordance with EN 29053

Reaction to Fire A1, -,-In accordance with EN 13501-1

Water absorption (short term), declared, WS ≤1 kg/m2

In accordance with EN 1609

Water absorption (long term), declared, WL (P) ≤3 kg/m2

In accordance with EN 12087

Water vapor resistance for coating, declared Zi 0.06 m2 hPa/mg

Appr. weight/m3 160 kg/m3 ± 10%

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

30

Cutting to SizeWhen cutting insulation sheets, aPAROC knife and a straight edge arerequired. When a lot of cutting isnecessary, cutting tables are excellenttools that can help achieve the correctangles and sizes. PAROC UNSproducts are fitted between beams andstuds with an oversize of 5-10 mm inorder to obtain a good filling withoutany cracks or gaps, The oversize isimportant for the function of thestructure in terms of both thermalinsulation and fire safety. The use ofsmall pieces (200 mm) increases therisk of gaps occurring and thereforeshould be avoided. The thickness ofthe standard slabs can be adapted tothe measurements of the timber andthe width to the stud distance inquestion.

General Instructions for Insulation Work

FillingThe performance of the insulation willbe affected by how well the space to beinsulated has been filled. It isimperative that the insulation lies wellagainst the warm side of the structure.Continuous gaps on the warm side ofthe insulation should be avoided andit is particularly important that thesegaps do not make contact with thecold side in order to prevent asignificant reduction in insulationfunction.

Handling and StoringInsulation is an important componentof any building and should thereforebe handled with great care in order toavoid any damage, which might affectits performance. Storing on site untilinstallation time should be carefullyplanned. The totally sealed plasticpackaging protects the product fromtemporary weather stresses butadditional covering should be usedwhen storing outside for longerperiods. The packages should bestored so that the slabs rest on theiredges. Should the insulation becomedamp, the packages must be openedand the sheets dried indoors beforefitting – never fit wet insulation. If theinsulation becomes wet after fitting itmust not be covered until dry.

31

W E L L I N S U L AT E D V E N T I L AT E D F A Ç A D E S

Warranty: The information in this brochure represents the sole and comprehensive description of thecondition of the product and its technical properties. However, the content of this brochure does notmean granting a commercial guarantee. In so far as the product is used in an area of use which is notprovided for in this brochure, we cannot warrant its suitability for said area of use unless the suitabilitywas expressly confirmed by us upon request. This brochure replaces all previous brochures. As a result ofconstant further development of our products we reserve the right to make alterations to brochures.

PAROC OY ABBuilding InsulationNeilikkatie 17, PO BOX 294FIN-01301 Vantaa, FinlandTelephone +358 204 55 4868Telefax +358 204 55 4738www.paroc.com

A MEMBER OF PAROC GROUP2044BIEN0404

PAROC GROUP is one of the leading manufacturers of mineralwool insulation products and solutions in Europe. Paroc productsand solutions include building insulation, technical insulation,marine insulation, structural stone wool sandwich panels andacoustics products. We have production facilities in Finland,Sweden, Lithuania, Poland and Great Britain. We have sales andrepresentative offices in 13 countries in Europe.

Paroc building insulation is a widerange of products and solutions for alltraditional building insulation. Thebuilding insulation is mainly used for thethermal, fire and sound insulation ofexterior walls, roofs, floors andbasements, intermediate floors andpartitions.

Paroc technical insulation is usedfor thermal, fire and sound insulation inbuilding techniques, industrial processesand piping, industrial equipment andship structures.

Paroc Fire Proof Panels are steel-faced lightweight panels with a corematerial of stone wool. Paroc Panelsare used for façades, partition wallsand ceilings in public, commercial andindustrial buildings.