Valve Testing Standards

Transcript of Valve Testing Standards

-

7/28/2019 Valve Testing Standards

1/6

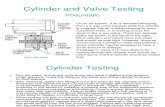

Testing, Testing:Todays Valve Standards

URL:http://www.unitedvalve.com/art-valve_testing.htm

THE INCREASE IN GLOBALLY SOURCED PRODUCTS AND MUCH-REDUCED

DOMESTIC MANUFACTURING HAS CAUSED EVERYONE IN THE VALVE SUPPLYCHAIN TO REQUEST AND REQUIRE MORE TESTING. HERES A LOOK AT SOME OFTHE MOST COMMON VALVE TESTING STANDARDS IN USE TODAY.

Testing, testing, 1 2 3 Weve all heard those words before as some nervous master-of-ceremonies tries to test the performance of the sound system over the tinkle of glass and the low

roar of the after-dinner crowd. Wouldnt life in the valve world be a whole lot easier if we could

just utter a few words and become instantly convinced as to the quality and performance of our

valves?

Today, more than ever before, testing is extremely important in the valve industry. The increase

in globally sourced products and much-reduced domestic manufacturing has caused everyone inthe valve supply chain to request and require more testing.

In order to effectively test a valve, there first must be an established testing procedure, combined

with the acceptance criteria or performance standards that the valve is expected to meet or

exceed. When it comes to testing standards though, one size does not fit all. There are different

standards for bronze valves, steel gate valves, iron valves, pipeline valves, control valves andpressure-relief valves.

Up until about 1968, the acceptance criteria for most valve types were pretty simple: Theywerent expected to leak during testing. The most common valve design standard for the past 50

years has been the American Petroleum Institute (API) valve standard for refinery use, knowntoday as API 600, Bolted Bonnet Steel Gate Valves for Petroleum & Natural Gas Industries.For 20 years, the document also contained valve testing criteria, and that criteria was pretty

tough: Valves shall show no leakage when subjected to a hydrostatic (or air) seat test.

Today, most valve manufacturers strive for and achieve a zero closure test leakage rate during

initial factory testing of their metal seated gate and globe valves. However, the predominant

valve testing standard, API 598, Valve Inspection and Test, does have allowable leakage ratesfor these types of valves in sizes above NPS 2. Virtually all test specifications for resilient-seated

valves require they exhibit zero leakage during the test period.

Determining Test Pressures

The first order of business in valve testing is determining the pressures at which the tests are to

be performed. Many standards, such as API 598, do not list detailed pressures, only theprocedure for testing. The actual test pressures are derived from pressure ratings that have been

developed based on the materials of construction and design criteria, such as wall thickness.

In the early days of valve manufacturing, only two common valve materials were available, cast

iron and bronze, and three pressure ratings: standard, medium and extra heavy. There was alsono common definition of any of these ratings. Catalogs often described the factory tests and in

http://www.unitedvalve.com/art-valve_testing.htmhttp://www.unitedvalve.com/art-valve_testing.htmhttp://www.unitedvalve.com/art-valve_testing.htmhttp://www.unitedvalve.com/art-valve_testing.htm -

7/28/2019 Valve Testing Standards

2/6

some cases included the actual bursting pressure, so users could assign whatever working

pressure and safety factor they wished.

Around 1930, the American Standards Association (ASA), in its B16e document, Flanged and

Welding-End Steel Wedge Gate and Plug Valves for Refinery Use, created a common set of

pressure ratings for the various valve classes we know todayclass 150, class 600, etc... Exceptfor class 150, all of the ratings were based on the class numbers pressure rating at 750o F steam.

Class 150 for some reason was based on steam at only 500o F steam.

Figure 1Original ASA pressure temperature ratings

Class Rating pressure &

temperature

150 150 psi @ 500o

F

300 300 psi @ 750o

F

600 600 psi @ 750o

F

900 900 psi @ 750o

F

1500 1500 psi @ 750o

F

The successor to B16e was the currently in-use standard by the American Society of MechanicalEngineers, ASME B16.34, Valves-Flanged, Threaded, and Welding End. B16.34 is the mother

document from which many testing specifications establish their baseline test pressures. The

ASME document specifies the working pressure for the established pressure classes in a vastrange of materials from low-carbon steel to exotic alloys. From this working pressureforexample, 285 psi for WCB, class 150 valvesthe test pressures are derived.

If we were using API 598 as our testing standard, the 285 psi class 150 working pressure wouldbecome 325 psi for the backseat and high-pressure closure test (285 x 1.1) and 450 psi for the

shell test (285 x 1.5). The actual results are rounded up to the next 25 psi point. ASME B16.34

does contain a testing procedure; however, its closure test protocol contains no acceptancecriteria as that data is deemed out of the scope of the document.

International Standards

The U.S. valve industrys shift to a more global posture, combined with the huge increase in

foreign valve manufacturers, has put increasing focus on international valve standards. Theprimary International Organization of Standardization (ISO) valve standard is ISO 5208,

Industrial Valves Pressure Testing of Valves. The standard is similar to the API 598

document, but recent updates have separated it more and more from the U.S.-developed

standard. One of the key differences between ISO 5208 and API 598 is that the ISO documenthas a choice of four leakage rates, from gross leakage to zero. The ISO document also widens the

users vocabulary by one wordobturator. An obturator is the closure element of a valve and

in the ISO document it replaces the term disc or wedge.

-

7/28/2019 Valve Testing Standards

3/6

Another difference in many ISO valve standards is that they also include testing criteria within

their base design document. This has not been the case for the past 40 years for most steel and

alloy valves in the United States. However, there is more and more talk at standards developmentmeetings about adding test criteria to design specifications, such as many of the API valve

standards.

While steel valve specifications such as API 600 have yet to be augmented with testing criteria,

there are several U.S. valve standards that do have self-contained testing procedures. These are

primarily iron and bronze valve standards and are covered by a host of ManufacturersStandardization Society (MSS) documents.

Special Valves, Special Tests

Control and pressure relief valves (PRV) are special purpose valve types and it follows suit their

test procedures are unique as well. The primary goal of PRV testing is to confirm that the valve

will both lift (open) at the correct pressure and provide the prescribed rate of flow. A control

valve is normally tested to measure its rate of flow as well. Both PRVs and control valves arealso tested to confirm the integrity of their pressure envelope.

PRVs are tested in accordance with two primary standards: ASME PTC 25, Pressure Relief

Devices and API 527, Seat Tightness of Pressure Relief Valves. The common testing

standards for control valves are ISAthe Instrumentation, Systems and Automation Society ofAmerica ISA-S75.19 and Fluid Controls Institute (FCI) FCI 70-2, Control Valve Seat

Leakage.

The upstream pipeline and petroleum valve industry also have their own testing specification. It

is located within the pages of the API 6D, Pipeline Valves valve design document. API 6D

leakage rates are very close to those of API 598, but its holding times are longer.

Increasingly stringent clean air regulations have created the need for a new type of valve test, the

fugitive emissions (FE) test. In FE testing, the goal is to determine the degree of minute leakage,if any, from the packing and gasket areas. The test requires pressurization of the pressure

envelope with either methane or helium. Then the sealed valve is inspected with a sniffer device

that measures any leakage in parts per million. The goal of most FE testing is to confirm thatleakage rates are lower than 100 ppm or in some cases 50 ppm. The most common FE testing

standards are ISO 15848, Industrial Valves, Fugitive EmissionsMeasurement, Test and

Qualification Procedures and API RP622, Type Testing of Process Valve Packing for Fugitive

Emissions, although specific end-user standards are also very prevalent.

Nearly all valve test standards are designed to test valves at ambient temperatures, generally

from 60 F to 120 F. But what about valves designed for low-temperature operation, such asliquid natural gas (LNG) or gas separation service? These cryogenic valves have their own

testing standards, the most widely used being the British Standard Institutions BS6364, Valves

for Cryogenic Service. MSS has also developed a cryogenic standard that contains test criteria,SP-134, Valves for Cryogenic Service, including Requirements for Body/Bonnet Extensions.

A third cryogenic testing standard is currently under development by an ISO work group.

Figure 2Common valve types and their related test standards

-

7/28/2019 Valve Testing Standards

4/6

Valve type Common test standard

Steel gates, globes and checks API 598

Cast Iron gates API 598, MSS SP-70*

Bronze gates, globes and checks MSS SP-80*

Pressure seal valves ASME B16.34*

Steel valves larger than NPS 24 ASME B16.34*

Pipeline valves API 6D*

Cast iron globes API 598, MSS SP-85*

Cast iron checks API 598, MSS SP-71*

Cast iron plugs API 598, MSS SP-78*

Steel ball valves API 598

Steel butterfly valves API 598

Cryogenic valves BS 6364, API 598

Pressure relief valves ASME PTC 25, API 527

Control valves ISA-S75, FCI 70-2

*Test requirements contained within design standard

Key Valve Testing Standards

Here is a summary of some of the most common valve testing standards:

API 598, Valve Inspection and TestThe most widely used test specification in the world

today. The document covers all types of valves in sizes through NPS 24. It also includes leakagerates and testing criteria for metal-seated and resilient-seated valves.

API 527, Seat Tightness of Pressure Relief ValvesThis document covers the seat tightness

of pressure relief valves. It also includes allowable leakage rates for testing with steam, waterand air.

ASME B16.34, Valves Flanged, Threaded and Welding EndThe primary valve design

document, it also contains charts for determining the working pressures of valves to be used in

conjunction with other test standards, such as API 598. B16.34 contains a test procedure, but noseat leakage acceptance criteria.

ASME PTC 25, Pressure Relief DevicesThe main reference document for the testing ofpressure relief valves, PTC 25 contains detailed procedures for testing relief valves with air or

steam.

-

7/28/2019 Valve Testing Standards

5/6

FCI 70-2, Control Valve Seat LeakageThis document contains detailed test procedures

and leakage rate classes for control valves. The leakage classes are also occasionally referenced

by other documents and used as acceptance criteria.

ISA-S75, Hydrostatic Testing of Control ValvesIt provides a procedure for the

hydrostatic shell testing of control valves. Closure testing and acceptance criteria are out of thescope of this document and usually are covered by referencing FCI 70-2.

ISO 5208, Industrial Valves, Pressure Testing of ValvesISOs primary testing standard,this document covers all types of valves and has four levels of allowable closure test leakage.

MSS SP61, Hydrostatic Testing of Steel ValvesSimilar to API 598, this document has

some subtle differences in test holding times and leakage rates.

MSS SP70, Cast Iron Gate Valves, Flanged and Threaded EndsThe primary designdocument for cast iron gate valves, it also contains testing procedures and acceptance criteria.

MSS SP71, Cast Iron Swing Check Valves, Flanged and Threaded EndsThe primarydesign document for cast iron check valves also contains testing procedures and acceptance

criteria.

MSS SP78, Cast Iron Plug Valves, Flanged and Threaded EndThe primary design

document for cast iron plug valves also contains testing procedures and acceptance criteria.

MSS SP80, Bronze Gate, Globe, Angle and Check ValvesThe primary design documentfor commodity bronze valves also contains testing procedures and acceptance criteria.

MSS SP85, Cast Iron Globe & Angle ValvesThe primary design document for cast ironglobe valves also contains testing procedures and acceptance criteria.

What Lies Ahead?

What does the future hold for valve testing standards? As mentioned earlier, there is a trend in

some standards-creating bodies to include the testing specifications within the primary design

document, and we may see more of that practice sooner rather than later. The fugitive emissionsissue could also foster the creation of a user friendly, production-type FE valve test method. The

current FE testing protocols are primary design or prototype verification procedures and not

easily adapted to production testing usage.

Valve testing techniques have changed over the years and at the same time test procedures havebecome more thorough. But one thing is for certain: As long as men and women, or automated

robots for that matter, are building valves, there will always be a need for valve testing and

effective testing standards to govern those tests.

Where On The Web

American Petroleum Institute www.api.org

American Standards Association www.ansi.org

American Society of Mechanical Engineers www.asme.org

British Standards Institution www.bsi-global.com

-

7/28/2019 Valve Testing Standards

6/6

Fluid Controls Institute www.fluidcontrolsinstitute.org

International Organization for Standardization www.iso.org

ISA (Instrumentation, Systems and Automation Society of America) www.isa.org Manufacturers Standardization Society of the Valve and Fittings Industrywww.mss-hq.com