UTC Point2Point Newsletter April 2016 · Title: UTC Point2Point Newsletter April 2016 Author:...

Transcript of UTC Point2Point Newsletter April 2016 · Title: UTC Point2Point Newsletter April 2016 Author:...

Experts at UTC Overseas’ Cement Plant Competence Center recently completed delivery of two key components of an OPEX project for one of the largest cement-producing facilities in the world, located in the state of Missouri, USA. The project involved ocean and barge delivery of a Japanese-built state-of-the-art tyre ring and a kiln shell. The kiln is where raw materials for cement are processed under high heat. It is supported and rotated by the tyre. UTC’s experts, working to meet the challenges of time-sensitive, multiply-sourced deliveries, crafted a precise logistics method statement and risk assessment plan for each component.

The kiln shell (nearly 100 MT/106T and 6.8M/22.5 feet in diameter) was manufactured in France. In December, following the plan, it was barged to Antwerp and transferred to a UTC-chartered ocean vessel, directly routed to the port of New Orleans. There it was direct-discharged to barge for transport to the project plant site at St. Genevieve, Missouri over 600 miles/1,000KM up the Mississippi.

Meanwhile, in Japan, UTC experts carefully elaborated a shipping plan and coordinated the loading of the massive tyre ring (9.2 meters/30.2’ in outside diameter - 216 MT/238T)

UTC DELIVERS KEY COMPONENTS FOR CEMENT PLANT MODERNIZATION

Global Logistics SolutionsPoint2point

...Read more

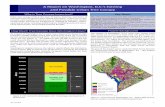

The 216 metric ton tyre ring is discharged from the barge used to transport it from New Orleans to the project site in St. Genevieve, Missouri. UTC planners made sure the support stands on the barge were high enough to allow the hydraulic transport trailer to roll underneath the load and then move it to the plant site about a half mile away.

UTC Honors TwoUTC Overseas recently honored U.S. Senator Lindsey Graham (R-SC) and Capt. William G. Schubert, President of International Trade and Transportation, Inc. and former head of the U.S. Maritime Administration for their outstanding efforts in promotion of the U.S. maritime industry and the recent Congressional re-authorization of the U.S. Export-Import (Ex-Im) Bank. After the presentations, Senator Graham provided those gathered with an update on the Bank’s status and its work of underwriting loan guarantees for American–exported projects, large and small. A video of the presentations and Sen. Graham’s remarks can be seen here: https://www.youtube.com/watch?v=RIAauFym16s

Left to right: Martin Whitmer, Marco Poisler, Senator Lindsey Graham and Brian Posthumus

April 2016 Volume 5, Issue 4

Point2Point Newsletter 1

aboard a second charter vessel, also bound for New Orleans.

“Projects like these often involve multiple global sourcing, and success requires detailed project and technical management planning allied with a detailed method statement,” explains Project Manager, Charles McCann. “Our customer’s construction schedule was based on a detailed master plan. We met with their manufacturers in Europe and Japan to review their timetables for production and transport, completed our logistics plans and then plugged those milestones into the master plan. It was then our responsibility to continually update the customer on any changes to that plan and how we were handling them. We also engaged third-party cargo surveyors to provide independent verification of our own engineering plans.”

“The master plan called for the kiln shell to arrive first, followed two weeks later by the ring. Each piece had to be handled based on specific guidelines provided by the manufacturer and the customer,” added UTC’s Capt. Shashi Bahl, who met

with manufacturers, vendors, and UTC staff in Europe and Japan, and developed risk-assessment plans and loading methods for the two moves.

“We had about two months to charter vessels, barges and crews with the resources and experience to safely and efficiently handle these loads,” Bahl said. “For the river journey, the tyre ring was supported on stands welded to the 150-foot/ 45-meter barge deck. We had to make sure those stands were tall enough to roll a hydraulic heavy haul trailer underneath the load for the Missouri discharge. We also double-checked the load’s center of gravity on the trailer before it was trucked ashore for delivery to the plant, about a half-mile away.

“UTC has a strong record of quality service in meeting the complex challenges of cement plant construction and modernization projects,” McCann concluded. “Our success depends on our global office network, including Europe, Asia and North America, and the skills and experience of our Cement Plant team.”

UTC DELIVERS FOR CEMENT PLANT (continued)

Join UTC Overseas

May 2 - 5 Booth #3423 IEEE PES T&D Conversion Congress & Exposition Dallas, TX http://www.ieeet-d.org/

May 2 - 5 Booth #2541-I Offshore Technology Conference Houston, TX http://2016.otcnet.org/

May 23- 26 Booth #214H2 Breakbulk Europe Antwerp, Belgium http://www.breakbulk.com/

The UTC Overseas method statement scheduled deliveries of the huge kiln shell (just under 100 MT/106T in weight) from Antwerp and the tyre ring from Japan two weeks apart in accordance with the customer's construction master plan.

[email protected].+1-713-869-9939

Point2Point Newsletter 2

April 2016, Volume 5, Issue 4