USER INTERFACE Advanced Monitoring & Diagnostics60 70 10 15 25 35 Flow -SCFM Cycles Per Minute...

Transcript of USER INTERFACE Advanced Monitoring & Diagnostics60 70 10 15 25 35 Flow -SCFM Cycles Per Minute...

Haskel Q-Drive <70dBA

Designed with smart servo electric-drive technology, Q-Drive is built to offer optimal performance and high volumes.

■ Clean, quiet compression

■ Smart, virtual self-diagnostics

■ Infinite controllability

■ Energy efficient

Available in six models, this breakthrough compression technology is smart, clean and delivers unmatched efficiency

danger

safe 10dB

20dB

40dB

60dB

80dB

100dB

120dB

140dB airplane take-off

rock concert

lawn mower

conversation

birds chirping

leaves rustling

normal breathing

USER INTERFACE Advanced Monitoring & DiagnosticsQ-Drive’s user interface optimizes operational user capabilities and safety and improves gas booster functionality.

Q-Drive’s intuitive design features smart controls that allow for increased visibility of the system’s operations. The fully digital user interface can be programmed for maximum efficiency and allows operators to set parameters, adjusting settings as needed for improved performance. The remote access capability allows for quick and easy access to diagnostics and troubleshooting. This reduces the costly and time consuming process of technical service in the field and system downtimes. The system's predictive maintenance feature delivers automated maintenance reminders to ensure top performance.

*OSHA max exposure level

*OSHA recommends that employees not be exposed to noise levels greater than 85dBA

ADVANCED TRANSFER AND COMPRESSION TECHNOLOGY

PERFORMANCE BY MODEL

QGT-90/63

QGT-150/63

QGT-150/90

Output Performance

Minimum Gas Inlet (Ps).................75 psig

Maximum Gas Inlet (Ps)...........2,000 psig

Maximum Gas Outlet (Po)........6,500 psig

Maximum Gas Compression Ratio....25:1

Output Performance

Minimum Gas Inlet (Ps).................75 psig

Maximum Gas Inlet (Ps)...............350 psig

Maximum Gas Outlet (Po).........6,500 psig

Maximum Gas Compression Ratio.....25:1

Output Performance

Minimum Gas Inlet (Ps).................75 psig

Maximum Gas Inlet (Ps)..............400 psig

Maximum Gas Outlet (Po)........3,800 psig

Maximum Gas Compression Ratio....25:1

0

10

20

30

40

50

60

70

10 15 25 35

Flow

-S

CFM

Cycles Per Minute

Ps=100 psi Ps=200 psi Ps=300 psi Ps=350 psi

0

20

40

60

80

100

120

140

160

10 15 25 35

Flow

-S

CFM

Cycles Per Minute

Ps=500 psi Ps=1,000 psi Ps=1,500 psi Ps=2,000 psi

0

10

20

30

40

50

60

70

80

90

10 15 25 35

Flow

-S

CFM

Cycles Per Minute

Ps=100 psi Ps=200 psi Ps=300 psi Ps=400 psi

PERFORMANCE BY MODEL

QGD-63

QGD-90

QGD-150

Output Performance

Minimum Gas Inlet (Ps).................75 psig

Maximum Gas Inlet (Ps)...........6,500 psig

Maximum Gas Outlet (Po)........6,500 psig

Maximum Gas Compression Ratio......5:1

Output Performance

Minimum Gas Inlet (Ps).................75 psig

Maximum Gas Inlet (Ps)...........3,850 psig

Maximum Gas Outlet (Po)........3,850 psig

Maximum Gas Compression Ratio......5:1

Output Performance

Minimum Gas Inlet (Ps).................75 psig

Maximum Gas Inlet (Ps)...........1,250 psig

Maximum Gas Outlet (Po)........1,250 psig

Maximum Gas Compression Ratio......5:1

0

50

100

150

200

250

300

10 15 25 35

Flow

-S

CFM

Cycles Per Minute

Ps=500 psi Ps=1,000 psi Ps=1,500 psi Ps=2,000 psi

0

50

100

150

200

250

300

10 15 25 35

Flow

-S

CFM

Cycles Per Minute

Ps=500 psi Ps=1,000 psi Ps=1,500 psi Ps=2,000 psi

0

50

100

150

200

250

300

350

10 15 25 35

Flow

-S

CFM

Cycles Per Minute

Ps=100 psi Ps=200 psi Ps=500 psi Ps=800 psi

1-888-WAINBEE (924-6233) | www.wainbee.com | [email protected]® is a brand of Ingersoll Rand (NYSE:IR). For more information, visit www.ingersollrand.com

PART NUMBER NOMENCLATURE

Q—Quiet Electric Drive

Application: G—Gas Boosting C—Liquid CO2

Type: D—Single Stage T—Two Stage

Gas Piston(s) Size: Single Stage: 150, 90, 63 Two Stage: 150/90, 150/63, 90/63

Gas Barrel Construction: 1—15-5 PH (non—H2 service) 2—A286

Gas Section O-Ring: Blank—Viton 32—NBR—90 (CO2 service) 30—Kalrez 13—EPR

Electrical Supply: 3—380/50/3 4—480/60/3

Electrical Rating: 0—Non-hazardous environment A—ATEX/Hazardous environment

Drive Power Output in KW

QGD — 150 — 1 — 45 — 0 — 4 — 32

(94.00)

(42.99)

(65.11)

(36.13)

(24.16)

(60.13)

(15.97)

(11.87)2x

(2.18)

(7.16)

(6.18) 2x

(19.84)

(36.13)

(88.00)

(27.38)TYP

(6.68)TYP

(8.24)TYP

(4.63)TYP

(34.00)

(17.00)

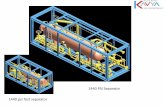

ELECTRICALCABINET

GAS SECTION

AIR DRIVEN VALVES (BLOCK & BLEED)

HEAT EXCHANGER

OIL CIRCULATION

CONTACT WAINBEE

![Draft amendment [2], as updated in the informal working ... · IHRA PS 273] INF GR/PS/88 Second interim report to GRSP 35 INF GR/PS/89 A study on the feasibility of measures relating](https://static.fdocuments.in/doc/165x107/5f040f647e708231d40c1eed/draft-amendment-2-as-updated-in-the-informal-working-ihra-ps-273-inf-grps88.jpg)

![P 4 [1 05]=PSI Plant Safety Inspection (35) Jul.2012](https://static.fdocuments.in/doc/165x107/577cd9491a28ab9e78a3241e/p-4-1-05psi-plant-safety-inspection-35-jul2012.jpg)