Use of Short Term Multiple Rate Flow Tests to Predict Performance of Wells Having Turbulence

-

Upload

andres-camilo -

Category

Documents

-

view

62 -

download

8

Transcript of Use of Short Term Multiple Rate Flow Tests to Predict Performance of Wells Having Turbulence

Society of Petroleum Engineers of AIME6200 N. Central ExpwyDallas, Tex. 75206

Use ofTo

Lloyd G. Jones

Short Term Multiple Rate Flow TestsPredict Performance of Wel Is

Having Turbulence

and E. M. Blount, Mobil Research and Development Corp., and O. !i.,Glaze,Mobi1 Oil Corp., Members SPE-AIME

THIS PAPERISSUBJECT TOCORRECTION

@Copyright 1976American Institute of Mining, Metallurgical, and Petroleum Engineers, Ir?c.

Thispaper wasprepared forthe 51st Annual Fall Technical Conferen~eand Exhibition of the Society of PetroleumEngineers of AIME,held in New Orleans, Oct. 3-6, 1976,Permissionto copyisrestricted to an abstract of not morethan 300 words, Illustrations may not be copied. Theabstract should contain conspicuous acknowledgment ofwhere and by whom the paper is presented. l%blication elsewhere after publication in the JOURNAL OFPETROLEUMTECHNOLOGYor the SOCVETYOFPETROLEUMENGINEERSJOURNALis usually arantedu~onrequest to the Editor of the appropriate journal, provided agreement to give proper credit is made. Discussion ofthis paper is invited

ABSTRACT has been appliedto a hi~h-rateoil well. It

!3includesand exten s the techniquereportedby

A method is presex~~edfor predictingwell Phipps end Khalil, if theirn value is two● Inperformanceand analyzingcompletionand particular,the procedures}mld provideafractureeffactiveness. The new procedureuses powerfulanalyticaltool in areaswhere mostproductiontests,rather than builduptests,to wells have high productionpotential.determinewhetherturbulenceis a major factorin reducinga wents flow capacity. If the The procedurecan be used in wells requir-pressvredrop from turbulentflow is greater ing send controlmeasuresand in hydraulicallythen expected,the well probablyhas an fracturedwells to determineif the cross+inefficientcompletion, For a perforated sectionalarea open to f10.,into the wellboreiscompletion,this may mean too few open perfora- sufficient, It also providesan indicationof

tions;for a fracturedwell, it may indicate perforationeffectivenessin normallyccmp!.etedthat the fractureis too narrow. The analysis wells becausean abnormallyhigh turbulenceprocedureis applicableto most gas wells and to coefficientindicatestoo few open perforations.oil wells with high flow rates. Field cases are Incidentalto determinationof a turbulenceshownfor two gas wells cnd one high-rateoil coefficient,the procedureprovidesa laminsrwell, flow coefficientthat includesskin effect. If

permeabilitythicbess is hewn, an estimateofINTRODUCTION skin effectcan Le msde from the lsminarflow

coefficient. Also includedin the theoryis enAn er,alyticalprocedureis describedhere ex@snation of the effectsof partialcompletion

for predictingwell performanceand analyzing or a chsngein completiongeometry!on presswecompletioneffectivenessof wells that have a buildupresultswhen the turbulencepressuresignificantpressuredrop from turbulence.* It &op is significant.is more applicableto gas well completionsbut

The analysisprocedureNermitsdetermina-*In t~s discussion,we use the term turbulenceto describeboth turbulenceand ali other

tion of turbulenceeffectson completion

1

efficiencyirrespectiveof skin effectendrate-dependentdeviaions from darcy flow such lsminsr(darcy)flow. The requireddata areas inertfaleffects.Referencessnd illustrationsat end of paper

either (1) two or more stabilizedflow tests,or

—— — —.

USE OF SHORT-TERMMULTIPLERATE FIOW TESTS ‘IU~EDICTPliRF7)IWMANCR(M’WET.TSHAVTNf?TUREUTJ!TUCE Smi!Ala’. -- -------- -- ..— . .... —.- . . ..--—. -- -. - w -<.

(2) two or more isochronalflow tests. Flow P@ = flowingwell pressure~psirates and bottom-holeflowingpressuresmust be q = oil flow rate,STB/Dknown in eithercase. Transientpressuredata Q=

tgas flow rate, Scf/D

are not needed and bottom-huleflowingpressures = laminarflow coefficient.for oil orcalculatedfrom surfacepressuresmay often be gas wells (definedin AppendixA)sufficient. D = turbulencecoefficientfor oil or ga

The previousmeans of determiningthewells (definedin AppendixA)

turbulencecoefficienthave ?equiredsome means From 13q.1 it is apparentthat for gas wells aof obtainingkh; usua21ya buildupt~st coupledwith severalproductiontests or a seriesof P’ - Pwf2 \

builduptests.y~~ These were used to determine plotof ‘s vs Qg has a slopeof D, and

a total.skin effect,s?, which includedthe 2Q9turbulenceterm. The St valueswere t,~+mplot- ~ = l’ifll“~ For oilwells$ a plot ofted vs flow rates. Actual ekin effec’,and Q~OQ “turbulencecoefficientswere then calculated

s!P - Pwf

from the interceptand slope. The method Ws

describedhere avoidsthe necessityfor tran--- vs q has a slopeof ll,,and

qsientdata from a buildupor drawdowntest and ~ = Iim 4permitsa directplot of pressuredata vs rate. The plots apply to both linearThe added simplicityshouldmake this procedure

q-o q“,

much more usefulin directfield applications. and radial flow. With these values alone,flowrates can be predictedfor these completionsat

THEDRY other arbitrarilychosenflowingpressures.

Steady-stateradial and linearflow equa- However,the major value of the analysistions includin turbulentflow are’availablein

!?will probablybe in obtainingvaluesfor D and

the literature~b for both oil and gas wells. using them to determinewhether a completioncanThese equationsapply directlyto stabilized be improved. In calculatingpotentialbenefitsproducingweZls; i.e.,wells that have produced to be obtainedby changingcompletiongeometry,long enoughso that the pressuretransienthas it is necessaryto defineD in terms of thereacheda long distanceinto the reservoir. The factorsthat can be affectedby changesinequ..ionsare readilyadaptedto nonstabilized completionprocedures. The followingcases arewe’..sby using isochronaltests;i.e., short those MfJSt likely to be of interest.flow tests of equaltime duration,with eachseparateflow test followedby a shut-inperiod LinearFlow - Gas or Liquidtclallowwellborepressureto rise nearly backto initialreservoirpressurebeforethe next For linearflow, it @ shown in AppendixAflow test is performed. The isochronaltesting thatprocedureshouldprove particularlyuseful indeterminingwhebherthe fracturewidth is suffi- ~= 1+ L1 %2, ocient in fracturedwells. A seriesof very ● ● (3)

short testsmay be sufficientwhere.otherwisea ‘2 132L2A,2 ““” *o..long-termbuildupwould be required.

If, as often is the case,only the area is

Z@M?Mchanged$

A simplediagnosticprocedurecsn be used > = A22—., . . . .. O.(L. .(L.to analyzecompletioneffectivenessof both g sand oil wells. Using Forchheimertsequation,8 ‘2 %2it is shownin AppendixA that flow rate and Ir~these equations,pressuredrop can be relatedby the followingequations,For gas wells

f3= turbulencefactor,ft-lL = flow path length,ft

P2A = crclss-scwtionalarea open to linearflow

Ws - Pwf2= c+D@ ● , 0 0 ● . (1) Subscripts1 and 2 refer to conditionsbefore

—~ ‘9 and afterthe changeti flow geometry.For oil wells

Radial Flow--Gas or LiquidP Ws - Pwf

q= C+m , ● , ● , . ● (2) Radial flow is,thebase case for determina-

tion of completioneffectivenessin ordinary

where ~s . averageformationpressure,psiwells. The followingequationis developedin

.

SPW Al‘?? T..f%..T(3NES.E. M. RTfNINT. and 0. H. GLAZEe. - w -,, -. -. - -.. — -. . . . -— -.. . --- -. --- .—— —<

AppendixA. is no reasonfor a workoveror stimulation.However,it illustratesthe type of test results

‘2r obtainedfor wells that are good candidatesfor

$ %2 W2improvement. Wheneverthe slopeof the plot is

~= lage in comparisonwith the intercept,the effi

‘2 bciencyof t e completionis suspec.

!! ‘?t~e~hp12>, , ...0..(5) value of llp/Qg at npximunAp2 (AP = Pws ) Ismr?e than two or three times as large as thevalue at the intercept,the indicationis that

where h is the lengthof the completedintervalandrw?s thewell radius. Ifonlythecomple-

area open to flow near or at the well is smallerthan desirable. For certaincompletions,such

tion lengthis altered, as insidecasinggravelpacks or fracturedwellsin thin producingformations,this is expected.

~2 Then it is necessaryto use @s. 3 snd4toD, P2 check whetherperformanceis acceptable. In-—= ~. ● ● ** , , ● ● ● .* (6) ordinarycased and perforatedwells, a large‘2

%]slopeis not expected,and its occurrenceindi-cates that the numberof effectiveperforationsis small. Such a completionhas excesspressure

EXAMPLES drop from both turbulenceend a large skineffect. Improvementwill reduceboth the slope

Example 1. Analvsisof Gas-Well end the intercept,and the ir~creasein produc-Flow Test Data tivitycan be dramatic.

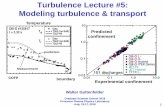

Either a sequenceof completelystabilized IsochronalFlow Test Databackpressuretests .m a seriesof isochronaltests providethf?ideal data for evaluationof Cullender~sisochronal.flow test data forgas wells. Cullendertsexcellentpaperl~pro- WellNo. 1 are givenin Table 2? AppendixB.tides the data used here to illustratethe The resultsare plottedon Fig. 2. The slope,analysistechniquefor

?P~~~~~~s~~e~~~~R&D, is approximatelythe same for each isochronal

lizedwells. Fetkovich set,with a value of 1.70x 10-10. The C valuedata for oil wells. variesfrom 0.C02’7for the 0.2-hourisochronal

set to 0.00775for the 24-hourset. The~tabilizedWell Test Data increasein C is due to the chsngein drtiage

radiuswith time, and C will.continueto increasData from Cullender?sWall No. 5 =e given until the well is stabilized. The value of D

in Table 1, AppendixB. The data are plottedon for this well i.s within the expected range, andFig. 1, The points all fallen the straigb.tline exceptfor the lowestrate, where an error

reperforatirigprobabSywill riotcause a drsmaticchsngein productivity.

of two-tenthsof & pound in readingabsolutepressurewill accountfor the deviation. The fact that D can be obtainedirom a

From the slopeof the line,D = 1.26 xseriesof very shortisochronaltests is significant. The time requiredfor pressurerecovery

10-10,and from the ‘intercept,C =0.CXXM. The ~ter a l~or 15-~nute flow test isor~~ilylow value of C is ~indicativeof = exceptionally not long;perhapssrihour or two. This provideshigh value of kh for this particularwell. The the possibilityfor rapid snd MexpensiveD value of 1.26 x 10-10is quite high for such determinationof nesr-wellflow restrictions,a low vaiue of C and probablyindicatesthat even in wells that will not stabiliserapidly.flow into the we?llboreis eitherttiougha small For example,for hy&aulically fractured.wells,number of perforationsor a shortproducing almst all pressuredrop from turbulencewil.lbeinterval. in the fracturesend perforations. Flow restric

tions in these locationscsnbe pinpointedbyWith C aridD known, a true calculatedopen-

flow potentialcan be determinedwith Eq. 1.analysisof shortisochronaltests,eventhoughthe formationflow characteristicsare not knowr

For en averagereservoirpressureof 439.0 psi, and could be obtainedonly with a long-termbuildupt+st.

d = 0.00028+ 1.26x 10-10Qg 9 Analysisof Back PressureTest DataQ9

where Qg is now the calculatedopen flow ~ten- Cullenderalso reportedbackpressuretesttiaIof 3E.OMMscf/D data for Well No. 1. It is usef%lto analyze

these data SQ as to ilJ.usiratethe ptentialS~nceWell No. 5 has a large calculated pitfallsin using backpressuretest data on

absoluteopen-flowpotential,thereprobably unstabilize dwells.The data are givenin

USE OF SHORT-TERMMULTIPLERATE FLOW TESTS TO l?UZDICTPERFORMANCEOF WELLS HAVING TURBULENCE SPE 6133

Table 3, AppendixB. Each of the data pointsisfor a 24-hourflow period. The firstpoints ofeach backpressuretest sequencemade up the 24-hour data of Fig. 2. The backpressuretestresults=e plottedon Fig. 3. As expected,the slope,D, is greaterthan the slopefromisochronaltestswhen the backpressuretestsequenceis run with the low rate first end islowerwhen the backpressuretest sequenceis runwith the highestrate first. Both of thesevariationsresult from the increasein drainageradiuswith time h an unstabilizedwell.

Examle 2. Analysisof High RateOil-WellFlow Tests

A new oil discoverywas tested at highproductionrates througha limitedcompletioninterval. Prwsuxe &op from turbulencewasevidentbecausethe productivityindex (PI)declined”asthe rate increased. The problemisto calculatepressuredrawdownat higherratesand to estimatePI if the perforatedintervalisincreased.

The well was tested.at three differentflowrates. Test data are give~lin Table 4 ofAppendixB. Since the producin~zone is ex-tremelypermeable,the well stabilizedsorapidlythat no transientcould be observed.All test data we.)etaken above the bubble-pointpressure,~lhichis less than 4,000 psi. Initialshut-inprcssu??ewas 5$94$PSiC

The resultsare plottedon Fig. 4. TheinfinitePI a+.a rate of 1,446 B/D merelyindicatesthat the preseuredrop was too smallto read on a 10,000-psigauge. From Fig. 4tthe lami.nar.flow coefficient,C, in Eq. 2 isnesrly zero? end the turbulencecoefficient D?is 9.8 X 10-7. The laminarflow coefficienthasto be greaterthan zero,but in this case,kh isapparentlyso great that pressuredrop fromlaminarflow is negligible.

Pressuredrawdownat higherrates can becalculatedwith Eq. 2 or by extrapolatingthestrtightline of Fi . 4 to the desiredrate to

?obtain a value for pequals I/PI. - ~$~w’~~ch alsOAt a ra~~ of .

PWs - PwfF ~q= 9.7 x 10-7

qx 30,000

= 0.0294

and

PI = 1/0.0294 = 34.

Drawdownrequiredto attain30,000 B/D, there-fore, is

AP c 30)000/34 = 882 psi .

At a rate of 20,~0 B/D, PI would equal 51 anddrawdownwould be 392 psi.

Since C Z O, the adjustmentin PI causedbyextendingthe lengthof the perforatedintervalcan be estimatedas follows:

~“ 2.P12 D, P2

z—%~

‘2 ~“”*””””” *(7

Therefore,PI in this well cen possiblybe quad-rupledby doublingthe lengthof the perforatedinterval.

The largeD value in this case probablyindicatesinadequateperforationsin the sensethat most of the effectof turbulenceoccurs atthe perforations. Therefore,reperforattigthecame intervalor doubtig the perforationdensityto 8 shots/ft may also increasethe PIby a fectorof 4.

.

DISCUSSION

The analysisprocedurepresentedhereallowspredictionof well performanceand diag-nosis of meny well completionproblemswithkexpensive short-termtests. The procedureisparticularlyapplicableto gas wells in “good”formationswhere completionproblemsare apt tooccur. The resultsallow separationof mechani-cal problems,such as too few open perforationsor too narrow fractures,from formationdamageor low permeability. This permitsthe engineerto choosethe type of stimulationor workovermost likelyto solve the existingproblem. Theabilityto pinpointreasonsfor low productivityshouldmake the test procedurea valuablenewengineeringtool.

ACKNOWLEDGMENT

The authorswish to expressappreciationtoMobil Researchand DevelopmentCorp. and toMohll Oil Corp. for permissionto publishthispaper.

REFERENCES

1. Geertsma,J.: ~tEstimatingthe Coefficientof InertialResistancein Fluid FlowThroughPorousMedia,r’Soc. Pet. EnR. J.(Oct. 1974)No. 5, 445.

2. Phipps,S. C. end Khalil,J. N.: ‘rAMethodFor Determir@g the lhqwnentValue in aForchheimer-TypeFlow E@ation,‘fJ. Pet.Tech. (July 1975)883.

3. ~h, R; V.: “Unsteady-StateGas FlowInto Gas Wells,”Trans.,AIME (1961)1151.

4. Ramey,H. J.~ Jr.: ~Won-DsrcyFlow andWellboreStorageEffectsin PressureBuild-up and ‘Drawdownof Gas Wellst” J. pets

SPE 6133 L. G. JONES, E. M. BLOUWT,and O. H. GLAZE 5

5*

6,

7*

8.

9.

10.

11.

Tech. (Feb. 1965)223.~, D. L., et al.: Handbookof Natural

%%%%%%%:-Hi” ’00’ ‘O”’Forckeimer, Ph.: Zeits V. deutschIng.(1901) ~, 17$2. -Cooke.Claude: “Conductivityof FractureProppbts in MultipleLayers,” J. Pet.Tech. (Sept.1973) 1106c~st L. G. and Watts,J. W.: “Esti~mattigSkin EffeJt in a l%xt?iallyCom-pletedDamagedWell,”J. pets Te~h* (Feb~1971) 249*Jones,L. G. and Slusser,M. L.: “TheEstimationof ProductivityLoss Caused byPerforations- ln~ludingPartialComple-tion and FormationDmage,” paper SPE4798 presentedat SPE-Jit~A9thAnnu~lFall Meeting,Houston,Tex., Oct. 6-9,1974.Cullender,M. H.: ~lThe,IsochronalPer-formanceMethodof Determiningthe FlowCharacteristicsof Gas Wells,”Trans.!AIm (1955)*, 137.FetkovichtM. J.: ‘tThe.IsochronalTestingof Oil Wells,”paper SPF 4529 presentedat SPIMIME 48 th AnnualFall Meeting,LasVegas,Nev., Sept. 3Wct. 3! 1973*

APPENDIXA

I)evelopmentand Discussionof Equations

LinesrFlow - Gas

Linear gas flow is a major contributortopressuredrop for wells prcducingthroughinsidecastiggravelpacks or fractures. FcIreithercase,pressuredrop from turbulenceis fre-quentlythe major factorin limitingproductionrate.

For lineargas flow througha porousmediaof lengthL,5

2 8.93zTPQL ,PWs - Pwf2 =

kA

1.247 X 10-16

OZTy LQg2+

A2‘9

● *..*. .***** ****** (A-1)

where Z . dimensionlessgas compressibilitycoefficient

T= reservoirtemperature,*RM = viscosity,CpL = flowpath length,ftk = permeability,mdA= ;ross-sect”onalerea open to linear

flow, ft2

@ . turbulencefactor,ft-l

7%“ gas gravity (air= 1.0)

This csn be written

$ -C+ R9, . . . . . . . . .(A-29

where the dsrcy or laminarflow term is givenby

C . _ . . . . . . . . . . (A-3..

and the turbulenceflow term is

1.247 X 10-16

EIY ZTL

Ix$ “A2

QgO. . (A-4

A plot of 42/’g vs Qghas a slopeof D, and

llm ~c ‘Q~O Q

. Thus, if most of the pres-9

sure drop OCC-WSin a lineargeometry,the dsrcyend turbulenceflow terms can be determinedsolong as L is known. ,

The above analysisshouldbe particularlyuseful for completionswith tisidecasainggravelpacks. Since L, p, andk are fairlywell lmownfor that case, the area,A, canbe calculated.From A, the number of effectiveperforationscar‘oedetermined. This will allow evaluationofvariousperforattigprocedures.

In calculatingpotentialbenefitsto beobtainedby changingthe completiongeometry?anew turbulencecoefficientcan be estimatedfromthe previouslymeasuredvalue ‘bytaking ~ ratio.Thus,

2‘1 %LlA2~“ . (A-$

62~2A12”””””. ..c

If, as often ia the case, only the area ischsngeri~

2@l= ‘2

—,* . ● ● . ● ● ● ● * ● ● ● (A-6‘2 A,2

This anslysis,also csn be appliedto frs.c-turedwells in relativelytight formations. Inthat case,L and A2 are more or less tiseparableProbablythe best tests to performwould beshort-termisochronalflow tests at substan-tiallydifferentrates. If the twbtience flowterm is large,the obviouscorrectiveprocedureto use for obtaininghighe~ flow rates is tO

widen the fracturesinceA appearsin thedenominatorof-theturbulenceflGw term. Wesuspechthab pressuredrop from turbulenceis amajor factorin limitingflow rates from f.’ac-turedwells when the fracturedformationisrelativelythin. Based upon evaluationof anumberof frac~uredwells,the fracturedesigns

USE OF SH~T-TIRM MULTIPLERATE l?WW TFSTS TO FREDICTPEWORMANCE OF WELIS HAVINGTURBUIXNCE SPE 6133

couldbe alteredto take adventageof optimumflow conditions. Also, h those caseswhereturbulenceis obviouslya major probleminlimitingflow rate, restimulationjobs producinggreaterfracturewidths might be considered.

Radial Flow -Gas

The base case for determinationof compl.e-tion effectivenessfor ordinarywells is radielflaw. The equationdescribingradielsemisteady-stat.+gas flow is4”

21.424MzTQ

P - pwf2 ‘- kh q (ln 0.472>Ws w

, s, , 3*16X‘:’,f%z!(i-t’),~● .**.*. ● ****9* ● ***-

where re = externaldrainageradiusfft

rw = well radius,fth = producingformationthickness,fts = skin effectexcludingturbulence

effects

Eq. A-7 can also be rewrittenas

!$ = C+DQ9“”*”*””

. (A-2)9“

where now the dsrcy term is

1.424vzTc= (In 0.472

~-7T7

~ + S) . (A-8)w

and, since I/renormallyis very smsll,theturbulenceterm is

3.I6 X 10-’8 BY ZT 1

lx+ =h2 “ TQ9”

● *****S ● S***** ● d* (A-9)

A plot ofAp2/Qg vsQg againhas a slopeof

D,andC=lim A&

Q~O Q “’9

TheAp2/Qg vs Q plot allowsdifferentia-

Stion betweensmple amage end problemsinvo~vingthe turbulenceterm for radial flow.

Correlationsare availablefor expectedvaluesof 19for given valuesof k,5f7 Occasion-ally tha IQg term will be ordersof magnitudehigherthen expectedfor the known formationkh.In that case, it is obviousthat the completionis inefficientend that more end deeperperfora-tions are needed or that the completionintervalshculdbe lengthened.

PartialCompletionEifects- The turbulence

term i% writtenabove as thoughthe wholeintervalwas completed. This is seldomthe caseend it is useful to considerwhat happensto theturbulenceterm in a partiallycompletedwell.In that case, flow convergesfrom the entireproducingintervalinto the completedinterval.In most cases the last few feet of flow pathsare essentiallyradiel.~~9 Also, most of theturbulencepressurei~op takes place in thislast few feet of the flow path sincethe areaperpendicularto flow becomeevery smellin thatzone. Therefore,for practicalpuzpses, thevalue of h h the turbulenceterm can be re-placedby the lengthof the completedzone,~.Then,

, 3*MX 10 “8” ~yZT ~—.

% = ~ 2 ‘-. Q9rP

w

● 9***** ● *.***, ● **e (A-1O)

3.I6 X 10”18 f3~ZTsnd D=

..hp2 rW ‘““ “ ● “ “ ‘A-l’)

This formulationfor D has considerable@plica-t,ionsconcerningwell test results. The vaheof D will shsngeeach time somethg is done tothe we”Ll~hat changesthe flow patternsinto thewellbore. The effectson the turbulenceco-efficientof changingcompletionlength,or wellradius,w alteringthe formationcan be esti-mated by comparingbefore eni aftercompletionconditions. Thus?

~ 1%22rw2~= . . (A-12)‘2 ~h2r””o”

2 P] WI

If only the completionlengthis altered,asoften will be the case,

hz

5=P2~ ‘ “ “ “ ● ● ‘ ““” ●

(A-13)‘2

P1

LinearFlow - Oil

Linear oil flow also has a darcypressuredrop and a turbulencepressuredrop. In manycases the turbulenceterm is quite low end canbe neglected. However,for high rate wells innaturallyfractkmedzones,or for insidecasinggravel-packedcompletions,the linearflowturbulenc$componentof pressuredrop can becomethe major factorM I.imiiingflow capacity.

++Notehere that o~ def~tiOn of D is relatedto that of Rsmey4 by the equation

D =-r~, where ~is Rameyrsvalue.”

1

I

sPl?61~~ L. G. J-. E. M. BWUN’T.and 0. H, GLAZE-. - . -== —.-. . . ..——.— ---- -

For liquidflow, Forchheimertsequation6cm be written

dJ?= qMB

1.127 x 10-3kA

9.o8 X 10-’3 pq2B2p+

A2 * ● ‘A-u)

Therefore,for linear flow,

qpBL

P2 -PI=1.127 X 10-3kA

9.08 X 10’13 fjq2~2~L

+——A2

,(A-15)

where p2 = pressureat the entranceof thelinearflow path, psi

PI = pressureat the efit of the flowpab, psi

L . len@h of the flow path, ftA = cr -sectionalarea perpendiculart

I“1OW,fta:. flowrate, STB/D= formationvolume factor,RB/STB

p . fluid density,lb/cu ft

This can be writtenas

& = C+Dq, . . . . . . . . . . (A-16o1

p BLwhere c = ● *** (A-17

1.127+ lO-3kA

9.08x 10-’3 6B2PLand D = 9 ,*, * (A-la

A plot ofAp/q vs q fives the laminarflow termIim &

C, as C sq-o ~

~ and the turbulenceflow

term,D, as the slope.

Exceptfor oil wells with exceptionallyhigh flow rates,the turbulenceflow termshovldbe negligiblewhen comparedwith thelaminarflow term. If this is not the case, t~completiondesign shouldbe reviewedcarefullybecausethe flow srea is probablytoo small.Even thoughthe turbulenceterm is not a largepercentageof the total pressuredrop for snoil well, its noticeablepresenceindicatesthat’the laminsrflow term can-alsobe droppedconsiderablyby providingmore srea for flowinto the wellbore.

Radial Flow - Oil

The turbulenceterm in radialoil flowshouldbe negligiblefnr most oil wells. Ifthe term is measurableand if pressuredrop is

appreciable,the well probablyshouldbe stimu-lated or reperforatedor the completedintervalshouldbe extended.

For radSsl flow,

~= qvB

1.127X 10-3kA

9.08 X 10-’3 Bq2B2p+

A2 1 . (A-19)

where A = 2firh. This is easyto integratesnd

q PB ‘2P2 -p,= in~

1.127 X 10-3( 2mkh) I

()9.08 X 10-13 @q2B2p I I—-—

4 n2 h2 ‘2 ‘1 “● **.*.* ● .***** ● *** (A-20)

where p2 is the pressureat some outer ratiustr2, and pl is the pressureat the innerradius$rl. Ifwe letp2=pws, r2=re~ P1 =Pw~ ~d

rl = rw; if we accountfor skin effectandpseudosteady-stateflow in the laminsrflowterm; and if we assumere is fairlylarge,then

qVBP Ws - Pwf =

1.127x 10-3(2~kh)

. ( in 0.472 ~~s )\ r ./

()’13 9q2B2~, I9.08x iO

+— — . . (A-21:4 TI2h2 r

w

once againwe obtti the form

4 = c+.Dq , . . . . . . . . . (A-16:q

where C, the laminarflow coefficient,is givenby ,

PBc=

1.127X 10-3(2nkh)”

(● inO.472

)

~+s‘ rw ● ** (A-22

.

and the turbulencecoefficientis

9.08x 10’13 fjB2pon —St c’- (A-23;

b m2h2rw

USE OF SHORT-TEH$lMULTIPLERATE F’K)WTESTS TO PREDICT.PERFORMANCEOF WELIS HAVING TUR13ULRiCE SPE 6133

Once again,a plot of ~p/q vs q has a slopeof Again, a comparisonof completionsskmildti-

D,snd C=Iim & elude an adjustmentfor the lengthof the com-

q-o q ●pletion. Thus, assumingeverythingelse isconstsnt,for two differentcompletion

partialCom@etion Effects-It is worth lengthsnotinghere that D sgsin is very much a fun,c- ~2tion of the lengthof the completedinterval..If ori’ypsrt of the’interval.is comp~eted,h >=~*is’replacedby ~ and . (A-25)

‘2 h 2 ● ’” “ “*” ●

P]

9.o8x 10’13 BB2P

DE~n2h2r ““””* (A-24)

~ .b*

APPENDIX B——

WELL TEST DATA FOR EXAMPLES

Table 1Performance Data of Gas Well No. 5

ShutinPressure Flew Rate 2 $2!

psia MSCF/D PWs - Pw;q

439.6 2,231 1,010 .000453439.8 4,841 4,320 .000892439.0 8,373 11,270 .00134439.0 12,484 23,250 .00186439.0 16,817 40,600 .00241

Table 2Isochronal Oata of Gas Well No. I

Isochronal 0.2 hr. data

QO X 10=3 X2 x lo=3 AP2/’Qa

2009 5.68 .00283

299~ 9.21 .00307

4130 12.72 .00308

7327 26.09 .00356

3 hr. data—.

1980 10.38 .00524 s

2905 15.72 .00541

4587 27.26 .00594

6887 42.99 .00624

Isochronal 1 hr. ‘data

Q X 10_3 ~~x @&2/~—.

1994 8.26 .00414

2937 12.87 .00438

2941 13.28 .ool+52

4052 18.40 .00454

46s6 22.52 .00484

7092 35.52 .00500

24 hr. data

1447 14.56 .00748

4440 38.67 .00871

9900 97.70 .00987

.

Table 3Back Pressure Test Data on Gas Well No. I

DateQ X 10-3 2x 10-3’ AP2/Q ‘

10-3-44 9900 97.70 .00987

7091 70;73 ● 00997

4360 46.16 .01059

10-24-k4 4440 38.67 .0087

6$)82 79.17 .0108

8212 $2.35 .0112

12-11745 1947 14.56 .00748

2841 25.07 .00882

3941 38.82 .00985

5165 50.53 .00978

Table 4Performance Data for High Rate Oil Well

BottomHole

Rate Pressure&

@@ PI

1446 5448 0 0 0

6199 5410 38 .00613 163

8115 5383 65 .008 125

20,(100* 5056* 392* .0196* 5I*

30,000* 4566* 882k .029* 34.0*

*Calculated Values -

.0026

n.0024 -

/ ‘.0022

1.0020 -

.0010

.0016 {

.0014da mGo

.W12/~

.0010A

.000 $

.0006

.0004

.0c412-

00 2 4 6 S’lo 12 14 16 [e

Qg Z 10-*

FIG, 1 - ANALYSIS OF STABILIZED WELL TEST DATA, WELL NO. s,

.0(0

.009

.008

.004

.003

.002

.001

0

0 /

0#- ‘

/

/ ‘/

6678

024 HIA 3HIo I HI❑ .2HI

FIG, 2 - ANALYSIS OF ISOCHRONALFLOWTEST DATA, WELL Nfi, 1,

. . . . ... ..o~o —

.018 “

.016 —

.014 —

.012 —

.-- = .O1o40

.Oos —

0.00 6—

4

.00 4—

.00 2-

00QQ E 10-8

FIG, 3 - ANALYSIS OF BACK ?RESSURE TEST, WELL NO, 1,

.020

.016

.016

.012

.00B

.00 2

00 2000 4000 6000 8000 10,000 12,000 I 4,000 16,000 18,000 20,000

q(bbl/doy)

FIG, 4- ANALYSIS OF HIGH RATE OIL WELL FLOW TESTS,

: