U.S. Army Watervliet Arsenal's September 2014 newsletter: The Salvo

-

Upload

us-army-watervliet-arsenal -

Category

Government & Nonprofit

-

view

513 -

download

1

description

Transcript of U.S. Army Watervliet Arsenal's September 2014 newsletter: The Salvo

U.S. Army Watervliet Arsenal

Sept. 30, 2014

THE SALVOHow to Gauge Future Wars?

Story on Page 3

Page 2 Salvo Sept. 30, 2014

The Arsenal Salvo is an authorized monthly publication for members of the Department of Defense. Contents of the Salvo are not necessarily the official views of, or an endorse-ment by the U.S. Government, the Department of Defense, the Department of the Army, or the Watervliet Arsenal. News may be submitted for publication by sending articles to Public Affairs Officer, 1 Buffington Street, Bldg. 10, Watervliet, NY 12189, or stop by office #102, Bldg. 10, Watervliet Arsenal. The editor may also be reached at (518) 266-5055 or by e-mail: [email protected]. The editor reserves the right to edit all information submitted for publication.

Commander, Col. Lee H. Schiller Jr.Public Affairs Officer, John B. SnyderEditor, John B. SnyderPhotographer: John B. Snyder

Arsenal Facebook Page @http://on.fb.me/sq3LEm

Lee H. Schiller Jr.Commanding

Manufacturer 6

Commander’sCorner

This is an interesting time of the year when the calendar drives much of our activity today and in the near future. By the time you read this column, we will have closed out another successful manufacturing year having gener-ated nearly $87 million in revenue. But if all we looked at was revenue, then we would have missed the critical piece of information about how we generated that revenue. During the course of fiscal year 2014, we manufactured thousands of parts for our troops, as well as for allied armies. Products that ranged from a firing pin for a mortar system to a cannon for a 155mm howitzer left here en route to direct armed combat or to support those in training. With every product shipped there was also a tremendous sense of pride in the quality of each piece. Visitor after visitor who spent time with us this past year said that they were amazed at the significant amount of quality that we place on each major machining operation. No one does it better. The calendar also forces us to enter a new fiscal year. In some ways this is a rebirth, as we reset our financial books and delivery rate percentages. But that can be a little mis-leading as there is no clear delinking of the two fiscal years from each other. For example, as we close out one year we work hard to shape the operational environment of the next year. We do this by doing such things as ordering raw materials for products that will be manufactured in the next year to hav-ing the right-sized workforce to support future delivery schedules. Therefore, the process of shaping our environ-ment does not start on October 1st of the new fiscal year or end on September 30th of the last fiscal year. Suffice it for me to say, we are on good ground as we enter fiscal year 2015. The calendar also reminds us of our sense of duty to remember and recognize those who have proudly served in

our military. Earlier this month, I had the pleasure to be the keynote speaker at a POW/MIA Recognition Ceremony hosted by the Albany VA Medical Center. When I looked into the faces of the former prisoners of war, I was overwhelmed by level of personal courage and degree of selfless service each Veteran had displayed on the battlefield. Although their numbers are not as large as in previous ceremonies, their importance to who we are as a nation is no less. Soon, we will be participating in the City of Albany’s Veterans’ Day Parade on November 11th. This is the larg-est community event that we participate in each year and one that I hope you will share with me as I march through Albany with our emergency service vehicles, floats, and marchers. Supporting this event is a great way to thank our nation’s Veterans, as well as to demonstrate to the commu-nity that the Watervliet Arsenal is still open for business.

Watervliet, such as the M20 75mm recoilless rifle, are still widely used by several countries today to include those in NATO. During the 2012 Libyan Civil War, the Libyan

Liberation Army, which helped overthrow Colonel Muammar Gaddafi from power, is reported to have used truck-mounted M20 recoilless rifles in close combat. Even the U.S. Defense De-partment had recently turned to a 1960s 105mm cannon design for outfitting AC-130 aerial gunships. Had it not been for the ar-senal’s stored drawings, tools, and the gauges for the original cannon system, restarting pro-duction after a 40-year absence would have been extremely costly for the U.S. military said Jake Peart, the arsenal’s chief of production planning and con-trol. The point here is that old, low-tech weapon systems still have value even in a world driven by high tech. When one considers the dramatic decline in recent defense budgets, proven low-tech weapons may become

in vogue again. Just how many gauges does the arsenal have on its property books? According to Seth Frank, an instrument mechanic

70,000 examples of how the arsenal will ‘Gauge’ future wars

Page 3 Salvo Sept. 30, 2014

Photo by John B. Snyder

By John B. Snyder

Story continues on page 4, Gauge

With a 201-year history of continuous operation, the Army’s Watervliet Arsenal has a common chal-lenge that homeowners face every day ̶ How to re-duce clutter. Anyone who has ever owned a home with either a basement or an attic knows just how diffi-cult it is to go through and purge items that they may not have laid eyes on in years. Sometimes it is the sentimental value that stands in the way of making room in a very valued and lim-ited storage space area. For others, as well as the arsenal, it is often a belief that “I cannot get rid of that because someday I will need it” that fuels the hesitance to purge stor-age areas. Without a doubt, there is a lot of sentimental, as well as histori-cal, value placed on the build-ings and machinery that have supported the arsenal through many wars. But for the arsenal to maintain thousands of gauges, which some date back to the Ko-rean War, might boggle the mind unless one looks at some of the weapon systems in use today. Weapon systems the arsenal may have manufactured 50, 60, or even 70 years ago are still finding utility in many foreign militaries, as well as in armed insurgent groups. According to Wikipedia, the M101 105mm howit-zer system that went into production at Watervliet in the 1940s is still in use today by the Lithuanian, Mexi-can, as well as by the armies in 50 other countries. Other World War II era weapons manufactured at

Instrument Mechanic Work Leader Seth Frank, left, pulling out a star gauge for inspection with Instrument Mechanic Gregory Ciraulo. Some of the gauges date back to the 1950s but are still operational.

Page 4 Salvo Sept. 30, 2014

Gauge Cont.

work leader, “We have retained more than 70,000 gauges that have supported thousands of product lines since the early 1950s.” Some of the challenges of retaining such a large quantity of gauges go beyond simply finding adequate storage areas, it has more to do with inventory control and calibration. “At any one time, there may be hundreds of gauges in use in multiple manufacturing build-ings,” Frank said. “So, the shear scope of keep-ing track of these gauges is tough but not as tough as the requirement to keep these gauges cali-brated.” Just as tools wear, so too do gauges, Frank said. Some of the gaug-es are required to be calibrated by a calendar date, such as annually, while other gauges need to be calibrated after so many uses. Frank said that there are only five personnel at the arsenal who ensure the serviceability of the 70,000+ gauges. What the gauges do is that they ensure that machin-ing operations are to the prescribed standards as stated in technical data packages that accompany the orders. In essence, the gauges ensure absolute quality con-trol at each major operation in the product design and manufacturing process. The arsenal retains gauges for such weapon systems as the M101 105mm cannon to the main gun on the M60 tank to today’s 155mm can-non for the M777 towed howitzer. If the storage of the gauges was not enough of a logistical challenge, throw in the fact that the arsenal

also retains the complete history of every product manufactured at the Arsenal, from a firing pin for an 81mm mortar to the 16-inch gun for World War II battleships. “Our files go back to World War II,” said Thomas Ruchlicki, the arsenal’s chief of production planning. Ruchlicki said that each file explains the quote process, the tools required, the production schedule, the speed of machines, down to the length of each

cut made on a piece of steel to manufacture that product, Ruchlicki said. The files also contain any lessons learned dur-ing the manufacturing process. The lessons learned speak about such things as to whether or not a specialized heat treat-ment worked, did the Ar-senal use the right angles of cuts on the product, and what processes and procedures were not required that resulted in

reduced manufacturing time. The arsenal has just completed a 100 percent in-ventory of the gauges and there are some here who believe it is time to purge some of the gauges that have not been used in decades. But just when that type of discussion begins, images arrive from some foreign battlefield that shows some of the arsenal’s legacy weapons still in use. Just maybe, we will need them again.------------------------Gauges vs. Gages…There was a discussion at Watervliet on the proper use of the term gauge. Army forms call the measuring tools “gages,” while the Associated Press Stylebook and Merriam-Webster Dictionary say the appropriate or best word use is “gauges.” You decide…

Instrument Mechanic Work Leader Seth Frank pulling out a gauge for in-spection. Frank oversees the day-to-day management for more than 70,000 gauges.

Photo by John B. Snyder

Page 5 Salvo Sept. 30, 2014

By John B. Snyder

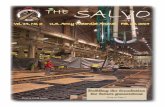

Even with a drawdown, $87M revenue achieved

Story continues on page 6, see Revenue

As September draws to a close, so does the Ar-my’s fiscal year when Army units try to ensure that they either don’t exceed their annual budgets or that they do not fail to obligate funds for established re-quirements. The arsenal also must deal with those end-of-year issues, as well as with other significant challenges such as trying to reach annual revenue targets and im-proving its on-time delivery rate before October 1. “There are two things that are critical to our clos-ing out the fiscal year in September,” said Col. Lee H. Schiller Jr., the arsenal commander. “One, we must make as many on-time deliveries as possible over the course of the next 30 days to help our 12-month on-

time delivery average. Secondly, we must work ex-tremely hard to ensure that we have set the conditions for success for a seamless transition into the next fis-cal year.” Much of the arsenal’s end of year activities are di-rectly tied to production, said Jake Peart, the arsenal’s chief of production planning and control. “Although my focus is more on the percentage of items that we have shipped on time per our produc-tion schedule, I still cannot lose sight on the revenue that September’s shipments will produce at the end of the year,” Peart said. “Nevertheless, if we hit our de-livery schedules, then the revenue will follow.” As Peart said that, there was significant activity on

Photo by John B. SnyderA mixture of 155mm, 120mm and 105mm tubes at various stages of painting and packaging for a September shipment.

Page 6 Salvo Sept. 30, 2014

Revenue Cont.

A variety of 105mm tubes and 120mm cannons ready for shipment at the end of September.

the production floors this month ensuring that if there was any product that could be shipped, it would get shipped before the end of the year. After all, those in resource management had built the arsenal’s 2014 budget based upon a planned revenue goal for this fis-cal year. And so, every dollar earned is critical to the arsenal’s ability to be fiscally responsible. As important as it is to hit revenue targets before the end of the fiscal year, that effort will not be done by moving 2015 scheduled work into 2014. “We build our execution workload plan two years out,” Peart said. “If we play with the schedule and move workload to surge at the end of the year by moving forward work from the next fiscal year, we then place both years at risk of not making schedule.” This doesn’t mean that Peart and his team don’t build flexibility into the schedule, because they do to account for such things as unplanned orders and equipment repair. Given that the arsenal has more than 600 manufacturing machines, keeping these ma-chines operational is a continual challenge to produc-tion. Another reason why it is difficult to move sched-uled work from one year to the next is due to the dynamics of working with contracted vendors. Be-

cause of the quality thresholds as established in the technical data packages, as well as by the uniqueness of materials required for weapon systems, it may take a vendor up to 18 months to provide the arsenal with raw materials. Additionally, even if the arsenal had the machin-ists available to accommodate an increased end-of-year workload effort, there are other key personnel who are part of the manufacturing process, such as painting, welding, packaging, and shipping, who may not be able to support if the unplanned increased re-quirement was not due to an urgent need. Through it all, the arsenal’s manufacturing team will close out a very solid production year having achieved about $87 million in revenue. It should go without saying, but will be said any-way. More important than delivery schedules and revenue is the fact that there is a serviceman or wom-an waiting for the arsenal’s products ̶ Something that Soldiers have been doing for more than 200 years. The Arsenal’s dedicated and highly-skilled work-force contributes to our national security by providing U.S. and foreign militaries the most advanced, high-tech, high-powered weaponry for cannon, howitzer, and mortar systems. The Arsenal is also DoD’s sole manufacture of large caliber cannons, from 105mm to 155mm, as well as DoD’s manufacture of choice for 60mm, 81mm, and 120mm mortar systems.

Photo by John B. Snyder

Page 7 Salvo Sept. 30, 2014

The World Trade Center towers had 110 floors and that is exactly how many floors two arsenal firefighters symbolically marched up yesterday to honor their fallen comrades who perished in New York City on 9/11. Mathew Kolodzie, who has been an arsenal firefighter since 2006, said he wanted to do something more dramatic this year to gain a better appreciation for what his fellow firefighters in New York City experienced that fateful September morning. “I knew this challenge was not going to be easy, but nothing was easy on 9/11,” Kolodzie said. “It is hard to imagine the amount of determination those firefighters had as they ran up the towers because many of them must have known that they were not coming out alive.” Armed with his idea, Kolodzie challenged one of the newest arsenal firefighters, Adam Kraus, to put on more than 60 pounds of equipment and join him in the arsenal gym to symbolically walk up 110 floors. Kraus, a former army scout who has been at the arsenal for about 15 months, took up the challenge and joined Kolodzie on what would become a 45-minute, non-stop exercise that will forever give them a better sense of 9/11. “There is something special about being a firefighter in that we all share the 9/11 story of bravery and sac-rifice, as if those New York City firefighters were our family,” Kraus said. “Walking up 110 flights of stairs today was extremely difficult but nothing as difficult as experienced by those firefighters who entered the World Trade Center carrying significantly more equipment, battling smoke, as well as the unknown.” Kolodzie and Kraus are already looking forward to next September so that they can export this shared sense of remembrance to others at the Watervliet Arsenal.

Remembering 9/11One Step at a Time

By John B. Snyder

Photo by John B. Snyder

Page 8 Salvo Sept. 30, 2014

During the months of August and September, we said a solemn goodbye to Peter “Scott” Ashton and Glen Lavarnway who each had a signifi-cant impact on the arsenal’s ability to support our men and women in uniform. From left, Col. Lee H. Schiller Jr. saying a few words during Lavarnway’s service, while Dale King had kind words to say about Scott Ashton.

Photos by John B. Snyder

Farewell to Former Commander

Much of the news this month was about the re-membrance of the attacks on 9/11. But among the numerous ceremonies that marked this date was a quiet, formal military ceremony at the Arlington National Cemetery to bury a com-bat Veteran of World War II ... and a military officer who commanded the Watervliet Arsenal from 1971 to 1973.

Col. Christopher S. Maggio was laid to rest on Sept. 11, 2014.

Farewells to

Arsenal Brothers

Photo by Chris Maggio Jr.

Page 9 Salvo Sept. 30, 2014

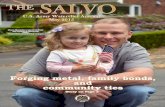

Exchange (ing) new ideas

is not a fun game

It has been about five years since I played the “Match It” game at the arsenal’s Exchange store and so, I thought I would check back to see if the Exchange still played that game. A lot has changed since 2009 when former Exchange manager Leon Williams led me from aisle to aisle challeng-ing me to pick an item for him to match the price. For one thing, the small store in 2009 was called a Troop Store, op-erated by the Army & Air Force Exchange Service. Today, the store is simply called the Exchange. Back then, Leon said that he priced his products in line with local Rite Aid and Stewart shops, to include sale prices. He also said that he would match any price within $10 without a sales advertisement because he trusted his customers. If his customers told him the price was cheaper elsewhere, he would take their word for it. As I recall, I challenged Leon to match the price on a case of beer that for some reason was on my mind as being on sale at a local market that week. It must have been the large ad placement that drove my question on beer or the fact that I was in Leon’s alcohol aisle that led me to throw out the beer challenge. Leon matched the price … or should I say he would have matched the price if I wasn’t on duty. Here we are five years and three managers later and I wasn’t sure if the “Match It” game was still on and so, I stopped into the Exchange earlier this month unannounced. Store Manager Reggie Matias had only been at the arsenal for less than two weeks when I walked into his of-fice. The look on his face was as if a reporter from CBS’ 60 Minutes had just walked in. After all, I was armed with two cameras and a reporter’s note pad. Without giving Reggie an opportunity to assess the situ-ation, I hit him immediately with the “Match It” game. I challenged him with a variety of recent sales items that I had seen in the Sunday advertisements leading off with … beer. I just wanted to see if the prices had changed from 2009.

Before I could get the second challenge out, Reggie said that he would match the prices of all sale items. This took all the fun out of the game. Not wanting to have this new guy stump me in my own backyard, I looked at other ways I could challenge Reggie. I recalled that last month the Exchange Senior Enlisted Advisor had visited the arsenal. During his visit, Chief Master Sgt. Anthony “Tony” Pearson toured our Exchange facility and talked with Sol-diers and Department of the Army civilians about how the Exchange can better serve them. One of the Soldiers told Pearson that she would visit the store more often if there was a better selection of healthy foods, such as fresh fruit. Not thinking that Reggie would be privy to this visit, I challenged him to tell me about what he is going to do to provide a more healthy selection of food products. I sat back with a smug smile and waited for his response. He said that is a good question … aha, I got him, I thought! That was until Reggie showed me an information flyer for a program called Operation BEFIT. The program high-lights healthy food options, and the Exchange’s dietitian ensures all items in the assortment meet military standards. The idea of eating balanced meals full of healthy carbohy-drates and lean proteins, staying hydrated and making sure to replenish the calories during workouts may be applied to anyone who wants to improve their lifestyle. Reggie said he wanted to make one wall available to support the Operation BEFIT program. So, if he was giving up a wall to accommodate a health-ier selection of products, then he would be in essence

By John B. Snyder

Story continues on page 10, Exchange

New Exchange Manager Reggie Matias.Photo by John B. Snyder

Page 10 Salvo Sept. 30, 2014

giving up space he is currently using for other products. I threw that tidbit of an observation out to Reggie. Reggie knocked down my observation by saying he planned to modify a storage room into product floor space. Thus, giving arsenal customers a broader selection of items. Just as with Leon, I quickly tired of this conversation with Reggie. Somewhat disgruntled that the new manager beat me on my own field, I asked Reggie why I would ever want to come back to the Exchange store. Reggie reminded me that historically, two-thirds of Ex-change earnings are returned to Morale, Welfare and Recre-ation programs. In fact, nearly $30,000 was returned to the arsenal in 2013 to support MWR activities. And, to ensure military families at smaller installations enjoy the same selection and savings as larger Exchange locations, the Watervliet Exchange participates in a Shuttle Program with the Fort Drum Exchange. If Watervliet shop-pers can’t find an item, they can ask the manager to see whether it can be brought from Fort Drum. So, the next time you have an urge to shop, you may want to try the Exchange. Not only will arsenal customers get a great price, part of the earnings will also remain here.

Exchange Cont.

Paying tribute to Uncle SamFor many years now, the Watervliet Arsenal has sup-ported Troy’s annual Uncle Sam Graveside Ceremony, a ceremony that helps the community recognize an American icon who sup-ported the arsenal and the nation during the War of 1812.

Left: Arsenal Commander with George Jacques, a 90-year old World War II Veteran who also worked at the arsenal from 1960 to 1984.

Right: Uncle Sam listening to the commander speak.

Photos by John B. Snyder

Photo by John B. SnyderReady-made sandwiches are available at the Exchange.

Page 11 Salvo Sept. 30, 2014

Albany County’s Veterans’ Day Parade11 November

11 a.m.You have a chance to join us this November as we honor our Nation’s Veterans by marching in this year’s Albany County Veterans’ Day Parade. In addition to two Arsenal/Benét Labs floats, we plan to field several of our emer-gency service vehicles and several historic military vehicles from the Hudson-Mohawk Military Vehicle Club.

So, please gather your family members and march with us as we pay proper recognition to our Veterans, as well as to showcase the Arsenal to the commu-nity. If you have any questions, give John Snyder a call @ 266-5055.

SAVE THE DATE

Nov. 11, 2013

Veterans Day Parade

Save the Date

11 November 2014

Photo by John B. Snyder

Page 12 Salvo Sept. 30, 2014