Us 2627160 patent

-

Upload

gedi-minster -

Category

Documents

-

view

216 -

download

0

Transcript of Us 2627160 patent

-

8/10/2019 Us 2627160 patent

1/5

F e b .

3 ,

1953 G . c .

MaODONALD 2 , 6 2 7 , 1 6 0

ROCKET

IGNITER

Filed

A p r i l

1 ,

1 9 4 7

2

SHEETSSHEET

1

Q w a s m m Q m m m

INVEN O R .

Wm ? -

AJMJ

-

8/10/2019 Us 2627160 patent

2/5

2 , 6 2 7 , 1 6 0

e b .

3 , 1953 G . c . MaGDONALD

ROCKET IGNITER

2

S H E E T S ~ S H E E T

2

iled April

1,

1 9 4 7

-

8/10/2019 Us 2627160 patent

3/5

P a t e n t e d

F e b .

3 , 1 9 5 3

UNITED STATES

2 , 6 2 7 , 1 6 0

PATENT

OFFICE

2,627,160

ROCKET

IGNITER

Gilmour C r a i g MacDonald, Ames,

Iowa

A p p l i c a t i o n A p r i l

1 , 1 9 4 7 , S e r i a l N o .

7 3 8 , 6 0 1

( 0 1 .

6 0 - 3 5 . 6 )

Granted

un d e r T i t l e 3 5 , U. S .

C o d e

( 1 9 5 2 ) ,

s e c . 266)

4 Claims.

This i n v e n t i o n

d e s c r i b e d

h e r e i n may e manu

factured

a n d u s e d

b y or f o r the G ov e r n m e n t for

governmental

p u r p o s e s ,

without

t h e

payment

' t o

me

f any r o y a l t y

t h e r e o n .

This

invention r e l a t e s

t o

rocket i g n i t i n g m e a n s

and m o r e

p a r t i c u l a r l y

t o

simple

m e a n s f o r i g n i t

i n g

t h e m a i n

r o c k e t p r o p e l l a n t charge c o i n c i

d e n t a l l y

w i t h

v e n t i n g t h e p r o p e l l a n t chamber.

I t i s an

o b j e c t

o f t h i s invention

t o

p r o v i d e

means whereby

an

e x p l o s i v e c h a r g e , employed

t o

rupture the

n o z z l e c l o s u r e o f a r o c k e t , a l s o i g n i t e s

t h e m a i n p r o p e ll a n t c h a r g e .

I t i s a

further

o b j e c t

o f

the invention t o

s i m

p l i f y s o l i d f u e l r o c k e t s , o f t h e

t y p e

p r o v i d i n g f o r

o p t i o n a l

d i r e c t i o n

o f t h r u s t through

the use

o f

dual o r m u l t i p l e

n o z z l e s , by

u t i l i z i n g

two

o r m o r e

o f the r o c k e t i g n i t i n g means h e r e i n d i s c l o s e d i n

s u b s t i t u t i o n

f o r

the conventional

r o c k e t

?ring

means.

C e r t a i n

important advantages i n improving

t h e low temperature

i g n i t i o n c h a r a c t e r i s t i c s

o f

rocket thrust u n i t s

accrue

t o t h i s invention i n that

the e x p l o s i v e

r u p t u r i n g

charge

and

t h e n o z z l e c l o

sure m e a n s may e s o

design ed

that

the

ruptur

ing charge prod uces only a small hole

i n

the

c l o

s u r e , t h e

b a l a n c e

o f t h e c l o s u r e blowing

and/or

e r o d i n g o u t o f t h e n o z z l e o n l y w h e n t h e p r e s s u r e

within the rocket c h a m b e r approaches the n o r

m a l operating p r e s s u r e .

By t h i s

means, the

r a t i o

o f p r o p e l l a n t

burning

s u r f a c e

t o

n o z z l e

area may

b e

i n c r e a s e d d u r i n g t h e

c r i t i c a l i g n i t i o n

p e r i o d ,

which will s u b s t a n t i a l l y improve i g n i t i o n

o f

t h e

p r o p e l l a n t ,

e s p e c i a l l y

a t

l o w t e m p e r a t u r e s .

A

urther

advantage o f t h i s invention i s that

the

rocket u n i t

may r e ma i n

permanently an d

h e r m e t i c a l l y s e a l e d a f t e r manufacture,

and

t h e

i n i t i a t i n g charge may e

i n s e r t e d i n

t h e

e x t e

r i o r p o r t i o n

o f

the

n o z z l e .

This i s

i n

c o n t r a s t

with

t h e p r e s e n t

system

o f

i n s e r t i n g

an

i n t e r n a l

i g n i t e r p r i o r t o

u s e ,

w h i c h

may cause

s e r i o u s

i n t e r n a l e ? e c t s d u e

t o e x c e s s i v e

humidity, or the

hazardous p r a c t i c e o f handling

and s h i p p i n g t h e

u n i t

with

t h e

i g n i t e r i n

p l a c e

and with the ?ring

c i r c u i t

wires

a t t a c h e d .

Other

o b j e c t s

and advantages o f t h i s i n v e n

t i o n w i l l

be apparent

during the

c o u r s e o f the

f o l l o w i n g d e s c r i p t i o n , r e f e r e n c e b e i n g m a d e

t o

t h e a t t a c h e d

drawing

w h e r e i n :

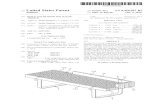

Figure

1

d e p i c t s

a

l o n g i t u d i n a l

s e c t i o n

view

o f

a

p o r t i o n o f a r o c k e t t h r u s t u n i t

e m bo dy in g

my

i n v e n t i o n . Figu re 2

i s

a

s e c t i o n

view

s i m i l a r

t o

Figure l

but

d e p i c t i n g the detonation o f t h e rup~

t u r i n g

charge and

t h e

r e s u l t a n t r u p t u r e o f

t h e

blowout e l e m e n t .

Figu re

3 i s a

s e c t i o n

view s i m i

l a r t o F i g u r e 2

b u t d e p i ct i n g t h e c o n d i t i o n

o f t h e

1 0

25

45

50

2

b lowout elem ent when the

r o c k e t

i s

a t the

n o r

m a l

operating

p r e s s u r e .

Figure

4 i s a l o n g i t u d i

nal

s e c t i o n a l

view

o f

a

dual

n o z z l e

type

o f

rocket

m o to r

i l l u s t r a t i n g

t h e a p p l ic a t i o n t h e r e t o o f t h e

rocket i g n i t i n g m e a n s o f the i n v e n t i o n . F i g u r e 5

i s a

longitudinal s e c t i o n a l

view

o f

a

portion

of

a

rocket

thrust unit e m b o d y i n g a m o d i ? e d f o r m

o f c l o s u r e .

T u b e

i s screwed i n t o

n o z z l e

2 f o r m i n g

the

combustion chamb er con?ning

p r o p e l l a n t

3 and

i g n i t e r 4 . Blowout element 5 i s

secured

i n the

nozzle at the inner o r c h a m b e r e n d o f the l a t t e r

i n spaced r e l a t i o n t o the p r o p e l l a n t as s h o w n

and

e f f e c t s c l o s u r e

o f

the n o z z l e 2 u n t i l such t i m e

a s

rupturing charge 6 i s detonated

by

an e l e c t r i c a l

c u r r e n t p a s s i n g

through

t h e

conductor

1

o f the

? r i n g

c i r c u i t

( n o t

shown).

T h e r u p t u r i n g

c h a r g e

6 i s

p o s i t i o n e d

and s u p p o r t e d s u b s t a n t i a l l y a t

t h e

a x i a l center o f the

n o z z l e

2 b y m e a n s 8 , wh i c h

may

e a spider or oth e r

conventional

s t r u c t u r e .

Closure

e l e m e n t 5 as presently shown s a c u p

shap ed member

placed

i n

the

n o z z l e a s s h o w n

a n d

design ed

t o f a i l

a t pressures i n

e x c e s s o f the

normal

o p e r a t i n g

p r e s s u r e but l e s s than t h e de

ter m in ed

b u r s t i n g p r e s s u r e o f t h e

combustion

chamber.

T h e

d e t o n a t i o n

o f

r u p t u r i n g

charge

6 which

may

r not em p lo y

the hollow

charge shape

shown)

r u p t u r e s the blowout element 5 , t h e

i n

candescent

p a r t i c l e s

f r o m

s a i d

detonation

and

r u p t u r e

t r a v e l l i n g

almost i n s t a n t a n e o u s l y t o t h e

i g n i t e r

4 w hich

i g n i t e s t h e

p r o p e l l a n t 3 i n t h e

u s u a l man n e r . In

the p r a c t i c a l

a p p l i c a t i o n

o f

the

i n v e n t i o n ,

the rupturing charge

may,

i f

d e s i r e d ,

be

s o

pro po rtioned a s t o q u a n t i t y , s i z e ,

e t c . ,

that

the

b l a s t i n g o r e x p l o s i v e e f f e c t

t h e r e o f w i l l sub

s t a n t i a l l y d i s i n t e g r a t e and

d e s t r o y

i t s a s s o c i a t e d

c l o s u r e o r blowout e l e m e n t . _ Im provem ent i n t h e

low temperature i g n i t io n c h a r a c t e r i s t i c s o f

the

r o c k e t

i s

o b t a i n a b l e , h o w e v e r , i f

t h e

charge i s

shap ed

t o

have a

rupturing

f o r c e e f f e c t i v e t o

pro

d u c e

only

a small vent

hol e in

the

closure

m ea n s .

The r e s u l t s

achieved

f r o m the u se o f

a

s h a p e d

charge are

a p pa r en t f r o m Figu res

1 an d

2 w h e r e

i n i s

s h o w n

a

rupturing

member f the

hollow

charge shape c o m p r i s i n g a

r i g h t

c y l i n d e r 6 o f

e x p l o s i v e

having a

c o n i c a l c a v i t y

9

i n

o n e

e n d

a n d

su ppo rted

within the

n o z z l e

2

a n d

n ea r the

outer

face

o f

b lowout elem ent

5 s o

that the

base

o f the

cone 9 f a c e s

the

blowout

e l e m e n t . T h e

d i

r e c t i o n a l

c o n t r o l and

d e e p

p e n e t r a t i o n v o b t a i n

a b l e

with such a

shaped

c h a r g e ' i s u s u a l l y c a l l e d

t h e

c a v i t y

e f f e c t pheno m eno n. T h e

pro

nounced d i r e c t i o n a l e f f e c t and

deep

p e n e t r a t i o n

w hich i s

obtainable

with a r i g h t c y l i n d e r o f ex

-

8/10/2019 Us 2627160 patent

4/5

2 , 6 2 7 , 1 6 0

3

p l o s i v e having

a

c o n i c a l c a v i t y

i n

one

e n d

have

l o n g

b een

k n o w n i n the

a r t and

the p h e n o m e n o n

i s

s o m e tim es

ref erred t o as

the

M o n r o e

e f f e c t

as

a

r e s u l t o f the i n v e s t i g a t i o n an d

s t u d i e s

made

b y

M o n r o e

i n

the U n ited

S t a t e s . Additional

i n

formation r e g a r d i n g

t h i s

p h e n o m e n o n and t h e

i n v e s t i g a t i o n s

by

Monroe and

o t h e r s w i l l be

f o u n d

o n

p a g e

18 of

the

w o r k

b y

Co lo nel

L e s l i e E .

Simon,

U n i t e d

S t a t e s

Army,

e n t i t l e d ,

German

Research in W o r l d War I I a n d pu b lished i n

10

1947

b y

J o h n

Wiley

8 : Sons, I n c . , New Yo r k .

Figure

2 o f

t h e drawings d e p i c t s t h e d e v i c e a t t h e

i n s t a n t

o f

detonation o f

t h e

r u p t u r i n g

charge

6

w h i c h , b y reason

o f the

c a v i t y e f f e c t p h e n o m

e n o n

ref erred t o above, p r o j e c t s a

thin to ngu e or

j e t

o f incandescent gas

u n d e r

extr em e pressure

which r u p t u r e s an d

p i e r c e

t h e blowout

element

as s h o w n a t

H ) .

Incandescent gas a n d

m e ta l p a r

t i c l e s f r o m the detonated charge a n d the r u p

tured element

t r a v e l

t o a n d s t r i k e the i g n i t e r

4

w hich f l a r e s

u p ,

i g n i t i n g the p r o p e l l a n t

3 i n

t h e

usual man n e r . F i g u r e

3

i l l u s t r a t e s the condition

o f the p a r t s f o l l o w i n g

a short

p er iod o f time a f t e r

the

rocket unit has r e a c h e d n o r m a l

operating

p r e s s u r e .

At

t h i s

phase

o f the

o p e r a t i o n , the pro

p e l l a n t 3 i s burning

o n

a l l exposed

surfaces an d

the n o z z l e

passage

i s s u b s t a n t i a l l y

c l e a r o f

a l l

o b s t r u c t i o n s ;

t h e blowout element 5

having been

b l o w n

a n d / o r

e r o d e d ? u s h with the internal n o z

z l e

s u r f a c e by t h e high temperature and p r e s s u r e

o f

the gases o f combustion. D u r i n g the

c r i t i c a l

i g n i t i o n

p e r i o d o c c u r r i n g

between

t h e

r e s p e c t i v e

c o n d i t i o n s

i l l u s t r a t e d

i n Figures

2

an d

3 ,

the

r a t i o

o f

p r o p e l l a n t

b u rn ing

s u r f a c e

t o n o z z l e area i s

substantially

increased with the r e s u l t

that

t h e

continued i g n i t i o n o f t h e

p r o p e l la n t , p a r t i c u l a r l y

at low temperatures,

i s m a t e r i a l l y p r o m o t e d

and

i m p r o v e d .

T h e

assembly

o f

blowout element

an d

ruptur

i n g

charge

s h o w n

i n Figures 1 and 2 i s designed

primarily for u se

with a rocket o f the unidirec

t i o n a l

or

s i n g l e n o z z l e t y p e . W i t h a

s i n g l e

rocket

o f

the dual

or

multiple

nozzle t y p e , t w o

or m o r e

assemblies o f blowout

element

an d ru ptu ring

c ha r g e are u s e d t o g i v e a choice o f

thrust

d i r e c

t i o n

o f

the

r o c k e t . This i s

i l l u s t r a t e d i n

Figure

4

w h e r e i n i s

shown

rocket thrust unit

o f

th e

dual

n o z z l e type comprising a r o c k e t body

having

op

p o s i t e l y

d i s p o s e d n o z z l e s

and

I 2 connected

with

a common

r o p e l l a n t

c h a m b e r I 3 contain

i n g

t h e

p r o p e l l a n t

I 4 and the

p r o p e l l a n t i g n i t e r s

l 5

an d

I 6 . E a c h

n o z z l e

i s s h o w n provided with

a c l o s u r e

o f

the type

i l l u s t r a t e d

i n Figur e 1

a n d

including

a

b l o w o u t e l e m e n t

5 ,

ru ptu ring

mem

her 6

o f

the h o l l o w charge

s h a p e , detonating

w i r e s 1 , and

charge-supporting

m ean s 8 . Th r ust

i n the

d e s i r e d

d i r e c t i o n i s obtained

b y

detonating

t h e

rupturing charge

i n t h e s e l e c t e d n o z z l e f o r

i g n i t i n g

t h e

p r o p e l l a n t c o i n c i d e n t l y

w i t h

v e n t i n g

the n o z z l e . In

Figure

4 ,

the blowout element 5

o f nozzlel

i s s h o w n

ruptured

and

the p r o p e l l a n t

I 4

i g n i t e d

b y detonation o f

i t s a s s o c i a t e d charge

6 while the blowout element 5 o f

the nozzle

[ 2 i s

s h o w n i n t a c t . I t i s e s s e n t i a l t o

the

m aintenance

o f the d i r e c t i o n

an d duration o f

the

thrust

that

f a i l u r e

o f

the blowout element o f the non-vented

nozzle

shou ld not occur d u ring the operating

p e

r i o d o f

the r o c k e t .

I t i s o b v i o u s , t h e r e f o r e ,

that

ea c h

nozzle

closure

or

b l o w o u t e l e m e n t u s e d

in

a

rocket

g i v i n g

a choice

o f

thrust d i r e c t i o n

m u s t

be a b l e ,

w h i l e

i n i t s non-ruptured c o n d i t i o n , t o

stand n o r m a l c h a m b e r p r e s s u r e s without f a i l u r e

an d

a t the s a m e

t i m e

b e protected

against

the

high

temperature

o f t h e g a s e s o f

c o m b u s t i o n .

A c c o r d i n g l y , the blowout element 5 i s m a d e o f

2 0

25

3 0

40

60

65

7 0

4

su ch material

a n d

design herein d i s c l o s e d a s

t o

withstand p r e s s u r e s i n the p r o p e l l a n t c h a m b e r i n

excess o f

the n o r m a l

operating pressures

but l e s s

than

the

determined

b u r s t i n g p r e s s u r e

o f

t h e

p r o p e l l a n t chamber. In a d d i t i o n , a p r o t e c t i v e

s h i e l d

l l

o f any s u i t a b l e heat i n s u l a t i n g mate

r i a l

i s

used with

the

blowout

elementy5

t o

i n s u

l a t e

the

e l e m e n t

f r o m

the

h eat

o f

the

hot

gases

o f the

c o m b u s t i o n c ha m b e r .

This insulating

ma

t e r i a l may e a p p l i e d , as s h o w n in F i g u r e 4 , as a

c o v e r i n g

l a y e r

u p o n the

s i d e o f

the element

f a c

i n g t h e

i g n i t e r

and

t h e

p r o p e l l a n t . U p o n

r u p t u r e

o f

the

blowout element b y detonation

o f

t h e

shaped e x p l o s i v e c h a r g e ,

i t s a s s o c i a t e d

i n s u l a t o r

i s

a l s o

r u p t u r e d

b y

th e j e t f o r m at i o n o f the

b l a s t

wh i c h t r a v e l s t o and i g n i t e s the

p r o p e l l a n t

i g n i t e r . In the

operation

o f

the

d u a l - n o z z l e

r o c k e t t h r u s t u n i t sh o w n

i n

Figure 4 ,

w h e n

t h e

b l o w o u t e l e m e n t

5

of

nozzle

I I i s v en t e d t o give

the

d e s i r e d

d i r e c t i o n

o f

t h r u s t , the blowout e l e

m e n t 5

o f n o z z l e I 2

i s l e f t

i n t a c t f o r the dura

tion

of

the thrust unless cancellation or n e u

t r a l i z a t i o n

o f

thrust

i s

d e s i r e d ,

i n

w h i c h

c a s e

i t

i s ruptured b y detonation o f i t s

a s s o c i a t e d

rup

t u r i n g

charge

6

t o vent

the

n o z z l e

l 2 f o r

s e t t i n g

u p

a

c o u n t e r t h r u s t .

H e n c e ,

w h i l e o n e nozzle of

the dual n o z z l e

r o c k e t

i s i n operation t o g i v e the

d e s i r e d d i r e c t i o n o f t h r u s t ,

the

other nozzle p ro

v i d e s

a u x i l i a r y

venting m e a n s wh i c h i s

o p e r a b l e

u n d e r m a n u a l d i r e c t i o n t o

vent

the propellant

c h a m b e r

t o c o n t r o l

the duration

o f

the

t h r u s t

a n d operable a l s o in

response

t o propellant cham

b e r

p r e s s u r e t o

automatically vent the

p r o p e l l a n t

c h a m b e r before pressures in the c h a m b e r i n

ex

cess of t h e

n o r m a l

o perating

p r es s ur e r e a c h

bursting

pressure.

Many

other

types o f c l o s u r e s are a l s o a p p l i

cable

t o t h i s i n v e n t i o n . A m o d i ? e d

f o r m

o f

closure is

i l l u s t r a t e d

in F i g u r e 5 .

The

l o s u r e or

blowout element

t h e r e i n d e p i c t e d

i s

p r e f e r a b l y

of m o u l d e d p l a s t i c

a n d has a m a i n b o dy

or

p lug

1 8

w h i c h

is

seated i n

the

nozzle

2 at

t h e

inner or

p r o p e l la n t chamber i d e

of

the

throat

or

r e

s t r i c t e d

portion I Q

o f

the

n o z z l e , i n

spaced

r e l a

t i o n t o the p r o p e l l a n t 3 , an d c l o s e s the n o z z l e

pa ssa g ew ay in t h e

manner

h o w n . P l u g

I 8

i s r e

tained i n

i t s

n o z z l e - c l o s i n g p o s i t i o n i n

any

con

v e n t i o n - a 1 a n d suitable

manner not

s h o w n )

a n d

has a

hollow

s t e m 2

w h i c h is an i n t e g r a l

part

o f

the p l u g . The t e m 2 | i s o n the outer face of the

plug and extends

l o n g i t u d i n a l l y o f the n o z z l e

f r o m

the plug

t o

the outer

or

f a r s i d e

o f the

n o z z l e

t h r o a t I S ,

t h e

diameter o f

t h e

stem

b e i n g

so

much l e s s

t h a n

the d i a m e t e r

of

the

nozzle

t h r o a t t h a t

the

stem i s s u b s t a n t i a l l y

spaced

f r o m

an d centered

b e t w e e n

the

enco m passing w a l l

o f the n o z z l e .

The ho llow

s t e m

2 |

c a r r i e s the

c y l i n d r i c a l r u p t u r i n g charge

6 a

which i s p l a c e d

in the b o re or cavity 2 2

o f

the

stem.

A c u p 2 3

o n

the

inn er f a c e o f

plu g

[ 8 provides a

r e c e p

t a c l e

f o r

the

i g n i t e r 4a w h i c h maybe e l l e t e d i n

place

or

r eta in e d

as

a p o w d e r

b y

any c o n v e n

t i o n a l retaining means, .

e . ,

a

f o i l c o v e r i n g .

This

type of

closure serves

as a carrier

for

b o t h the

c l o s u r e

r u p t u r i n g

charge

6 a

and

t h e p r o pe l l a n t

i g n i t e r

4 a . Closure 1 8 may

l s o

be design ed s o

that the

ru ptu ring

charge

l e a v e s

a

portion

o f

t h e

c l o s u r e i n t a c t

u n t i l

the

r o c k e t

approaches

the

normal o p e r a t i n g p re s s u r e when t h e c l o s u r e i s

broken

up

and

x p e l l e d .

I t w i l l

b e

u n d e r sto o d that the scope o f

t h i s

i n

vention i s not l i m i t e d

t o the exemplary s t r u c t u r e

i l l u s t r a t e d

and

s p e c i ? c a l l y d e s c r i b e d , but i s l i m

i t e d o n l y

b y the

s c o p e

o f

t h e

f o l l o w i n g c l a i m s .

-

8/10/2019 Us 2627160 patent

5/5

2 , 6 2 7 , 1 6 0

5

I c l a i m :

1 . In a r o c k e t t h r u st d e v i c e , t h e combination r

a

p r o p e l l a n t ,

a combustion c h a m b e r

c o n ?n i n g

the p r o p e l l a n t

an d having an o u t l e t n o z z l e , a

r u p t u r a b l e

blowout element

s e c u r e d i n

t h e

n o z z l e

a t

the inner

o r c h a m b e r e n d o f the

l a t t e r i n

spaced r e l a t i o n

t o

t h e

p r o p e l l a n t and c l o s i n g

t h e

n o z z l e a t such e n d , a p r o p e l l a n t i g n i t e r b etw een

the s a i d element an d

the

s a i d p r o p e l l a n t , m e a n s

f o r

r u p t u r i n g t h e

s a i d

element and i g n i t i n g t h e

p r o p e l l a n t

i g n i t e r

i n c l u d i n g

a charge

r

e x p l o s i v e

w i t h i n

t h e n o z z l e ,

s a i d e x p l o s i v e

b e i n g

o f

t h e

h o l l o w

charge

shape

comprising a

r i g h t c y l i n

der o f e x p l o s i v e having a c o n i c a l

c a v i t y

i n one

e n d and supporting means f o r the s a i d

charge

p o s i t i o n e d

i n

the

n o z z l e

adjacent

t h e o u t e r s i d e

o f the blowout element and supporting the s a i d

c h a r g e s u b s t a n t i a l l y s p a c e d f ro m

and

c e n t e r e d

b etw een the encompassing

w a l l o f t h e n o z z l e

with

the

base

o f the cone

facing the

blowout

element.

2 .

In

a

r o c k e t t h r u s t d e v i c e , the

combination

o f

a p r o p e l l a n t ,

a

c o m b u st i o n c h a m b e r c o n ?n i n g

t h e p r o p e l l a n t

and

having m u l t i p l e

o u t l e t

n o z z l e s

angularly d i s p o s e d t o g i v e a c h o i c e

o f

d i r e c t i o n

o f t h r u s t ,

a b lowout n o z z l e c l o s u r e i n

each n o z z l e

an d c l o s i n g the

same, a

p r o p e l l a n t

i g n i t e r

be

tween t h e

p r o p e l l a n t

a n d

each n o z z l e c l o s u r e , and

m e a n s o p e r a t i v e l y a s s o c i a t e d with

each

n o z z l e

f o r

blowing o u t t h e

n o z z l e c l o s u r e

and

i g n i t i n g

the p r o p e l l a n t

i g n i t e r ,

s a i d

m e a n s i n c l u d i n g

a

charge o f e x p l o s i v e w i t h i n t h e n o z z l e

and a d j a

cent the o u t e r s i d e o f

the

n o z z l e c l o s u r e .

3 . In a

rocket

thrust

d e v i c e ,

the combination o f

a p r o p e l l a n t ,

a

c o m b u st i o n c h a m b e r c o n ? n in g the

propellant a n d having two o r m o r e o u t l e t n o z z l e s

a n g u l a r l y d i s p o s e d t o g i v e a c h o i c e o f d i r e c t i o n o f

t h r u s t ,

a

r u p t u r a b l e

blowout element

i n

each

n o z z l e

a t

the inner o r c h a m b e r e n d

o f

the

n o z z l e

an d c l o s i n g the n o z z l e a t such e n d , a p r o p e l l a n t

i g n i t e r between

t h e p r o p e l la n t and

each

r u p t u r

a b l e

b lowout

element,

a n d

m e a n s o p e r a t i v e l y a s

s o c i a t e d

with

each n o z z l e f o r

r u p t u r i n g the e l e

C a

1 5

20

25

30

40

6

ment and i g n i t i n g t h e

p r o p e l l a n t

i g n i t e r ,

i n c l u d

i n g

a shaped c h a r g e o f e x p l o s i v e m a t e r i a l wi t h i n

t h e

n o z z l e an d adjacent

t h e o u t e r

s i d e o f the

blowout e l e m e n t .

4 . In a rocket thrust d e v i c e , the combination

o f

a

p r o p e l l a n t ,

a

combustion c ha m b e r co n? n ing

t h e

p r o p e l l a n t

and

having

m u l t i p l e o u t l e t n o z z l e s

angularly d i s p o s e d

t o

g i v e

a

c h o i c e

o f d i r e c t i o n

o f

t h r u s t ,

a b lowout n o z z l e

c l o s u r e i n

ea c h nozzle

an d c l o s i n g the same, s a i d

c l o s u r e

being f o r m e d

o f a material having s u f f i c i e n t

p h y s ic a l s t r e n g t h

t o

r e ma i n i n t a c t a t

combustion c h a m b e r

p r e s

sure i n excess o f the n o r m a l

operating

p r es s ur e

but l e s s

than the

d e t e r m i n e d

bursting pressure

o f t h e combustion chamber, a p r o p e l l a n t i g n i t e r

between

t h e p r o pe l l a n t

and each n o z z l e

c l o s u r e ,

a c l o s u r e p r o t e c t i v e s h i e ld o f

heat-insulating

m a t e r i a l

p o s i t i o n e d

between

each n o z z l e

c l o s u r e

an d p r o p e l l a n t i g n i t e r , and m ean s

o p e r a t i v e l y

a s s o c i a t e d with each n o z z l e

f o r

blowing out the

n o z z l e c l o s u r e

and

i g n i t i n g

t h e

p r o p e l l a n t i g n i t e r ,

s a i d

m e a n s

including

a charge

o f e x p l o s i v e

within

t h e n o z z l e an d adjacent the o u t e r s i d e o f the

n o z z l e

c l o s u r e .

GILMOUR CRAIG MAcDONALD.

REFERENCES CITED

T h e following references are

o f

record i n the

? l e

o f

t h i s p a t e n t :

UNITED

STATES

PATENTS

Number

Name Date

4 0, 092 Dib bl e __________ - _ S e p t . 29, 1 8 6 3

2,423,837 Martin ____________ July 1 5 , 1 9 4 7

2, 455, 015

Mace

____________ _

Nov.

30, 1 9 4 8

2, 457, 839 Skinner

__________

_

Ja n .

4 ,

1 9 4 9

FOREIGN PATENTS

N u m b e r

Country Date

330, 4 93 Great Britain ____ _- June

2 ,

1 9 3 0

8 6 4 , 8 2 2

France ____________ _

Feb.

1 9 4 1