Urban Pool XL 6.50 m x 3.50 m - Bespoke Pool Enclosures · URBA POOL BWT myPOOL 2019/01 - Indice de...

Transcript of Urban Pool XL 6.50 m x 3.50 m - Bespoke Pool Enclosures · URBA POOL BWT myPOOL 2019/01 - Indice de...

1/762019/01 - Indice de révision : C - Code : 37321URBAN POOL BWT myPOOL

GB | PAGE 1

INSTALLATION AND OPERATING INTRUCTIONSto be read carefully and kept for future reference

Urban Pool XL6.50 m x 3.50 m with integrated automatic cover

2/76 2019/01 - Indice de révision : C - Code : 37321 URBAN POOL BWT myPOOL

1. PRESENTATION ............................................................................................ 6

2. FOREWORD ................................................................................................... 62.1 Storage.....................................................................................................................................62.2 An above-ground kit ...............................................................................................................62.3 Safety .......................................................................................................................................62.4 Assembly .................................................................................................................................7

2.4.1 Assembly steps ............................................................................................................72.4.2 Tools.............................................................................................................................72.4.3 Assembly time..............................................................................................................7

3. NOMENCLATURE .......................................................................................... 83.1 Wood and coping pack ...........................................................................................................83.2 Accessories pack ...................................................................................................................8

3.2.1 Screws for the pool structure .......................................................................................83.2.2 Pool structure metalwork .....................................................................................................103.2.3 Integratedcartridgefiltrationsystem ..........................................................................103.2.4 Accessories ............................................................................................................................11

3.3 Automatic cover pack...........................................................................................................113.3.1 Mechanical assembly and automatic cover slat apron ..............................................113.3.2 Ladder rails ................................................................................................................11

4. WOOD, A NATURAL MATERIAL .................................................................. 124.1 Colour variations ..................................................................................................................124.2 Resin beads ...........................................................................................................................124.3 Salt stains ..............................................................................................................................124.4 Greying ..................................................................................................................................124.5 Splitting and cracking ..........................................................................................................134.6 Knots ......................................................................................................................................134.7 Surface mould .......................................................................................................................134.8 Joined wood ..........................................................................................................................134.9 Curved wood .........................................................................................................................13

5. EARTHWORKS ............................................................................................ 145.1 Introduction ...........................................................................................................................145.2 Creating the excavation .......................................................................................................14

5.2.1 Material quantities ......................................................................................................145.2.2 Excavation .................................................................................................................145.2.3 Drainage ....................................................................................................................145.2.4 Stone bedding ............................................................................................................16

5.3 Installing the supporting braces .........................................................................................165.4 Pouring the concrete slab ....................................................................................................19

5.4.1 Rebar .........................................................................................................................195.4.2 Slab dimensions.........................................................................................................20

6. ASSEMBLING THE WOODEN STRUCTURE ............................................... 216.1 Introduction ...........................................................................................................................216.2 Application of the bituminous strips ..................................................................................236.3 Assembling the slats ...........................................................................................................236.4 Mountingthefinishingtrimonthesupportingbraces .....................................................256.5 Mounting the coping brackets .............................................................................................256.6 Assembling the wooden access ladder ..............................................................................266.7 Mountingthemetalfittings ..................................................................................................276.8 End grain sealer ....................................................................................................................276.9 Finishing trim ........................................................................................................................27

3/762019/01 - Indice de révision : C - Code : 37321URBAN POOL BWT myPOOL

7. INSTALLATION OF THE FILTRATION SYSTEM .......................................... 287.1 Filtration group components ...............................................................................................29

7.1.1 Rigid module ..............................................................................................................297.1.2 Returnfitting...............................................................................................................297.1.3 Skimmer .....................................................................................................................297.1.4 Filtration group ...........................................................................................................29

7.2 Skimmer .................................................................................................................................307.3 Returnfittingbody ................................................................................................................317.4 Filtration pipework ................................................................................................................31

7.4.1 Installation of the rigid descending modules ..............................................................317.4.2 Assemblingthefilter...................................................................................................337.4.3 Pump/filterandmanifoldmodule ..............................................................................347.4.4 Pipe connections........................................................................................................35

8. PARTS FOR THE AUTOMATIC COVER ........................................................ 368.1 Throughwallflange ..............................................................................................................368.2 Bearing mounting unit..........................................................................................................37

9. IN-POOL LADDER ....................................................................................... 389.1 Assembling the in-pool ladder ............................................................................................389.2 Drilling holes to mount the ladder.......................................................................................38

10. FITTING THE WATERPROOFING MEMBRANE .......................................... 3910.1 Installing the liner locking track ..........................................................................................3910.2 Drilling for the beam mounting unit ....................................................................................3910.3 Applying self-adhesive gaskets ..........................................................................................4010.4 Fitting the underlay...............................................................................................................4010.5 Fitting the liner ......................................................................................................................4010.6 Underwater light cable ties ..................................................................................................4110.7 Filling the pool with water ....................................................................................................4110.8 Installingflangesonplasticpoolfittings ..........................................................................41

10.8.1 Returnfittingflange ....................................................................................................4210.8.2 Throughwallfittingflange ...........................................................................................4210.8.3 Bearingmountingunitflange .....................................................................................4310.8.4 Skimmerflange ..........................................................................................................43

10.9 Installation of the ladder rails ..............................................................................................43

11. ASSEMBLY OF THE AUTOMATIC COVER .................................................. 4411.1 Assembly of the automatic cover axle ...............................................................................44

11.1.1 Installation of the stainless steel shaft .......................................................................4411.1.2 Fitting the axle into the bearing mounting unit ...........................................................4411.1.3 Fitting the automatic cover shaft into the axle............................................................44

11.2 Beamandbeamflanges .......................................................................................................4511.3 Installing the pit wall and the underwater light ..................................................................4611.4 Automatic cover apron and safety fasteners ....................................................................46

11.4.1 Advice prior to installation ..........................................................................................4611.4.2 Assembling the slat cover ..........................................................................................4711.4.3 Locking the slats in position .......................................................................................4711.4.4 Installing the cover apron safety fastener ..................................................................4811.4.5 Securing and releasing the slat cover .......................................................................48

11.5 Water level in the pool for correct operation of the cover ................................................49

4/76 2019/01 - Indice de révision : C - Code : 37321 URBAN POOL BWT myPOOL

12. INSTALLATION OF THE COPING AND FINISHING ELEMENTS ...................... 5012.1 Coping ...................................................................................................................................5012.2 Assembling and installing the duckboarding ....................................................................5112.3 Ladder hand rail ....................................................................................................................5212.4 Wiring .....................................................................................................................................5212.5 Automatic cover motor.........................................................................................................53

12.5.1 Safety advice concerning the motor...........................................................................5312.5.2 Assembly of the automatic cover motor ....................................................................53

12.6 Electrical panel: mounting and wiring ................................................................................5312.6.1 Mounting the electrical panel on the wall ...................................................................5412.6.2 Electrical panel power supply ....................................................................................5412.6.3 Connectingthefiltrationpump ...................................................................................5412.6.4 Connecting the underwater light ................................................................................5412.6.5 Connecting the motor ................................................................................................5412.6.6 Connecting the end of travel sensors ........................................................................5512.6.7 Connecting the key switch .........................................................................................55

12.7 Adjusting the ends of travel and anti-tear ..........................................................................55

13. COVER PIT FOR URBAN POOLS ................................................................. 5713.1 Nomenclature ........................................................................................................................58

13.1.1 Hardware ...................................................................................................................5813.1.2 Wooden elements ......................................................................................................58

13.2 Cover pit exploded view .......................................................................................................5913.3 Assembly ...............................................................................................................................60

13.3.1 Assembling the walls .................................................................................................6013.3.2 Mountingthefinishingtrimontheendsofthewalls ..................................................6113.3.3 Swapping out the pool corner cleat ...........................................................................6113.3.4 Fastening the cover pit to the pool .............................................................................6113.3.5 Fastening the hinges to the cover pit .........................................................................6213.3.6 Duckboarding assembly.............................................................................................6213.3.7 Positioning the coping on the cover pit ......................................................................6213.3.8 Assembling the lock ...................................................................................................63

14. SAFETY ....................................................................................................... 6414.1 Electricalsupplyandfiltrationpumpsafety ......................................................................6414.2 Safety of all users .................................................................................................................6414.3 Safety of children ..................................................................................................................6414.4 Safety cover...........................................................................................................................65

15. WATER TREATMENT .................................................................................. 6615.1 Waterfiltration .......................................................................................................................66

15.1.1 Usingthefiltermutli-portvalve...................................................................................6615.1.2 Commissioningthefilter.............................................................................................6615.1.3 Cleaningthepre-filterandthefilter ............................................................................6615.1.4 Lengthofthefiltrationcycle .......................................................................................67

15.2 Maintaining pool water quality ............................................................................................68

16. MAINTENANCE OF YOUR URBAN POOL ........................................................6916.1 Maintenance of the pool structure ......................................................................................6916.2 Maintenanceofthefiltrationpump .....................................................................................6916.3 Maintenance of the cover .....................................................................................................6916.4 Winterizing the pool ..............................................................................................................70

5/762019/01 - Indice de révision : C - Code : 37321URBAN POOL BWT myPOOL

17. GUARANTEE CONDITIONS ......................................................................... 7117.1 Guarantee covering the wooden components ...................................................................7117.2 Guarantee covering accessories ........................................................................................71

17.2.1 Liner guarantees ........................................................................................................7117.2.2 Guaranteecoveringthesandfiltrationpump .............................................................7217.2.3 GuaranteecoveringABSfittings(skimmer,returnfitting) ..........................................72

17.3 Guarantee covering the automatic cover ...........................................................................7217.3.1 Guarantee covering the automatic cover mechanical assembly ...............................7217.3.2 Guarantee covering the PVC slats of the cover apron ..............................................73

6/76 2019/01 - Indice de révision : C - Code : 37321 URBAN POOL BWT myPOOL

1. PRESENTATIONForyourcomfortandsafety,URBANpoolsarefittedwithasubmergedautomaticcoverthatcomplieswiththeFrenchpoolsafetystandard(NFP90308),anattributeusuallyassociatedwithlarge,topoftherangepools. Housed under the coping the submerged cover keeps the pool water warm and provides discreet protection for your pool.

2. FOREWORDOnceyouhavebuiltyourpool,keep thedocumentation(installation instructions, invoice,etc).Youwillneed these for any future exchanges with our various services.

Greatcarehasgoneintothemanufactureofyourpool,however,someprecautionsarenecessaryforitscorrect assembly and use. We strongly recommend that you read the installation instructions carefully beforebeginningassemblyofthepool,andthatyoukeepthemforfuturereferenceconcerningtheuseand maintenance of the pool.

Intheeventofanyclaim,youwillneedtoquotethepool’strackingnumberthatyouwillfindattheendofthis document.

2.1 StorageIfyoudonotintendtoassembleyourpoolimmediately,donotunpackthecomponents,storetheboxesinasuitable,wellventilated,coolareaprotectedfromthesunandbadweather.Thepurposeistoavoiddeformationofthewoodenelementsthatwouldmakeassemblymoredifficult.

Deformation of the wood could only be caused by storing the wood other than as recommended. If you had tounpackyourpool,youmustrepackandrestrapthepalletofwoodenelements.

Oncethewoodenelementsareunpacked,proceedwithassemblywithinthenext24to48hours.Whilestoringtheboxes,werecommendthatyouremovethefilmandinsertwoodenwedgesbetweeneachlayerof wood to facilitate the circulation of air.

2.2 An above-ground kitThekitdeliveredisforanabove-groundinstallation.Ifthepoolistobeinstalledin-ground(orpartiallyin-ground)someextraworkandmaterialswillberequired:

• acquiretheURBANpoolwoodenplanthousing;• carryoutthenecessaryexcavationwork;• createadrainandareliefwelladaptedtotheterrainaroundtheperipheryoftheconcreteslab;• coverthein-groundsectionsofwallwithafoundationmembrane;• backfillbehindthewallswith10/20rolledgravel.

The necessary supplies are not included in the kit.

2.3 SafetyYourelectricalinstallationmustcomplywiththestandardineffectinthecountryofinstallation(C15-100inFrance).Notably,theelectricalsupplyofthepumpshouldbeprotectedbya30mAresidualcurrentdevice.Do not hesitate to have this work carried out by a professional to ensure the compliance of your installation.

Thekitprovidedwillallowinstallationofthefiltrationsystem3.5mfromthepoolinaccordancewiththeFrenchsafetystandardNFC15-100.

Subject to the condition that the cover is mounted according to the installation instructions provided in this document,thesafetycoverequippingyourUrbanpoolwillsecureaccesstothepoolinaccordancewiththeFrenchsafetystandardNFP90308(December2013).

7/762019/01 - Indice de révision : C - Code : 37321URBAN POOL BWT myPOOL

Children should only use the pool under the supervision of an adult. This pool is intended for private use only.

Installationofthepoolbeneathtreesisnotadvised,installationbeneathelectricalwiresisstrictlyprohibited.

2.4 Assembly2.4.1 Assembly steps• excavation• assemble the supporting braces• pour the concrete slab• assemble the wooden structure• installthefiltrationsystemandpoolfittings• assemble the vertical section of the ladder• laythewaterproofingmembrane• assemble the automatic cover• installthecopingandfinishingtrim• wiring

2.4.2 ToolsExcludingthematerialsrequiredforexcavationandpouringtheconcreteslab,werecommendthatyouhave the following equipment on hand:

• measuringtools:decameter,rope,bigspiritlevel• mallet• drillanddrillbits,flatheadscrewdiver,crossheadscrewdriver,drillbitdiameter10mm• cuttingtools:Stanleyknife,metalsaw,holesawdiameter60mm• tubeorsocketwrench(13and17mm),setofAllenkeys• finishingtools:sandpaper,limefine• toolsforglueingpipework:mediumsandpaper,PVCstripper

2.4.3 Assembly timeExcavation and earthworks: 2 DAYS DEPENDING ON THE MATERIALS USED

Supporting braces: ½ DAY (WITH 2 PEOPLE)

Pouring the slab: ½ DAY (WITH TWO PEOPLE) DEPENDING ON THE MATERIALS USED

Wooden structure and cover: 2 DAYS (WITH TWO PEOPLE - THE TIME INDICATED DOES NOT INCLUDE THE CONCRETE CURING TIME)

Curing of the concrete slab: 21 DAYS (3 WEEKS)

8/76 2019/01 - Indice de révision : C - Code : 37321 URBAN POOL BWT myPOOL

3. NOMENCLATURE

3.1 Wood and coping packQTY DESCRIPTION FIGURE REF DIMENSIONS (MM) TYPE

4 Wall slat Figure 7 n°1 1700 × 78 × 45 Male60 Wall slat Figure 7 2 1700 × 145 × 45 Male/female

2 Wall slat Figure 7 3 1700 × 145 × 45 Male/female,machinedtoreceivethereturnfitting

2 Wall slat Figure 7 4 1700 × 145 × 45 Male/female,machinedtoreceivethethroughwallflange

2 Wall slat Figure 7 5 1700 × 145 × 45 Male/female,machinedtoreceivethethroughwallflange

2 Wall slat Figure 7 n°16 1700 × 145 × 45 Male/female,machinedtoreceive the skimmer

1 Wall slat Figure 7 n°6 523 × 137 × 45 Left female for skimmer1 Wall slat Figure 7 n°8 691 × 137 × 45 Left female for skimmer1 Wall slat Figure 7 n°7 523 × 137 × 45 Right female for skimmer1 Wall slat Figure 7 n°9 691 × 137 × 45 Right female for skimmer

36 Wall slat Figure 7 n°10 1570 × 145 × 45 Male/female1 Wall slat Figure 7 n°11 1700 × 137 × 45 Female left1 Wall slat Figure 7 n°12 1700 × 137 × 45 Female right4 Wall slat Figure 7 n°13 1570 × 70 × 45 Female2 Wall slat Figure 7 n°14 1700 × 70 × 45 Female left2 Wall slat Figure 7 n°15 1700 × 70 × 45 Female right

16 Trim Figure 7 - 1290 × 137 × 45 For supporting braces14 Coping bracket Figure 7 - 180 × 150 × 45 For coping1 Ladder rail Figure 7 - 1330 × 95 × 35 For steps4 Ladder tread Figure 7 - 600 × 145 × 27 For steps8 Coping Figure 7 - 1295 × 70 × 45 Tofinishthecorners2 Coping Figure 50 n°1 1570 × 145 × 28 Interior left2 Coping Figure 50 n°2 1570 × 145 × 28 Interior right4 Coping Figure 50 n°3 1716 × 145 × 28 Exterior left4 Coping Figure 50 n°4 1716 × 145 × 28 Exterior right1 Coping Figure 50 n°5 1621 × 145 × 28 Interior left1 Coping Figure 50 n°6 1621 × 145 × 28 Interior right8 Coping Figure 50 n°7 1500 × 145 × 28 Interior and exterior2 Mitered cleat Figure 50 n°8 206 × 70 × 28 Corner2 Mitered cleat Figure 50 n°9 412 × 70 × 28 Corner

10 Straight cleat Figure 51 - 585 × 70 × 28 For duckboarding20 Duckboarding Figure 51 - 600 × 145 × 28 -2 Wall slat - ≈290×145×45 For martyr block

3.2 Accessories pack

3.2.1 Screws for the pool structureQTY DESCRIPTION KIT PURPOSE

3 Torxsafetyscrew6×30, A2 SS Y Fasten the elastic strap underneath the duckboarding

4 HexscrewM8×120,A2SS,DIN931 Y Fasten the beam and counter plate to the polyamide blocks

from outside the pool

4 Screw,M8×70DIN603A4(roundhead,squareneck) Y Fasten the beam and counter plate from inside the pool

4 Countersunk screws, 4.2×19,A4SS,DIN7982 Y Fastenthepolyamideblockstothepitwallflanges

9/762019/01 - Indice de révision : C - Code : 37321URBAN POOL BWT myPOOL

7 Stove screws, M8 × 16, A4 SS torx Y

Fasten the elasticstrapatthebottomofthepitwallmodules(x3)Fastenthepitwalltothebeammountingplate(×4)

8 Hexscrews,M8×20,A4SS, Y Assembly of the pit wall modules

23 NutM8,A4SS Y

Fasten the pit wallbracketstothebeammountingplates(4nuts&4washers)Fasten the beamandcounterplatefrominsidethepool(4 nuts & 4 washers)Assemblyofthepitwallmodules(16 nuts & 16 washers)Fastenstrapstothepitwall(3 nuts & 3 washers)Fastenthepitwalltothebeammountingplate(4 nuts & 8 washers)

35 WasherM8,A4SS Y

Fasten the pit wallbracketstothebeammountingplates(4nuts&4washers)Fasten the beamandcounterplatefrominsidethepool(4 nuts & 4 washers)Assemblyofthepitwallmodules(16 nuts & 16 washers)Fastenstrapstothepitwall(3 nuts & 3 washers)Fastenthepitwalltothebeammountingplate(4 nuts & 8 washers)

56 Nut,M10,zincplatedsteel A Fasten the 3 jacks to each of the four supporting braces8 Nut,M8,A4SS,DIN934 B

Fasten the ladder hand rail to the coping8 Washer M8 SS A4 B

8 Mushroom head screw,M8x50,A2SS B

160Countersunk screw, 5 ×40A4SS, torx, threadedover 25 mm

C Lock the slats together at the supporting braces

80 Torxsafetyscrew6×30, A2 SS D Fasten the wall slats to the supporting braces from outside

the pool

416 Torxsafetyscrew6×20, A2 SS G Fasten the coping modules to the coping brackets

100Countersunkscrew,4×35A4 SS, torx, threadedover 20 mm

H Mount the Hung track under the coping

24 Domedheadnail,2.8×60, A2 SS I Fastenthefinishingtrimtothewalls(3nailsperprofile)

16Countersunk screw 5 × 60 zincplatedtorxthreadedover 35 mm

K Assembly of the wooden steps: fasten the 4 treads to the 2 rails

4 Countersunk screw 4 × 25 zincplatedtorx K Mount the warning panel

28Countersunkscrew5×100,A4 SS, torx, threaded over 60 mm

L Mount the wooden coping brackets on the walls (2×14consoles)

48Countersunk screw 5 × 80,A4 SS, torx, threaded over50 mm

L Fasten the trim over the supporting braces

10/76 2019/01 - Indice de révision : C - Code : 37321 URBAN POOL BWT myPOOL

56Countersunk screw 5 × 40,A4SS,torx,threadedover 25 mm

M Fasten the metallic plates to the wooden coping brackets (4x14)

16 HheadscrewM8x25zincplated steel M Mount the skimmer bracket

16 M8nutzincplatedsteel XMount the upper connecting plates

16 Countersunk screw 5.5x25 SS A4 torx X

80Countersunk screw 5 × 40 SS A4 torx threaded over 25 mm

Z Assemblyoftheduckboarding(4x13duckboarding)

1 Torx bits J T20;T25;T301 Wood drill bits 4 × 75 mm J Pre-drillthelinerlockingrail(hung)

3.2.2 Pool structure metalwork QTY DESCRIPTION

1 Steel mounting elements kit:

Copingmodulefittings(×12right,×12left)Cornercopingmodulefittings(×4)Jacksforthesupportingbraces(×12back,×8front)

1 Metalwork kit:

Beammountingunitcounterplate(×2)Handrailbracket(×1right,×1left)Skimmerblockingbracket(×2)Pitwallbracket(×2)Pitwallflange(×2)

14 Metallicplates to fasten thecopingmodules(only14of the17plateswillbeused)

8 Steel support braces

3.2.3 IntegratedcartridgefiltrationsystemQTY DESCRIPTION

1 Filtration pump and unions

2 skimmer suction modulesSuction manifold 2 inlets FiltrationpumpP-AP8m3/h,1phPump baseSandfilterP-FS500EHFilter baseThree 25kg of sandIsolationmoduleforP-FSfilterYmoduleforreturnfittings2returnfittingmodules21 m of grey pipes D45

1 Packofpoolfittings2completeskimmers(body,flangeandtrim,seals,setofscrews,weir)2completereturnfittings(body,flange,eyeballandtrim,seals,setofscrews)

11/762019/01 - Indice de révision : C - Code : 37321URBAN POOL BWT myPOOL

3.2.4 Accessories QTY DESCRIPTION

1 Installation instructions1 Warning panel to mount on the pool wall1 Bitumous strips to provide insulation between the pool walls and the concrete slab2 Roll of black plasticised PVC to protect the liner against screw heads1 Underlay1 Grey liner16 1.18 m length of PVC liner locking track 2 SS hand rails

3.3 Automatic cover pack3.3.1 Mechanical assembly and automatic cover slat apronQTY DESCRIPTION

1 Anodisedaluminiumaxle,Ø150,length2790mm,withtwostands,abearingandthreesupportsto attach the slat apron

1 SSmotorshaft,309mm,forthethroughwallflangewithplasticlockingpinandscrew1 Throughwallflange(body,gaskets,flangeandscrews)1 Bearing(body,gaskets,flangeandscrews)

1 Automaticcoverapron(49slats)fittedwiththreeconnectionstrapsontheaxlesideandtwosafetyfastening straps

2 Automatic cover safety fastener

1 Electrical panelwith control pad for theautomatic cover, key switch, filtration timer andwaterslinger(o-ring)fortheSSmotorshaft,309mm,insertedinthethroughwallflange

1 Urbanpoolreductiongearedmotorwithpins(pinforSSshaftandUshapedpin)

1 Lacqueredaluminiumbeam60x87x1988mmwithgaskets (4washersand4plates)and2polyamide blocks

3 Pit wall module1 LED underwater light3 Black elastic strap to hold the automatic cover apron

3.3.2 Ladder railsQTY DESCRIPTION

2 Aluminiumrails,Ø40,andballjoints3 ABS treads with aluminium screws2 Support,shellandadhesivegasketswithSSscrews2 Bumpers to protect the liner

12/76 2019/01 - Indice de révision : C - Code : 37321 URBAN POOL BWT myPOOL

4. WOOD, A NATURAL MATERIALBeinganaturalmaterial,woodwillhavesomeimperfections.Thesearenormalandhavenoimpactontheservice life of the product.

Acertainnumberaresuperficialanddonotfallwithinthescopeoftheguarantees.

4.1 Colour variationsColour variations are common to every species of wood. Treatment brings them out because the depth of penetration of the product depends on the wood density and grain. Weathering of wood outdoors will significantly attenuate these colourvariations.

4.2 Resin beadsWhen resinouswood species are autoclaved, the alternatingpressure and vacuum can cause sticky residue to rise to the surface. To remove it, scrape it carefully with an appropriatetool, being careful not to touch the wood. Turpentine spiritscouldalsobeeffective,butcouldstainthewoodiftoomuchisapplied.

4.3 Salt stainsSmall green stains are frequently found on the surface of autoclaved wood. These can be removed with light sanding. If leftuntreated,thiscolourwilldisappearovertime.

4.4 GreyingWood exposed to the sun and the moon is susceptible to greying. Some of the wood could already be greyed due to the storage conditions of the various elements of the structure.

This is a natural phenomenon that has no impact on the structural integrity of the product. The colour of the whole structure will even out after a few months of exposure..

13/762019/01 - Indice de révision : C - Code : 37321URBAN POOL BWT myPOOL

4.5 Splitting and crackingWood expands and contracts when exposed to variations in humidityandtemperature.Asitdries,woodcontractsunevenlyresulting in the appearance of cracks. While these can seem to becauseforconcern,theyhavenoimpactonthemechanicalproperties of the product and therefore do not fall within the scope of the guarantee.

4.6 KnotsKnots mark the places where branches were attached. The quantity and size depends on the species of wood and thesortingprocess.Foroutdoorinstallations,smalladherentknotsare acceptable.

4.7 Surface mould

.

Mould, caused by microscopic fungi, can grow on wood,particularly on resinous species, on which the growth canappearas“blueing”.Itisasurfacephenomenon,exacerbatedbyheat,humidityandinadequateaerationandischaracterisedby stains ranging from light to dark blue. They can be removed by wiping the surface.

Remember that class IV treated wood is protected against attack by fungi that could destroy the physical and mechanical properties of the wood

4.8 Joined woodToensure the highest quality in the selection of ourwood, itis sorted meticulously before planing. Sections that features defects on both sides are removed and the wood is then joined together(seeimage).

This is no way penalises the mechanical properties of the wood.

4.9 Curved woodDuetotheconstantpressureexertedbythewater,thewallsofthepoolmaycurveslightlyovertime.

Thisphenomenon,attributabletothenaturalelasticityofwood,willstabiliseofitsownaccordandinnoway would lead to failure of the wooden slats.

Itisnotadefect,andwouldnotconstitutegroundsforaguaranteeclaim.

14/76 2019/01 - Indice de révision : C - Code : 37321 URBAN POOL BWT myPOOL

5. EARTHWORKS

5.1 IntroductionAfterdeterminingtheidealpositionforyourpool(preferably,orientthepoolsothatskimmersfaceintodominantwinds),startwiththeexcavationrequiredtoaccommodatetheconcreteslabthatwillsealinthesupport braces and form the base of your pool. Seek the assistance of a professional if required.

Neverbackfillunderthepooltoachievealevelsurface,thelayerofstonebeddingandtheslabmustbeseated on stable ground.

Inthissectiononearthworks,informationprovidedtakesintoaccounttheplanthousingandthedrainagesystemrequiredforanin-groundorpartiallyin-groundinstallation.Foranabove-groundinstallation,theplant housing and drainage systemare not required.The excavation and the slabwill be rectangles, 7190 mm long and 4190 mm wide.

5.2 Creating the excavation5.2.1 Material quantitiesThe quantities of materials required are shown in the table below

Estimated volume of stone bedding 3,7m3 20/40 gravelGeotextilesurfacearea(poolfloor) 31,6m² nonwoven feltPolyane surface area 31,6m² polyethylene sheetTheoreticallengthoftheØ80mmdrain 31,6m PVCRebar 34 m ST25C rebarSlab,15cmthick 5,2m3 C25/30 concreteProtectivemembraneforin-groundwalls(rolls1.5mhigh) 33 ml polyethyleneBackfill 20 m3 10/20 rolled gravel

5.2.2 ExcavationDigoutanarea,thelengthandthewidthofwhichshouldcorrespondtothelengthandwidthoftheinnerwallsofthepoolincreasedby0.55maroundtheentireperipheryofthepool,thatis,7.14.1mforapoolwithout a plant housing.

For an above-ground installation, so that the slab is flush with the ground, excavate to a depth of0.26 m. For partially in-ground installations, the depth of the hole is determined by the installer.Forexample, tosink thepool1m into theground (leaving33cmaboveground), theholeshouldbe 1.26 cm deep.

Toinstallthepoolfullyin-ground(bottomofthecopingflushwiththeground),theholeshouldbe1.56mdeep.

Takecare,thismeasurementmybegreaterifthemoisturecontentofthewoodishighwhenthepoolisinstalled(woodstoredinahumidorpoorlyventilatedarea).

5.2.3 DrainageInthecaseofanin-groundinstallation,createadrainaroundtheentireouterperipheryofthepool.Thedrain,whichshouldhaveadiameterof80cm,shouldbeconnectedtoareliefwelllocatedinoneofthecornersontheoutsideedgeoftheexcavation.Thereliefwellshouldbe0.5mdeeperthantheflooroftheexcavation and should have a diameter of at least 0.3 m to accommodate a lift pump.

15/762019/01 - Indice de révision : C - Code : 37321URBAN POOL BWT myPOOL

peripheralØ80drain

peripheral drain

Root barrier or felt

Wooden frame

Drainage gravel

Geotextile feltStone beddingWaterproofingfilm

Concrete slabMin depth 150 mm

Undisturbed earth

Relief well, 500 mm deeper than the floor of the excavation (outlet of the peripheral Ø80 drain)

Figure 1 – Drainage system installation diagram

16/76 2019/01 - Indice de révision : C - Code : 37321 URBAN POOL BWT myPOOL

5.2.4 Stone beddingLeveltheflooroftheexcavationasmuchaspossible,andthenrolloutthegeotextiletocovertheentirefloor.Using 20/40 mm gravel lay hardcore to a depth of 110 mm around the entire periphery of the excavation. Correcttampingofthegravelwillensureaneatfinishoftheexcavationfloor,andfacilitateinstallationofthe supporting braces.

Remove the gravel at the positions shown in Figure 2 in order to create four 500 × 650 mm recess 90mmdeep(asmeasuredfromthesurfaceofthestonebedding).Therecesseswillaccommodatethesteelbraces,onceimprisonedintheconcrete,thesebraceswillsupportthepoolstructure.

Recesses Contour of the excavation

Figure 2 – Positions of the recesses created to accommodate the supporting braces

5.3 Installing the supporting bracesThe reinforcing metallic structure is comprised of metal posts joined together at the top and the bottom with flatbars(Figure 3).NotehowthepartsoverlaptoallowcorrectpositioningofthestructureTheflatbarsatthe top will be removed once the concrete slab has been poured.

17/762019/01 - Indice de révision : C - Code : 37321URBAN POOL BWT myPOOL

a)Dependingontheversion,theflat barsaredelivered in twosections to be bolted together

b)Figure 3 – a and b – Assembling the flat bars on the support braces

Install the supporting braces in each of the eight locations, having first fitted the recesseswith jacks(Figure 3 and Figure 4).Use8doubleactingjacks,12singleactingjacksand56screwswithadiameterof10mm(bagA).Thetopscrewsshouldbeinsertedaftertheheightofthebottomscrewshasbeenadjusted.

Thesepostsarejoinedtogetheratthebottomwith12flatbars(B)1.6mlongboltedtogetherat2points.Thedistancebetweeneachpost isdeterminedby theseflatbars: itshouldbe1.5m.Theyare joinedtogetheratthetopby4flatbars(B)1.6mlong(identicaltotheflatbarsatthebottomofthestructure)and4flatbars(C)thatare2.253mlonginthecorners(screwinbagA,seeFigure 5).

Ateachendoftheflatbarstherearefourholes.Atthebottom,theouterholes(Figure 5)shouldbeusedtofixtheminposition,whiletheinnerholesshouldbeusedatthetopofthestructure(Figure 3).

18/76 2019/01 - Indice de révision : C - Code : 37321 URBAN POOL BWT myPOOL

Adjusted using jacks Topofthepoolwall(underthecoping)

Figure 4 – Position of the support braces and top and bottom connecting bars

19/762019/01 - Indice de révision : C - Code : 37321URBAN POOL BWT myPOOL

Figure 5 – Installation of the jacks under the supporting braces

The supporting bracesmust under no circumstances extend above the top of the poolwall (justbeneaththecoping)afteradjustmentofthesupportingbracejacks.Onthecontrary,itisnotproblematicif the top of the supporting braces are 1 or 2 cm below the top of the pool wall.

Afterassembly,adjustthesupportingbracesandcheckcarefullythattheyarecorrectlypositioned:plumb,level,correctalignmentofthesupportingbraces.Toensurethatthesupportingbracesstayinplaceafteradjustment,youcanpre-sealthemwithasmallamountofconcrete.

TIP:Youcanusethesupportingbracestovisualisehowhightheconcreteslabshouldbeonceithasbeenpoured.Todothis,takingthetopofthepoolwall,belowthecoping,aslevel0measure1.303mand mark this distance on the front of the supporting brace. This mark will correspond to the height of the finishedconcreteslab.

The height of the pool under the coping may be over 1.303 m if the moisture content of the wood is highatthetimeofinstallationofthepool(woodstoredinahumidorpoorlyventilatedarea).

Takeparticularcarewhilecarryingouttheseassemblysteps,theywilldeterminethequalityofthepool finish. Incorrect positioning of the supporting bracesmay render assembly of the poolwallsimpossible.

Check that all the dimensions quoted in Figure 4 are correct before proceeding with the next step.

5.4 Pouring the concrete slab5.4.1 RebarBeforepouringtheconcrete,laythetoplayerofweldedrebarmesh(typeST25C)overtheflooroftheexcavation(themeshshouldbesetback3to5cmfromtheedgearoundtheentireperiphery).Somecutting around the supporting braces will be necessary. The mesh should overlap by one and a half squares and should be connected together using metal ties. The mesh should be raised using spacers to ensurethatwillsitinthecentreoftheslab.Ifyouareusingself-levellingconcrete,youshouldplacealayerofpolyethylenesheetingundertherebarmeshbecausetheconcreteisveryliquidandcouldflowintothespaces between the gravel. Use C25/30 grade concrete as a minimum.

20/76 2019/01 - Indice de révision : C - Code : 37321 URBAN POOL BWT myPOOL

5.4.2 Slab dimensionsThe characteristics of the concrete slab are provided in Figure 6. The dimensions of the slab are such the feetofthewoodenpoolaccessladderwillnotrestontheslab.However,werecommendthatthefeetoftheladderrestonasolidsurface(cementblocksorslabforexample).

Supporting brace

Concrete slab

Stone bedding

Figure 6 – Characteristics of the concrete slab

Whilepouringtheslabovertheflooroftheexcavation,makesurethattheupperrebarmeshisproperlyencased in the concrete: the layer of concrete above the mesh must be at least 3 cm thick.

Refer to Figure 6 todeterminethedepthoftheslabtobepoured:itshouldbe150mmthick,andofaheight to ensure that the distance between the surface of the slab and the top of the excavation is 1303 mm if the pool is to be installed in-ground.

Level and smooth the slab carefully to void surface defects that will have to be corrected later.

The slab provides seating for the wooden structure. Any levelling defects will become apparent when thepool isfilledwithwater.Similarly,significantsurfacedefectswilldetract fromthequalityof thefinishofthepoolfloor.

21/762019/01 - Indice de révision : C - Code : 37321URBAN POOL BWT myPOOL

6. ASSEMBLING THE WOODEN STRUCTURE

6.1 IntroductionYoumaybeginassemblyof thepoolwalls2 to3daysafter theslab ispouredwithoutwaiting for theconcretetocurecompletely.However,youmustwaitatleast3weeksfortheconcretetocurebeforefillingthe pool with water.

Beforestartingtoassemblethewoodenwalls,makesurethattheslabisfreefromanydefectsandthatitisperfectlylevel.Thefinishoftheconcreteslabwilldeterminethecorrectseatingofthewalls,thequalityofthepoolfloorandthefinishofthepool.Aleveldefectwillbeaccentuatedandvisiblewhenteepoolisfilledwithwater.Itcouldalsomakeitimpossibletoassemblethepoolwalls.Ifnecessary,correctdefectsby sanding or resurfacing the slab.

Yourpooliscomprisedofseveralslatreferences,thepositionsoftheslatsareillustratedonvariousdiagrams(Figure 7).Therearespecificslatstohousethepoolfittings(skimmer,returnfitting,beammountingunitandthroughwallflangerequiredtomounttheautomaticcoveraxle).Assemblyofthisstructureisdescribedstep by step in this section.

22/76 2019/01 - Indice de révision : C - Code : 37321 URBAN POOL BWT myPOOL

NUMBER QUANTITY DIMENSIONS (MM)

TYPE SPECIFIC

1 4 1700 x 78 x 45 male slat2 60 1700 x 145 x 45 male/ female slat3 2 1700 x 145 x 45 male/ female slat returnfitting4 2 1700 x 145 x 45 male/ female slat throughwallflange5 2 1700 x 145 x 45 male/ female slat throughwallflange6 1 523 x 145 x 45 male/ female slat left skimmer7 1 523 x 145 x 45 male/ female slat right skimmer8 1 691 x 145 x 45 male/ female slat left skimmer9 1 691 x 145 x 45 male/ female slat right skimmer10 36 1570 x 145 x 45 male/ female slat11 1 1700 x 137 x 45 female slat left12 1 1700 x 137 x 45 female slat right13 4 1570 x 70 x 45 female slat14 2 1700 x 70 x 45 female slat left15 2 1700 x 70 x 45 female slat right16 2 1700 x 145 x 45 male/ female slat skimmer

Figure 7 – Exploded view of the wooden structure

23/762019/01 - Indice de révision : C - Code : 37321URBAN POOL BWT myPOOL

6.2 Application of the bituminous stripsStartbyunrollingthebituminousstripthatwillinsulatethewoodenstructurefromtheconcreteslab(Figure 8

Figure 8 – Laying the bituminous strips

6.3 Assembling the slats Layoutthe½slatsthatconstitutethepoolwidths,then,inthecorners,slotintheslatsthatconstitutethepoollengths.Afterlayingoutthefirstrowofslats,makesurethatthediagonalsareequal.Fittheslatstogether,accordingtotheassemblydiagramshowninFigure 9 and taking care to position the machinedslatscorrectly(seeFigure 7).Thetonguesshouldalwaysbeorientedupwards,andthegroovesdownwards.

female half-slat(70x45)

female slat(137x45)

male/ female slat(145x45)

female half-slat(78x45)

Figure 9 – Slotting together the wooden slats

Whileassemblingthepoolwalls,makesureasofthefirstrowsthattheslatsarefullyengagedinthegrooves.

Afterassemblingthefirstrow,checkthattheslatsareperfectlylevel,screwtogethertheslatsconstitutingthe pool lengths:

• referring to Figure 10, screw the slats together using 2 screws per pair of slats in each of the10rows,thatis,160countersunkscrews5×40A4SStorxthreadedover25mm(bagC);

• fix themto the8supportingbraces(thesearepre-drilledasshown inFigure 11)using72 torxsafetyscrews6×30A2SS(bagD).

24/76 2019/01 - Indice de révision : C - Code : 37321 URBAN POOL BWT myPOOL

Figure 10 – Screwing the slats together

Figure 11 – Fastening the slats to the supporting braces

Forcorrectassembly,itmaybenecessarytouseamalletandclamptoremedylightslatdeformationscausedbystorage.Donotstrikethewoodenslatsdirectly,usetheprotectivemartyrblocks.

Theheadsofscrewsinsertedfromtheinsideofthepoolshouldbeflushwiththepoolwalltoavoiddamaging the liner.

The height under the coping of the assembled pool will only be 1.303 m if the moisture content of the woodisnormalandtheslatsareproperlyfittedtogether.

Remove any splinters raised by the screws as you go.

25/762019/01 - Indice de révision : C - Code : 37321URBAN POOL BWT myPOOL

6.4 Mounting the finishing trim on the supporting bracesPut thesupportingbracefinishing trims inposition.Theyshouldbeflushwith the topof thepoolwall.Working from the insideof thepool, insert screwsasshown inFigure 12 using 3 countersunk screws 5×80A4SStorx,threadedover50mm(bagL)perhalftrim,thatisatotalof48screws.The2halftrimsdonotmeet,themetallicbracewillremainvisible.

Shoulditbenecessarytoresizethetrims(forexample,ifthepoolisinstalledpartiallyin-ground)orientthecut surface upwards so that the cut side is not in contact with the ground.

Figure 12 – Mounting the supporting brace finishing trim

6.5 Mounting the coping bracketsFastenametallicmountingplate to eachof the14woodenbrackets using4 countersunk zincplatedscrews5x40,torx,threadedover25mm(bagM),thatisatotalof56screws,asshowninFigure 13: the edge of the width of the metal plate should be aligned with the vertical surface of the bracket that is in contact with the pool wall.

Referring to the diagram provided in Figure 14 fasten the wooden brackets, furnished with metallicmountingplates,tothepoolwallusingtwoscrewsperbracket,thatisatotalof28countersunkscrews, 5x100A2SS,torx,threadedover60mm(bagL).Themetallicmountingplatesshouldbefacingupwards.

Inanycase,themetallicmountingplatesshouldbeflushwiththetopofthepoolwall.Checkthattheplatesare level to allow subsequent mounting of the coping.

Figure 13 – Fastening metallic plates to the wooden brackets

26/76 2019/01 - Indice de révision : C - Code : 37321 URBAN POOL BWT myPOOL

Figure 14 – Coping mounting bracket positions

6.6 Assembling the wooden access ladderAssemble the ladder according to Figure 15using16zincplatedcountersunkscrews5×60,torx,threadedover35mm(bagK),andfastenthehandrailbracketstotherightandlefthandsideoftheladderusing 8SStorxsafetyscrews,6x20(bagG).

Next,with8safetyscrews6x20,A2SS(bagG),usetheleft-andright-handhandrailbracketstofastenthe ladder to the pool wall as shown in Figure 16.

Figure 15 – Assembling the wooden access ladder Figure 16 – Fastening the access ladder to the pool wall

Foryouowncomfort,werecommendthatyoumounttheladderonthewalloppositetheskimmer.Inanycase,donotlocatetheladderwithinthethirdofthepoolthatcontainstheautomaticcoveraxle.

The ladder must be located at least 30 cm from the corners of pool. Remember that wooden access ladder and in-pool ladder should face each other.

27/762019/01 - Indice de révision : C - Code : 37321URBAN POOL BWT myPOOL

6.7 Mounting the metal fittingsThemetalfittingsareintendedtosupportthecopingandallowthemtobefixedinposition.Makesurethattheyarecorrectlypositioned.Theyshouldbeflushwiththetopofthepoolwallandalignedwitheachotherand the coping bracket plates.

• Ontopofeachofthe8metallicsupportingbracesandthetwowoodensupportingbraces,placea‘right-hand’fittinganda‘left-hand’fittingfromthe‘Fasteningelements’kitasshowninFigure 17. Use 6 safetyscrews6×20inA2SS(bagG)perfitting,thatisatotalof96screws.

• Ineachofthecorners,mountaright-handfitting,aleft-handandacornerfittingasshowninFigure 18.Use4safetyscrews6×20,A2SS(bagG)percornerfitting6safetyscrews6×20inA2SS(bagG)perfitting,thatisatotalof64screws.

Figure 17 – Mounting the fittings on top of the supporting brace Figure 18 – Mounting the fitting in the corners

6.8 End grain sealerUsingabrush,painttheendsoftheslatsineachcornerwithanendgrainsealertolimitdeformationovertime.

Thisproductiswhiteonapplication,butbecomescolourlesswhendry.Dryingtimeis2to3hours.Ifthetemperatureishighorthedryingtimeistoofast,applyasecondcoat.Followthesafetyinstructionsonthecontainer. Rinse the brush after use.

6.9 Finishing trimUse3domedheadnails,2.8x60A2SS(bagl)tofastenthewoodenfinishingtrimtotheedgeofeachwall.Thenailsshouldbeevenlyspacedandthefinishingtrimshouldbepre-drilledusingadrillbitwithadiameterof4mm.(Figure 19).

Apply an adhesive strip (roll provided) to thevertical joins on the inner walls of the pool taking care to ensure that the screw heads are covered (Figure 20).Thiswillprotectthelinerfromthescrewheads that could damage it.

Figure 19 – Wooden trim Figure 20 – Protective adhesive strip

28/76 2019/01 - Indice de révision : C - Code : 37321 URBAN POOL BWT myPOOL

7. INSTALLATION OF THE FILTRATION SYSTEM

Thepump’selectricalsupplymustbeprotectedbya30mAupstreamfromtheinstallation.

Thefiltrationsystemassuppliedinthekit,alongwithallotherelectricaldevices,shouldbewiredininaccordance with the standards in effect in the country of installation.

Do not hesitate to seek the assistance of a professional to ensure the compliance of your installation.

Thefiltershouldbeinstalledataheightbelowthewaterlevel.Ataheightabovethewaterlevel,thereis a risk of deformation due to de-pressurisation. The maximum acceptable height is the level of the coping.Ifthefilterisinstalledabovethewaterlevel,acheckvalvemustbemountedonthereturnfittingsandaneasilyaccessiblecheck-valveshouldalsobeinstalledonthesuctionline(theseitemsareavailablefrompoolsuppliers).

Figure 21 – Proposed position of the filtration group

Theinstallationdescribedisasampleinstallation,thekitprovidedallowsforinstallationofthefiltrationgroup at a distance of 3.5 m from the pool in accordance with standards in effect. It may be necessary toadjustthepipelengthsdependingontheconfigurationoftheinstallationsite,thetypeofinstallation(above-ground,partiallyin-ground,in-ground),thetypeofplanthousingandotherrestrictionsimposedby the installation.

Refertotheinstructionsformountingthesandfilterprovidedbelow,andthepump’soperatinginstructions.Notethesketchofthefiltrationsystemthatshowsallthevariouscomponentsandconnection information.

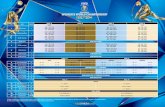

DESCRIPTION

FLOWRATE, NO DIRECTIONAL JET ON THE

RETURN FITTINGS

FILTER DIAMETER SAND FILTRATION SURFACE AREA

VOLUME FILTERED

IN 24 HOURS

URBAINE6.5× 3.5 6 m3/h 500 mm 3 × 25 kg 0;2m² 232.8 m3

29/762019/01 - Indice de révision : C - Code : 37321URBAN POOL BWT myPOOL

7.1 Filtration group componentsThevariouscomponentsofthefiltrationgrouparelistedbelow.

7.1.1 Rigid module

REF DescriptionA Suctionmodule(rigiddescent)B Union under the skimmerC Returnmodule(rigiddescent)D "Y"moduleforreturnfittings

7.1.2 ReturnfittingREF DescriptionO1 BodyO2 SealO3 FlangeO4 Directional jet

7.1.3 SkimmerREF DescriptionI1 LidI2 BasketI3 Flange sealI4 Screw 5.5 x 25I5 FlangeI6 WeirI7 Flange trimI8 Lid housingI9 Blanking capI10 Crush resistant pipeI11 Body

7.1.4 Filtration groupREF DescriptionE Pipe 45mmF Suctionisolationmodule(manifold)G PumpH Filter tankI Filter baseJ Pump baseK Returnisolationmodule(valve)L Hosetail(waste)

30/76 2019/01 - Indice de révision : C - Code : 37321 URBAN POOL BWT myPOOL

7.2 SkimmerWhenmountingtheABSfittings,donotover-tighten,thiscouldfracturetheparts.Tightenthescrewsbyhand. Make sure that seals have been correctly positioned and correctly applied. Once the liner has been fitted,itwillbedifficulttocorrectaforgottenstepormistake.

Figure 22 – Assembly of the skimmer

First,mounttheprefixflangeontheskimmerusingthecountersunkwoodscrews3×25(thesecomponentscanbefoundinthepoolfittingsskinpack).

Mountthegreytube,externaldiameter63mmontheskimmerbody(Figura 23).Pushitinfully,butdonotuseglue.Thistubewillwedgetheskimmer,holdingitinitsverticalpositionagainstthewoodenwall.

Puttheskimmerinposition,makingsureitisproperlymatedagainsttheprefixflange.Fastenitinpositionusingthecountersunkscrews5×16,andtheassociatedwashersandnuts.

Figure 23 – Mounting the skimmer bracket

Gluethefirstself-adhesivegasket(poolfittingskinpack) inposition,makingsurethat theholes intheskimmer and the gasket are correctly aligned.

As shown in Figure 23fitthemetallicbracketovereachskimmertoblockitinposition.Fastenthebracketstothewallusing16countersunkscrews5.5×25SSA4(bagM).

31/762019/01 - Indice de révision : C - Code : 37321URBAN POOL BWT myPOOL

Gluetheskimmersealstothefrontface,takingcaretoensurethattheholesintheskimmerandgasketarecorrectlyaligned.Thelinermustbefittedwithinthenext48hours((Paragraphe10.5,page40)). Ifthisisnotpossible,delaymountingthegasketuntiljustbeforethewaterproofingmembranewillbefitted.Therestofthepart(gasketandflange)willbeaddedafterthelinerhasbeenfittedtoensurealeaktightfinisharoundtheskimmer.

7.3 Return fitting bodyWorkingfrominsidethepool,pushthereturnfittingbodyintotheopeninginthemachinedslat(Figure 24).Fastenittothewallusing8countersunkpozidrivewoodscrews,A4SS(bagofscrewsenclosedwiththereturnfitting).

Applytheself-adhesivegaskettothethroughwallflange.Asinthecaseoftheskimmer,thelinermustnowbefittedwithinthenext48hours.Ifthisisnotpossible,delayapplicationofthegasketuntiljustbeforethewaterproofingmembraneisfitted.Therestofthepart(gasketandflange)willbeaddedafterthelinerisfittedtoensureleaktightnessatthereturnfitting.

Figure 24 – Mounting the return fitting body and gasket

7.4 Filtration pipeworkNotoolsarerequiredtotightenthebarrelunions(isolationvalves),theyshouldbehandtightenedonly:overtighteningcoulddamagethethreadingontheunionsorthegaskets,leadingtoleaks.Use3or4turnsof sealing tape on connections with no gaskets.

Onlythecollarclamps(cerflex)needtotightenedwithaflatheadscrewdriver.Takecarenottoovertighten.Do not forget to thread the protective rings that will over the collar clamps onto the pipe before tightening.

7.4.1 Installation of the rigid descending modules

ApplyTeflontothevariousconnectionswhereappropriateandcheckthatallgasketsareinposition.

Whileinstallingtherigiddescendingpipe,youcanorientthelowersectiontofacilitatesubsequentinstallation of the pipes.

32/76 2019/01 - Indice de révision : C - Code : 37321 URBAN POOL BWT myPOOL

Screw the unions B under the skimmers,donotforgettowrqpteflonaround the 2 threadings.

Cut the pipe at the mark corresponding to the height of your pool. Chamfer the cut slightly to facilitate insertion of the pipe into the compression uion. Check that the pipe is inserted fully then tighten the green barrel union taking care to ensure that the connection is leaktight. Screw the rigid descending pipe to the union under the skimmer.

Union under the skimmer Rigid descending pipe under the skimmer

Screw the rigid descending pipe C ontothereturnfittingnozzleelbow,donot forget to check that the o-ring is in position. Cut the vaccum fitting rigiddescendingpipe (asdescribedaboveand according to the height of your pool)andinstallit.

After wrapping teflon (accessoriesskin pack) 4 or 5 times around therigiddecendingpipeelbowsC(returnfittings), screw them onto the nozzleoutlets,donotforgettoputtheo-ringsprovidedinthepoolfitttingsskinpackinto position. Hand tighten to avoid crushing the o-ring. Next, screw theupper union of the rigid descending pipeontothetworeturnfittingelbows.Elbow union on the return

fittingRigid descending pipe under

thereturnfitting

33/762019/01 - Indice de révision : C - Code : 37321URBAN POOL BWT myPOOL

7.4.2 AssemblingthefilterJointhepumpandfilterbasestogetherusingthescrewsandcapnuts,donotforgetthespacers.

REF Description1 Pump base2 Filter base3 Countersunk screw 3x16 SS A24 Nylonspacer,thickness4mm5 Cap nut M3 SS A2

REF Description1 Filter tank2 Tank collector pipe3 Laterals4 6-way valve5 Pressure gauge6 6-way valve o-ring7 6-way valve collar clamp8 Filter drain

• Beforeassemblingthefilter,makesurethatitisrestinginitsbaseandinitsfinallocation.Checkthatthedrain plug is in place.

• Insertthecollectorintothefilterandscrewthelateralstoitbeingcarefulnottoovertighten.Coverthetopof the collector pipe with adhesive tape. Make sure that the collector is properly centred.

• Centrethecollectorinthebottomofthefilterandholditinplacewithsomesand.• Fill with water until the water level is 5 cm above the laterals.• Pourthesandincarefullytoavoiddamagingthelaterals.Beforebeginningtofillthefilter,makesurethat

collector is properly centred and that the laterals are not touching the bottom of the tank. This couldimpedeinstallationofthevalve.Fillatmostupto2/3ofthefilterheight.

• Afterremovinganysandontopofthefilterandthecollector,removetheadhesivetape.

Check that the o-ring is present in its groove inside the valve before putting it in position.

34/76 2019/01 - Indice de révision : C - Code : 37321 URBAN POOL BWT myPOOL

Finishassemblybyfitting thecollarclamp.Tightenuntil thegapsbetweenthetwohalvesof thecollarclampareeven(15to20mm).Tightenbothsidesalternately.

Screwtheisolatingmodule(K),the2barbedunions,andthepressuregaugeontothe6-wayvalve.DonotforgettouseTeflononalltheconnections.

7.4.3 Pump/filterandmanifoldmoduleUsesilicongreaseorsoapywatertofacilitateinsertionofthepipes.Beforeconnectingthepipes,makesurethattheprotectiverubberbands(connectionskinpack)intendedtocoverthecerflexclampsafterthey have been tightened.

Mount the pump on its base. Ensure that the orientation of the assembly will facilitate subsequent installation of the semi-rigid pipes.

35/762019/01 - Indice de révision : C - Code : 37321URBAN POOL BWT myPOOL

Screw the 2-way manifold onto the pump inlet. Do not forget the o-ring enclosed in the pump pack.

Screw the screwed union from the pump pack onto the pump outlet (Donotforgettheo-ring).

Cut a length of tube to size andconnect it as illustrated between the pump outlet and the 6-way valve.

.

7.4.4 Pipe connectionsConnecttherigiddescendingpipesandthefiltrationgroupasillustratedinthediagrambelow.Thefiltrationkitsuppliedissizedforinstallationofthefiltrationgroup3.5mfromthepool,pipeandtubelengthsareindicative.Makesurethatyoumodifythelengthstofityourinstallation.

Oncehydraulicconnectioniscomplete,makesurethatallthevalvesareintheCLOSEDposition.

Pipe LengthPipe A and B +/- 2.9 mPipe C +/- 1.2 mPipe D +/- 0.2 mPipe E +/- 11.0 mPump/filterpipe +/- 0.7 m

Figure 25 – Positions of the various pipes

36/76 2019/01 - Indice de révision : C - Code : 37321 URBAN POOL BWT myPOOL

8. PARTS FOR THE AUTOMATIC COVER

8.1 Throughwall flange Thethroughwallflangeholds theaxle in thepoolwallandallowstransmissionofrotationbetweenthemotorandtheautomaticcoveraxle.Itshouldbemountedonthesamesideastheskimmer,asshowninFigure 26.

Location of the throughwallflange

Pool exterior

Pool interior

Figure 26 – Position of the throughwall flange

bass

in9

rieu

r du

b

10

Exté

ssin

12

35eu

r du

bas

8 7

45

6Inté

rie

Poo

l int

erio

r

Poo

l ext

erio

r

Figure 27 – Mounting the throughwall flange

Assemblyof the throughwall flange is set out stepby stepbelow.Thenumbers referred toare thosehighlighted in green in Figure 27.Thescrewsareprovidedinthebagenclosedwiththethroughwallflange.

• Working from inside thepool,put the throughwall flange (6),which isacollectionof threepartspre-assembled in the factory. Fasten it to the wooden pool wall using the 4 cross-head countersunk screws 4.2×25A4SS(7).

• Attachpart1topart4usingfourFHCscrews;6×20,A4SS(5).Workingfromoutsidethepool,attachthisassemblytopart6,makingsurethattheholes(10)inpart6arecorrectlyalignedwiththeholes(9)inpart1.Insertthetwo4mmdiameter,20mmlong,pins(2)intheseholes.

37/762019/01 - Indice de révision : C - Code : 37321URBAN POOL BWT myPOOL

• Working from inside thepool,put the throughwall flange (6),which isacollectionof threepartspre-assembled in the factory. Fasten it to the wooden pool wall using the 4 cross-head countersunk screws 4.2×25A4SS(7).

• Attachpart1topart4usingfourFHCscrews;6×20,A4SS(5).Workingfromoutsidethepool,attachthisassemblytopart6,makingsurethattheholes(10)inpart6arecorrectlyalignedwiththeholes(9)inpart1.Insertthetwo4mmdiameter,20mmlong,pins(2)intheseholes.

8.2 Bearing mounting unitThe purpose of the bearing mounting unit is to hold the axle in the pool wall opposite the motor and allow rotation of the axle.

Figure 28 – Mounting the bearing support unit

Assembly of the bearing mounting unit is set out step by step below. The numbers referred to are those highlighted in green in Figure 28. All the screws are provided in the bag enclosed with the throughwall flange.

Workingfrominsidethepool,putthebearingmountingunit(4)inposition,fastenittothewoodenwallusing4cross-headcountersunkscrews4.2×25A4SS(5).

Workingfromoutsidethepool,fastenthecounterplate(3)tothebodyofthebearingmountingunit(4)usingfoursocketheadcountersunkscrews6×20A4SS(1).Next,screwthecounterplatetothewoodenwallusing4cross-headcountersunkscrews4.2×25A4SS(2).

Lastly,gluetheadhesivegasket(6)tothebodyofthebearingmountingunit(4)makingsurethatholesin thegasketarecorrectlyalignedwith theholes in thepart.The linershouldbefittedwithin thenext 48hours(paragraph 10, page 39).Ifthisisnotpossible,delayapplyingthegasketuntiljustbeforethewaterproofingmembraneisfitted.

Therestofthepart(flangeandgasketwashers)willbeaddedafterthelinerisfittedinordertoensureleaktightness at the bearing mounting unit.

Poo

l ext

erio

r

Poo

l int

erio

r

38/76 2019/01 - Indice de révision : C - Code : 37321 URBAN POOL BWT myPOOL

9. IN-POOL LADDERAssemble the ladder as shown in Figure 29. The numbers referred to are those highlighted in green in this diagram.

9.1 Assembling the in-pool ladderStartbymountingtheABStreads(3)onthealuminiumtubes(1)usingthe6aluminiumscrew,washerandnutassemblies(diameter8mm)(12,13et14).Onlyusealuminiumscrews,usingscrewsotherthanaluminiumscrewscouldleadtoariskofgalvaniccorrosion.Ifnecessary,tapthescrews(12)inusingamalletorahammerandmartyrblock,takingcarenottodamagethealuminiumtube.

Installaball(2)ateachendofthetwotubes,theninserttheballsonthebottomintotheprotectivebumpers(10),thatwillallowyoutousetheladderwithoutdamagingtheliner.

Attachthetwosupports(4)justunderthefirsttreadbyscrewingthemtotheirshells(7)usingfourA4SSscrews6×40(9)andwashers.Donotover-tighten,theenclosedtubeshouldbeabletoslideupanddownto allow the support to be positioned opposite a full slat and not straddle two wall slats.

9.2 Drilling holes to mount the ladder

• Position the ladder in thepool,centring itoppositethe wooden access ladder that was assembled previously. The bumpers should rest against the poolfloor.

• Tracethepositionoftheladdersupports(4)onthepoolwall,onafullslat.

• Removetheladderandusethegasket(11)tomarkthe position of the two holes through which the screws(5)willbeinserted.

• Nextdrillthefour10mmdiameterholesinthepoolwall to fasten the ladder in position after the liner hasbeenfitted.

Figure 29 – Assembling the ladder

39/762019/01 - Indice de révision : C - Code : 37321URBAN POOL BWT myPOOL

10. FITTING THE WATERPROOFING MEMBRANE

10.1 Installing the liner locking trackBeforestartingtoinstallthelinerlockingtrack,makesurethatthestructurehasbeencorrectlyassembled.Todothis,checkthattheentireperipheryishorizontal(useaspiritlevel),andthatthediagonalsareequalinlength.Ifnot,rectifytheseimperfectionsbeforecontinuing.

Startinstallationofthelinerlockingtrackinacorner.Continuearoundtheperipheryofthepool,takingcarewith the joins between each 1.18 m length of track. Each section of track must be perfectly aligned with the two adjacent sections of track to avoid damaging the liner. Joins between sections of liner locking track do notneedtocoincidewiththestructure’ssupportingbraces.

It may be necessary to trim the track at the end of a lengthorwidth:todothis,measurethedistancetobe covered and cut a bar to that length. Remember to deburr the track after trimming.

Thetrackshouldbeflushwiththetopofthewoodenstructure.Beforefixing the liner tracking track intoposition,pre-drillthetrackusingthe4mmdiameterdrillbitprovided(bagJ).Insertthescrewsprovidedat approximately 20 cm intervals (countersunkscrews4×35,torx,threadedover20mminA4SS,bagH).Donotovertighten,topreventscrewsfrompassing completely through the rail.

Figure 30 – Pose du rail d’accrochage

10.2 Drilling for the beam mounting unitBeforefittingtheliner,youwillneedtodrillholestomountthebeamoneachsideofthepool.Thisbeamwill support the duckboarding that will cover the area of the pool that contains the automatic cover axle. Thebeammountingplateandcounterplateareinstalledafterthelinerisfitted.Usinga10mmdrillbit,drillblind holes to a depth of about 20 mm.Position the beam mounting counter plate outside the pool as shown in Figure 31. The top of the counter plateshouldbeflushwiththetopofthepoolwall.Checkthatthepartiscorrectlypositionedverticallyandmarkthelocationofthefourholesonthewood.Usinga10mmdiameterdrillbit,make4blindholes.

Working from inside thepool,position thecounterplate445mm from thepoolwall,mark the futureposition of the screws and drill blind holes. The blind holes drilled from inside and outside the pool should meet to form 4 holes.Repeat this procedure on both sides of the pool.

Theholesdrilledshouldbeperfectlyhorizontaland perpendicular to the pool wall to facilitate subsequent insertion of the beam mounting plate screws.

Figure 31 – Position of the beam mounting counter plate

40/76 2019/01 - Indice de révision : C - Code : 37321 URBAN POOL BWT myPOOL

10.3 Applying self-adhesive gasketsMakesurethatthegasketsarecorrectlypositionedandapplied.Itwillbedifficulttorectifyanomissionormistakeafterthelinerhasbeenfitted.Checkthattheholesinthevariouspoolfittings(skimmer,throughwallflange,coverbearingmountingunit,etc.)andtheholesinthewoodenwallarecorrectlyalignedwiththeholes in the gaskets.

Gaskets should be applied to the following:

• poolfittings(ifyoudidnotapplythemwheninstallingthepart):skimmerandreturnfitting,throughwallflangeandautomaticcoveraxlebearingmountingunit;

• the wooden wall: over the holes drilled to attach the two beam mounting plates and over holes drilled to fastentheladder(paragraph 10.2, page 39).

10.4 Fitting the underlayBeforespreadingtheunderlayovertheconcrete,makesurethatthesurfaceoftheconcreteissmooth,flatandclean.

Theunderlayisprecuttothepooldimensions,notrimmingwillbenecessary.Makesurethattheunderlaycompletely covers the bitumous strips. Smooth out crease as much as possible before installing the liner.

10.5 Fitting the liner

Beforefittingthewaterproofingmembrane(liner),makesurethatthesurfacesarefreeofsplintersorany other surface defects that could damage the liner.

Ensure that all the gaskets have been correctly applied paragraph 10.3, page 40.

Theidealtemperatureforfittingalinerisbetween18and25°C.Put the linerpack in thepool (takecare, the liner isveryheavy). Remove the liner and unfold it across the poolwidth(seeFigure 33)thendownthelength.Beforestartingto actually fit the liner, allow the liner to rest for a whileatambient temperature(between18and25°C)so that itbecomesmoresuppleandeasiertofit.Climbbarefootintothepool,checkthatthecornersoftheliner wall are properly aligned with the corners of the pool structure. It is important to spread the liner out properly. Push the liner beading into the liner locking track in the corners and then continue along the pool walls. Use half clothes pegs to block the liner in position as you proceed (notprovided),particularlyinthecorners(Figure 32).The liner is deliberately manufactured to be 1.5% smaller than then pool structure dimensions, this is to avoid theappearance of creases or folds. It is therefore normal for the liner to be under tension when installed.

Figure 32 – Blocking the liner in position using half clothes pegs

Figure 33 – Unfolding the liner

41/762019/01 - Indice de révision : C - Code : 37321URBAN POOL BWT myPOOL

Checkthatthelineriscorrectlypositioned(noexcessivestressloading,nocreasesonthepoolfloororwalls).

Shouldthelinerneedtoberepositionedwhilefitting,neverpullitalongthetrack.Releasethelinerand reposition it to avoid the risk of tearing

Iftherearecreasesinthepoolfloor,smooththemoutasmuchaspossiblebeforebeginningtofillthepoolwithwater.Checkthatthelineriscorrectlyengagedinthetrack,particularlyinthecorners,beforefillingthepoolwithwater.Continuetocheckwhilethepoolisfilling.Leavethehalfpegsinplaceuntilthepoolisfilled.

Fill thepoolwitha fewcmofwater,andsmoothoutanycreasespushingthemfromthecentreof thepooltowardsthewalls.Oncethewaterisdeeperthan10cm,itwillnolongerbepossibletosmoothoutcreases.Oncecreaseshavebeensmoothedout,continuefillingthepooluntilthewateris45cmdeep,thatis20cmbelowthebottomofthereturnfitting.

Residual creases in the liner caused by folding it are normal and will disappear over time.

10.6 Underwater light cable tiesInthemiddleofthepoolwidth,onthecoverside,gluetwoadhesivemountstotheliner(Figure 34)theyshouldbeverticallyalignedand70cmapart,thetoponebeinggluedapproximately3cmfromthetopofthepoolwall.Thesetieswillbeusedtoholdatube,diameter16mm,throughwhichtheunderwaterlightpower cable will be run.

Figure 34 – Adhesive mounts to hold the cable ties

10.7 Filling the pool with waterInthecaseofanin-groundinstallation,checkforleaksbeforeburyingthepipesandtheirconnections.Open the various valves to allow water into the circuit. Make sure that their are no leaks at the connection points.Beforestartingthepump(whichshouldundernocircumstancesbeallowedtorun‘dry’)makesurethatthepre-filterisfilledwithwater.Ifnecessary,opentheprefilterbasketandfillitwithwateralongwiththeSkimmer line in order to facilitate priming of the pump.Putthe6-wayvalvetoWashtobackwashthefilterbeforeputtingitintooperationinfiltrationmode.Formore information concerning this procedure refer to paragraph 15.1.2, page 66

10.8 Installing flanges on plastic pool fittings Beforecontinuingtofillthepool,installflangesonthefollowingpoolfittingsinorder:

• thereturnfitting(whenthewaterlevelis20cmbelowthereturnfitting)• thethroughwallflangeandtheautomaticcoveraxlebearingmountingunit(whenthewaterlevelis5cm

undertheparttowhichtheflangeistobeapplied)• theskimmer(whenthewaterlevelis5cmundertheskimmer)

Installationoftheflangesandtheirgasketsisdescribedstepbystepinthefollowingfourparagraphs.

42/76 2019/01 - Indice de révision : C - Code : 37321 URBAN POOL BWT myPOOL

TIP:Recommendationsapplytotheinstallationofallflanges:• locatetheholesinthepoolfittingunderneaththelinerandmarkthemwithapen,• checkthatthemarkslineupwiththeholesinthecorrespondinggasketbyholdingthegasketoverthem,• tightenthevariousflangescrewsalternatelyinordertoensurealeaktightfit,• tightenbyhand,applyingtoomuchtorquecouldsplittheflange,• usingaStanleyknife,cutawaythelinerinsidetheflange.

Checkforleakswhilethepoolisfilling.ThewaterlevelinthepoolshouldbeasshowninFigure 49

Ifwhilefilling thepool, the linercomesaway fromthe track,stopfilling thepoolbeforere-engaging it.Dependingonthedepthofwaterinthepool,itmaybenecessarytopartiallyemptythepoolbeforere-engaging the liner.

10.8.1 ReturnfittingflangeTheproceduretofollowforinstallationofthereturnfittingflangeisillustratedinFigure 35 :

• locateandmarkthefourscrewhousingsunderneaththeliner.Piercethelineratthemarkedpositions,• gluetheadhesivegaskettotheflange,takingcaretoensurethattheholesinthegasketlineupwiththe

holesinthepart,• screwtheflangeontothebodyofthereturnfittingusingfourcountersunkscrews5×16,A4SS(enclosed

withthereturnfitting),• usingaStanleyknife,cutawaythelinerinsidetheflange,• lastly,screwtheeyeball-union-trimassemblyontothereturnfittingbody.

Figure 35 – Installing the return fitting flange

10.8.2 ThroughwallfittingflangeTheproceduretofollowforinstallationofthethroughwallfittingflangeisillustratedinFigure 36(inthisfigure,thelinerissandwichedbetweenparts4and5):

• locatethepositionsofthefourthroughwallfitting(5)holesunderneaththelinerandmarkthem.Piercethelineratthemarkedpositions;

• gluetheadhesivegasket(4)ontotheflange(3),takingcaretoensurethattheholesinthegasketandthepartarecorrectlyaligned;

• screwthegasket(3)ontothereturnfittingbody(5)usingfoursocketheadcapscrews,10×40,A4SS(1)equippedwith4washers(2).Thescrewsandwashersareprovidedinthebagofscrewsenclosedwiththethroughwallfitting;

n

sin

r du

bas

si

ur d

u ba

ss

Exté

rieu

r

5Inté

rieu

1 2 3 41

Figure 36 – Mounting the throughwall fitting flange

Poo

l int

erio

r

Poo

l ext

erio

r

43/762019/01 - Indice de révision : C - Code : 37321URBAN POOL BWT myPOOL

10.8.3 BearingmountingunitflangeThe procedure to follow for installation of the bearing mounting unit is illustrated in Figure 37(inthisfigure,thelinerissandwichedbetweenparts4and5):

du b

assi

n

du b

assi

n

Exté

rieu

r d

5

ntér

ieur

d

4

E

I 1 2 3 2

Poo

l int

erio

r

Poo

l ext

erio

r

Figure 37 – Assembly of the bearing mounting unit

• locate thepositions of the four holes in thebearing (5) underneath the liner andmark them;usingapointedobjectpiercethelinerinthecentreofeachscrewhousing;

• assemble in order: the four socket head cap screws, 10 × 40,A4SS (1)with fourA4SSwashers,diameter10mm(2),thebearingmountingunitflange(2),theotherfourA4SSwashers,diameter10mm,thentherubberwashers(4).Screwthisassemblyontothebearingmountingunit.Thescrewsandwashers are provided in the bag of screws enclosed with the bearing mounting unit.

• adjustthehorizontalpositionofthebearingmountingunitflangebeforetighteningcompletely,suchthatthecentralverticalmarkisthesamedistancefromthewidthwallasthethroughwallflangeshaftonthemotorside;

• usingaStanleyknife,cutawaythelinerinsidetheflange.10.8.4 SkimmerflangeTheproceduretofollowforinstallationoftheskimmerflangeisillustratedinFigure 38 :• gluethesecondgasketontotheinnersurfaceoftheskimmerflange;• locatethe4holesinthecornersoftheskimmerunderneaththelinerandmarkthem;• screwtheflangeontotheskimmerthroughthe4cornerholes.Proceedfasteningtheskimmerinplace

usingthe18countersunkscrews,5.5×25,A4SS,tightenthescrewsalternately(providedinthebagenclosedwiththeskimmer);

• usingaStanleyknife,cutawaythelinerinsidetheskimmer.Keepthelinercutoutsforfuturerepairs.

Figure 38 – Mounting the skimmer flange

Next,installtheskimmerweir,smoothsidefacingtowardsthepool,bypushingthetabsintothenotchesprovidedforthatpurposeinthebottomoftheskimmer.Theweirshouldswingfreely,howeveritshouldnotbeabletoswingoutoverthepool(thestopperatthetopoftheskimmershouldpreventthis).Lastly,clip on the skimmer face plate.

10.9 Installation of the ladder railsGluethetworemaininggasketsontotheladdersupports(partno.4inFigure 29 page 38).

Installtheladderinthepool,fixitinpositionbyinsertingthe4socketheadcapscrews,10x80,A4SS(5) intothetwosupports(4).Finishassemblystartedinparagraphe 9.1tighteningthesupports(4)intheirshells(7).

44/76 2019/01 - Indice de révision : C - Code : 37321 URBAN POOL BWT myPOOL

11. ASSEMBLY OF THE AUTOMATIC COVER