Uravu Bamboo Study

-

Upload

stanly-sunny -

Category

Documents

-

view

145 -

download

2

Transcript of Uravu Bamboo Study

KALPETTA BAMBOO CLUSTERUnder

Ministry of Micro, Small & Medium Enterprises, Govt of IndiaUravu, Thrikkaipetta P.O Kalpetta

Wayanad district, KeralaPIN:673577

DIAGNOSTIC STUDY REPORT

Nodal AgencyKhadi & Village Industries Commission

Govt. of India

Technical AgencyNABARD

Implementing AgencyUravu Indigenous Science and Technology

Thrikkaipetta P.O, KalpettaWayanad District, Kerala

PIN : 673577

Submitted ByT.S. Sreekumar

Cluster Development Agent

CONTENTS

CHAPTER INDEX PAGE NO

Acknowledgement 3

Executive Summary 4

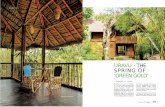

1 Introduction: Bamboo as green gold 7

2 Cluster Profile 13

3 Stakeholders profile 21

4 Production process & Value chain analysis 27

5 Analysis of Business operation 35

6 SWOC Analysis 38

7 Cluster map and Institutional Matrix 40

8 Our Vision 44

9 Suggestions & Action Plan 45

2

ACKNOWLEDGEMENT

This study would not have been possible without the active support from

State Directorate of KVIC. I also acknowledge the timely expert guidance

and support from the NABARD who is the Technical Agency for this cluster,

during conduct of the diagnostic study and preparation of the report.

My sincere thanks go to the President and secretary of Uravu and staff

members, especially Smt. Rema K.M. for the wholehearted help and

cooperation in completing the study and preparation of the report. I owe my

gratitude to all those artisans and stakeholders of this cluster for providing

me with every information and data required for the report.

The academic support from nimsme, Hyderabad is also thankfully

acknowledged.

Finally I thank them all those who are involved in the study process directly

or indirectly.

T.S. Sreekumar

Cluster Development Agent (CDA)

Kalpetta Bamboo Cluster

3

EXECUTIVE SUMMARY

Introduction

For many years bamboo related activities had been one of the traditional

occupation/craft in Kerala. The artisans of this craft are mainly located in

forest area especially in Wayanad district. As they belong to the unorganized

sector the artisans had been exploited by the middlemen. The Uravu

indigenous science and technology study centre, an NGO registered under

the Charitable trust Act (Reg No 122/96:) in 1996 and having its Head

Quarters at Thrikkaipetta, Kalpetta, Wayanad district of Kerala State has

been actively involved in the development of bamboo sector in the past 9

years. Under various interventions Uravu has regenerated this peculiar craft

sector and now more than 500 artisans/person including bamboo cultivators,

cutters and building workers have been working in this sector and earn their

livelihood. With this rich experience, Uravu have decided to take up

development of these scattered units in the nearby village of Kalpetta block

and posed a proposal to Khadi Village & Industries Commission (KVIC). After

a preliminary study and discussion, KVIC has agreed to support the proposal

under SFURTI, its participatory model of cluster development and identified

Uravu Indigenous Science and Technology study centre as Implementing

agency (IA), NABARD as Technical Agency (TA) and, Shri T.S.Sreekumar,

appointed by the IA as Cluster Development Agent from the panel provided

by KVIC.

4

The Study

India has a rich tradition in traditional industries. The eco-friendly products of

traditional industries not only have great potential for growth in production

and export but can also lead to wide spread generation of employment

opportunities in the rural areas of the country. With a view to making the

traditional industries more productive and competitive and facilitating their

sustainable development, the Central government announced a Scheme

SFURTI with the objective to develop clusters of traditional industries in

various parts of the country over a period of 5 years commencing

2005-2006. The Khadi & Village Industries Commission which is the Nodal

Agency identified the Kalpetta Bamboo Cluster in Wayanad district under

SFURTI. Accordingly the study has been undertaken in Kalpetta Bamboo

cluster from 3rd May 2007 to July 2007.

OBJECTIVES OF THE STUDY:

1) To understand the socio – economic profile of the craft persons.

2) To gain better insight into the problems and issues to be identified and

the potentials for the sustaining livelihood around bamboo in an

environmentally sound manner.

3) To identify and propose priority areas of action and specific issues in

promoting development of bamboo, taking into consideration its

demand profile, whole value chain addition, various players involved in

value addition, socio economic, technological, environmental and

institutional dimensions.

4) To develop a broad strategy framework and guidelines for sustainable

livelihood development around bamboo.

5) To make sure the whole hearted co-operation of all the members in

the production and marketing by developing effective networks.

6) Provide adequate awareness and introduce bamboo products as an eco

friendly alternative for plastic products.

5

7) Physical and financial interventions required for overall development of

the cluster in a period of 5 years.

The major issues, constrains and problems faced by cluster units emerged

during the study were related to infrastructure, Finance, production, market

etc. as summarized below.

• Majority of the producer groups are working in rented buildings. They

have to spend a huge amount from their remuneration for rent.

• The cluster actors are mainly depends on local banks/cooperative

societies for their working capital requirement.

• Market competition from other parts of the country, Competition from

China in export market.

• Non-implementation of effective management system to improve

business performance

Absence of private, public partnership to promote R & D for value added products to explore new markets.

• Migration of artisan to tertiary sector like construction

• Inefficient linkages of the production-consumption chain of the cluster

The market potential of the tourism sector in Wayanad is not effectively tapped.

The existing tools and machineries of the cluster is insufficient to meet large orders.

• Major problem faced by the artisans is absence of raw material storage

facility. During rainy season it is very difficult to keep the raw material

dry and during summer there is need to keep the raw material away

from direct sunlight.

• Due to poor financial health of the group, many times the artisans do not get their wages regularly and in time.

6

CHAPTER 1

Introduction:Bamboo as Green gold

Bamboo is woody grass belonging to the sub-family

Bambusoideae of the family Poacae. Worldwide there

are more than 1,250 species under 75 genera of

bamboo, which are unevenly distributed in the

various parts of the humid tropical, sub-tropical and

temperate regions of the earth. This natural resource

plays a major role in the livelihood of rural people

and in rural industry. This green gold is sufficiently

cheap and plentiful to meet the vast needs of human

populace from the "child's cradle to the dead man's

bier". That is why sometimes it is known as "poor

man's timber". Bamboos has versatile uses as

building material, paper pulp resource, scaffolding,

food, agriculture implements, fishing rods, weaving material, substitute for

rattan, plywood and particleboard manufacture. Pickled or stewed bamboo

shoots are regarded as delicacies in many parts of the country. The major

user of bamboo in India is paper industry, which consumes sizeable

proportion of the total annual production. s are good soil binders owing to

their peculiar clump formation and fibrous root system and hence also play

an important role in soil and water conservation.

Genetic Diversity of bamboo

As already stated, India has 124 species of bamboo

distributed through out the length and breadth of

the country. North-east India supports about 50%

of the total genetic resources which is followed by

peninsular India where the Eastern and the

Western Ghats are located which accounts for

7

about 23% of the genetic resources occurring naturally. North-western India,

Indo-Gangetic plains and the Andaman & Nicobar Islands account for the

remaining diversity. More than 50% of bamboo species occurring in India are

endemic, and roughly 19 species are rare and threatened.

Research work on collection and evaluation of genetic resources of bamboos

started in India in the 1970s, but the pace of work was rather slow. A

provenance trial on Dendrocalamus strictus was laid at Forest Research

Institute, Dehra Dun. This was followed by the work on selection, evaluation

and ex-situ conservation of several economically important bamboos of

north-eastern region at State Forest Research Institute, Itanagar. Under the

aegis of All India Coordinated Research Programme on under-utilized and

under-exploited plants, a beginning was made at the coordinating centre at

Bashar, Siang district in Arunachal Pradesh to collect the available

germplasm from Arunachal Pradesh and Meghalaya and to evaluate the

material.

Bamboo Utilization

Bamboo is utilized for various purposes depending upon its properties. It

plays an important role in the daily life of people; for house construction,

agricultural tools and implements, as food material and weaponry etc.

Besides being a convenient source of cellulose for paper manufacture and

rayon, it supports a number of traditional cottage industries. Bamboo craft is

one of the oldest of traditional cottage industries in India. The origin of this

rural craft is traced from the beginning of the civilization when man started

cultivation of food crops thousands of years back. People started making

baskets, mats and many other products of household use with bamboo that

was abundantly available in nearby forests. Later, tribal and rural people in

the vicinity of bamboo forest took up this as a means of livelihood. Now

bamboo craft is spread in all rural areas of the country and it feeds millions

of traditional workers.

8

Bamboo is emerging as a major source of raw material for several processed

products primarily due to its fast growth, wide spread occurrence and its

multiple uses. The ten major species used in India for commercial purposes

are Bambusa bambos, B. balcoa, B. nutans, B. tulda, Dendrocalamus

strictus, D. hamiltonii, Melocanna baccifera, Ochlandra ebracteata, O.

scriptoria and O. travancorica.

MARKET AND SOCIO-ECONOMICS

Bamboo Markets

There is a high demand of bamboo in different markets. It is normally

marketed either as commercial or as industrial. The former is produced from

live bamboo culms, which are more than 2.5 m in length. The bamboo

pieces, which are less than 2.5 m. in length, are classified as industrial. of 2

m and 1 m length, known as bahi and sarava, respectively, are sold in the

northern states. However, in most states, with lengths varying from 3 m to 9

m finds use in construction of houses.

Price of commercial bamboo depends on its length and basal girth. The

bamboo Trade Bulletin, a periodical published by ICFRE, gives prices in about

20 markets spread all over India. According to March 1998 bulletin (ICFRE

1998), depending on market location and species, the price of 100 bamboo

of about 3 m length and about 20 cm girth lies between Rs.1500-1600; of

about 5 m length and 20 cm girth between Rs.3500-5000; and of about 6 m

length and 25 cm girth between Rs.5000-6000 (US $1 ~ Rs.42).India has

been exporting s on a large scale. The export of bamboo as raw material is

generally not permitted but value added products are allowed to be exported

as well as imported.

Departmentally harvested bamboo is transported to sale depot for auction

and to different departmental outlets for sale to local people for their

domestic and occupational uses. There are traders and purchasers from

departmental sale depots who convert the s into marketable sizes as per the

9

demand of the consumers. s on private lands are sold to the consumers as

rates are negotiated between producer and consumer. In some states, where

bamboo is a nationalized produce, private producers at standard market

rates sell it to forest departments. However, where bamboo does not come

under state trading monopoly, it is sold by cultivators and growers through

market channels (Singhal and Gangopadhaya, 1999). Information on

different channels of production to consumption of bamboo in different parts

of the country indicating market channels statewise, mode of marketing and

constraints experienced in marketing is given in Table-8.

Bamboo in Kerala

Twenty-eight species of bamboo and two varieties belonging to six genera

are recorded as native of Kerala. These include genera such as Bambusa,

Dendrocalamus, Pseudoxytenanthera, Schizostachyum, Sinarundinaria and

Ochlandra. Besides these, over 10 species such as Bambusa vulgaris, B.

vulgaris var. wamin, B. multiplex, B. polymorpha, B. balcooa,

Dendrocalamus brandisii, D. giganteus, D. longispathus, D. hamiltonii,

Thyrosostachys oliveri, T. regia etc. are cultivated in home gardens and

forest plantations. The majority of bamboos in Kerala are found at an

elevation of 50-1500 m above sea level. The species belonging to the genera

such as Ochlandra, Bambusa and Dendrocalamus are seen extensively

growing in large forest areas as brakes and reed brakes. The species like

Bambusa bambos and Dendrocalamus strictus are adapted to the dry plains

and hilly tracts. Their distribution is abundant in the most deciduous

forests. Bambusa bambos is generally found at an elevation between 50m –

1000 m and distributed throughout Kerala. Dendrocalamus strictus is

distributed in the forests of Attappady, Nilambur, and Chinnar at an altitude

of 150-750 m above sea level.

10

Industrial Scenario

The global scenario

It is estimated that about 2.5 billion people use bamboo in one form or the

other at the global level. The annual turnover is estimated more than USD 10

billion and this is estimated to shoot up to USD 20 billion by the 2015. China

is the biggest player among the bamboo exporting countries. The total export

value of bamboo products of that country id $550 billion per annum.

Advanced research activities are conducted to utilize bamboo for efficient fuel

generating systems. Networks like the international network for bamboo and

Rattan (INBAR) are functioning at the international level. The Govt oif India

is a signatory to this bamboo network. At the global level, primary processing

and product manufacturing is shifting to a highly mechanized mode.

Bamboo in India

India is the second richest country in terms bamboo genetic diversity with a

total of 136 species under 75 genera. It encompasses about 8.96 million

hectares of forest area, which is equivalent to 12.8 percent of the total forest

cover of the country. The North East India holds the largest tock and

diversity of s next to the N E, the Western Ghats area has the second largest

diversity of s.

Though India has a wide area under, the yield per ha is estimated around 0.4

tonnes, which is very low in comparison to other countries like china,

Malyasia & Costarica etc.

It is estimated that 8 million bamboo artisans are dependent on this craft for

their livelihood. The annual turnover of the bamboo sector in India is

estimated to be around Rs 6505 crores. By and large, this is a totally

unorganized sector and has always been considered from the craft point of

view and if considered other wise, for pulp making only. The livelihood

11

support provided by bamboo to the rural poor and the agricultural sector was

overlooked.

Bamboo craft has been practiced by the north Eastern States for centuries

as their prime livelihood and income source and, in the process, the weaving

skill of the artisans had involved to levels comparable with the craft persons

from high skilled societies like Japan, China etc. though the product diversity

still remains undeveloped.

The Kerala Scenario

In Kerala, 28 species of bamboo are found to occur. The main species found

in Kerala are Bambusa bambos, Ochlandra travancorica, Dendraocalamus

strictus etc. Kerala has a large number of (around 11) types of thin walled

bamboos called reeds mainly of Ochlandra genera, which are used primarily

for weaving purposes by the traditional artisans. Exotic varieties like

Dendrocalamus giganteus, Dendrocalamus brandisii are also cultivated by

farmers in areas like Wayanad district. The Kerala forest bamboo is supplied

to the artisans through State Bamboo Corporation and to the pulp units

through KFD. Unlike the rest of India, 67.3% of the extracted bamboo in

Kerala comes from home gardens rather than from the forest.

It is estimated that there are about a lakh people in the state dependent on

bamboo for their livelihood. Recent data from the Panchayats indicate that

from the early seventies onwards there has been a great drain in the number

of artisans from the sector to semi skilled and unskilled jobs in the tertiary

sectors like construction.

12

CHAPTER 2

CLUSTER PROFILE

History of the cluster:

Till the early part of the 19th century, bamboos s were found abundant in the

forest and home gardens in Kerala. Until recently, every village and almost

every medium/large household used to have its own sufficient stock of

bamboos. Every panchayats had its own bamboo working artisan families

from the traditional communities. It was this traditional family of artisans,

especially from the paraya (SC) community, who satisfied the requirement of

the agrarian economy. Baskets, mats and winnowers were the main items

produced. The artisan used to have direct access to their customers and this

helped them in maintaining the demand supply chain successfully. Bamboo

was also available in the common lands and stream banks, fringes of the

forest areas etc.

The traditional inhabitants of Wayanad are the tribal population. They were

utilizing bamboo for their primary needs of food, shelter, hunting etc. Even

today bamboo is a common item for making huts, temporary sheds, fence

ladders etc. During the 1950’s with the progress in plantation crops, people

from the plains started migrating to Wayanad and in the process settled

down. Significant areas of bamboo forests were destroyed to set up

plantation sites. Along with the settlers came the bamboo working

communities who started weaving items for the new agrarian sector that was

coming up. Since Wayanad district has borders with Tamil Nadu, traditional

bamboo working communities from these areas also settled in selected

pockets.

The main items produced in Wayand are: Baskets/winnowers/mats/rain

guards etc. Since the late 70s there was a boom in the construction sector

and the traditional weaving communities started shifting to this sector. The

higher wages paid by the sector was also an attraction. The shifting from

paddy cultivation to cash crops like papper/coffee/ginger etc. created lesser

13

demand for the bamboo artifacts. The enforcement of the forest laws also

restricted the availability of forest reeds for the communities. The net effect

was that the traditional bamboo-weaving sector came to a crisis.

The newly created affluence of the 90’s from the higher prices obtained for

the cash crops and the awareness on the social stigma attached to the

bamboo artisans distracted the younger generation from taking up the

bamboo work or upgrading the production systems or product diversification.

Entry of Uravu

Uravu Indigenous science and technology study center, a charitable trust,

realizing the wide scope of bamboo, started working in 1996. The core idea

that led to the setting up of Uravu in 1996 was that revitalization of

indigenous science and technology and up gradation of the productive skills

of rural people was necessary for ensuring sustainable development. The

integrated effort of Uravu during the last 10 years could make sustainable

advancements in the bamboo sector in Wayanad district, especially in

propagation of specie suitable for commercial application, treatment of

bamboo, designing and production of bamboo craft, training and setting up of

micro enterprises, marketing etc. The agency is also making efforts for

changes in the policies in favour of increased usage of bamboo.

The studies conducted by Uravu revealed that the involvement of the

communities other than the traditional community is necessary to remove

the stigma attached to the craft. It was one of the reasons for the reluctance

of the new generation in the traditional bamboo community form taking on to

bamboo work. It was rightly observed that modernization and diversification

of the sector with respect to the product and design, technology and

marketing is much needed for the survival and growth of the sector. That

paved way to the ongoing developmental activities in the sector.

Interventions of other Agencies/Departments

14

Since 2003 NABARD sanctioned a project for establishing mother unit and

satellite unit in bamboo sector in the proposed cluster area. Under that

programme 20 craftsmen were imparted one year training as well as a

machine room. In the same year CAPART was given a 6-month skill up

gradation training to other 30 artisans.

Rastriya Sam Vikas Yojana (RSVY) is an ongoing project for establishing

Micro Enterprises in the bamboo sector under the programme of the Govt of

India.

Cluster area

The project shall be implemented at Kalpetta

Block in Wayanad District, Kerala State, for a

period of five years. This area consists of

several bamboo artisan families and plenty

of bamboo, which is the very basic raw

material for the craft. The goal of the project

is to ensure the livelihood of the poor rural

artisans through the enhancement and value

addition of bamboo craft/ product.

One of the important characteristic feature

of this district is the large adivasi population,

consisting, mainly of Paniyas,

adiyas, Kattunaykan and

Kurichiyans. Wayand district

stands first in the case of

Adivasi population (About

36%) among other districts in

the state. Wayanad has large

settler population. The Janis

from Karnataka came in the

15

13th century. The Nair’s from Kottayam made an entry in the 14th century and

established their feudal life. They were followed by Muslims. There was large-

scale migration from southern Kerala in the early 40’s. Their hard work and

sacrifice helped them to prosper. On the other hand, the last few decades

have seen the complete marginalization of the indigenous people. Alienated

from their land and victimized by the state, their status is a blot on the

progressive ideals of Kerala Society. Syrian Christians, who came in the

1950’s from Travancore, were well established as plantation crops. Chola

Naickens, who used to be proud people, were very hospitable to early

settlers are now the worst affected, under abject poverty.

In recent times Wayanad is struggling to deal with an agrarian crisis

precipitated by the economic reforms. The farmer suicides of Wayanad have

hit the headlines of national dailies along with that in other part of the

country. It is witnessing to frequent farmer agitation for resolving the issue

of debt trap, low prices for agricultural produces etc. Due to various

problems, from the early seventies onwards there has been a great drain in

the number of artisans from the bamboo sector to semi skilled and unskilled

jobs in the tertiary sector like construction etc.

Presently most of the cluster actors are concentrated in Kalpetta Block area.

But there is a scope for spread out to the whole district in a phased manner.

Therefore, it is suggested that the cluster development activities may be

concentrated in Kalpetta Block in the first phase and gradually extended to

the other parts of the district as more actors turn up in those area as part of

the training conducted under different programs and projects.

Socio economic status of the cluster actors

A baseline survey in order to identify the socio economic background of the

bamboo craft/workers in Kalpetta Block was made according to the guidelines

provided by the Technical Agency (NABARD office). The survey was mainly

concentrated in Meppadi, Muttil, Vythiri, Kaniyambatta panchayats and one

municipality. Prior to the survey CDA was conducted Focus Group

16

Discussions in each unit. Among the 500 stakeholders 120 person were

selected as random sampling and through direct interview and questionnaire

the information were collected. The details of the survey are as follows.

.

(i) DISTRIBUTION OF THE TYPE OF HOUSE OF BAMBOO WORKERS

The Table explains that out of the 120 houses, only 14.6% are good houses.

Others are either kacha type or incomplete. This shows the low standard of living of

these artisan/worker.

Type of House Number of Houses Percent

Pucca 17 14.66 Kacha 86 71.66

Incomplete 17 14.66 Total 120 100

(ii) DISTRIBUTION OF THE AVAILABILITY OF SANITARY TOILETS FOR BAMBOO WORKERS

From the table, it is clear that only 72.5 percent of the bamboo workers having

sanitary toilets. Others are relying upon the open space for toilet facility.

(iii) DISTRIBUTION OF THE AVAILABILITY OF DRINKING WATER

FOR BAMBOO WORKERS

The table shows that out of the 120 houses, only 25% have their own drinking

water source in their compound. The rest have to depend upon the public water

distribution system or on the neighbor’s well.

Toilets Frequency PercentNo 33 27.5Yes 87 72.5

Total 120 100

Water Source Frequency PercentOwn source 30 25

Neighborhood Source 33 27.5Public Tap 57 47.5

Total 120 100

17

(iv) DISTRIBUTION OF THE AVAILABILITY OF ELECTRICITY CONNECTION TO THE HOUSES OF BAMBOO WORKERS

The table analyses the availability of electricity connection in

houses of the bamboo workers. Out of the 120 houses surveyed, only 71

houses are electrified. The rest 49 are depending upon kerosene for

lighting at night.

Electricity Frequency PercentNo 49 40.83Yes 71 59.17

Total 120 100

(v) COMMUNITY BASED DISTRIBUTION OF BAMBOO WORKERS

Following table shows that 40% of bamboo workers belongs to the SC/

ST community.

Community Number of craft persons Percent

General 19 15.83 OBC 53 44.17 SC 11 9.17 ST 37 30.83

Total 120 100.0

(v) DISTRIBUTION OF THE EDUCATIONAL STATUS OF BAMBOO WORKERS

The table shows that out of the 120 bamboo workers, 5 are illiterate

and 34 persons have studied only up to the primary level. Only 2

persons have reached the graduation level.

Educational Status Frequency PercentLiterate 5 4.17Illiterate 6 5Primary 34 28.33

Secondary 52 43.33Higher Secondary 21 17.5

Graduate 2 1.67Diploma 0 0Total 120 100

18

(vii) DISTRIBUTION OF THE SIZE OF THE FAMILY OF BAMBOO WORKERS

The table analyses the size of the family of bamboo workers. Out of the 120

families, 65 are having only 4 or less than 4 members and 55 families have

members between 5 to 9 members.

Size Frequency Percent1 0 0

2-4 65 54.17 5-9 55 45.83

10-15 0 0 Total 120 100.0

(vi) DISTRIBUTION OF TOTAL LAND POSSESSED BY BAMBOO

WORKERS

From the table, it is clear that 22.5 percent of the bamboo workers have no

land for their own.

Land Frequency PercentNo own land 27 22.5

1-4 cents 18 15 5-10 29 24.17 11-20 11 9.17 21-50 26 21.67

51-1 acre 6 5 Above 1 acre 3 2.5

Total 120 100.0

(vii) DISTRIBUTION OF THE MARITAL STATUS OF BAMBOO WORKERS

Table analyses the marital status of bamboo workers identified.

Status Frequency

Married 78 Unmarried 35

Widow 5 Divorced 2

Total 120 (x) AGE-WISE DISTRIBUTION OF BAMBOO WORKERS

The table shows that out of the 120 workers, 470 are below 50 years of age.

This indicates that these craft cluster has a lot of potential and can carry out

this craft for many decades.

19

(xii) DISTRIBUTION SHOWING TOTAL NUMBER OF DAYS SPENT BY ARTISAN FOR

BAMBOO WORK

The table analyses the number of days spent by the bamboo workers for

craft/product. It shows that majority of the bamboo workers are really

involved in craft. However we also have to appreciate the fact that it is

impossible to dry the raw material in the rainy periods and also the dried

bamboo often set fungal attack during these months. So only a few craft

persons who have already stored adequate quantity of well-dried bamboo

before the rainy season could do craft during the monsoon months.

(xiii) DISTRIBUTION OF THE MONTHLY INCOME OF BAMBOO WORKERS

The table analyses the monthly income gained by bamboo workers from

bamboo activity. 63.33 percent of the bamboo workers receive less than Rs.

1000/- per month. This situation clearly indicates that a systematic and

scientific intervention in the bamboo craft sector is utmost necessary. Such

an integrated intervention could uplift the artisans from the poor state.

Age FrequencyBelow 35 yrs. 33

36-50 72 51-60 13

Above 60 2 Total 120

Frequency Percent

51-100 10 8.33 101-150 30 25 201-250 12 10 251-300 68 56.67

Above 300 days 0 0

Total 120 100

20

Frequency Percent501-1000 76 63.33

1001-1500 20 16.67 1501-1750 16 13.33 Above 2000 8 6.67

Total 120 100.0

CHAPTER 3

STAKEHOLDER’S PROFILE

The stake holders of the project are cottage level traditional artisans SHGs

engaged in bamboo craft items, curtains, art work, dry flower making group,

shoot products, cultivators, cutters, Uravu Eco link Ltd etc. The role of each

of these actors is explained below.

Bamboo shoot processing Unit

This is a ten women-working unit. The major activity

of this group is preparation of bamboo pickles,

Chammandi powder etc. The tribes in this area collect

bamboo shoots from forest and sell this to the group.

The group buys it an average of Rs 10/Kg. Except

Aug-Oct months the tribes supplied shoot

uninterruptedly. In a peculiar way the unit prepare

their product. For selling their pickles and other related products the group

mainly depends on local merchants, Uravu eco links, exhibitions and

sometimes they get order from neighboring districts. Even though the unit is

totally unaware about the new technological application in the premise of

pickle sector and they didn’t get opportunity to visit modern pickle

establishments. Now the average daily income of a unit member is Rs 60/-

only.

Bamboo Curtain units

21

There are about 24 artisans working in the unit,

including male and female. The group members

together collect the reeds and bamboo from the forest

then after they treat the raw material. The major

activity of this group is making curtains using bamboo

blinds. Presently the unit produces 10 models of

bamboo curtains, price range from Rs 40 to Rs.80 per

sq ft. The group has only two traditional looms so that the productivity is

comparatively very low. When the wavers work in the loom rest of the group

members shall be engaged in splicing the reeds. Presently the unit produces

10 models of bamboo curtains and found that they are being “sold as hot

cake”.

The major problem facing the unit is as follows:

a) All works are done manually so the productivity is comparatively

low.

b) The artisan in the unit using traditional looms and technology there

is no other technological interventions applied in the unit yet.

c) The existing working premise is not sufficient for the 25 artisans.

d) During rainy season it is very difficult to drying the raw material so

a drier machine is needed.

e) Exporting opportunity is not exploited yet.

Bamboo Bag Unit

This is the unit run by 5 men and

provides job opportunity to other 6 people. The

unit produces a wide range of products like

handbags, purses, mobile pouches etc. Using

bamboo blinds, jute etc. This item have already

undergone test market and proved to be of great

demand in market. At present the unit has been

22

working in the NGO premise, lacking adequate special and mechanical

facilities they can’t achieve their optimum level.

Major short coming of the unit.

1. Even though the unit is formed as Self Help Group, monthly meeting

and minute keeping are not functioning properly.

2. In the present stage the unit is working in a very small room that is

not sufficient for their work.

3. Now they have only three stitching machine because of the financial

problem of the unit there is no more technological intervention

applied.

4. The skill of the unit members and design of their products are not

sufficient to compete in market.

5. Now their marketing operations are limited with in two or three

districts.

Dry flower unit

This unit is working as Self help group and having

10 members. And they give job opportunity to

other 10 members of nearby area. The women in

the unit themselves collects bamboo flower from

the forest, sometimes they seeking help from men

and give wage for their work. Apart from bamboo

flowers they use other dry leaves like areca nut

palm, sisill etc. other raw materials they buy from

Cochin market. The group didn’t get any training

for product diversification and skill up gradation yet. The unit is also a

member of ‘Kudumbashree’ (State poverty alleviation mission) and from

Kudumbashree they got 200000/- as revolving fund, 50% is subsidy.

23

Using this amount the unit shifted their work in to a rented building. Each

member earns 1000/- per month from his or her unit.

1. The unit knew that dry flower has good demand in the market, but the

poor rural women do not have enough idea about marketing

strategies.

2. They are mainly focusing exhibitions for selling their products, so they

have to spend much money as rent.

3. The total work of the unit is done manually. No other technical

intervention applied yet.

4. In the case of design and skill the unit is comparatively poor.

Bamboo Craft producers

There are more in 12 groups engaged in

production of modern bamboo craft

items. Majority of the artisans are

women. The artisans have got trained in

the production of select items with the

financial assistance of various

government programmes.

There are around 240 artisans out of which 60% work regularly. 90% of

the artisans are from Kalpetta Block area. 20 to 30% of the artisans are

multi skilled and can do a range of products

whereas the others can produce only a small

range of products. The income also varies from

Rs.40 to Rs 150/- per day depending on skill and

the product range. Marketing is done mainly

through the buy-back arrangements with Uravu Eco Links Ltd, a

marketing company promoted by Uravu.

24

Bamboo artwork

The bamboo artwork units are located in Thrikkaipetta

and Kalpetta having 8 members. The unit creates

murals and pictures on treated bamboo pieces as well

as draw pictures on other craft products for value

addition. The treated raw materials are sourced mainly

from Uravu. This unit has scope for diversification in

products, designs and methods. In addition to these some individuals

have also stated artwork in the district. The products have good demand

in the tourism market. More inputs in terms of designs and quality are

required.

Bamboo growers

There are around 100 bamboo growers in the cluster

area who grow select bamboo species, which have

commercial value. The bamboo is grown mainly in

homesteads. This activity is picking up momentum as

the demand is increasing.

Traditional bamboo artisan

There are about 25 individual families

in Kalpetta block area belonging to the

traditional craft communities. They are

producing traditional item like baskets,

winnower, etc. Majority of the

traditional artisan belongs to ‘Kavara’

community (ST), they used to sell their product directly to the customers

in the villages. The decline of paddy cultivation affects their work

adversely, because their products are mainly depending on paddy

25

cultivation and harvesting. Non-availability of raw material is major

issues, which led to the stagnation of the traditional activity.

Bamboo cutters and Suppliers

There around 15 persons who regularly supply raw bamboo for the needs

of the cluster. They collect bamboo and reeds from forest, cultivators etc.

and supply to Uravu. Where they are subjected to primary processing

(cutting to size etc) and chemical treatment. In addition to this some of

the craft units collect raw materials on their own.

Consumables and Hardware shops

The adhesive, polishing material and other consumables required by the

artisan are usually purchased from the local shops in Kalpetta or other

trading centers in the district. Specialized consumables not available in

the local market are often purchased in small quantities. Purchase of big

volumes through a common facility center would help the production units

to get good quality materials at reduced rates.

Kerala State Bamboo Corporation

Reed is also procured from the Ankamali Depot of KSBC at times when

sufficient reed is not available locally. (The corporation does not run a

depot in Wayanad or other neighboring districts). The cluster is less

depending on this source as the costs of transportation and the chances

for damage are high.

Uravu Eco Links Ltd

This is the marketing hand of Uravu. The company purchases products

from bamboo artisans/producer groups and markets through its 3 outlets

located in Wayanad and one each in Kochi, Kerala’s business capital and

Thekkadi, one of the important tourist destination in the state. The

company also participates in exhibition at local/stat/national levels and

26

has developed trade relationships in major cities/towns across the

country.

CHAPTER 4

Production Process & Value Chain Analysis

Production flowchart of Craft items

27

Procurement of pen reed from local vendors

Selection of material for

each component

Chemical treatment of RM

Cutting components to size

Design

Process flow chart of bamboo curtains

28

Assembling components

Shaping and other related work

Papering and finishing

Polishing

To Uravu Eco Link

Procurement of reed and bamboo from local

vendors/forest

Cutting to size/silvering

Colouring

Chemical treatment of RM

Weaving on the loom

Fixing attachments

Finishing

Polishing Fitting at site

Flow chart of making dry flower arrangements

29

Collection of bamboo flowers and other

material

Grading of materials

Coloring

Cleaning washing

Designing

Assembling into the pattern

Fixing attachment

Polishing

Finishing

Market

Value Chain analysis

• Primary Activities

Inbound Logistics

Sourcing of bamboo: Sourcing of the raw material that is mainly done from

three sources:

o Local suppliers

o Kerala State Bamboo Corporation

o Direct Cutting rights from forest.

The reason for maintaining these different sources for bamboo has been the

quality and the special categories of bamboo required. There is also a

significant difference between the different sources in terms of price as well

as the kind of activities involved in the process of procurement.

Local suppliers: In the case of local suppliers the materials are usually

brought to the Uravu site at Thrikkaipetta with their own conveyance and the

organization is only involved in buying the products at a price agreed over by

both the parties. The quality check and other associated activities are done

right at the site itself. So there is no additional cost involved both in the

process of procurement as well as paper work and additional manpower

involved in it.

KSBC: In the case of material procured from Kerala state Bamboo

corporation the company ha to take the complete responsibility in sending

their employees over to the auction site, making sure of the quality

requirements are met and transfer the product to the organization with their

own transportation means. In this case there is some additional cost involved

in the entire process, which involves both manpower and transportation. It is

to be noted that in spite of the quality checks done rejection rate is

comparatively higher which also increases the total cost of procurement.

30

Direct cutting rights: Here there is additional cost of negotiation with the

forest department, arranging for personnel involved in cutting the s as well

as transportation from the source (forest) to the organization is much higher

relative to the other two sources.

• Inventory management:

Raw material: Usually the raw bamboo coming from different sources, are

stored in the company facility and care is taken to prevent any fungal attack

before the treatment could begin. There is no explicit inventory policy or

system maintained through out the organization as such and is done on an

ad-hoc basis. The orders for new raw material are usually generated under

two circumstances. The orders are mostly generated keeping in mind the

demand for different products j the market. But the demand evaluation is

mostly done intuitively and there s no set rule for the same., In the case of

any bulk order, mainly for construction purposes, the order is placed with

KSBC.

In process inventory: This mainly includes the different grades of s treated

for further working as well as materials, which are being worked upon. There

is no means of tracking of materials at different stages of the production

process.

Finished goods inventory: Usually the company maintains a high amount

of finished goods inventory is usually stored either in the company owned

stores or the company facility. Finished goods inventory has been a major

problem for the organization in recent past mainly due to the fact that some

of the slow moving goods have been stored for a long time and are

susceptible to fungal attack and further degradation. Moreover there is also a

problem of locked up working up working capital. Better forecasting

technique is expected to provide some benefit in this respect.

31

• Operations:

Initial dressing: In the operations the raw bamboo coming from different

sources are dressed to remove all the unwanted materials including mud,

branches etc and are cut into required length to facilitate the next process i.e

treatment. This is a labor intensive process and done manually.

Treatment: This process is carried out to protect the materials from

degradation from fungal attack and other natural agents like moisture. This

process is done manually. But currently the company has invested in

machineries to make this process faster as well as less labour intensive. This

will help in increasing the overall capacity of the organization.

Working: The bamboos purchased from the different sources are provided in

the units for woodworking and product development.

o Model 1: In this model the processed bamboo together with the other

materials are sold to the units at a predetermined price. After the

working has been done the units are bought back by the company.

o Model 2: In this case the bamboo and other materials are provided to

the units and the final products are taken back after the unit have

been paid a price for the labour involved.

Polishing and Painting

This activity is carried out on the finished products to give them the final look

and feel. Painting requires skilled labour and is usually done only by

specialized people.

• Outbound logistics:

32

There are different means by which products are being sold by the

units.

To tourists visiting company facility: In this case there is no extra cost

involved for transportation and selling.

In exhibitions: Here cost is incurred in transportation.

From company owned Outlets: Here cost is incurred during

transportation and other overheads.

Direct selling to the local merchants/people

• Marketing and sales:

There is a separate entity, which looks into the marketing and sales of the

products. There is no specific policy regarding marketing. Advertising is

mainly carried out through exhibitions and products display at shops and

some of the local hotels.

Support Activities

Procurement: As mentioned before the procurement of the main raw

material; i.e. bamboo is carried out from three different sources. The

procurement is mainly done on an ad-hoc basis and no particular

policy is there for the same.

Enterprise Infrastructure: The Company uses some of the very

basis tools for its wood working process as well as provides some

services for the units. The company has contract with the

manufactures of the machines for the maintenance of the machines.

33

Value Chain Analysis of making

one ‘ Rain Maker’

34

Consumable ( Rs 13.50)

Transportation ( Rs 10.50)

Over head expenses like rent, maintenance etc (Rs50.50)

Treatment (Rs.10.00)

Transportation charge (Rs 51.00)

Damage (10%) Rs 69.85)

Labor (Rs 48.50)

Painting (Rs 54.50)Papering & Polishing (Rs 59.00)

Packing and storage charge (Rs 63.50)

2 ½ F bamboo (Rs 7.50)

Rs 70/-

CHAPTER 6

ANALYSIS OF BUSINESS OPERATION

There are more than 500 producers who make bamboo products through

SHG/producers group. Among them the traditional bamboo workers are

unorganized. They are producing the products their own way and selling

those items in village level. The producers belong to poor, marginalized

families, more than 80% are women About 75% of the producer group have

made contracts with Uravu and Uravu Eco link Ltd for the supply of raw

material and buy back the products as well as participating in the exhibition

and direct marketing.

Product Range

The cluster actors are making variety of products. Some of them have

demand in the market and some others are yet to be market tested/modified

to the market preferences.

The important products are as follows.

1. Woven lamp shades

2. Carved lamp shades

3. Script O pen

4. Mobile phone Holders

5. Baskets

6. Bamboo curtains

7. Bamboo art work

8. Bamboo bags

9. Bamboo & dry flower products

10. Bamboo shoot pickles etc.

35

Availability of raw materials.

The raw materials are collected mainly from local farmers, wastelands

etc. More than 100 grow bamboo suitable for commercial applications.

The bamboo collectors include people belonging to traditional

communities. As part of this program a bamboo cultivator’s forum

should be formed that forum will ensure the sustainability of raw

material. The primary processing- chemical treatment against attack of

borer and fungi, cutting to size etc. are done at Uravu before supplying

to the units.

Availability of infrastructure

Machinery and tools are the major requirements to facilitate

production of quality products. Introduction of mechanization would

improve both output and quality needs. At present units have some

minor tools, which is not sufficient for making quality products. The

NGO Uravu has a mini machine room; a few artisans can use these

machines.

Existing technology and need for skill up gradation

The technology interventions in the bamboo sector have been minimal

at all level. Even at Bamboo Corporation no significant change has

happened as regarding the scientific extraction, processing and

product diversification of bamboos. Today, access to the latest

technologies, designs and products are available and what is required

is the vision to integrate the activities to the set goal.

The quality of the product is a challenge the rural units will have to

overcome. In the agrarian economies like Wayanad to orient the

artisans to adopt such levels will be a tedious task. Awareness building

by letting the artisans interacts with the customers during exhibitions,

site visits, discussions etc will have to be undertaken to achieve the

above results. A regular center catering to such requirements will be

an essential part of the cluster that can be developed in Wayanad.

36

Scope of collective effort

In the current market, bamboo products have a wider demand. But these groups

cannot know its current possibilities. Through the formation cluster consortia they

can be unified under one control and bring up their skills and social awareness.

Through this, they can be made aware of the current possibilities in the market and

as a result they will be able to make products according to the taste of the

customers. In addition, by forming them as an approved consortium they can gain

governmental schemes and grow further in the competitive market.

Scope for Diversification

Bamboo is said to have more than 1500 applications including high value

industrial products. Presently the cluster products are restricted mainly to

crafts, which forms a small part of the bamboo market. The other

activities such as production of bamboo curtains, bags, dry flowers, shoot

products etc had started only recently. All these activities have ample

scope for development as well as diversification. Apart from these, there

is scope for starting units in the following products in the cluster area.

1. Mechanized incense stick making

2. Agarbathies with bamboo sticks

3. Match sticks

4. Bamboo blinds based products

5. Bamboo charcol

6. Bamboo furniture etc

Marketing

Uravu Eco links Ltd is the main agency involved in marketing the products

of the cluster. The company has a relatively good network with 5 eco

shops and trade relations with a number of retailers in different states.

After the preliminary discussion with company management, they are

agreed to give majority of its share to bamboo producers. So that there is

no need for establish a parallel marketing system in the cluster. The

company is enough to strengthening the marketing capacity of the

cluster.

37

CHAPTER 6

SWOC Analysis

Production Market Financial

Strength

• Eco-friendly, Biodegradable and medicinal value of the Raw material.

• Assistance from NABARD.• Cluster actors are

geographically placed together.

• Organized women force available under the SHGs

• Traditional and skilled labour

• Upliftment of women of the marginalized group

• Alternative to Plastic.

• Market potential through product diversification innovation and new applications.

• Increasing demand for eco friendly bamboo products

Status of Wayanad district as a tourism destination.

Chance for export

Existence of Bankers and developmental financial institution in the cluster area.

Weakness

KSBC not operational in the district. The nearest KSBC depot located at Nilambur in Malappuram District.

No standard pricing for the products.

Poor production management techniques exist.

Lack of institutional linkages.

Productive skill levels not comparable with artisans of other regions in the craft sectors.

Absence of effective market research

Pricing to be standardized

No presence in possible market segments such as corporate,exports etc. Which would help to gain more returns.

Priority of financial institutes for bamboo sector not existing.

Lack of awareness about available financial supports.

Opportunity

To ensure resource availability, bamboos can be cultivated in forest lands, farmlands river and stream banks etc utilizing the scheme under PFM, Environment protection and waste land development programs of the state and Central govt agencies.

Commons show room at prime location to provide marketing support.

Trade fair participation to explore new markets.

Provocative approach of bankers for extending micro credits to SHGs

Availability of finance under Cluster Development market.

38

Scope for technology up gradation to develop innovative products

Setting up research centre to explore new application of bamboo as building material.

With eco friendliness becoming major concern for global customers, bamboo products hold tremendous market potential.

The market

potential of the tourism sector in Wayanad can be effectively tapped.

Modern technologies like E-marketing can be introduced

Challenges Non-Application of technology may affect sustainability.

Non-implementation of effective management system to improve business performance

Absence of private, public partnership to promote R & D for value added products to explore new markets.

Regulated selling and transportation

Migration of artisan to tertiary sector like construction.

Labour oriented since the sector is in its nascent state.

Inefficient linkages of the production-consumption chain of the cluster.

Cheaper and competing products in plastic etc

Market competition from other parts of the country

Competition from China in export market.

Low or nil margins for artisans may effect substantially.

Non provocative bankers may not support sufficient working capital for units

39

CHAPTER 7

PRESENT, POST CLUSTER MAP AND INSITUITONAL MATRIX

SBT SBI CBI Co-op Banks

BAMBOO CRAFT UNIT (9 nos)

BAMBOO SHOOT PROCESSING UNIT

BAMBOO CURTAIN & WEAVING UNIT

BAMBOO BAG UNIT

DRY FLOWER UNIT

TRADITIONAL ARTISAN

Bamboo

Procurement agentBamboo harvestersBamboo farmers

METAL FABRICATORS

BAMBOO TREATMENT

UNIT

BAMBOO SHOOT COLLECTORS

LOCAL MERCHANTSDIRECT SALE

URAVU ECO LINK

EXHIBITIONS

Retail outletsBulk Buyers

Kudumashree KVIB

CHAPTER 8

Vision of the Cluster

The Kalpetta Bamboo Cluster will establish a

niche market at both domestic and

international levels by the year 2011. The

producer groups will be equipped to become

100% competitive and self reliant through skill

up-gradation, cost reduction through common

purchase, product diversification and export

marketing.

CHAPTER 9

Suggestions and Action Plan

I. Social interventions

STRENGTHENING OF SELF HELP GROUPS (SHGs)

Even though the artisans are working as group basis but this group are

not formally registered as Self Help Group. For getting other

departmental benefit to this group it is essential to form these groups

as SHG. A total of 20 SHGs shall be formed/strengthen as part of this

project. Each group shall have 20 members.

II. Technological interventions

SKILL UPGRADATION TRAINING:

Compare to products from other states and countries the artisans’ level of

skill at present is very poor for making products. This has to be improved

and upgraded through a series of skill up gradation Programmes. Each

training shall be for a period of 2 months. A total of 400 artisans can undergo

skill training as part of this project. Skill up gradation Programmes shall

include:

Splicing: Easy and convenient methods of splicing and reeds using very

simple tools.

Weaving: Different methods of weaving curtains with most modern loom,

especially power loom.

Blending: Blending bamboo with other natural fiber is something, which has

not been attempted so far. (Eg: blending bamboo with jute and cane ) This

is having great scope and it has to be developed in an intensive manner.

Dyeing: Special care and expertise is needed for using dyes, especially

vegetable dyes on natural fiber. There is a special Research and

Development team functioning in Uravu for this purpose. But this team needs

to be strengthened with adequate support.

2

Packing: Utmost care and efficiency is necessary for safe and attractive

packing of the products made by the artisans. The artisans need to be

trained in this regard.

(b) DESIGN DEVELOPMENT WORKSHOPS:

Design development is a very important aspect for developing new and value

added products. Special care shall be taken for designing new products

which can be conveniently used as alternatives for some of the plastic

products. Empanelled designers of the Government of India or alumni of the

National Institute of Design shall be the resource persons for the same. Each

design development workshop s hall be for a duration of 15 days.

(c) Dye workshops

In addition to produce the products in various designs, it is needed to

send these products into the markets in various colours. To give color on is

some what hard. For this natural and chemical dyes can be used. But

artisans do not know how to give this colour. So as a part of the training they

should be taught how to give colour to blintz. Two months training will be

given to selected 5 members from each batch ie total 100 members. After

the training, they will impart training to other members of the batch.

(d) Leadership Training

A strong leadership is needed for a micro enterprise to have a constant

growth. For the artisans who lack leadership qualities, cluster approach will

help in bring out some people who have leadership skills. The people who are

having leadership qualities shall be identified through group approach and

provided leadership-training classes. Three-day workshops for 60 identified

artisans from 20 such groups are required.

3

III. Infrastructural related interventions.

(a) TRAINING CENTRE (On rental Basis)

At present the artisan working together as group basis in rented

building. These buildings are not available for long-term work.

So it is suggested that to build a common working shed for each

group is necessary. And a training center shall be hired for

conducting skill up-gradation training. One portion of the same

can be used for conducting Design Development Workshops.

This training center shall be at least 3000 sq. ft. and it can be

taken for rent throughout the duration of the project (five year)

After completing the skill up-gradation training, the artisans

shall produce the products at their own respective work shed.

The artisans can conveniently do this, as all of them will be

supplied with tool kits during the training.

(b)Common facility Centre (C F C)

Towards the end of the project the SHG federation shall

have a common facility centre of its own to pursue the activity

on a commercial and sustainable basis. The feasibility of

construction a CFC under SFURTI with land provided by the

Panchayath/district Panchayath/PWD to be explored.

IV. Financial interventions

The SHGs formed with artisans will be linked to State Bank of

India, respective branches to meet the credit requirement of the

artisans. The bank will be associated from the initial stage itself.

Similarly, the Lead Bank of Kalpetta branch (Canara Bank) also

expected to associated for credit needs of the artisans.

4

V. Marketing interventions

(a). EXHIBITIONS:

Exhibitions are a must for the proper marketing as well as dissemination of

the possibility of making and using bamboo products. This is utmost

necessary for exploring the local and domestic markets. Such exhibition of

the products made by the artisans shall be conducted twice in every year for

duration of 15 days as part of this project in a prominent city of India.

(b) MARKET SURETY FOR THE PRODUCTS

Some value added products have already undergone test marketing and

proved to be of great demand in domestic market. There is no doubt that

these products will fetch good prices. Uravu has facilitated the existing

cluster artisans for conducting several exhibitions/melas of their products

and found that these products facing threat from North East products. This

eco-friendly alternative for plastic has great potential all over the world.

Uravu shall always provide its already developed marketing network (Uravu

eco link Ltd) for the artisans of this project.

( c ) Website hosting

Towards the end of the project the federation of artisans shall have

their own website for promotion and marketing of the products for

which all support will be extended by Uravu.

VI . Other interventions.

(a) ENSURING THE SUSTAINABLE SUPPLY OF BAMBOO AS A RAW

MATERIAL.

Encouraging the local people for massive planting of bamboo along the

borders of inland water bodies, wet lands is must for the constant supply of

raw material. A few plantations also have to be developed as insurance for

the constant supply of bamboo. People in the area should be encouraged for

planting in their own compound. It is legitimate to expect that people will be

5

happy to do the same as one bamboo stem (30-40 feet) costs around Rs.

120/-, which can be an income generation activity without any establishment

cost.

The stem can be cut once in every year. Large scale planting of bamboo will

be an additional advantage in ensuring the sustainable supply of the raw

material, for which commercial plantation of the crop by entrepreneurs /

NGOs is to be promoted.

(b) Documentation and video presentation

Documentation of programme of the cluster every year as well as

video presentation of the interventions like skill up gradation, design

development workshop ,new products developed as well as success story of

the artisans is suggested for motivating others and promoting market for the

products.

(c) Introduction of appliance

At present majority of the units engaged in the craft manually

especially for weaving and splicing etc. So their productivity is comparatively

low. It is noticed that the new electrical device should improve both the

quality and the productivity of the unit. A few most modern machines should

be purchase as part of this programme.

(D) Raw material stock yard/ Smoke house: One of the major problem

facing the units is lack of raw material storage facility. During rainy season it

is very difficult to dry the raw material. To overcome this problem a raw

material store and smoke house is necessary.

(E) Exposure visit:

Majority of the units are not aware or they are doubtful of the cluster

development programme, an exposure visit to other cluster should increase

the confidence level of the artisan.

6

![mohana uravu[1]](https://static.fdocuments.in/doc/165x107/577d296b1a28ab4e1ea6ba92/mohana-uravu1.jpg)