Uputstvo Za Pumpu

-

Upload

ivana-rajic -

Category

Documents

-

view

261 -

download

0

description

Transcript of Uputstvo Za Pumpu

-

00X31YG36100 2011 Honda Motor Co., Ltd.All Rights Reserved

Owner s ManualPUMP

WB20XT/WB30XT

POM31V20611 FRC800 Cover.ai 11/2/2011 11:12:53 AM

-

Keep this owners manual handy so you can refer to it at any time.This owners manual is considered a permanent part of the waterpump and should remain with the water pump if resold.

The information and specifications included in this publication were ineffect at the time of approval for printing. Honda Motor Co., Ltd.reserves the right, however, to discontinue or change specifications ordesign at any time without notice and without incurring any obligationwhatever. No part of this publication may be reproduced withoutwritten permission.

The engine exhaust from this productcontains chemicals known to the State

of California to cause cancer, birthdefects or other reproductive harm.

11/08/01 15:03:19 31YG3610_001

-

1INTRODUCTION

Congratulations on your selection of a Honda water pump. We arecertain you will be pleased with your purchase of one of the finestwater pumps on the market.

We want to help you get the best results from your new water pumpand to operate it safely. This manual contains the information on howto do that; please read it carefully.

As you read this manual, you will find information preceded by asymbol. That information is intended to help you avoid

damage to your water pump, other property, or the environment.

We suggest you read the warranty policy to fully understand itscoverage and your responsibilities of ownership. The warranty policyis a separate document that should have been given to you by yourdealer.

When your water pump needs scheduled maintenance, keep in mindthat your Honda servicing dealer is specially trained in servicingHonda water pumps. Your Honda servicing dealer is dedicated to yoursatisfaction and will be pleased to answer your questions andconcerns.

Best Wishes,Honda Motor Co., Ltd.

11/08/01 15:03:26 31YG3610_002

-

2INTRODUCTION

A FEW WORDS ABOUT SAFETY

Safety Labels

Safety Messages

Safety Headings

Safety Section

Instructions

Your safety and the safety of others are very important. And using thiswater pump safely is an important responsibility.

To help you make informed decisions about safety, we have providedoperating procedures and other information on labels and in thismanual. This information alerts you to potential hazards that couldhurt you or others.

Of course, it is not practical or possible to warn you about all thehazards associated with operating or maintaining a water pump. Youmust use your own good judgment.

You will find important safety information in a variety of forms,including:

on the pump.

preceded by a safety alert symbol and oneof three signal words, DANGER, WARNING, or CAUTION.

These signal words mean:

You WILL be KILLED or SERIOUSLY HURT ifyou dont follow instructions.

You CAN be KILLED or SERIOUSLY HURT ifyou dont follow instructions.

such as IMPORTANT SAFETY INFORMATION.

such as PUMP SAFETY.

how to use this pump correctly and safely.

This entire book is filled with important safety information pleaseread it carefully.

You CAN be HURT if you dont followinstructions.

11/08/01 15:03:38 31YG3610_003

-

3CONTENTS

..........................................................................................PUMP SAFETY . 5

................................................................................................CONTROLS . 8

.............................................................................BEFORE OPERATION . 13

............................................................................................OPERATION . 16

.......................................................................SERVICING YOUR PUMP . 26

................................................IMPORTANT SAFETY INFORMATION . 5................................................................SAFETY LABEL LOCATIONS . 7

............................................COMPONENT & CONTROL LOCATIONS . 8..........................................................................................CONTROLS . 10

..............................................................................Fuel Valve Lever . 10.................................................................................Ignition Switch . 10

.....................................................................................Choke Lever . 11..................................................................................Throttle Lever . 11

...........................................................................Recoil Starter Grip . 12

...............................................ARE YOU READY TO GET STARTED? . 13........................................................IS YOUR PUMP READY TO GO? . 14

....................................Check the General Condition of the Pump . 14.......................................Check the Suction and Discharge Hoses . 15

.............................................................................Check the Engine . 15

...................................................SAFE OPERATING PRECAUTIONS . 16............................................................................PUMP PLACEMENT . 17

.......................................................SUCTION HOSE INSTALLATION . 18..................................................DISCHARGE HOSE INSTALLATION . 19

...........................................................................PRIMING THE PUMP . 20....................................................................STARTING THE ENGINE . 21...................................................................SETTING ENGINE SPEED . 23....................................................................STOPPING THE ENGINE . 24

............................................THE IMPORTANCE OF MAINTENANCE . 26....................................................................MAINTENANCE SAFETY . 27

..............................................................MAINTENANCE SCHEDULE . 28..........................................................................................REFUELING . 29

.............................................................FUEL RECOMMENDATIONS . 30................................................................ENGINE OIL LEVEL CHECK . 31

.........................................................................ENGINE OIL CHANGE . 32....................................................ENGINE OIL RECOMMENDATION . 33

11/08/01 15:03:42 31YG3610_004

-

4CONTENTS

SERVICING YOUR PUMP (continued)

................................................................................................STORAGE . 40

.....................................................................................TRANSPORTING . 46

.....................................TAKING CARE OF UNEXPECTED PROBLEMS . 47

..................................................................TECHNICAL INFORMATION . 49

.................................................................CONSUMER INFORMATION . 58

...........................QUICK REFERENCE INFORMATION . Inside back cover

....................................................................AIR FILTER INSPECTION . 34.......................................................................AIR FILTER CLEANING . 35

...............................................................SEDIMENT CUP CLEANING . 36.......................................................................SPARK PLUG SERVICE . 37

.........................SPARK ARRESTER SERVICE (optional equipment) . 39

..................................................................STORAGE PREPARATION . 40...........................................................................................Cleaning . 40

...................................................................................................Fuel . 41.........................................................................................Engine Oil . 44

.................................................................STORAGE PRECAUTIONS . 44..............................................................REMOVAL FROM STORAGE . 45

................................................................................................ENGINE . 47......................................................................Engine Will Not Start . 47

........................................................................Engine Lacks Power . 47...................................................................................................PUMP . 48

.............................................................................No Pump Output . 48...........................................................................Low Pump Output . 48

..................................................................Serial Number Location . 49..................Carburetor Modification for High Altitude Operation . 50

..........................................Emission Control System Information . 51...........................................................................................Air Index . 53

..................................................................................Specifications . 54

..................................................DEALER LOCATOR INFORMATION . 58.......................................................................Honda PUBLICATIONS . 58

.......................................................Customer Service Information . 59

11/08/01 16:11:30 31YG3610_005

-

5IMPORTANT SAFETY INFORMATION

Refuel With Care

Pump Operation

Operator Responsibility

PUMP SAFETY

Honda WB20XT and WB30XT pumps are designed to pump only waterthat is not intended for human consumption, and other uses can resultin injury to the operator or damage to the pump and other property.

Most injuries or property damage can be prevented if you follow allinstructions in this manual and on the pump. The most commonhazards are discussed below, along with the best way to protectyourself and others.

Gasoline is extremely flammable, and gasoline vapor can explode.Refuel outdoors, in a well-ventilated area, with the engine stopped andthe pump on a level surface. Do not fill the fuel tank above the fuelstrainer shoulder. Never smoke near gasoline, and keep other flamesand sparks away. Always store gasoline in an approved container.Make sure that any spilled fuel has been wiped up before starting theengine.

Pump only water that is not intended for human consumption.Pumping flammable liquids, such as gasoline or fuel oils, can result ina fire or explosion, causing serious injury. Pumping sea water,beverages, acids, chemical solutions, or any other liquid thatpromotes corrosion can damage the pump.

Be sure that anyone who operates the pump receives properinstruction. Do not let children operate the pump. Keep children andpets away from the area of operation.

It is the operators responsibility to provide the necessary safeguardsto protect people and property. Know how to stop the pump quickly incase of emergency. If you leave the pump for any reason, always turnthe engine off. Understand the use of all controls and connections.

11/08/01 15:03:56 31YG3610_006

-

6PUMP SAFETY

Hot Exhaust

Carbon Monoxide Hazard

The muffler becomes very hot during operation and remains hot for awhile after stopping the engine. Be careful not to touch the mufflerwhile it is hot. Let the engine cool before transporting the pump orstoring it indoors.

To prevent fire hazards, keep the pump at least 3 feet (1 meter) awayfrom building walls and other equipment during operation. Do notplace flammable objects close to the engine.

Exhaust contains poisonous carbon monoxide, a colorless andodorless gas. Breathing carbon monoxide can cause loss ofconsciousness and may lead to death.

If you run the pump in an area that is confined, or even partly enclosed,the air you breathe could contain a dangerous amount of exhaust gas.

Never run the engine inside a closed garage, house, or confined area.

11/08/01 15:04:03 31YG3610_007

-

7PUMP SAFETY

SAFETY LABEL LOCATIONS

The labels shown here contain important safety information. Pleaseread them carefully. These labels are considered permanent parts ofyour pump. If a label comes off or becomes hard to read, contact anauthorized Honda servicing dealer for a replacement.

11/08/01 15:04:21 31YG3610_008

-

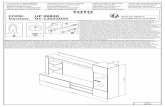

8

COMPONENT & CONTROL LOCATIONS

WB20XT

CONTROLS

THROTTLE LEVER

IGNITION SWITCH

SUCTION PORT

OIL DRAIN PLUG

DISCHARGE PORT

MUFFLER

PUMP DRAIN CAP

FUEL FILLER CAPCHOKELEVER

OIL FILLERCAP/DIPSTICK

STRAINER

PRIMING WATERFILLER CAP

AIR CLEANER

FRAME

FUEL VALVELEVER

RECOIL STARTER GRIP

11/08/01 15:04:29 31YG3610_009

-

9

CONTROLS

THROTTLE LEVER

IGNITION SWITCH

SUCTION PORT

OIL DRAIN PLUG

DISCHARGE PORT

MUFFLER

PUMP DRAIN CAP

FUEL FILLER CAPCHOKELEVER

OIL FILLERCAP/DIPSTICK

STRAINER

PRIMING WATERFILLER CAP

AIR CLEANER

FRAME

FUEL VALVELEVER

RECOIL STARTER GRIP

WB30XT

11/08/01 15:04:35 31YG3610_010

-

10

CONTROLS

CONTROLS

Fuel Valve Lever

Ignition Switch

FUEL VALVE LEVER

OFF

ON

ON

IGNITION SWITCH

OOFFFF

The fuel valve lever must be in theON position for the engine to run.

When the engine is not in use,leave the fuel valve lever in theO F F p o s i t i o n t o p r e v e n tcarburetor flooding and to reducethe possibility of fuel leakage.

The ignition switch controls theignition system.

The ignition switch must be in theON position for the engine to run.

Turning the ignition switch to theOFF position stops the engine.

The fuel valve opens and closesthe passage between the fuel tankand the carburetor.

11/08/01 15:04:46 31YG3610_011

-

11

CONTROLS

Choke Lever

Throttle Lever

OPEN

CHOKE LEVER

FAST

THROTTLE LEVER

CCLLOOSSEEDD

SLOW

The choke lever opens and closesthe choke valve in the carburetor.

The CLOSED position enrichesthe fuel mixture for starting a coldengine.

The OPEN position provides thecorrect fuel mixture for operationafter starting, and for restarting awarm engine.

The throttle lever controls enginespeed.

Moving the throttle lever in thedirections shown makes theengine run faster or slower.

Pump output is controlled byadjusting the throttle lever. Atmaximum throttle position, thepump will deliver the highestoutput volume. Moving thethrottle lever toward the idleposition will decrease the outputvolume of the pump.

11/08/01 15:04:56 31YG3610_012

-

12

CONTROLS

Recoil Starter Grip

RECOIL STARTER GRIP

Pulling the recoil starter grip operates the recoil starter to crank theengine.

11/08/01 15:05:01 31YG3610_013

-

13

BEFORE OPERATION

ARE YOU READY TO GET STARTED?

Knowledge

Your safety is your responsibility. A little time spent in preparation willsignificantly reduce your risk of injury.

Read and understand this manual. Know what the controls do andhow to operate them.

Familiarize yourself with the pump and its operation before you beginpumping. Know what to do in case of emergencies.

Be sure of what you are pumping. This pump is designed to pumponly fresh water that is not intended for human consumption.

11/08/01 15:05:08 31YG3610_014

-

14

BEFORE OPERATION

IS YOUR PUMP READY TO GO?

Check the General Condition of the Pump

For your safety, and to maximize the service life of your equipment, itis very important to take a few moments before you operate the pumpto check its condition. Be sure to take care of any problem you find, orhave your servicing dealer correct it, before you operate the pump.

Improperly maintaining this pump,or failing to correct a problembefore operation, could cause amalfunction in which you could beseriously injured.

Always perform a preoperationinspection before each operation,and correct any problem.

To prevent a possible fire, keep the pump at least 3 feet (1 meter) awayfrom building walls and other equipment during operation. Do notplace flammable objects close to the engine.

Before beginning your preoperation checks, be sure the pump is on alevel surface and the ignition switch is in the OFF position.

Look around and underneath the pump for signs of oil or gasolineleaks.

Remove any excessive dirt or debris, especially around the enginemuffler and recoil starter.

Look for signs of damage.

Check that all nuts, bolts, screws, hose connectors and clamps aretightened.

11/08/01 15:05:17 31YG3610_015

-

15

BEFORE OPERATION

Check the Suction and Discharge Hoses

Check the Engine

Check the general condition of the hoses. Be sure the hoses are inserviceable condition before connecting them to the pump.Remember that the suction hose must be reinforced construction toprevent hose collapse.

Check that the sealing washer in the suction hose connector is ingood condition (see page ).

Check that the hose connectors and clamps are securely installed(see pages and ).

Check that the strainer is in good condition and is installed on thesuction hose (see page ).

Check the engine oil level (see page ). Running the engine with alow oil level can cause engine damage.

Check the air filter (see page ). A dirty air filter will restrict air flowto the carburetor, reducing engine and pump performance.

Check the fuel level (see page ). Starting with a full tank will helpto eliminate or reduce operating interruptions for refueling.

18

18

18

19

31

34

29

11/08/01 15:05:27 31YG3610_016

-

16

OPERATION

SAFE OPERATING PRECAUTIONS

To safely realize the full potential of this pump, you need a completeunderstanding of its operation and a certain amount of practice withits controls.

Before operating the pump for the first time, please review theIMPORTANT SAFETY INFORMATION on page and the chapter titledBEFORE OPERATION.

For your safety, avoid starting or operating the engine in an enclosedarea, such as a garage. Your engines exhaust contains poisonouscarbon monoxide gas that can collect rapidly in an enclosed area andcause illness or death.

Pump only fresh water that is not intended for human consumption.Pumping flammable liquids, such as gasoline or fuel oils, can result ina fire or explosion, causing serious injury. Pumping sea water,beverages, acids, chemical solutions, or any other liquid thatpromotes corrosion can damage the pump.

Exhaust contains poisonous carbonmonoxide gas that can build up todangerous levels in closed areas.Breathing carbon monoxide cancause unconsciousness or death.

Never run the engine in a closed, oreven partly closed area wherepeople may be present.

5

11/08/01 15:05:35 31YG3610_017

-

17

OPERATION

PUMP PLACEMENT

DISCHARGEHEAD

TTOOTTAALL HHEEAADD

SUCTION HEADLESS THAN26 feet (8 meters)

For best pump performance, place the pump near the water level, anduse hoses that are no longer than necessary. That will enable thepump to produce the greatest output with the least self-priming time.

As head (pumping height) increases, pump output decreases. Thelength, type, and size of the suction and discharge hoses can alsosignificantly affect pump output.

Discharge head capability is always greater than suction headcapability, so it is important for suction head to be the shorter part oftotal head. The maximum available suction head will vary based onthe operating conditions. However, the suction head can never exceed26 feet (8 meters) and should always be kept as low as possible.

Minimizing suction head (placing the pump near the water level) isalso very important for reducing self-priming time. Self-priming timeis the time it takes the pump to bring water the distance of the suctionhead during initial operation.

11/08/01 15:05:42 31YG3610_018

-

18

OPERATION

SUCTION HOSE INSTALLATION

SUCTION HOSE

HOSE COUPLER

HOSE CLAMP

SUCTION HOSE

SUCTION PORT SSEEAALLIINNGG WWAASSHHEERR

HOSE CLAMP RING

HOSE CLAMP

HOSE CONNECTOR(commercially available)

HOSE CLAMPSTRAINER

HOSE CONNECTOR(commercially available)

Use a commercially available hose and hose connector with the hoseclamp provided with the pump (if necessary). Most hoses come withthe connectors already installed. The suction hose must be reinforcedwith a noncollapsible wall or braided wire construction and cannotcontain any perforations.

Do not use a hose smaller than the pumps suction port size.

The suction hose should be no longer than necessary. Pumpperformance is best when the pump is near the water level and thehoses are short.

Use a hose clamp to securely fasten the hose connector to the suctionhose in order to prevent air leakage and loss of suction. Verify that thehose connector sealing washer is in good condition.

Install the strainer (provided with the pump) on the other end of thesuction hose, and secure it with a hose clamp. The strainer will help toprevent the pump from becoming clogged or damaged by debris.

Never operate the pump without the strainer installed.

Securely tighten the hose connector on the pump suction port.

Minimum hose size: WB20XT=WB30XT=

2 in (50 mm)3 in (80 mm)

11/08/01 15:05:53 31YG3610_019

-

19

OPERATION

DISCHARGE HOSE INSTALLATION

DISCHARGE HOSE

HOSE CONNECTOR

HOSE CLAMP

It is best to use a short, large-diameter hose, because that will reducefluid friction and improve pump output. A long or small-diameter hosewill increase fluid friction and reduce pump output.

Tighten the hose clamp securely to prevent the discharge hose fromdisconnecting under pressure.

Use a commercially available hose and hose connector and clampprovided with the pump (if necessary).

11/08/01 15:05:59 31YG3610_020

-

20

OPERATION

PRIMING THE PUMP

PRIMING WATER FILLER CAP

BOARDS

DISCHARGE HOSE

Before starting the engine, remove the filler cap from the pumpchamber, and completely fill the pump chamber with water. Reinstallthe filler cap and tighten it securely.

Operating the pump dry will destroy the pump seal. If the pump hasbeen operated dry, stop the engine immediately, and allow the pumpto cool before priming.

Driving over a discharge hose while the pump is running, or evenpossibly when the pump is stopped, may cause pump case failure.

If the discharge hose must run across a roadway, the hose shouldcross the roadway perpendicular to traffic flow. Also, heavy boardsshould be placed next to the hose so the motor vehicle weight doesnot shut off the discharge as vehicles cross over the hose.

11/08/01 15:06:07 31YG3610_021

-

21

OPERATION

STARTING THE ENGINE

FFUUEELL VVAALLVVEE LLEEVVEERR

ON

CHOKE LEVER

CLOSED

THROTTLE LEVER

SSLLOOWW

Move the throttle lever away from the SLOW position about 1/3 ofthe way toward the FAST position.

To restart a warm engine, leave the choke lever in the OPEN position.

To start a cold engine, move the choke lever to the CLOSED position.

Move the fuel valve lever to the ON position.

Prime the pump (see page ).1.

2.

3.

4.

20

11/08/01 15:06:17 31YG3610_022

-

22

OPERATION

ON

IGNITION SWITCH

RECOIL STARTER GRIP

Turn the ignition switch to the ON position.

Pull the recoil starter grip lightly until you fill resistance, and thenpull briskly.

Do not allow the recoil starter grip to snap back against the engine.Return it gently to prevent damage to the starter.

5.

6.

11/08/01 15:06:24 31YG3610_023

-

23

OPERATION

SETTING ENGINE SPEED

OPEN

CHOKE LEVER

FAST

SLOW

THROTTLE LEVER

If the choke lever was moved to the CLOSED position to start theengine, gradually move it to the OPEN position as the engine warmsup.

After starting the engine, move the throttle lever to the FAST positionfor self-priming, and check pump output.

Pump output is controlled by adjusting engine speed. Moving thethrottle lever in the FAST direction will increase pump output, andmoving the throttle lever in the SLOW direction will decrease pumpoutput.

7.

11/08/01 15:06:31 31YG3610_024

-

24

OPERATION

STOPPING THE ENGINE

THROTTLE LEVER

SLOW

IGNITION SWITCH

OOFFFF

To stop the engine in an emergency, simply turn the ignition switch tothe OFF position. Under normal conditions, use the followingprocedure.

Move the throttle lever to the SLOW position.

Turn the ignition switch to the OFF position.

1.

2.

11/08/01 15:06:39 31YG3610_025

-

25

OPERATION

FUEL VALVE LEVER

OFF

Turn the fuel valve lever to the OFF position.

After use, remove the pump drain plug (see page ), and drain thepump chamber. Remove the filler cap, and flush the pump chamberwith clean, fresh water. Allow the water to drain from the pumpchamber, and then reinstall the filler cap and drain plug.

3.

41

11/08/01 15:06:45 31YG3610_026

-

26

SERVICING YOUR PUMP

THE IMPORTANCE OF MAINTENANCE

Maintenance, replacement, or repair of emission control devices andsystems may be performed by any engine repair establishment orindividual, using parts that are certified to EPA standards.

Good maintenance is essential for safe, economical, and trouble-freeoperation. It will also help reduce air pollution.

Improperly maintaining this pump,or failure to correct a problembefore operation, can cause amalfunction in which you can beseriously hurt or killed.

Always follow the inspection andmaintenance recommendations andschedules in this owners manual.

To help you properly care for your pump, the following pages includea maintenance schedule, routine inspection procedures, and simplemaintenance procedures using basic hand tools. Other service tasksthat are more difficult, or require special tools, are best handled byprofessionals and are normally performed by a Honda technician orother qualified mechanic.

The maintenance schedule applies to normal operating conditions. Ifyou operate your pump under severe conditions, such as sustainedhigh-load or high-temperature operation, or use in unusually wet ordusty conditions, consult your servicing dealer for recommendationsapplicable to your individual needs and use.

Remember that your servicing dealer knows your pump best and isfully equipped to maintain and repair it.

To ensure the best quality and reliability, use only new, HondaGenuine parts or their equivalents for repair and replacement.

11/08/01 15:06:54 31YG3610_027

-

27

SERVICING YOUR PUMP

MAINTENANCE SAFETY

Safety Precautions

Carbon monoxide poisoning from engine exhaust.

Burns from hot parts.

Injury from moving parts.

Some of the most important safety precautions follow. However, wecannot warn you of every conceivable hazard that can arise inperforming maintenance. Only you can decide whether or not youshould perform a given task.

Failure to properly followmaintenance instructions andprecautions can cause you to beseriously hurt or killed.

Always follow the procedures andprecautions in the owners manual.

Make sure the engine is off before you begin any maintenance orrepairs. This will eliminate several potential hazards:

Be sure there is adequate ventilation whenever you operate theengine.

Let the engine and exhaust system cool before touching.

Do not run the engine unless instructed to do so.

Read the instructions before you begin, and make sure you have thetools and skills required.

To reduce the possibility of fire or explosion, be careful whenworking around gasoline. Use only a nonflammable solvent, notgasoline, to clean parts. Keep cigarettes, sparks, and flames awayfrom all fuel-related parts.

11/08/01 15:07:01 31YG3610_028

-

28

SERVICING YOUR PUMP

MAINTENANCE SCHEDULE

ITEMREGULAR SERVICE PERIOD (3)

Perform at every indicatedmonth or operating hourinterval, whichever comes first.Engine oil

Air cleaner

Spark plug

Spark arrester(applicable types)Sediment cupIdle speedValve clearanceCombustionchamberFuel tank and filterFuel tubeImpellerImpeller clearancePump inlet valve

Check levelChangeCheckCleanCheck-AdjustReplaceClean

CleanCheck-AdjustCheck-AdjustClean

CleanCheckCheckCheckCheck

Every 2 years (Replace if necessary) (2)

Eachuse

(1)

After every 500 hrs. (2)

(2)

(2)(2)

(2)(2)(2)

For commercial use, log hours of operation to determine propermaintenance intervals.

Failure to follow this maintenance schedule could result in non-warrantablefailures.

These items should be serviced by your Honda servicing dealer, unlessyou have the proper tools and are mechanically proficient. Refer to theHonda shop manual for service procedures.

Service more frequently when used in dusty areas.(2)(1)

(3)

Firstmonth

or20 hrs.

Every3 months

or50 hrs.

Every6 months

or100 hrs.

Everyyearor

300 hrs.

11/08/01 15:07:12 31YG3610_029

-

29

SERVICING YOUR PUMP

REFUELING

MAXIMUM FUEL LEVEL

FUEL TANK TOP

1 inch(25 mm)

With the engine stopped and on a level surface, remove the fuel tankcap and check the fuel level. Refill the tank if the fuel level is low.

Gasoline is highly flammable andexplosive.

You can be burned or seriouslyinjured when handling fuel.

Stop the engine and keep heat,sparks, and flame away.

Wipe up spills immediately.Handle fuel only outdoors.

Refuel in a well-ventilated area before starting the engine. If the enginehas been running, allow it to cool. Refuel carefully to avoid spilling fuel.Do not fill the fuel tank completely. Fill tank to approximately 1 inch(25 mm) below the top of the fuel tank to allow for fuel expansion. Ifmay be necessary to lower the fuel level depending on operatingconditions.After refueling, tighten the fuel tank cap securely.

11/08/01 15:07:21 31YG3610_030

-

30

SERVICING YOUR PUMP

FUEL RECOMMENDATIONS

Never refuel the engine inside a building where gasoline fumes mayreach flames or sparks. Keep gasoline away from appliance pilot lights,barbecues, electric appliances, power tools, etc.

Spilled fuel is not only a fire hazard, it causes environmental damage.Wipe up spills immediately.

Fuel can damage paint and plastic. Be careful not to spill fuel whenfilling your fuel tank. Damage caused by spilled fuel is not coveredunder warranty.

This engine is certified to operate on unleaded gasoline with a pumpoctane rating of 86 or higher.

You may use regular unleaded gasoline containing no more than 10%ethanol (E10) or 5% methanol by volume. In addition, methanol mustcontain cosolvents and corrosion inhibitors.

Use of fuels with content of ethanol or methanol greater than shownabove may cause starting and/or performance problems. It may alsodamage metal, rubber, and plastic parts of the fuel system.

Engine damage or performance problems that result from using a fuelwith percentages of ethanol or methanol greater than shown aboveare not covered under warranty.

If your equipment will be used on an infrequent or intermittent basis,please refer to the fuel section of the STORAGE chapter (page ) foradditional information regarding fuel deterioration.

Never use stale or contaminated gasoline or an oil/gasoline mixture.Avoid getting dirt or water in the fuel tank.

41

11/08/01 15:07:31 31YG3610_031

-

31

SERVICING YOUR PUMP

ENGINE OIL LEVEL CHECK

OIL FILLER NECK

OIL FILLER CAP/DIPSTICK

UPPER LIMIT

LOWER LIMIT

Check the engine oil level with the engine stopped and in a levelposition.

Remove the oil filler cap/dipstick and wipe it clean.

Insert and remove the dipstick without screwing it into the filler neck.Check the oil level shown on the dipstick.

If the oil level is low, fill to the edge of the oil filler hole with therecommended oil (see page ).

Screw in the oil filler cap/dipstick securely.

Running the engine with a low oil level can cause engine damage. Thistype of damage is not covered by the Distributors Limited Warranty.

1.

2.

3.

4.

33

11/08/01 15:07:41 31YG3610_032

-

32

SERVICING YOUR PUMP

ENGINE OIL CHANGE

DRAIN PLUG

OIL FILLER CAP/DIPSTICK

OIL LEVEL

SEALING WASHER

Drain the used oil while the engine is warm. Warm oil drains quicklyand completely.

Place a suitable container below the engine to catch the used oil,and then remove the oil filler cap/dipstick, drain plug and sealingwasher.

Screw in the oil filler cap/dipstick securely.

Allow the used oil to drain completely into an approved container,then reinstall the drain plug with a new sealing washer, and tightenit securely.

With the engine in a level position, fill to the edge of the oil filler holewith the recommended oil (see page ).

0.59 US qt (0.56 L)0.61 US qt (0.58 L)

Improper disposal of engine oil can be harmful to the environment.If you change your own oil, please dispose of used motor oilproperly. Put it in a sealed container, and take it a recycling center.Do not throw it in the trash, pour it on the ground, or pour it down adrain.

1.

2.

3.

4.

Engine oil capacitiesWB20XT:WB30XT:

33

11/08/01 15:07:51 31YG3610_033

-

33

SERVICING YOUR PUMP

ENGINE OIL RECOMMENDATION

AMBIENT TEMPERATURE

Oil is a major factor affecting performance and service life. Use4-stroke automotive detergent oil.

Use 4-stroke motor oil that meets or exceeds the requirements for APIservice category SJ or later (or equivalent). Always check the APIservice label on the oil container to be sure it includes the letters SJ orlater (or equivalent).

SAE 10W-30 is recommended for general use. Other viscosities shownin the chart may be used when the average temperature in your area iswithin the recommended range.

11/08/01 15:07:57 31YG3610_034

-

34

SERVICING YOUR PUMP

AIR FILTER INSPECTION

AIR CLEANER COVER

AIR FILTER

WING NUT

COVER WASHER

GRID

Unscrew the wing nut and remove the air cleaner cover. Check the airfilter to be sure it is clean and in good condition.

If the air filter is dirty, clean it as described on page . Replace the airfilter if it is damaged.

Reinstall the air filter and air cleaner cover. Be sure all the parts shownbelow are in place. Tighten the wing nut securely.

Operating the engine without an air filter, or with a damaged air filter,will allow dirt to enter the engine, causing rapid engine wear. This typeof damage is not covered by the Distributors Limited Warranty.

35

11/08/01 15:08:05 31YG3610_035

-

35

SERVICING YOUR PUMP

AIR FILTER CLEANING

AIR FILTER

A dirty air filter will restrict air flow to the carburetor, reducing engineperformance. If you operate the pump in very dusty areas, clean theair filter more frequently than specified in the Maintenance Schedule(see page ).

Clean the air filter in warm soapy water, rinse, and allow to drythoroughly. Or clean in nonflammable solvent and allow to dry.

Dip the air filter in clean engine oil, and then squeeze out all excessoil. The engine will smoke when started if too much oil is left in thefoam.

Wipe dirt from the air cleaner base and cover, using a moist rag. Becareful to prevent dirt from entering the air duct that leads to thecarburetor.

1.

2.

3.

28

11/08/01 15:08:12 31YG3610_036

-

36

SERVICING YOUR PUMP

SEDIMENT CUP CLEANING

SEDIMENT CUP

Move the fuel valve lever to the OFF position, then remove the fuelsediment cup and O-ring.

Gasoline is highly flammable andexplosive.

You can be burned or seriouslyinjured when handling fuel.

Stop the engine and keep heat,sparks, and flame away.Handle fuel only outdoors.Wipe up spills immediately.

Place the O-ring in the fuel valve, and install the sediment cup.Tighten the sediment cup securely.

Move the fuel valve lever to the ON position, and check for leaks.Replace the O-ring if there is any leakage.

Wash the sediment cup in non-flammable solvent, and dry itthoroughly.

1.

2.

3.

4.

11/08/01 15:08:23 31YG3610_037

-

37

SERVICING YOUR PUMP

SPARK PLUG SERVICE

SPARK PLUG CAP

SSPPAARRKK PPLLUUGG WWRREENNCCHH

SEALING WASHER

0.028 0.031 in(0.7 0.8 mm)

In order to service the spark plug, you will need a spark plug wrench(commercially available).

BPR6ES

0.028 0.031 in (0.7 0.8 mm)

Measure the spark p lugelectrode gap with a suitablegauge.Correct the gap, if necessary, bycarefully bending the sideelectrode.The gap should be:

Inspect the spark plug. Replaceit if the electrodes are worn, orif the insulator is cracked orchipped.

Incorrect spark plugs can cause engine damage.

For good performance, the spark plug must be properly gapped andfree of deposits.

Remove the spark plug with a 13/16-inch spark plug wrench.

Disconnect the spark plug cap, and remove any dirt from around thespark plug area.

Allow the engine to cool before servicing the spark plug.

1.

2.

3.

4.

Recommended spark plug: (NGK)

11/08/01 15:08:35 31YG3610_038

-

38

SERVICING YOUR PUMP

Attach the spark plug cap.

A loose spark plug can overheat and damage the engine.Overtightening the spark plug can damage the threads in thecylinder head.

If installing a new spark plug, tighten 1/2 turn after the spark plugseats.

If reinstalling the used spark plug, tighten 1/8 1/4 turn after thespark plug seats.

After the spark plug seats, tighten with a 13/16-inch spark plugwrench to compress the washer.

Install the spark plug carefully, by hand, to avoid cross-threading.

6.

7.

5.

11/08/01 15:08:42 31YG3610_039

-

39

SERVICING YOUR PUMP

SPARK ARRESTER SERVICE (optional equipment)

8 mm NUTS

MUFFLER

MUFFLER PROTECTOR

SPARK ARRESTER SCREEN

5 mm SELF-TAPPINGSCREWS

4 mm SCREW

GASKET

SPARK ARRESTER

Your engine is not factory-equipped with a spark arrester. In someareas, it is illegal to operate an engine without a spark arrester. Checklocal laws and regulations. A spark arrester is available fromauthorized Honda servicing dealers.

The spark arrester must be serviced every 100 hours to keep itfunctioning as designed.

If the engine has been running, the muffler will be very hot. Allow themuffler to cool before servicing the spark arrester.

Remove the two 8 mm nuts, and remove the muffler.

Remove the four 5 mm self-tapping screws, and remove the mufflerprotector from the muffler.

Remove the 4 mm screw from the spark arrester, and remove thespark arrester from the muffler.

The spark arrester must be freeof breaks and holes. Replacethe spark arrester if it isdamaged.

Use a brush to remove carbondeposits from the spark arresterscreen. Be careful to avoiddamaging the screen.

Install the spark arrester, muffler protector, and muffler in thereverse order of disassembly using a new gasket.

1.

2.

3.

4.

5.

11/08/01 15:08:53 31YG3610_040

-

40

STORAGE

STORAGE PREPARATION

Cleaning

Proper storage preparation is essential for keeping your pump trouble-free and looking good. The following steps will help to keep rust andcorrosion from impairing your pumps function and appearance, andwill make the engine easier to start when you use the pump again.

Wash the engine and pump.

Wash the engine by hand, and be careful to prevent water fromentering the air cleaner or muffler opening. Keep water away fromcontrols and all other places that are difficult to dry, as waterpromotes rust.

Using a garden hose or pressure washing equipment can forcewater into the air cleaner or muffler opening. Water in the aircleaner will soak the air filter, and water that passes through theair filter or muffler can enter the cylinder, causing damage.

Water contacting a hot engine can cause damage. If the enginehas been running, allow it to cool for at least half an hour beforewashing.

Wipe dry all accessible surfaces.

Fill the pump chamber with clean, fresh water, start the engineoutdoors, and let it run until it reaches normal operatingtemperature to evaporate any external water.

Dry operation will damage the pump seal. Be sure the pumpchamber is filled with water before starting the engine.

1.

2.

3.

11/08/01 15:09:04 31YG3610_041

-

41

STORAGE

Fuel

PUMP DRAIN PLUG

Depending on the region where you operate your equipment, fuelformulations may deteriorate and oxidize rapidly. Fuel deteriorationand oxidation can occur in as little as 30 days and may cause damageto the carburetor and/or fuel system. Please check with your servicingdealer for local storage requirements.

Gasoline will oxidize and deteriorate in storage. Old gasoline willcause hard starting, and it leaves gum deposits that clog the fuelsystem. If the gasoline in your engine deteriorates during storage, youmay need to have the carburetor and other fuel system componentsserviced or replaced.

After the pump is clean and dry,touch up any damaged paint,and coat areas that may rustwith a light film of oil. Lubricatecontrols with a silicone spraylubricant.

Remove the pump drain plug,and flush the pump with clean,fresh water. Allow the water todrain from the pump chamber,and then reinstall the drain plug.

Stop the engine, and allow it tocool.

The length of time that gasoline can be left in your fuel tank andcarburetor without causing functional problems will vary with suchfactors as gasoline blend, your storage temperatures, and whetherthe fuel tank is partially or completely filled. The air in a partially filledfuel tank promotes fuel deterioration. Very warm storagetemperatures accelerate fuel deterioration. Fuel deteriorationproblems may occur within a few months, or even less if the gasolinewas not fresh when you filled the fuel tank.

The Distributors Limited Warranty does not cover fuel systemdamage or engine performance problems resulting from neglectedstorage preparation.

You can extend fuel storage life by adding a fuel stabilizer that isformulated for that purpose, or you can avoid fuel deteriorationproblems by draining the fuel tank and carburetor.

4.

5.

6.

11/08/01 15:09:14 31YG3610_042

-

42

STORAGE

Adding a Fuel Stabilizer to Extend Fuel Storage Life

Short Term Storage (30 90 days)

FUEL VALVE LEVER

OFF

If your equipment will not be used for 30 90 days, we recommendthe following to prevent fuel-related problems:

Add fuel stabilizer following the manufacturers instructions.When adding a fuel stabilizer, fill the fuel tank with fresh gasoline. Ifonly partially filled, air in the tank will promote fuel deteriorationduring storage. If you keep a container of gasoline for refueling, besure that it contains only fresh gasoline.

If it takes more than 3 months to use the fuel in your storage container,we suggest adding a fuel stabilizer to the fuel when you full thecontainer.

After adding a fuel stabilizer, run the engine outdoors for 10 minutesto be sure that treated gasoline has replaced the untreated gasolinein the carburetor.

Dry operation will damage the pump seal. Be sure the pumpchamber is filled with water before starting the engine.

Stop the engine, and move the fuel valve lever to the OFF position.3.

1.

2.

11/08/01 15:09:25 31YG3610_043

-

43

STORAGE

Draining the Fuel Tank and Carburetor

Long Term or Seasonal Storage (greater than 90 days)

DRAIN BOLT

FUEL VALVE LEVER

O-RING

SEDIMENT CUP

WASHER

After all the fuel has drained into the container, reinstall the drainbolt and sediment cup. Tighten them securely.

Remove the carburetor drain bolt and sediment cup, and then movethe fuel valve lever to the ON position.

Place an approved gasoline container below the carburetor, and usea funnel to avoid spilling fuel.

Wipe up spills immediately.Handle fuel only outdoors.

Keep heat, sparks, and flameaway.

Gasoline is highly flammable andexplosive.

You can be burned or seriouslyinjured when handling fuel.

1.

2.

3.

11/08/01 15:09:36 31YG3610_044

-

44

STORAGE

Engine Oil

Engine Cylinder

STORAGE PRECAUTIONS

Align notch on pulley withhole at the top of cover.

Change the engine oil (see page ).

Pull the recoil starter grip slowly until resistance is felt and the notchon the starter pulley aligns with the hole at the top of the recoilstarter cover. This will close the valves so moisture cannot enter theengine cylinder. Return the recoil starter grip gently.

Reinstall the spark plug.

Pull the starter grip several times to distribute the oil in the cylinder.

Pour a teaspoon (5 cc) of clean engine oil into the cylinder.

Remove the spark plug (see page ).

Unless all fuel has been drained from the fuel tank, leave the fuel valvelever in the OFF position to reduce the possibility of fuel leakage.

If possible, avoid storage areas with high humidity, because thatpromotes rust and corrosion.

If your pump will be stored with gasoline in the fuel tank andcarburetor, it is important to reduce the hazard of gasoline vaporignition. Select a well-ventilated storage area away from any appliancethat operates with a flame, such as a furnace, water heater, or clothesdryer. Also avoid any area with a spark-producing electric motor orwhere power tools are operated.

1.

2.

3.

4.

5.

37

32

11/08/01 15:09:49 31YG3610_045

-

45

STORAGE

REMOVAL FROM STORAGE

Place the pump on a level surface. Tilting can cause fuel or oil leakage.

With the engine and exhaust system cool, cover the pump to keep outdust. A hot engine and exhaust system can ignite or melt somematerials. Do not use sheet plastic as a dust cover. A nonporous coverwill trap moisture around the pump, promoting rust and corrosion.

Check your pump as described in the BEFORE OPERATION chapter ofthis manual.

If the fuel was drained during storage preparation, fill the tank withfresh gasoline. If you keep a container of gasoline for refueling, besure that it contains only fresh gasoline. Gasoline oxidizes anddeteriorates over time, causing hard starting.

If the cylinder was coated with oil during storage preparation, theengine may smoke briefly at startup. This is normal.

11/08/01 15:09:56 31YG3610_046

-

46

TRANSPORTING

If the pump has been running, allow the engine to cool for at least 15minutes before loading the pump on the transport vehicle. A hotengine and exhaust system can burn you and can ignite somematerials.

Keep the pump level when transporting to reduce the possibility offuel leakage. Move the fuel valve lever to the OFF position.

11/08/01 15:10:00 31YG3610_047

-

47

ENGINE

Engine Will Not Start

Engine Lacks Power

TAKING CARE OF UNEXPECTED PROBLEMS

Possible Cause Correction

CorrectionPossible Cause

Fuel valve OFF.Choke open.

Ignition switch OFF.Out of fuel.Bad fuel; pump stored withouttreating or draining gasoline, orrefueled with bad gasoline.Spark plug faulty, fouled, orimproperly gapped.Spark plug wet with fuel (floodedengine).

Fuel filter clogged, carburetormalfunction, ignition malfunction,valves stuck, etc.

Air filter clogged.Bad fuel; pump stored withouttreating or draining gasoline, orrefueled with bad gasoline.Throttle lever in slow position.Fuel filter clogged, carburetormalfunction, ignition malfunction,valves stuck, etc.

Clean or replace filter (p. 35 ).Drain fuel tank and carburetor (p. 43 ).Refuel with fresh gasoline (p. 29 ).

Move throttle to the FAST position.Take engine to an authorized Hondaservicing dealer, or refer to shopmanual.

Move fuel valve lever to ON position.Move choke lever to CLOSED positionunless engine is warm.Turn ignition switch to ON.Refuel (p. 29 ).Drain fuel tank and carburetor (p. 43 ).Refuel with fresh gasoline (p. 29 ).

Gap or replace spark plug (p. 37 ).

Dry and reinstall spark plug. Startengine with throttle lever in FASTposition.Take engine to an authorized Hondaservicing dealer, or refer to shopmanual.

11/08/01 15:10:10 31YG3610_048

-

48

TAKING CARE OF UNEXPECTED PROBLEMS

PUMP

No Pump Output

Low Pump Output

Possible Cause Correction

Possible Cause Correction

Prime pump (p. 20 )Replace suction hose (p. 18 ).Sink the strainer and the end of thesuction hose completely underwater.Replace sealing washer if missing ordamaged. Tighten hose connector andclamp (p. 18 ).Clean debris from strainer.Relocate pump and/or hoses to reducehead (p. 17 ).See page 47 .

Pump not primed.Hose collapsed, cut or punctured.Strainer not completely underwater.

Air leak at connector.

Strainer clogged.Excessive head.

Engine lacks power.

Replace suction hose (p. 18 ).

Replace sealing washer if missing ordamaged. Tighten hose connector andclamp (p. 18 ).Clean debris from strainer.Replace discharge hose (p. 19 ).

Relocate pump and/or hoses to reducehead (p. 17 ).See page 47 .

Hose collapsed, damaged, too long,or diameter too small.Air leak at connector.

Strainer clogged.Hose damaged, too long, ordiameter too small.Marginal head.

Engine lacks power.

11/08/01 15:10:20 31YG3610_049

-

49

TECHNICAL INFORMATION

Serial Number Location

WB20XTWB30XT

ENGINE SERIAL NUMBER

FRAME SERIAL NUMBER

Record the frame serial number (if assigned) and the engine serialnumber in the space below. You will need these serial numbers whenordering parts, and when making technical or warranty inquiries (seepage ).

Engine serial number:

Frame serial number:

59

11/08/01 15:10:28 31YG3610_050

-

50

TECHNICAL INFORMATION

Carburetor Modification for High Altitude Operation

At high altitude, the standard carburetor air-fuel mixture will be toorich. Performance will decrease, and fuel consumption will increase. Avery rich mixture will also foul the spark plug and cause hard starting.Operation at an altitude that differs from that at which this engine wascertified, for extended periods of time, may increase emissions.

High altitude performance can be improved by specific modificationsto the carburetor. If you always operate your pump at altitudes above5,000 feet (1,500 meters), have your servicing dealer perform this car-buretor modification. This engine, when operated at high altitude withthe carburetor modifications for high altitude use, will meet eachemission standard throughout its useful life.

Even with carburetor modification, engine horsepower will decreaseabout 3.5% for each 1,000-foot (300-meter) increase in altitude. Theeffect of altitude on horsepower will be greater than this if nocarburetor modification is made.

When the carburetor has been modified for high altitude operation,the air-fuel mixture will be too lean for low altitude use. Operation ataltitudes below 5,000 feet (1,500 meters) with a modified carburetormay cause the engine to overheat and result in serious engine damage.For use at low altitudes, have your servicing dealer return thecarburetor to original factory specifications.

11/08/01 15:10:34 31YG3610_051

-

51

TECHNICAL INFORMATION

Emission Control System Information

The U.S. and California Clean Air Acts

Tampering and Altering

Source of Emissions

The combustion process produces carbon monoxide, oxides ofnitrogen, and hydrocarbons. Control of hydrocarbons and oxides ofnitrogen is very important because, under certain conditions, theyreact to form photochemical smog when subjected to sunlight. Carbonmonoxide does not react in the same way, but it is toxic.

EPA and California regulations require all manufacturers to furnishwritten instructions describing the operation and maintenance of emis-sion control systems.

The following instructions and procedures must be followed in orderto keep the emissions from your Honda engine within the emissionstandards.

Honda utilizes appropriate air/fuel ratios and other emissions controlsystems to reduce the emissions of carbon monoxide, oxides ofnitrogen, and hydrocarbons.

Tampering with or altering the emission control system may increaseemissions beyond the legal limit. Among those acts that constitutetampering are:

Tampering is a violation of Federal and California law.

Altering or defeating the governor linkage or speed-adjustingmechanism to cause the engine to operate outside its designparameters.

Removal or alteration of any part of the intake, fuel or exhaustsystems.

11/08/01 15:10:44 31YG3610_052

-

52

TECHNICAL INFORMATION

Problems That May Affect Emissions

Replacement Parts

Maintenance

If you are aware of any of the following symptoms, have your engineinspected and repaired by your servicing dealer.

Hard starting or stalling after starting.

Rough idle.

Misfiring or backfiring under load.

Afterburning (backfiring).

Black exhaust smoke or high fuel consumption.

The emission control systems on your Honda engine were designed,built, and certified to conform with EPA and California emissionregulations. We recommend the use of Honda Genuine partswhenever you have maintenance done. These original-designreplacement parts are manufactured to the same standards as theoriginal parts, so you can be confident of their performance. The useof replacement parts that are not of the original design and qualitymay impair the effectiveness of your emission control system.

A manufacturer of an aftermarket part assumes the responsibility thatthe part will not adversely affect emission performance. Themanufacturer or rebuilder of the part must certify that use of the partwill not result in a failure of the engine to comply with emissionregulations.

Follow the maintenance schedule (see page ). Remember that thisschedule is based on the assumption that your machine will be usedfor its designed purpose. Sustained high-load or high-temperatureoperation, or use in unusually wet or dusty conditions, will requiremore frequent service.

28

11/08/01 15:10:52 31YG3610_053

-

53

TECHNICAL INFORMATION

Air Index

An Air Index Information hang tag/label is applied to engines certifiedto an emission durability time period in accordance with therequirements of the California Air Resources Board.

The bar graph is intended to provide you, our customer, the ability tocompare the emissions performance of available engines. The lowerthe Air Index, the less pollution.

The durability description is intended to provide you with informationrelating the engines emission durability period. The descriptive termindicates the useful life period for the engines emission controlsystem. See your Emission Control System Warranty for additionalinformation.

Descriptive Term

Moderate

Intermediate

Extended

Applicable to Emissions Durability Period

50 hours [0 80 cm (0 80 cc) inclusive]125 hours [greater than 80 cm (80 cc)]

125 hours [0 80 cm (0 80 cc) inclusive]250 hours [greater than 80 cm (80 cc)]

300 hours [0 80 cm (0 80 cc) inclusive]500 hours [greater than 80 cm (80 cc)]

1,000 hours [225 cm (225 cc) and greater]

11/08/01 15:10:59 31YG3610_054

-

54

TECHNICAL INFORMATION

Specifications

Dimensions and weight

Engine design and performance

Tune up

WB20XT

17.9 in (455 mm)14.4 in (365 mm)16.5 in (420 mm)

GX1204-stroke, overhead valve, single cylinder

46 lbs (21 kg)

7.2 cu-in (118 cm )[2.4 1.7 in (60.0 42.0 mm)]

LengthWidthHeightDry mass [weight]

Forced airTransistorized magnetoCounterclockwise

Spark plug gap

Idle speedValve clearance(cold)Other specifications

1,400 rpm0.15 0.02 mm0.20 0.02 mm

No other adjustments needed.

ModelEngine typeDisplacement[bore stroke]Fuel tank capacityCooling systemIgnition systemPTO shaft rotation

0.028 0.031 in(0.70 0.80 mm)

0.53 US gal (2.0 L)

Intake:Exhaust:

See page 37.

See shopmanual.

200150

11/08/01 15:11:14 31YG3610_055

-

55

TECHNICAL INFORMATION

Pump

WB20XT (continued)

92.4 ft (28 m)26.4 ft (8 m)

110 seconds at 16.4 ft (5 m)

151.9 US gal (575 L)

2.0 in (50 mm)2.0 in (50 mm)

Suction port diameterDischarge port diameterTotal head (maximum)Suction head (maximum)Discharge capacity (maximum)

Self-priming timeper minute

11/08/01 15:11:21 31YG3610_056

-

56

TECHNICAL INFORMATION

Dimensions and weight

Engine design and performance

Tune up

WB30XT

20.1 in (510 mm)15.2 in (385 mm)17.9 in (455 mm)60 lbs (27 kg)

GX1604-stroke, overhead valve, single cylinder9.9 cu-in (163 cm )[2.7 1.8 in (68.0 45.0 mm)]

LengthWidthHeightDry mass [weight]

Forced airTransistorized magnetoCounterclockwise

Spark plug gap

Idle speedValve clearance(cold)Other specifications

1,400 rpm

No other adjustments needed.

ModelEngine typeDisplacement[bore stroke]Fuel tank capacityCooling systemIgnition systemPTO shaft rotation

0.028 0.031 in(0.70 0.80 mm)

0.08 0.02 mm0.10 0.02 mm

0.82 US gal (3.1 L)

Intake:Exhaust:

See page 37.

See shopmanual.

200150

11/08/01 15:11:36 31YG3610_057

-

57

TECHNICAL INFORMATION

Pump

WB30XT (continued)

85.8 ft (26 m)26.4 ft (8 m)

150 seconds at 16.4 ft (5 m)

275.0 US gal (1,041 L)

3.1 in (80 mm)3.1 in (80 mm)

Suction port diameterDischarge port diameterTotal head (maximum)Suction head (maximum)Discharge capacity (maximum)

Self-priming timeper minute

11/08/01 15:11:43 31YG3610_058

-

58

DEALER LOCATOR INFORMATION

Honda PUBLICATIONS

Shop Manual

Parts Catalog

CONSUMER INFORMATION

To find an authorized Honda Servicing Dealer anywhere in the UnitedStates:Visit our web site:www.HondaPowerEquipment.com and click on Dealer Locator.

This manual covers complete maintenance and overhaul procedures.It is intended to be used by a skilled technician.Available through your Honda dealer or through Helm Inc. at 1 888-292-5395 or visit www.hondapowerequipment.com and click onProduct Manuals.

This manual provides complete, illustrated parts lists. Availablethrough your Honda dealer.

11/08/01 15:11:51 31YG3610_059

-

59

CONSUMER INFORMATION

Customer Service Information

Servicing dealership personnel are trained professionals. They shouldbe able to answer any question you may have. If you encounter aproblem that your dealer does not solve to your satisfaction, pleasediscuss it with the dealerships management. The Service Manager orGeneral Manager can help. Almost all problems are solved in this way.

If you are dissatisfied with the decision made by the dealershipsmanagement, contact the Honda Power Equipment CustomerRelations Office. You can write:

Or telephone: (770) 497-6400 M-F, 8:30 am to 7:00 pm ET

American Honda Motor Co., Inc.Power Equipment DivisionCustomer Relations Office4900 Marconi DriveAlpharetta, Georgia 30005-8847

When you write or call, please give us this information:

Model and serial number (see page )

Name of the dealer who sold the pump to you

Name and address of the dealer who services your pump

Date of purchase

Your name, address and telephone number

A detailed description of the problem

49

11/08/01 15:11:59 31YG3610_060

-

QUICK REFERENCE INFORMATION

BPR6ES

Type

Type

Capacity

TypeGap

Idle speedBefore eachuseFirst20 hoursSubsequent

0.028 0.031 in (0.70 0.80 mm)

1,400 rpm

Fuel

Engine Oil

Spark Plug

Carburetor

Maintenance

0.59 US qt (0.56 L)

0.61 US qt (0.58 L)

Unleaded gasoline with a pumpoctane rating of 86 or higher(page 30 )SAE 10W-30, API SJ, for generaluse (page 33 )

Check engine oil level.Check air filter.Change engine oil.

Refer to the maintenanceschedule on page 28 .

WB20XT:

WB30XT:

NGK:

(page 37 )200150

11/08/01 15:12:06 31YG3610_061

-

00X31YG36100 2011 Honda Motor Co., Ltd.All Rights Reserved

Owners ManualPUMP

WB20XT/WB30XT

POM31V20611 FRC800 Cover.ai 11/2/2011 11:12:53 AM

INTRODUCTIONA FEW WORDS ABOUT SAFETY

CONTENTSPUMP SAFETYIMPORTANT SAFETY INFORMATION

SAFETY LABEL LOCATIONSCONTROLSCOMPONENT & CONTROL LOCATIONSCONTROLSFUEL VALVE LEVERIGNITION SWITCHCHOKE LEVERTHROTTLE LEVERRECOIL STARTER GRIP

BEFORE OPERATIONARE YOU READY TO GET STARTED?IS YOUR PUMP READY TO GO?

OPERATIONSAFE OPERATING PRECAUTIONSPUMP PLACEMENTSUCTION HOSE INSTALLATIONDISCHARGE HOSE INSTALLATIONPRIMING THE PUMPSTARTING THE ENGINESETTING ENGINE SPEEDSTOPPING THE ENGINE

SERVICING YOUR PUMPTHE IMPORTANCE OF MAINTENANCEMAINTENANCE SAFETYMAINTENANCE SCHEDULEREFUELINGFUEL RECOMMENDATIONSENGINE OIL LEVEL CHECKENGINE OIL CHANGEENGINE OIL RECOMMENDATIONAIR FILTER INSPECTIONAIR FILTER CLEANINGSEDIMENT CUP CLEANINGSPARK PLUG SERVICESPARK ARRESTER SERVICE (OPTIONAL EQUIPMENT)

STORAGESTORAGE PREPARATIONCLEANINGFUELENGINE OILENGINE CYLINDER

STORAGE PRECAUTIONSREMOVAL FROM STORAGE

TRANSPORTINGTAKING CARE OF UNEXPECTED PROBLEMSENGINEPUMP

TECHNICAL INFORMATIONSERIAL NUMBER LOCATIONCARBURETOR MODIFICATION FOR HIGH ALTITUDE OPERATIONEMISSION CONTROL SYSTEM INFORMATIONAIR INDEXSPECIFICATIONS

CONSUMER INFORMATIONDEALER LOCATOR INFORMATIONHonda PUBLICATIONSCUSTOMER SERVICE INFORMATION

QUICK REFERENCE INFORMATION

save as: