Upfront Magazine - Issue 2

-

Upload

skanska-uk -

Category

Documents

-

view

215 -

download

2

description

Transcript of Upfront Magazine - Issue 2

Upfront

Keep on movingWider M25 arrives on time

Dream makersOpportunity knocks for future talent

Groundbreaking treatmentAward-winning redevelopment of central London hospital transforms care for cancer sufferers

in print onlineA Skanska publication

#2: 12, November

The progress

issue

Content

Welcome

Isaac Newton Academy is a green triumph for a school building in the UK

What a year it’s been. 2012 will definitely be remembered as the year of celebration. Starting with the pageantry of The

2012 Olympic and Paralympic Games – a true inspiration.

125-year anniversary with events around the world.

With one celebration after another, what better way to

Anna MannEditor

EditorAnna [email protected]

ContributorsChristina Hand Eva Harris Sarah Hayes Andrew Mothersele Clare O’Connor

Katie Sutton DesignTing-Kai Chang

ProductionChris Smith

Produced by Skanska UK’s corporate communications team

P16

Features

04 Lighting by royal appointment06 Comment When so many are in

the red, why go green? 10 Groundbreaking treatment16 Green designs for children’s

future22 Chain reaction 26 An energising retro!t30 Keep on moving34 A record-breaking hole38 Who leads?42 Power of the underworld48 Dream makers52 Sowing the seeds

Project feature Street lighting

[ 4 ]

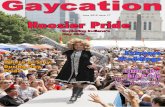

Upfront #2:12

Lighting by royal appointmentThings are looking brighter for the Royal Family after Skanska refurbished the street lamps on The Mall, the famous ceremonial route that leads to Buckingham Palace

Contact: [email protected] Web: skanska.co.uk/infrastructureservices

[ 5 ]

Project feature Street lightingUpfront #2:12

The Mall, which runs north east o" St. James’ Park to the Victoria Memorial, is lined with Galleon twin globe street lights,

each standing 8m-high and spaced 36m apart. Each globe contains a vertically mounted lamp and over the years a variety of replacements have been used, resulting in randomly di"erent areas of colour down the length of #e Mall. #is ranges from warm orange to cool blue – not the most aesthetically pleasing sight in the evenings on such an iconic road.

#e Galleon columns are an integral part of #e Mall’s image and therefore had to be retained, so the challenge was to enhance the lighting while reducing energy demand. Working for Taylor Woodrow Construction, now Vinci Construction, Skanska’s infrastructure services team installed the new Phillips CDM Elite lamp unit, providing consistent light levels but with substantial energy savings.

Commenting on the importance of the works, Project Manager Simon Woodford says: “I was pleased to

complete this prestigious project in time for the historic year that was upon us with #e Queen’s Jubilee celebrations and the 2012 Olympics.

“Refurbishing some of the lanterns that were over 80 years old was an interesting aspect to the works as they had to be treated delicately. #e globes are made of glass and part of the job was to replace some of the damaged bowls which we had to get specially made by a glass blower.”

During the three-month project earlier this year, the team also refurbished lamps on nearby Constitution Hill. Standing 4m-tall, these lighting columns are positioned in a staggered arrangement, spaced 15m apart. #e old gas light !ttings were replaced with identical replicas and !tted with a new 60-watt lamp, re$ector system and electronic gear. #is new electric !tting improves lighting levels without increasing the glare and generates substantial savings from reduced energy demand and carbon usage.

Simon adds: “#e team we had on the project worked well and the result on the ground is a great improvement that will keep #e Mall and Constitution Hill shining brightly for years to come.”

Left: The team works carefully under the

Simon Woodford, Infrastructure Services

Business feature Skanska Residential UK

[ 6 ]

Upfront #2:12Business feature Skanska Residential UK

Tony Juniper is a sustainability advisor, writer and former director of Friends of the Earth. He is a special advisor to Skanska on green issues. His new book What has Nature ever done for us? is published in January 2013

Business feature Skanska Residential UKBusiness feature Skanska Residential UK

[ 7 ]

Business feature Skanska Residential UKUpfront #2:12

Green issues have apparently been knocked o" the agenda. Right? #e most obvious reason

for this apparent downgrading of what was just a few years ago a vital new agenda is the recent period of economic di%culty.

So why should anyone bother about green priorities any longer. A&er all the world has moved onto other more immediate concerns, hasn’t it? And if people are now onto new challenges, why should companies or public bodies bother about dealing with problems that people have stopped talking about? Well, the answer is that there are a lot of reasons, and as time goes by they will become increasingly important.

For a start, several sustainability challenges are getting more pressing than ever, and transforming from possible future risks into causing real consequences in the here and now. Many analysts point to major systemic risks arising from rapidly rising trends that include climate

change, energy price volatility, urbanisation, threats to food security, water scarcity, population growth and demographic change, income inequality and the degradation of ecosystems. What is more, these di"erent trends will interact more and more, sometimes in quite unpredictable ways.

For instance, more frequent heat waves coming at the same time as power price rises will mean that poorer elderly people will more likely die from heat stroke because they will be less able to a"ord air conditioning. Combine that with high food prices and more heat island impacts from urbanisation, and the world we are entering for many groups in society could be quite challenging.

Never mind the ethical side of green issues, any company or country that is not prepared for the practical and economic consequences of these and other challenges is simply not living in the real world. #ey are also not reading the direction that policy-makers will need to travel.

During this period of uncertainty, now more than ever, is the right time to embrace the sustainability agenda, says leading campaigner Tony Juniper

Comment

When so many are in the red, why go green?

Business feature Skanska Residential UK

[ 8 ]

Upfront #2:12Business feature Skanska Residential UK

Despite the ever more complicated public debate about what rules, laws, policies and subsidies are necessary to achieve greener outcomes, governments in many parts of the world are developing the frameworks and incentives that will achieve them. Even many of the countries that appear to be environmental skeptics have fast-growing clean-tech sectors and are innovating to reduce pollution and waste. #is is not least because many have realised that global markets will demand stronger green performance in future, and that huge economic opportunities exist in meeting it.

Some of these emerging greener markets are, of course, already there, and now starting to grow fast. Companies in many sectors are !nding demands from their supply chain partners increasingly di%cult to ignore. More sustainable goods and services are being required in

sectors as diverse as leisure, retail, consumer goods, food and, of course, construction. Companies unable to supply what is increasingly wanted in terms of green performance among their business partners may !nd their competitors developing the kind of edge that leaves them at a distinct disadvantage.

And in this space there are plenty of opportunities to build new business models, o"er new products and innovate in ways that cut costs as well as pollution. #ere are a great many examples out there now of what can be achieved when the challenges are taken head on, and

the strategies put in place to meet them. #e companies that are seizing leadership roles are far from fringe green brands and range from the likes of Danone to Puma and from Unilever to Sainsbury’s.

And then there is the market for talent, and what the rising stars that will deliver future business success are looking for in their careers. People beginning their careers today are for the most part well aware of

Drivers for a more sustainable future – climate change, urbanisation, population growth, energy price volatility and a more socially aware youth

Business feature Skanska Residential UKBusiness feature Skanska Residential UK

[ 9 ]

Business feature Skanska Residential UKUpfront #2:12

and concerned about sustainability, environmental issues and questions of development, certainly compared to many of their predecessors.

#e graduates leaving schools and universities these days have been exposed to these and related matters for years, and they expect something to be done about them. Companies that are not delivering, or which have a reputation for laggardly behaviour, are less likely to be at the top of their list for places to build a career.

All of what I have just described is an increasingly mainstream agenda that is about real business risk, and a far cry from the somewhat fringe ethical o"erings that were coming from many companies just a few years ago. No longer is the green and sustainability challenge about

protecting brands with a few eye-catching but rather fringe initiatives, it is now a matter of strategic risk and coping with change in a dynamic and unpredictable world. #at is about core business, and that is where green questions are now being discussed.

#e good news is that there are many tools now available to help tackle sustainability challenges, including new measurement and reporting methods and di"erent kinds of technologies becoming more mainstream. #ere are many examples of how sustainability can be a winning frame for business success, assuming the ambition and leadership are in place.

#ose who are prepared for the new world, the one in which

sustainability challenges become very much more real, will build advantages and resilience for their businesses. #ose who believe that economic challenges are somehow more important than green ones, or that the world we have known is the same as the one that is coming, are likely to !nd themselves unprepared for the consequences that are just around the corner. #ese will range in scope from changed recruitment markets to volatility in raw material prices, and from interruptions to infrastructure to new demands from their supply chains and customers.

#is world of risk is also one of opportunity, however, so long as the thought and planning is in place to chart the best possible route to a more sustainable future.

Project feature Hospital redevelopment

[ 10 ]

Upfront #2:12

Groundbreaking treatmentAmbitious redevelopment of central London hospital scoops The Prime Minister’s Better Public Building Award

Manager of The Year

Contact: Web: skanska.co.uk/lse

UCH Macmillan Cancer Centre, Bloomsbury, London

[ 11 ]

Project feature Hospital redevelopmentUpfront #2:12

Groundbreaking treatment

Project feature Hospital redevelopment

[ 12 ]

Upfront #2:12

accommodate this late variation. Being a cancer treatment centre this project had touched all of our hearts and the team wanted to pull out all of the stops to make this one of the best facilities in the UK.”

From the very beginning, Skanska’s expertise of building hospitals was drawn on. A team was put together to carry out intensive studies to make certain the complex design of the rooms would function smoothly once used by sta" and patients.

Emma Dymond, Clinical Design Manager, explains: “#e client used our knowledge to con!rm the clinical designs and develop the detailed plans which showed the layouts of all the rooms. #is made certain they would function properly once they were in use.

“From past experience of building hospitals, early intervention avoids

technology, such as the world’s !rst PET MR machine. #is creates more detailed scans allowing patients to bene!t from the latest technological advances while reducing their exposure to radiation.

It was nearly half way through the project when the client approached Skanska to ask if plans could be changed to accommodate the installation of this machine. Weighing 10 tonnes – the equivalent of 10 family cars – meant a whole $oor area had to be redesigned. But the team quickly went back to the drawing board to !nd a solution, agreeing an extension of nine weeks to the building programme and additional costs with the client.

John Birch, Project Director, explains: “When we reached week 49 of the programme, the client approached us and asked if we could

Hundreds of cancer su"erers are being treated at a new, specialist London hospital a&er a

£63 million building project was completed on time by Skanska.

#e University College Hospital (UCH) Macmillan Cancer Centre, in Bloomsbury, near Euston, opened its doors in April this year a&er a 120-week construction period, which involved more than 250 Skanska sta" and trade contractors.

#e new hospital, more commonly known as the UCH Macmillan Cancer Centre, is named a&er the Macmillan charity which donated £10 million towards its funding.

Last minute challenges#e team overcame last minute challenges to ensure that the hospital became home to the latest

[ 13 ]

Project feature Hospital redevelopmentUpfront #2:12

unnecessary disruption and ensures the patients receive their treatment in a stress-free environment.”

Environmental distinction #e resulting building is an example of environmental distinction, exceeding energy conservation building regulations by 38% and certi!ed as BRE Environmental Assessment Method (BREEAM) Excellent.

One of the environmental design innovations – a glazing system – maximises the bene!t of natural light, creating a pleasant environment for the patients and sta". #is was an important feature as it’s widely acknowledged that natural light promotes a feeling of wellbeing which aids the recovery of sick, vulnerable patients.

#e centre has also hit the recent NHS environmental targets eight

years early, and has cut carbon emissions by a third.

Kieran McDaid, Director of Capital Investment at University College London Hospitals, says: “As the greenest company in the UK, Skanska has used its deep technical understanding of sustainability to come forward with unique construction ideas, which gained us invaluable extra BREEAM points.”

A good neighbour Working with the community and building up good relationships was a key objective of this project. During the planning process, the team worked with their neighbours to overcome objections, which had initially been put forward against the construction of the new hospital.

Common ground was achieved by introducing strict delivery hours to minimise noise at sensitive

1,000,143 total man hours

452,000 man hours without a reportable accident

2,966 site inductions carried out

38% more energy efficient than building regulations

John Birch

Former patient Derek

football with his grandson, Charlie. Derek puts his recovery down to the quality of care received at the centre. “I was diagnosed with a rare form of cancer, which required stem cell treatment,” he explains. “The centre provided me with the best chance of a full recovery as it was the only place in the UK where I could receive this groundbreaking treatment.”

Project feature Hospital redevelopment

[ 14 ]

Upfront #2:12

awards scheme – including trade contractors – to recognise and promote good practice, helping the team achieve a period of 12 months without any accidents

' everybody working on the project attending IFE orientation workshops – with 270 employees working on the site at any one time, this was no mean feat

' reopening an existing underground tunnel to avoid crossing a busy London road

A dedicated team#e team’s hard work and dedication to deliver the unique design and high standards of the centre was recognised by its success in the 2012 New London Health Award.

John Crawley, Operations Director for the London building team, says: “A joined-up approach made certain we delivered a high standard building to our client. All the hard work of the Skanska team is made worthwhile when you visit the hospital and see the di"erence the

facilities in this building make to the patients and their families.”

Great leadership John Birch, Project Director, led the Skanska team and relied heavily on the knowledge and skills he has built up during a 23-year career with Skanska to deliver this world-class facility.

John’s exceptional leadership was acknowledged at the 2012 Construction Manager of the Year Awards in November. He picked up the gold medal in the New Build and Refurbishment, £40 million to £100 million, category.

Commenting on the redevelopment, John says: “#is was by far the most interesting and rewarding project I have worked on in my career. I don’t think that I will ever work on a project like this again. What we have done here really makes a di"erence to people’s lives – it can mean the di"erence between life and death. Nothing compares to this.”

times, and regular two-way communications took place through updates and monthly meetings with local residents.

Kieran adds: “From the outset of this project, Skanska engaged with the local community to develop pragmatic working hours which minimised any disruption to our neighbours.”

Safety first Making sure everyone returned home safely to their loved ones every day was the number one priority for the team. And so Skanska’s Injury-Free Environment (IFE) programme was at the heart of this project.

Despite facing signi!cant challenges, the team made time to introduce key safety initiatives, such as:

' using de!ned safety routes – known as blue routes – so pedestrians could walk safely around the construction site

' a monthly health and safety

British Construction Industry Awards 2012

The Prime Minister’s Better Public Building Award Winner

Judges’ comment “A building designed around the needs of patients and staff, focusing on treatment, wellbeing and rehabilitation in an imposing complex which has achieved outstanding environmental as well as clinical excellence.”

[ 15 ]

Project feature Hospital redevelopmentUpfront #2:12

Project feature Isaac Newton Academy

[ 16 ]

Upfront #2:12Project feature Isaac Newton Academy

Showcasing the latest environmental technologies, the new Isaac Newton Academy opens it doors ready for the start of term

Green designs for children’s future

Contact: Web: skanska.co.uk/lse

Project feature Isaac Newton AcademyProject feature Isaac Newton Academy

[ 17 ]

Project feature Isaac Newton AcademyUpfront #2:12

£30 million, four-storey building in time for the !rst registration bell in September 2012.

For Skanska’s civil engineering and structural design team, the work started one year before the hoarding went up on site.

As the school year began, with shiny shoes, immaculate uniforms and satchels full of anticipation,

more than 1,200 pupils arrived for their !rst day at the pristine Isaac Newton Academy.

Nested in the heart of Ilford, in the London Borough of Redbridge, this brand new academy houses four individual schools, each with their own head teacher.

A&er a three-year project by Skanska, Isaac Newton Academy is the perfect place for learning with the most up-to-date science labs, a full-size sports hall, modern workshops for food, art and technology, and dedicated performance and practice facilities for music and drama.

James Williams, Project Director for Skanska’s London building division, says: “#e most satisfaction I got on this project was seeing the pupils start at their new school in September. We’ve built them a great school to go to – it’s the highest standard !nish I’ve seen at a school – and it’s going to make a di"erence to the local area.”

Split between key stage three and key stages four and !ve, the schools share specialist facilities but each has individual areas and entrances. With local primary schools at capacity, it will accommodate 240 11-year-olds for their !rst year at secondary school by 2019.

#is fresh facility is not only an education centre, but also a community hub, a place where local people can meet and learn with a score of adult, family and community classes on the agenda.

Despite its urban location, the new 11,500m2 school has the great outdoors at its heart with secret upper-level courtyards and roof decks for pupils and teachers to enjoy. Over 16,000 plants, 1,400 shrubs, 10,000 bulbs and 95 trees have been planted around the grounds. #ere is a stylish connection between the classroom and the outside world, providing inspiring and $exible teaching spaces.

#e rapid-paced, 19-month construction programme came to an end during the summer holidays, just as teachers and students were beginning to think about the term ahead. Skanska technically designed and built the

Left: Multi-purpose dining room and theatre with seating galleryAbove: The design is inspired by Isaac Newton’s law of universal gravitationBelow: Even the bathroom facilities have a modern and inspiring design

Exposed structure maintains temperature for an improved internal environment, aiding concentration in class Innovative façade

keeps building air tight to reduce heat loss

Project feature Isaac Newton Academy

[ 18 ]

Upfront #2:12Project feature Isaac Newton Academy

Skanska’s mechanical and electrical engineers introduced the EcoActive concept at the academy, reducing carbon emissions by 67% compared with a traditional school building, and cutting utility bills by 25%. Payback from the green technologies is due in around 15 years.

#e building is an environmental showcase with a host of technology focused on reducing the school’s carbon footprint. Ventilation and lighting automatically switch o" when

#e architectural design captured the client’s imagination by building part of the school – a sports hall and administration block – elevated on columns two-storeys in the air. #e innovative design maximised space but retained a vital 50-space capacity car park beneath the structure.

However, this 19m-wide, 54m-long raised building was at risk of dynamic loading – the $oor wobbling – during high impact sports like aerobics. Skanska’s in-house design team recognised the importance of the architectural feature but had to prepare for the most energetic sports students.

Chartered Structural Engineer Hardip Bansal, who project-managed the design, says: “From the analysis carried out, we gave the construction team several options like supporting props, shock-absorbing dampers or doing nothing at all. All of the options had risks – including upsetting the architect.”

Aiming to produce a low-risk solution, the !nal design moved the supporting columns closer together to reduce the span of the structure. It resulted in only the most subtle changes to the admired look of the space-saving building, and meant that even the most strenuous sports can now go ahead.

Communication and working together was key to the speed of the programme and meeting the deadline of the new school year. A combined Skanska team of construction experts and civil engineering and structural designers meant shared values, drivers and the main goal – to deliver an exceptional new educational facility.

#e technical design house worked closely with contractors, inviting

the steel fabricator design team to work at Skanska’s o%ce. It meant that the many design intricacies of the 1,269-tonne steel frame were ironed out with ongoing conversations and shared problem-solving. #e fabrication drawings were delivered in only two weeks, improving e%ciency and reducing the wasted time o&en spent exchanging and processing data between two companies.

Existing buildings at the site were demolished and the land was remediated of pollutants before construction works on the steel-framed structure started. #is complex construction project, combined with authentic brick-look and metal cladding features with structurally insulated panels, also keeps the warmth inside, reducing heating bills.

Rainwater harvesting for flushing toilets reduces water demand

Soil remediation to clean up old contaminated landfill

Sustainable urban drainage to reduce rainwater discharge to main sewers

Drainage pond and dry ditch reduce load on drainage system and provide education and nature resource

Floor beams and steel frame designed to reduce vibration from sports hall

Project feature Isaac Newton AcademyProject feature Isaac Newton Academy

[ 19 ]

Project feature Isaac Newton AcademyUpfront #2:12

no-one is in the room, and lights dim and brighten to accommodate natural brightness changes throughout the day. Rainwater harvesting and low $ush toilets all reduce water use. Windows are tinted to reduce sunlight glare and keep classrooms cool, and there is separate climate control for each room, reducing air-conditioning costs.

With nearly no impact on the environment, Isaac Newton Academy is a green triumph for a school building in the UK. And sustainability is not only part of the furniture at Isaac Newton but a learning opportunity, with access to the building’s energy performance data from every computer – all part of the curriculum which Skanska helped to develop.

1,269 tonnes of steel frame

4,164m! structurally insulated panels

2,395m! curtain wall

1,769m! metal cladding

785m! windows

58 eco-active units

[ 20 ]

News update Upfront #2:12

[ 21 ]

News updateUpfront #2:12

Hundreds of thousands of people downed tools on Skanska’s sites to take part in the world’s largest safety event in the last week of October.

Construction remains one of the most dangerous industries in which to work, but Skanska’s

accidents has seen it reduce its global safety statistics by 50% over the last six years.

Project feature Piling and foundations

[ 22 ]

Upfront #2:12Procurement feature Greening the supply chain

Contact: [email protected]: supplychainschool.co.uk

Chain reaction

sustainable construction

material

water

economy and community

sustainable procurement

climate change

biodiversity

environmental management

waste

ethical business

Construction industry commits to green education with the launch of the Supply Chain Sustainability School

Procurement feature Greening the supply chain

[ 23 ]

Procurement feature Greening the supply chainUpfront #2:12

gains strength. It can influence the way you build, and we want to get those sustainable credentials across.

David Rich, Lafarge’s UK Sustainability Engineer

Sustainability is transforming the construction industry, with top contractors all rating it highly on their

corporate agendas. Government legislation is leading the way, guiding the industry towards greener practice. But it is not just government and ethics spearheading the drive towards green: clients want it too.

To improve its green credentials, the whole industry needs to change the way it thinks about green. And that directly a"ects Skanska’s burgeoning supply chain.

#e Supply Chain Sustainability School, a free online learning environment, has been launched to enhance the green credentials of everyone in the construction supply chain. Targeting small and medium-sized businesses, it o"ers a wide-range of resources that develop knowledge and competency in green issues. It provides an opportunity for suppliers to understand the sustainability priorities of major contractors and clients and bene!t from a green education.

Skanska’s driver for establishing the school was an objective to realise deep green projects – infrastructure projects with near-zero impact on the environment.

Skanska initially developed the concept with Action Sustainability, a not-for-pro!t social enterprise, and Responsible Solutions, an environmental consultancy.

To secure funding for this unique and industry-leading resource, Skanska brought together a consortium of construction companies more o&en in direct competition with each other – Lend Lease, Morgan Sindall, Kier, Willmott Dixon, Sir Robert McAlpine and Aggregate Industries.

Meeting representatives from rival !rms for the !rst time might have been daunting, but the spirit of collaboration among top industry names resulted in a successful 12-month bid for £0.5 million of government funding.

Nick Baker, Sustainable Procurement Manager, says: “It was refreshingly

easy to secure support from our industry peers and has been a really rewarding experience. And no, we haven’t had any fall outs – it’s a truly collaborative environment. When I watch the promotional video we developed and see all the companies involved talking about the school with a single voice, it’s a very powerful message – there’s not many projects like this that bring the industry together in this way.”

Jennifer Clark, Skanska’s Director of Environment, adds: “We can’t be green without a green supply chain, and so we have collaborated with our competitors, who are now more colleagues than competitors. #ere are no hidden agendas, only openness and honesty.”

#is commitment shows clients that construction contractors are driving sustainability down through the whole supply chain. A greener supply chain will help Skanska to deliver the sustainable products and services that its clients are demanding, signi!cantly reducing costs and increasing e%ciencies during the construction process.

Procurement feature Greening the supply chain

[ 24 ]

Upfront #2:12

Since the launch of the school in June, interest from the supply chain has been high, with more than 1,600 individuals from over 1,000 companies signed up as members.

One of Skanska UK’s biggest suppliers, cement product manufacturer Lafarge, was one of the !rst companies to sign up to the school. A global organisation with 68,000 employees, Lafarge did not !t the target demographic for the school, but its management was really keen to get involved.

David Rich, Lafarge’s UK Sustainability Engineer, explains: “It’s good to see the businesses who are involved telling us what they think is important with regards to sustainability.

“It means we can share ideas and get a better understanding so that we all don’t go o" in our own direction and create confusion.

“It helps us know what they really want and provides a useful resource to aid our sustainability training.

“We’re not just a company with a concrete wagon that turns up to site – there’s a lot more to it than that. We work in an industry that now leads on sustainability though the Sustainable Concrete Forum and sector-wide engagement that is changing perceptions.

“Our products can be used in systems that improve the e%ciency of buildings – you can achieve more with concrete than just a material that gains strength. It can in$uence the way you build, and we want to get those sustainable credentials across.”

#e school o"ers suppliers a con!dential self-assessment tool that generates bespoke action plans, training workshops from recognised industry bodies, one-to-one support, e-learning modules and access to a resource library.

All services are available at no cost, with the school funded by the Construction Industry Training Board, otherwise known as CITB – ConstructionSkills. As Nick Baker says: “#ere’s nothing to lose, and a lot to gain.”

Procurement feature Greening the supply chain

[ 25 ]

News round-upUpfront #2:12

Skanska UK had good reason to celebrate in July when the team won the Employer of the Year Award at Construction News Awards 2012.

demonstrable results relating to talent management, training, diversity and corporate social responsibility. Evidence of senior management involvement is also important.

The award is open to construction-

with how Skanska integrated its people strategy and activities with the overall business plan, its competitive and tailored benefits packages, and the employee share scheme.

Left: Skanska’s HR team, with senior managers Lucy Jones and Mary Goodey, collected the Employer of the Year Award

Prize-winning people power

The award entry focused on how Skanska puts people development, diversity and talent management at the top of the agenda, and how its unique culture helps the company to attract like-minded people who value sustainability, ethics, safety and quality. Spotting and promoting stars early in their careers, providing varied experiences and putting the wellbeing of people first were attributes also recognised by the

Harvey Francis, Executive Vice President, says: “The whole HR team is absolutely delighted to have received this award. It is recognition for the huge strides forward the whole company has taken over recent years to make Skanska a great place to work.”

Skanska UK also won the Sustainability Award, recognising how the company has brought a sustainability focus to its procurement processes.

Skanska now provides specific guidance in six key areas of sustainable procurement: supply chain health and safety; ethical sourcing; supply chain equality, diversity and inclusion; environmental and green sourcing; best value procurement; and supply chain quality management.

Commenting on the award success, Technical Services Director Andy MacAskill says: “This award recognises the commitment, hard work and dedication of the whole procurement team to procure sustainably.”

Project feature Green retrofit

[ 26 ]

Upfront #2:12

Contact: [email protected] Web: skanska.co.uk/srw

Project feature Green retrofit

[ 27 ]

Upfront #2:12

Cambridgeshire school set to slash energy bills by £120,000 a year

An energising retrofit

Picture: Impington Village College, Cambridgeshire

Project feature Green retrofit

[ 28 ]

Upfront #2:12

Arriving at Impington Village College in Cambridgeshire, Skanska found one of the highest carbon

emissions rates in England.

With rising fuel costs and reducing budgets, the college, which operates as a secondary school and sixth form for 1,400 students, just couldn’t a"ord to do nothing.

#e college has been striving to !nd ways to reduce its current carbon commitment and has previously investigated a number of options, all of which have so far failed to meet its objective of reducing carbon use by at least 10%.

Skanska developed a bespoke retro!t of the school’s energy services, which are set to reduce carbon and energy consumption by half. #is is equivalent to more than £120,000 a year in guaranteed savings and new revenue for the school.

Vice Principal Fran Difranco comments: “#is exciting project o"ers a potential reduction in excess of 50%. Not only that, we believe this represents a unique and trailblazing opportunity which, if successful, could become a model of good practice throughout UK schools.”

And this impressive turnaround comes at no initial cost to the college, because it agreed an energy performance contract (EPC) with Skanska to fund the project.

#is means that funding for the project is being provided by private !nance so the school doesn’t have to fork out a penny. Instead, over seven years, the guaranteed savings and revenue generated from the new energy saving measures, which

project is now likely to improve the school’s energy certi!cation rating from an ‘F’ to a ‘C’.

“#is ambitious plan would just not be possible if le& to the public purse,” says Governor Jake Reynolds.

Richard Byers, Associate Director at Skanska, says: “#ese funded energy saving measures will enable and empower Impington Village College to proactively manage its energy consumption and carbon emissions, while guaranteeing savings and revenues in the long term.”

are independently measured and veri!ed, are used to pay back the funding.

Once the EPC period is up, the school can then reap the !nancial rewards for its own budget – and £120,000 a year will make a huge di"erence.

Skanska is installing a number of energy saving measures, including a biomass boiler, which alone will create annual revenue of nearly £60,000, and will reduce the college’s carbon emissions by approximately 30%. #e energy conservation

Energy saving measures:

monitoring

for staff and students

pellets

Project feature Green retrofit

[ 29 ]

Upfront #2:12

But Impington Village College has greater reasons for going green beyond the obvious energy reduction and cost savings. #e college o"ers international courses with links to numerous overseas schools and organisations many of which are involved in sustainable and ethical practices.

Students, who come from all over the globe, o&en travel as part of their course and experience !rst hand some of the devastating e"ects human actions can have on the planet. In contrast, they also get to see how sustainable practices can

bene!t some of the poorest – and the richest – communities across the world. “#e students will be able to see the energy saving measures in use at the college, and will also bene!t from an educational input as part of the curriculum,” comments Fran Difranco.

Martin Rigby, Chairman of the college’s governing body, says: “I am delighted with this imaginative partnership between Impington Village College and Skanska. It will put both organisations at the forefront of green energy in the education sector.”

Annual utility cost £183,000 (2009/10)

2 emissions 101.33 KgCO2/m!

Annual saving + revenue £61,369 + £58,236

Annual CO2 saving 50 KgCO2/m!

£693,000

7 years

age: 1939, mid-60s, 90s, 2005, 2010

Project feature M25 widening

[ 30 ]

Upfront #2:12

Skanska has delivered the £1 billion widening of one of the world’s busiest orbital motorways ahead of schedule – along with 15% savings shared with the client

Keep on moving

Contact: [email protected] Web: skanska.co.uk/civilengineering

[ 31 ]

Project feature M25 wideningUpfront #2:12

The three-year scheme, a joint venture between Skanska and Balfour Beatty, involved widening 62km of the M25’s

northern section from three lanes to four in each direction, and refurbishing Hat!eld Tunnel.

"e project had to be delivered in time to coincide with London’s Olympic Games in July 2012, so meticulous planning was needed right from the get-go in April 2009 to keep to the 38-month programme.

Not only was the project completed ahead of schedule, but the Skanska Balfour Beatty team reduced costs by 15% compared to the tender, and tra#c $ows were barely interrupted throughout the works.

In the beginning Describing the early stages, David Blackburn, Managing Director of the M25 project, says: “From the start, time was a key driver; we had to !nd every means of reducing the construction time or risk very heavy penalties.

“"e essence of the project was ‘to do what we said we would do every day and then a bit more’. We were constantly !nding new ways of reducing cost.

“We had 2,500 people employed on the project at its peak. Many were transferred from existing projects, like the M1 Junction 6a to 10 widening, which was also completed in joint venture with Balfour Beatty. So many of us already had a successful working relationship and it just grew from there.”

Getting the job done Project management was crucial so the scheme was split into three sections – Section 1, widening Junctions 16 to 23; Section 4, widening Junctions 27 to 30; and Section 6, refurbishing the Hat!eld Tunnel. "ere were project teams for each, and Sections 1 and 4 were further divided into sub-sections to maximise detailed planning.

To allow su#cient space for teams to construct the verge works, contra-$ow tra#c management schemes were adopted, meaning that only one verge could be worked on at a time. Each sub-section had to be fully complete before moving on to the next section.

Commenting on this critical sequencing, David says: “We had to get it right !rst time as we couldn’t

go back into the verge. In reality, getting things done faster is more about removing the blockers than creating a new system of work. However, when you do remove the blockers – you inevitably end up with a new way of working.”

As the project progressed, the teams continued to meet key deliverables, which was even more impressive following an initial delay and some severe winters.

Re$ecting on the di#cult weather conditions, David says: “We su%ered in two bad winters, but managed to pull it round with one good winter and one good spring. All in all we recovered !ve weeks delay at the start of the project and opened two months early. A fantastic achievement.”

Above: Working in the verge proved critical to keeping on programme

We challenged everything and then challenged the results of the challenge.

David Blackburn, M25 Managing Director

Project feature M25 widening

[ 32 ]

Upfront #2:12

Operational efficiency Once the team had the major elements in order, they then focused on how they could make improvements. With the help of an external consultant, project improvement teams were established on Sections 1 and 4 to look for process improvements, reduce waste and, ultimately, make savings. A total of 28 projects were undertaken using lean construction techniques.

David says: “We made a sizeable investment, but we got it back and more. We also invested heavily in design, working on two designs in parallel – one standard design and one design challenging the standard.

“We challenged everything and then challenged the results of the challenge. When we compare our !nished product to that of other

motorway projects, the cost savings we generated from design challenges are instantly recognisable.

“Of course it’s a balance of risk. We saved a lot of money through land purchase or leasing land for environmental bunds. We retained as much of what was there originally and didn’t replace anything that didn’t need replacing.

“#rough value engineering, the team saved approximately £2 million on one bridge alone – the Berry Lane Viaduct.”

From the beginning, the team set out to drive down costs and achieve high production levels jointly with the supply chain. Key subcontractors were incentivised to do this and they all shared in the gains made.

David cites an example: “Developed with the supplier, we introduced a new major engineering innovation – a combined barrier and retaining wall. #is resulted in a narrower verge behind the hard shoulder, with cables and ducts behind the wall – we completed 18km like that.”

[ 33 ]

Project feature M25 wideningUpfront #2:12

And finally With possible future projects on the horizon, David praised successful relations with the client. He says: “Considering it’s a !xed price lump sum contract, they have been exceptionally collaborative. #ey’ve been great.

“We hope to continue to work with them to help meet government objectives of delivering growth and reducing costs by 20% with demonstrable value for money.”

Green scene During the project, thousands of wild animals such as reptiles, newts, birds and badgers were relocated, and members of the team built a new home for a family of kestrels in the project’s batching plant.

#e team achieved 92% of aggregates from recycled resources, with the majority crushed and recycled in the site compounds.

#ey also patented a method of sheet piling which cut down on the amount of steel used, delivering equivalent savings of 35,000 tonnes of CO2 for steel alone.

The final stretch With the !nishing line in sight, the team’s consistently robust focus meant that the project was eventually completed with time to spare. David puts this down to his team never giving up.

Far left: The team prepares to lift a gantry with motorway communicationsLeft: The M25 today

He says: “We had an 18 month plan for Section 1 geared around the opening of Junction 19, an extremely congested area, well ahead of programme. We achieved this six months early – a real project highlight, as the impact on road users was stunning, relieving tra%c on the M1.

“I’ll always remember the date and time we did it – it’s stuck in my mind as though it was yesterday. It was 28 February 2011, a Sunday morning, and I had gone to take a few photos of the new sub-section, as it was due to be opened to tra%c at 11:30 in the morning. But when I got there, much to my surprise, the tra%c was running smoothly on all four lanes, as the team had already opened it the day before. I had a lump in my throat. It shows what you can really do when a team comes together.”

David Blackburn, Managing Director of the

Project feature Piling and foundations

[ 34 ]

Upfront #2:12

A record-breaking holeMassive dig in treacherous conditions

Contact: [email protected] Web: skanska.co.uk/cementation

[ 35 ]

Project feature Piling and foundationsUpfront #2:12

Six Skanska experts worked through cold winds and driving rain for more than four weeks to drill what is thought to be the UK’s

biggest ever hole.

And to make matters even more interesting, the 4.3m by 25.5m hole was situated deep into the seabed just off the Port of Dover.

The world-class technical skills and expertise from Cementation Skanska, the group’s specialist piling division, were required to extend Dover’s Eastern Docks, one of today’s busiest roll-on, roll-off ports in the world, serving around 13 million passengers each year. Pier A needed extending into deeper waters so that larger vessels could dock.

The Port of Dover, which dates back to the Bronze Age, serves as a hub for major shipping activities such as general cargo and cruise ships.

The Skanska team’s knowledge of large diameter rotary piling

Pictures: Cementation Skanska operatives prepare to core into the sea bed

techniques was drawn on to carry out the excavation deep into the sea bed, resulting in the gigantic hole to accommodate a 4.2m by 46m steel monopole.

The Cementation Skanska team was led by Project Manager Jonathan Manning and Construction Manager Paul Calleja, delivering the work for Dover Harbour Board, which operates the UK’s and continental Europe’s busy cross-Channel transport network.

Mark Bradshaw, Southern Projects Manager, says: “To carry out this phenomenal job, we had to work with specialist equipment, such as a jack-up rig. This contains a buoyant hull to enable transportation of the unit and all attached machinery to a desired location.

“Working against tough winter conditions, and with the unpredictability of the sea, the team was determined to get the job done to their best abilities, and we are very proud of their work.”

At 4.3m-wide, the hole at the Port of Dover is around twice the width of the foundations of Heron Tower, the tallest building in the City of London

All Saints’ Academy, Cheltenham

John Brennan Construction Manager of the Year 2012, New Build and Refurbishment £23 million – £40 million

Judges’ comment “John demonstrated exceptional leadership to finish early and within budget while delivering top-notch quality. He found craftworkers to deliver what seemed an unbuildable copper-clad chapel. And he cannily reused the material excavated for the archaeological dig as a piling mat and the sub-base for the sports pitches.”

People feature Developing talent

[ 38 ]

Upfront #2:12

with traditional leadership roles. #ey’ve just recognised that the people in these roles don’t have all the answers.

Skanska’s global Leadership Pro!le is designed not only to develop leadership skills across the company, but to bring the concept of collaborative working to life.

Harvey Francis, Skanska UK’s Executive Vice President, explains: “Over the last few years we have been thinking of how we can act as one team to harness the opportunities that being part of a large, diverse, multi-national business gives us. If you want to do that, you need to give people a common language and get the whole organisation to understand what capabilities are needed to succeed within Skanska.”

Are some people born to lead or can leadership be learnt? #e traditional view was that certain individuals

were natural leaders – visionary, charismatic risk-takers, who could inspire and energise others. Everyone else was a follower. But even before the !nancial crash brought down a string of celebrity bosses, thinking about leadership had moved on.

Leaders with big personalities can certainly deliver results, especially when a company is in its start-up phase or facing a major crisis. But success that depends on a single, ‘heroic’ leader tends to be short lived. It’s now widely recognised that people at all levels of an organisation can in$uence – and lead – their colleagues. #at’s why Skanska’s new

Leadership Pro!le is based on the idea that every single person who works for the company is a leader, no matter what their formal job role happens to be.

Other companies have also realised that shared leadership opens the door to continuous improvement by empowering employees to use their initiative. #e power and automation technology group ABB, for instance, is seeking to include all employees within its leadership model and is using a global learning programme to develop leadership skills at every level of the organisation.

Successful companies renowned for their shared leadership practices also include W.L Gore, Proctor and Gamble and Southwest Airlines. #ese companies haven’t done away

Contact: [email protected]

Who leads?Anat Arkin, correspondent for HR industry publication People Management, examines recent trends in leadership development with Skanska UK’s Executive Vice President, Harvey Francis

[ 39 ]

People feature Developing talentUpfront #2:12

Everyone can be a leader, says Harvey Francis

People feature Developing talent

[ 40 ]

Upfront #2:12

commitment to diversity, ethical conduct, the green agenda, health and safety and the one team approach, which unites the whole workforce around a common way of doing things. Including these values in a competency framework ensures that everybody in the organisation is clear about how they are expected to act.

Skanska recently launched a management development programme around the new competencies, as well as reframing its other learning and development activities. #e company has also produced a competency development guide to help employees navigate their way through the many learning opportunities available to them. Since people learn in di"erent ways, these range from formal courses to on-the-job training and e-learning.

All of this adds up to a major investment in developing Skanska’s people at a time when many other companies are cutting back

#e Leadership Pro!le sets out the core competencies that all employees are expected to cultivate, and replaces an older competency framework that applied only to senior executives. “#is new Leadership Pro!le applies to people right across the organisation, but it’s $exible enough to !t all roles,” says Harvey. “So there are generic competencies that apply to everyone and then there are a number that are role-speci!c. Whether you are managing yourself, other people, an organisation or a large part of an organisation, the competencies needed will be di"erent.”

#e 17 core competencies outlined in the Leadership Pro!le are split into four groups: ‘living our values’, ‘managing operations’, ‘developing the business’ and ‘leading yourself and others’. While some of the competencies listed under these headings are technical and functional, many others are concerned with interpersonal relations. For example, competencies appearing under ‘leading yourself and others’ include ‘composure’ – de!ned as being able to handle stress without showing frustration – and ‘interpersonal savvy’, which is about

relating well to all kinds of people and building strong relationships.

“We work on the premise that this business is all about relationships and about building trust in order to develop them. So the way that people conduct themselves and handle stress or manage con$ict is very much at the heart of being at Skanska,” explains Harvey.

What really makes the Leadership Pro!le stand out from other competency frameworks, however, is the section on living Skanska’s values. #is highlights the company’s

[ 41 ]

People feature Developing talentUpfront #2:12

on learning and development. According to the Chartered Institute of Personnel and Development’s 2012 Learning and Talent Development Survey, the prolonged economic downturn has had a knock-on e"ect on the resources available for learning and development. A third of the organisations responding to the

survey reported that resources had declined over the previous year, with the average annual training budget per employee shrinking from £350 to just £276.

Companies such as Skanska that are bucking these trends are doing so for sound commercial reasons. Pointing

out that one of the stated aspirations in the company’s 2015 Business Plan is to make Skanska a leader in people development, Harvey says: “#ere is a direct link between the new Leadership Pro!le and our business plan. We believe that by focusing on developing our people, we will get better business results.”

Britain’s employers are clinging to outdated methods to train their staff, according to the latest Learning and Talent Development Survey by the Chartered Institute of Personnel and Development (CIPD) and software provider Cornerstone OnDemand.

The survey found that integrating learning into people’s daily work is considered the most effective way of up-skilling them, while formal courses are among the least effective

methods. Yet, despite doubts about the effectiveness of classroom-based

respondents plan to reduce their reliance on this method.

Commenting on these findings, Dr John McGurk, Learning and Talent Development Adviser at the CIPD, says: “Many of the learning approaches used by organisations are legacies of a learning environment where the classroom, courses and ‘sheep-dip’

learning were the order of the day. However, in today’s environment, the skills of continuous collaborative and connective learning are paramount.

“Even compliance learning and advanced skills learning needs to be rethought with the advent of gaming and simulation. We need to take into account how generations learn and share knowledge.”

Web: cipd.co.uk

Employers urged to re-think approach to training

Project feature Underground power cables

[ 42 ]

Upfront #2:12

Power of the underworld

[ 43 ]

Project feature Underground power cablesUpfront #2:12

Skanska is fitting a series of new,

high-power electricity cables

through a 6km tunnel in London

– part of which runs under Old

Father Thames.

A team from Skanska’s utilities

division is tackling the £1.8 million

supply for UK Power Networks.

fitting six 132kV cables and all

associated fibre optic cables

through a tunnel running from

Wandsworth substation in south-

west London to Moreton Street

substation in Pimlico, in the heart

of the City of Westminster.

Contact: [email protected]: skanska.co.uk/services/utilities

Project feature Underground power cables

[ 44 ]

Upfront #2:12

#e main reason for this is safety, as there have been previous experiences of the steel bond snapping and whipping up. In a con!ned space this could cause injuries or damage circuits.

Overcoming these challenges would not have been possible without a committed team all working

All eyes will be on the project during the simultaneous ‘pushing and jointing’ of the 132kV cables, which runs from August through to December. #e team is going for a di"erent technique to pull the cable through, one which has rarely been done before, involving cable pushers as opposed to the conventional winch approach.

Starting in January 2012, the project team’s !rst job was to install the temporary tunnel lighting. “It was pitch black down

there because there wasn’t any natural light, you couldn’t see a hand in front of you,” remembered Project Manager Paul O’Hara. “It’s much better now we have the temporary lighting and throughout the course of the project we will install permanent lighting.”

Next came the mammoth task of !xing 3,000 brackets to the tunnel wall for the six cables to sit on. #e brackets, positioned one every 2m, were made at Cementation Skanska’s Doncaster site.

Transported on purpose-built trailers, the !rst delivery of 12 drums of 132kV cable arrived in July 2012. In total, 36 drums of the UK Power Networks-supplied, free-issue cable from Korea will be used.

Paul says: “Each drum measures 3.5m in diameter and weighs 16 tonnes, so due to their size and weight they need to be transported on a special trailer.

“#e logistics of getting a 4.2m trailer through the streets of London has been challenging. #e team has been dealing with local authorities, the Metropolitan Police and an assortment of other third parties to ensure deliveries don’t clash with any major events.”

[ 45 ]

Project feature Underground power cablesUpfront #2:12

Wandsworth

Pimlico

Lambeth

Wandsworth

Kensingtonand Chelsea

City ofWestminster

Hammersmithand Fulham

together, according to Paul: “#e team has all pulled together to overcome di%cult circumstances with issues o&en resolved using collaborative planning techniques.”

Access to the 6km tunnel is via eight sha&s, each with a 27m drop from the surface to the tunnel base, meaning workers face a !ve-ladder climb every time they enter or exit the tunnel.

#e tunnel is wide and tall enough for people to walk through, as long as they are less than six foot tall. But the team use three modi!ed electric golf buggies with trailers to transport tools and equipment from one end to the other – still a 40-minute journey. Describing the tunnel, Martin Hession, Project Engineer, says: “As the tunnel is only 20 years old, it’s quite clean compared to others. #ere is a little bit of surface water, but nothing to worry about. #e temperature is OK, although the guys do get pretty warm working down there wearing their personal protective equipment.”

#is equipment includes breathing apparatus, which turns carbon dioxide into oxygen (30 minute duration), gas monitor, !re$y (alarm triggered if a person is motionless), harness, $ame retardant overalls, safety glasses, high visibility vest, hard hat and gloves.

“At the Pimlico end there is a bit of a bottle neck,” adds Martin. “#ere is a very small sha& 2.5m in diameter, lots of other cables and little space to work. It gets very hot down there and it can feel a bit claustrophobic – not very pleasant.”

#anks to building information modelling (BIM), the team sees 3D images of the sha&s before they go in, helping them to compare sha&s, plan sca"olding and check designs from the safety of their desks.

Looking to the future, Paul says: “Hopefully this scheme will be the !rst of many, as UK Power Networks look to change its approach from laying cables under roads to installing them in tunnels.”

Hand arm vibration monitoring The cables sit on a network of 3,000 brackets, meaning the team has had to drill

from excessive vibration, the team is using a system called REATEC to measure hand power tools vibration levels.

Every individual has a personal plastic card which they swipe through the base station. This illuminates a small unit which they take with them to use that day. They attach the unit magnetically to the power tool and begin drilling. The unit will flash red, amber or green depending on the vibration level reached.

When finished, the individual returns the unit to the base station. The data captured is used by the health and safety team and occupational health experts to monitor team members’ exposure. The system is fully automatic, replacing paper-based records.

Allan Hogan, Safety Health Environmental Quality (SHEQ) Advisor, says: “This is a fantastic system that builds on the other health monitoring and education we provide. We did have some high readings in the first month of using it, which raised everyone’s awareness. Since then, the guys have gone from being sceptical to now realising the benefits and liking it.”

[ 46 ]

News round-up Upfront #2:12

Heron Tower, built by Skanska and completed in 2011, has been named best commercial work place at the 2012 British Council for Offices (BCO) Awards.

Gary Clifford, Operations Director for Skanska’s London building team, says: “This award is a true testament to each stakeholder involved in the successful delivery of such fantastic commercial office facilities and proves how we pulled together as a team to deliver one of London’s greatest landmarks.”

Heron Tower is located in Bishopsgate, central London, and stretches 230m into the skyline. It offers 36 storeys of office space, along with bars and restaurants on the ground and uppermost floors.

The best place to work

Skanska has been awarded a £33 million contract to undertake the design and construction of the new 2,500-place Thurrock Campus, located in Grays, Essex.

The facility, which has a target of achieving BREEAM Excellent, will incorporate green elements, such as rainwater harvesting. In addition, Skanska’s in-house team will deliver the structural and civil

utilising its expertise in BIM.

New campus for South Essex College

[ 47 ]

News round-upUpfront #2:12

A £2 million expansion of Hannah More Primary School in central Bristol has been

months, courtesy of Skanska.

Built on top of the existing school building – due to the lack of extra space – the extension provides six additional classrooms and accommodates

420 pupils – an extra 50%. The team also installed a new kitchen block and a high-level steel walkway to the new classrooms.

Mike Carter, Operations Manager (pictured), comments: “In order to avoid disruption to the pupils during the school term we used off site construction methods.

Smith, made certain everything was ready for the pupils to return to their classrooms at the end of their summer break.”

Primary school doubles up

The English Heritage chill out room

The nation’s records will soon be protected using the latest green technology, thanks to plant replacement works at the English Heritage Archives in Swindon.

The facility stores a nationally important collection of historic photographs and records and has to maintain strict environmental conditions in relation to both temperature and humidity to preserve the documents.

Ray Phillips, Associate Director, says: “We are usually responsible for creating a comfortable place to live, work or play. This exciting

skills and experience to help preserve and protect some of the country’s most precious records.”

Picture: York Minster, exterior from north west

People feature Future talent

[ 48 ]

Upfront #2:12

Dream makers

Contact: [email protected] Web: skanska.co.uk/srw

[ 49 ]

People feature Future talentUpfront #2:12

Many young people can only dream about helping to construct one of the tallest buildings

in Britain, working in America or being a part of the Olympics.

But for three individuals on the student training programme at Skanska’s mechanical, electrical and ceilings division, all three dreams came true.

#e programme recruits students who are typically in their late teens having just !nished school. “#is sort of vocational, on-the-job training is becoming ever more popular given the increasing cost of attending university,” explains Operations Director Nick Card.

One lucky recruit was Electrical Engineer Luke Busette who was still at school in East Finchley, London, !ve years ago, struggling with one of the biggest decisions he had ever had to make – which career path to choose. Luke had his heart set on an electrician apprentice scheme and when he heard about Skanska’s training programme through a family member, he applied.

Luke successfully passed the recruitment process and started out at one of Skanska’s central London o%ces working with the bid teams on the former Building Schools for the Future programme.

“A&er a few months, I started to ask myself if this was what I really wanted to do,” says Luke, now aged 21. “I wanted some real site experience and then an opportunity came up to work on the tallest building in central London at the time – Heron Tower.”

Luke transferred to the site team and before long was responsible for both the internal and external lighting requirements of the 46-storey, 230m-tall building. “#e scale of the project was massive,” says Luke. “I was just out of school with very little experience, but Skanska believed in me and gave me a chance.”

As the project started to wind down, Luke saw an opportunity to get involved with another record-setting project. “Brent Civic Centre is a project just around the corner from my house,” Luke says. “#is new building will not only house the council sta" but will become my new local library and community area. I want to be able to say, ‘I built this’.”

When complete, the civic centre will be UK’s !rst ‘Outstanding’ BREEAM-rated public building.

BREEAM is the world’s leading design and assessment method for sustainable buildings.

In addition to gaining valuable site experience, students enter into a formal education programme o&en through a day-release scheme with a local college. A&er !ve years, Luke gained a National Certi!cate in building services engineering. But it didn’t stop there.

Luke explains: “Although I’ve !nished the student programme,

Left: Luke Busette is on track to achieve a degree in building services engineering Above and right: James Pearce hopes to transfer knowledge gained in the US to the UK

People feature Future talent

[ 50 ]

Upfront #2:12

Skanska is still supporting me. I am now working towards a degree in building services engineering at South Bank University.”

And it’s not only Luke who Skanska is continuing to support, as Project Engineer James Pearce explains.

“Since completing the training programme in 2007, Skanska has helped me achieve a degree in building services engineering and made possible a six month secondment to America,” says James.

For several years, James had applied to be part of Skanska’s global employee exchange programme, Skanska Unlimited. “Although I successfully passed the initial stages, there was not a suitable exchange

that I could make due to the specialist nature of my work in the UK,” explains James.

Unbeknown to James, the senior team at Skanska had recognised his persistence and had no trouble recommending him when a temporary position became available in Skanska USA’s Mission Critical team. #is specialist division designs and builds data centres to house multiple IT servers, typically for !nancial institutions or large scale websites.

James, now aged 27, says: “I spent six months in New York working with the team on its innovative modular system where a data centre can be constructed o" site, delivered in sections, and assembled on site.

“Now that I have returned to Bristol, I am in charge of rolling out this new technology in the UK. I have gained the skills and knowledge from my secondment to design and deploy the solution to our clients.”

It’s not only engineering students who participate in the student training programme. Trainee Quantity Surveyor Lauren Hrachovec started out as an administration assistant on the Olympic Media Centre project back in 2009, having just !nished school.

Lauren explains: “#e project was really busy and six months a&er I started, I found myself helping out more and more with the commercial side of things. #is really interested me and when the Commercial

It’s a steeper learning curve and although daunting it is a fantastic experience. It is only possible due to the support of the team and Skanska

Lauren Hrachovec, Trainee Quantity Surveyor

[ 51 ]

People feature Future talentUpfront #2:12

“I am the main point of contact for the Cottons Centre project which brings with it a lot of responsibility. It’s a steeper learning curve and, although daunting, it is a fantastic experience. It is only possible due to the support of the team and Skanska.”

#is is a sentiment echoed by all the students on the training programme. “Stick with it,” says James. “It’s tough, it’s not always fun, but the support from Skanska means that, over time, things fall into place and start to make sense.”

#is year saw a record-breaking nine students graduate from the !ve year programme, bringing the total number of graduates to 85 over the last 18 years.

Speaking at the annual graduation event, Managing Director of Skanska’s mechanical, electrical and ceilings division, Martin Neeson, says: “It is very encouraging to see the commitment and investment that this business is making in the student training programme. We are training and developing the next generation of future talent, giving them a solid grounding to develop their careers and improve their skills within Skanska.”

Electrical Engineer Luke sums up the bene!ts of this approach: “At school, I was shy and reserved, but this programme has given me the con!dence boost that I needed. #e support provided by Skanska has allowed me to get where I am today.”

Manager approached me and told me about the student programme, I jumped at the chance.”

Lauren started a distance learning course to work towards a speci!c diploma in quantity surveying practices, which teaches how to apply commercial elements within the mechanical and electrical sector. Now in her second and penultimate year, she plans to continue her studies with a part-time degree at South Bank University in London.

Having completed the work on the Olympic Park, Lauren has moved to her current project – the redevelopment of the Cottons Centre at London Bridge. “My current role was a big leap from my last,” says Lauren, now aged 21.

Environment feature Seed funding

[ 52 ]

Upfront #2:12

Clients reap the benefits of Skanska-funded green solutions

Contact: [email protected]

Sowing the seeds

With a continual focus on the bottom line, it is easy to forget about going

green. But while reducing negative impacts on the environment is an admirable goal, being greener can also bene!t bank balances.

Skanska has launched a Green Fund to help clients adopt cost-saving green solutions without taking on any risk. Finance is available for the initial cost of choosing innovative products, technologies, services or processes that will use less carbon, energy, water or raw materials, or produce less waste.

Cecilia Fasth, Executive Vice President, says: “Green solutions can need investment to get them o" the ground, producing cost savings over time. #is has historically been the stumbling block to many good ideas not being implemented.

“Skanska’s new Green Fund will provide projects and bid teams with the seed capital to invest in green solutions that are attractive to clients, provide a return on investment and can be applied to the wider business and construction industry.”

#is means clients do not have to use their own capital to back new ideas, as Skanska has a fund of up to £200,000 available.

Project and bid teams can apply for seed funding for construction or operational solutions. Money can even be used to !nance research and testing, providing the much-needed business case for why something should be done.

Skanska has launched the Green Fund in partnership with CO2Sense, a not-for-pro!t, low-carbon expert company that helps organisations to improve their environmental performance.

Joanne Pollard, Chief Executive O%cer of CO2Sense, explains more: “We’re delighted to team up with Skanska to o"er this valuable seed capital. #is initiative will act as a catalyst to help construction projects enjoy the strong investment returns that low-carbon initiatives o&en deliver.”

In Sweden, Skanska is using a similar fund to back green solutions. It aims to help build deep green projects with near-zero negative impact on the environment.

So far money has been invested to create green sites in Sweden, providing a"ordable renewable energy to construction sites using mobile solar energy systems, heat pumps and wind turbines. #e equipment will be leased to each site, generating up to 75% of the energy needed each year.

Väla Gård, a deep green o%ce in Helsingborg, is also bene!ting from the investment, using it to !nance the design and production of green solutions. #e net-zero energy building cleverly uses daylight and LEDs (light emitting diodes) for ventilation and lighting. Summer sunshine will create more energy than the o%ce needs, meaning that any excess can be sold to the grid. #e project is targeting a record-breaking LEED environmental certi!cation, which would be above and beyond platinum accreditation.

Clients in the UK are now also set to bene!t from an extra injection of green, which will ultimately enhance the bottom line.

Right: Executive Vice President Cecilia Fasth looks forward to a more sustainable future

Environment feature Seed funding

[ 53 ]

Upfront #2:12

The next edition of Upfront will include a special profile on the UK housing market featuring the latest news from Homes by Skanska, which launched its first show home – in Cambridge – to critical acclaim in September.

What’s next...?

Your journey home

skanska.co.uk/homes0800 023 23 95

Sales office open daily 10am – 5pmSeven Acres, Kingfisher Gardens,off Addenbrooke’s Road, Trumpington, CB2 9AP

Now in Cambridge. Coming soon to Bath, Bristol and Cheltenham.

Sustainable solutions Open plan livingBuilt-in storageHigh ceilingsNatural light and connectivity to the outside