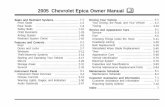

Unpacking an Epica Distribution Matrix · procedure for installing an Epica Distribution Matrix in...

Transcript of Unpacking an Epica Distribution Matrix · procedure for installing an Epica Distribution Matrix in...

Unpacking an Epica

Distribution Matrix

An Epica Distribution Matrix is shipped with one enclosure in each

palleted box. Each box contains one of each of the following items

(invoices are sent separately):

� Power cords (two or three depending on the enclosure)

� Enclosure

� Pallet (The enclosure is sitting on the pallet.)

The shipping boxes are marked as “Box #_of_,” where the first blank is

the box number and the second blank is the total number of boxes in the

shipment. Box #1 contains several additional items:

� Packing list

� Installation and Setup Guide

� User’s Operation Manual

� Quick Reference Guide (inside binder)

� Service Manual (At this printing, the Service Manual is still in

development. Please contact your authorized AutoPatch dealer for

availability.)

� Software (XNConnect and XNCC)

� Link cable (included with multi-enclosure systems)

� Other enclosure products

Installation & Setup Guide 1-1

Un

pa

ck

ing

Unpacking Tips

� Before fully unpacking the enclosure(s), examine the shipping

box(es) for any signs of damage. If a box is partially crushed or any

sides have been broken open, notify the shipping agency

immediately and contact your AutoPatch Salesperson or

Representative.

� Once unpacking is complete, closely check the physical condition of

the enclosure(s).

� Keep the enclosure(s) on the pallet for easy maneuverability with a

pallet jack or fork lift until the enclosure is installed.

� Collect all documentation and envelopes.

Note: AutoPatch is not responsible for damage caused by insufficient

packing during return shipment to the factory. Upon request, AutoPatch

will supply new shipping boxes at cost.

1.1 The Enclosure and Its PartsEnclosures are the structural basis of an Epica Distribution Matrix. Since

AutoPatch matrix switchers are custom built for each installation, factors

such as control method, signal type, and potential switches affect the

appearance and weight of each enclosure. This section describes:

� The front of a typical enclosure

� The rear of a typical enclosure

1-2 Installation & Setup Guide

Unpacking an Epica Distribution Matrix

Un

pa

ck

ing

Front of Enclosure

The front of an enclosure has the AutoPatch nameplate panel, Status

Indicator panel, and Matrix Resource display (see graphic below).

Installation & Setup Guide 1-3

Front of Enclosure

Un

pa

ck

ing

Front view of an Epica--128 enclosure

Matrix Resource Display

Status Indicator PanelPower Status indicatorPower Supply Status indicatorController Communication Status indicator

AutoPatch Nameplate PanelNameplate doorLocal Control Panel

(Behind nameplate door)

AutoPatch Nameplate Panel

The nameplate door swings open from the right, revealing the

Local Control Panel.

Local Control Panel

LCD screen: Displays instructions and selection entry fields. The

screen has 8 lines with 24 character capacity per line (including menu

areas).

Dynamic menu area: Displays different command and setting options

across the bottom and on the right of the control panel LCD screen

(depending on which screen is active). The setting options section on the

right of the LCD screen is occasionally unavailable.

Dynamic menu keys: Select commands and settings.

Control Dial: Scrolls horizontally to number selections and horizontally

and/or vertically and through long lists (depending on the need and the

screen).

1-4 Installation & Setup Guide

Unpacking an Epica Distribution Matrix

Un

pa

ck

ing

���������������� ���

���������������������� ���

���������������������� ��

�������������������� � �

��� ���� ��� �� !

"#$��%���&���%���'���%���(

The Local Control Panel is behind the nameplate door

LCD Screen

Dynamic Menu Keys

Dynamic Menu Area

Local Control PanelNameplate Door Control Dial

Working with the Local Control Panel

To interact with an Epica Distribution Matrix, you will use the dynamic

menu keys and the Control Dial to choose commands and values from

the dynamic menu area on the LCD screen. Each menu key lines up with

a different section of the dynamic menu area (see the graphic on page

1-4).

To choose a command, push the key that corresponds with the one you

want to choose.

To select values for fields (such as Level, Input, Output, and Preset

values), you can use a combination of the dynamic menu keys and the

Control Dial. Selecting a value with a menu key makes all the values in

the dynamic menu area change to fit a particular range around the value

you just selected. You can adjust the value by continuing to use the menu

keys, or you can use the Control Dial to scroll up or down to your final

value selection.

Status Indicator Panel

The Status Indicator panel has the following three lights.

Power Status Indicator

The Power Status indicator is the top light on the Status Indicator panel.

When the power flow is sufficient, the light is green; if the power flow is

interrupted, the light turns off.

Installation & Setup Guide 1-5

Status Indicator Panel

Un

pa

ck

ing

�����������������

��������������������

���������������

The Status Indicator panel

Power Supply Status Indicator(redundant power supply)

Power Status Indicator

Controller Communication Status Indicator

Power Supply Status Indicator

The Power Supply Status indicator is the middle light on the Status

Indicator panel. When all power supplies are functioning, the light is

green; if one or more of the redundant power supplies fails, the light

turns red.

Controller Communication Status Indicator

The Controller Communication Status indicator is the bottom light on the

Status Indicator panel. When communication between an enclosure and

an external controller or between multiple enclosures is transmitted, the

indicator blinks green. This indicator will periodically blink from

background network traffic even if you have not entered any commands.

Matrix Resource Display

LED Display

The Matrix Resource display is on the front of the enclosure below the

Status Indicator panel. These indicators report the number of switching

paths that are currently occupied by signals. Under normal operations for

a full system, expect 60-80% resource utilization.

1-6 Installation & Setup Guide

Unpacking an Epica Distribution Matrix

Un

pa

ck

ing

The Matrix Resource display

LED Display

Rear of Enclosure

The rear of an enclosure has the input and output connectors, expansion

slots, CPU, power supplies, and serial number (see the graphic below and

the one on the next page).

Installation & Setup Guide 1-7

Rear of Enclosure

Un

pa

ck

ing

����

������

��

� ���

� ���

���

������

����������������������������������������������������� �����

�������

!���!"#$"%&'����()*��+��

���

������

����������������������������������������������������� �����

�������

!���!"#$"%&'����()*��+��

���

������

����������������������������������������������������� �����

�������

!���!"#$"%&'����()*��+��

��,����������

��� �� �������� ���,

�����-�������� � ,�*

,./*�"$�����012#"3"4.0'5��#1*

20#065��

�����

��+���������

The rear view of an Epica--256 enclosure

Input Connectors

Output Connectors

Power SuppliesSerial Number

Expansion Slots

CPU Board

Input and Output Connectors

Input and output connectors are the attachment points for devices that

connect to the system. On the Epica–256, inputs for sources are on the

top part of the enclosure, and the outputs for destinations are on the

bottom. On the Epica–128, inputs are on the top part of the enclosure,

and the outputs are directly below them. A single enclosure can handle a

combination of analog audio, analog video, digital video, and sync

signals. Sync connectors are the same as input and output video

connectors; however, they are designed to pass sync signals in certain

systems (such as the H and V signals in an RGBHV system).

1-8 Installation & Setup Guide

Unpacking an Epica Distribution Matrix

� � � � � � �

Video connectors

���

������

����������������������������������������������������� �����

�������

!���!"#$"%&'����()*��+��

���

������

����������������������������������������������������� �����

�������

!���!"#$"%&'����()*��+��

���

������

����������������������������������������������������� �����

�������

!���!"#$"%&'����()*��+��

��,����������

��� �� �������� ���,

�����-�������� � ,�*

,./*�"$�����012#"3"4.0'5��#1*

20#065��

�����

��+���������

����

������

��

� ���

� ���

The rear view of an Epica--128 enclosure

Input Connectors

Output Connectors

Power Supplies

CPUBoard

Expansion Slots

SerialNumber

Un

pa

ck

ing

CPU

The CPU is on the rear of the enclosure and to the left, and has

connectors for attaching external control devices. The CPU also has a

system status indicator, a Ethernet status indicator, and ports for

controlling and for linking to other enclosures.

Expansion Slots

The expansion slots, located to the right of the CPU, are for future boards

that will increase functionality and add new features to your system. If

your system was ordered with vertical interval sync, the board will be

located in an expansion slot (see Appendix D for more information).

Serial Number

The serial number for the system is above the expansion slots.

Installation & Setup Guide 1-9

Rear of Enclosure

Un

pa

ck

ing

����

������

��

� ���

� ���

The CPU board

System Status Indicator

Ethernet Status Indicator

X Net Communication Link Port

Serial Ports

Ethernet Port

Power Supplies

All Epica series enclosures have standard redundant power supplies,

located to the far right of the CPU. There will be two or three, depending

on the model. Each power supply holds a power connector, a power

switch, and a fuse drawer.

Power Connectors

The power supply will accept all major, international, standard power

sources (see page B-2 for power supply specifications).

Power Switches

Toggle each power switch down to turn it on (toward the “1”), and toggle

each power switch up to turn it off (toward the “0”).

Caution: To avoid system damage, all power switches on an enclosure

must be turned on simultaneously for the enclosure to work properly.

Fuse Drawers

The fuse drawers are between the power connectors and the power

switches. Each drawer contains one fuse (see page B-2 for fuse

specifications).

1-10 Installation & Setup Guide

Unpacking an Epica Distribution Matrix

���

������

����������������������������������������������������� �����

�������

!���!"#$"%&'����()*��+��

���

������

����������������������������������������������������� �����

�������

!���!"#$"%&'����()*��+��

��,����������

��� �� �������� ���,

�����-�������� � ,�*

,./*�"$�����012#"3"4.0'5��#1*

20#065��

�����

��+���������

����

������

��

� ���

� ���

���

������

����������������������������������������������������� �����

�������

!���!"#$"%&'����()*��+��

The power supplies

Power Connector

Power Switch

Fuse Drawer

Un

pa

ck

ing

Placing the Enclosure(s)

This chapter covers site requirements and provides a step-by-step

procedure for installing an Epica Distribution Matrix in a rack.

2.1 Site RequirementsWhen placing the enclosure several site requirements should be

considered, including environment, chassis accessibility, cooling and

airflow, and power.

Environment

Choose a clean, dust free, (preferably) air-conditioned location. Avoid

areas with direct sunlight, heat sources, or high levels of EMI

(Electro-Magnetic Interference).

Caution: Avoid placing high heat-producing equipment directly above

or below the enclosure(s). The Epica Series Distribution Matrices are

designed to adequately dissipate the small amount of heat it produces

under normal operating conditions; however, this ability is defeated

when high heat-producing equipment is placed directly above or below

the enclosure(s). We recommend leaving at least 1 RU (1.75 in. or

4.45 cm) of open space above and 1 RU below an enclosure.

Installation & Setup Guide 2-1

Pla

cin

g

Chassis Accessibility

Make sure the front and rear panels of the enclosure are accessible, so

that you can monitor the LED indicators and access the control switches.

Leaving adequate clearance at the front and rear will also allow for easier

cabling and service.

Cooling and Airflow

The fan(s) cool the interior by drawing air through the vents and forcing

heated air out. Care should be taken in placement to avoid blockage of

the fan(s). The internal temperature should not exceed 122�F (50�C).

Caution: To protect the equipment from overheating, do not operate in

an area that exceeds the maximum recommended ambient temperature of

104�F (40�C). To prevent airflow restriction, allow at least 3 inches

(7.6 cm) of clearance around the enclosure openings for proper airflow.

Power

The source electrical outlet should be installed near the switch, easily

accessible, and properly grounded. Power should come from a building

branch circuit. Using a dedicated line for the system’s power is strongly

recommended. Use a minimum breaker current rating of 20A for 110V

or 12A for 230V. To avoid an overload, note the power consumption

ratings of all the equipment connected to the circuit breaker before

applying power.

2-2 Installation & Setup Guide

Placing the Enclosure(s)

Pla

cin

g

2.2 Installation ProcedurePlacing an enclosure in a rack usually requires more than one person (see

page B-2 for enclosure dimensions).

Tools for installation in a rack:

� Screwdriver

� Screws that fit your rack–for mounting the enclosure(s)

� Link cables (Ethernet cables are included with multi-enclosure

systems; otherwise, they are not needed.)

� The enclosure(s)

� An extra depth rack–to accommodate cabling

� Surge protector(s)–highly recommended

� A pallet jack or fork lift

Note: If the enclosure is to be operated in a temporary location, still

attached to the shipping pallet, be sure to remove the plastic wrap from

the underside of the enclosure to ensure air flow to the fan.

To place an enclosure in a rack:

1. After removing an enclosure from its box (and leaving the enclosure

on its pallet), use a pallet jack to move the enclosure close to its rack.

2. Place each enclosure in its own rack and attach front-mounting

screws to hold it firmly in place.

If the rack is not secured in place and you have room, you may find

it easiest to lay the rack face-up on the floor, set the enclosure inside

the rack, and attach the mounting screws before returning the rack to

its upright position.

Warning: To avoid damaging the front panel, do not lay the enclosure

face down.

3. If you have a multi-enclosure system, link the enclosures (see

Chapter 3, “Linking Enclosures”).

Note: A multi-enclosure system will not switch properly unless all

enclosures are linked.

Installation & Setup Guide 2-3

Installation Procedure

Pla

cin

g

4. Attach only the first two input and output signal cables to the correct

input and output connectors on the rear of the enclosure (refer to the

“Epica Series Cabling Guide” and Chapter 7, “Attaching Inputs and

Outputs,” of this guide).

5. Attach external power to each enclosure and turn on the entire

system (refer to Chapter 5, “Applying Power and the Startup

Sequence”).

Caution: To avoid system damage, turn on all power switches on an

enclosure at the same time. WE RECOMMEND ATTACHING ALL

POWER CORDS TO A SINGLE SURGE PROTECTOR AND/OR AN

AC LINE CONDITIONER.

6. Perform a test switch to ensure the system is working properly (see

Chapter 6, “Executing a Test Switch”).

7. When the test switch works correctly, disconnect the test switch, and

then attach all the input and output cables to the correct input and

output connectors on the rear of each enclosure (refer to the “Epica

Series Cabling Guide” and Chapter 7, “Attaching Inputs and

Outputs,” of this guide).

If the test does not work correctly, see Chapter 6, “Executing a Test

Switch.”

8. Remove the protective film from the Matrix Resource display area.

2-4 Installation & Setup Guide

Placing the Enclosure(s)

� � � � � � �

Attaching video cable to video connectors

Pla

cin

g

Linking Enclosures

An Epica Series enclosure can connect to other enclosures and any other

AutoPatch products with a compatible interface by using any of the ports

on the rear of each enclosure. We recommend linking enclosures via the

Ethernet ports. You can, however, choose a linking method based on the

enclosures, other AutoPatch products in the system, and the required data

transfer speed.

Link enclosures in a multi-enclosure system so that control information

can pass between them easily.

Link Port Cable Type Space between Enclosures (max)

Ethernet (these cables areincluded withmulti-enclosure systems)

RG-58 606.8 ft. (185 m)

XNNet

16 gaugetwisted pair 1312 ft. (400 m)

Serial (RS232)* Null Modemas specified in the EIA/TIA-232

standard

Serial (RS422)* Null Modemas specified in the EIA/TIA-422

standards

In a multi-enclosure system with an external controller, the enclosure

connected to the control device receives all control information and

passes on relevant information to other enclosures via the links. An Epica

Distribution Matrix can have a virtually unlimited number of linked

enclosures.

When linking two or more enclosures within a system, we recommend

connecting them with the Ethernet ports for consistent control speed.

*Requires specific configuration settings. Contact AutoPatch.

Installation & Setup Guide 3-1

Lin

kin

g

Note: If any of the linked enclosures were not in your original system,

you need a new configuration file (call AutoAssist; see Technical

Support, page vi).

You can link Epica Series enclosures in a daisy chain using link cables

and the connectors on the CPU.

To link two Epica Distribution Matrix enclosures using Ethernet

link connectors:

1. Fasten “T” connectors to the Ethernet ports on both enclosures.

2. Fasten the connectors on the ends of the Ethernet link cable onto the

“T” connectors. Add termination connectors as shown in the graphic

below.

3-2 Installation & Setup Guide

Linking Enclosures

Lin

kin

g

����

������

��

� ���

� ���

���

������

����������������������������������������������������� �����

�������

!���!"#$"%&'����()*��+��

���

������

����������������������������������������������������� �����

�������

!���!"#$"%&'����()*��+��

���

������

����������������������������������������������������� �����

�������

!���!"#$"%&'����()*��+��

��,����������

��� �� �������� ���,

�����-�������� � ,�*

,./*�"$�����012#"3"4.0'5��#1*

20#065��

�����

��+���������

���

������

����������������������������������������������������� �����

�������

!���!"#$"%&'����()*��+��

���

������

����������������������������������������������������� �����

�������

!���!"#$"%&'����()*��+��

���

������

����������������������������������������������������� �����

�������

!���!"#$"%&'����()*��+��

��,����������

��� �� �������� ���,

�����-�������� � ,�*

,./*�"$�����012#"3"4.0'5��#1*

20#065��

�����

��+���������

����

������

��

� ���

� ���

Linking enclosures using Ethernet connectors

Termination Connectors

Attaching

an External Controller

An Epica Distribution Matrix can be controlled with external controllers

using two types of communication protocols:

� Serial – serial connectors

� XNNet – all connectors (including serial)

Control systems and panels (such as SBCs* and remote control panels*)

usually connect to the XNNet Communication Link port. Third party

controllers and PCs usually connect to the serial connector. We

recommend using the Ethernet connector for linking enclosures.

*These controllers are not covered in this document.

Installation & Setup Guide 4-1

Exte

rna

lC

on

trolle

r

4.1 Serial ControllersA serial controller is any device that can send and receive ASCII code

via RS232 or RS422. You can connect a serial controller to either of the

two serial connectors on an enclosure’s CPU. Connect serial controllers

with standard RS232 (null modem) or RS422 connections (refer to the

following figures for RS232 and RS422 cable connector pin mappings).

The pin diagram above allows for hardware flow control. If this type of

control is not needed, connect pin #7 to pin #8 on the PC’s connector.

When controlling the system with a PC, use serial communication

software and make sure the BAUD rate is set correctly for the system.

Available BAUD rates for Epica Series systems are 9600, 19200, and

38400, and 57600; the default is 9600. For more information on

changing the BAUD rate, see Chapter 8, “Managing Configuration Files”

or Appendix E.

4-2 Installation & Setup Guide

Attaching an External Controller

Exte

rna

lC

on

tro

lle

r

���

���

���

���

���

���

��� ���

���

���

���

���

� �

RS232 pin diagram

PC: DB9 AutoPatch: DB9

GND #5 . . . . . . . . . . . . . . . . .GND #5RXD #2 . . . . . . . . . . . . . . . . .TXD #3TXD #3 . . . . . . . . . . . . . . . . . RXD #2RTS #7 . . . . . . . . . . . . . . . . . CTS #8CTS #8 . . . . . . . . . . . . . . . . . RTS #7DSR #6 . . DTR #4

PC: DB9 AutoPatch: DB9

���

���

���

���

���

��

RS422 pin diagram

GND #5RXD+ #6RXD- #1TXD+ #4TXD- #9

PC: DB9 AutoPatch: DB9 AutoPatch: DB9

Platform specific

Factory default settings for serial communication with an Epica

Distribution Matrix are:

BAUD 9600

Data Bits 8

Stop Bit 1

Parity NONE

Note: Make sure the communication settings on both the PC serial

communication software and the enclosure correspond to each other.

Installation & Setup Guide 4-3

Serial Controllers

Exte

rna

lC

on

trolle

r