UNIVERSITY OF MANCHESTER CEAS

Transcript of UNIVERSITY OF MANCHESTER CEAS

1

UNIVERSITY OF MANCHESTER – CEAS

A compositional breakage equation for

first break roller milling of wheat

A Thesis submitted to the University of Manchester for the degree of Doctor of Philosophy in the Faculty of Engineering and Physical Sciences

SILVIA PATRICIA GALINDEZ NAJERA

2014

Supervisor: Prof. Grant Campbell

Co-supervisor: Prof. Colin Webb

Satake Centre for Grain Process Engineering

School of Chemical Engineering and Analytical Science

Table of Contents

2

TABLE OF CONTENTS

TABLE OF CONTENTS .................................................................................................................... 2

LIST OF TABLES .............................................................................................................................. 7

LIST OF FIGURES ............................................................................................................................ 8

ABSTRACT ...................................................................................................................................... 11

ABBREVIATIONS .......................................................................................................................... 13

NOMENCLATURES ....................................................................................................................... 15

DECLARATION .............................................................................................................................. 17

COPYRIGHT STATEMENT ........................................................................................................... 17

DEDICATION .................................................................................................................................. 18

ACKNOWLEDGEMENTS .............................................................................................................. 19

CHAPTER 1 MODELLING OF WHEAT BREAKAGE ............................................................ 20

1.1 WHEAT, AN IMPORTANT CEREAL ................................................................................. 20

1.2 DEBRANNED WHEAT AND MODELLING OF WHEAT ROLLER MILLING.............. 21

1.3 SCOPE OF THE CURRENT WORK .................................................................................... 25

CHAPTER 2 UNDERSTANDING WHEAT, MILLING AND DEBRANNING ....................... 28

2.1 INTRODUCTION ...................................................................................................................... 28

2.2 WHEAT: A UNIQUE CEREAL GRAIN ................................................................................... 28

2.3 CLASSIFICATION OF WHEAT ............................................................................................... 31

2.4 THE STRUCTURE OF THE WHEAT KERNEL...................................................................... 32

2.4.1 The Endosperm................................................................................................................... 36

2.4.2 The Bran.............................................................................................................................. 37

2.4.3 The Germ............................................................................................................................ 39

2.5 CHEMICAL COMPOSITION OF WHEAT .............................................................................. 41

Table of contents

3

2.6 USES OF WHEAT ..................................................................................................................... 44

2.7 WHEAT MILLING .................................................................................................................... 45

2.8 DEBRANNING OF WHEAT – A NEW FRACTIONATION TECHNOLOGY ...................... 54

2.8.1 Definition and benefits of debranning................................................................................ 54

2.8.2 Debranning processes......................................................................................................... 55

2.9 SUMMARY ................................................................................................................................ 57

CHAPTER 3 UNDERSTANDING THE NATURE OF WHEAT BREAKAGE ........................ 59

3.1 INTRODUCTION ...................................................................................................................... 59

3.2 THE BREAKAGE EQUATION FOR ROLLER MILLING OF WHEAT ................................ 59

3.2.1 The Normalised Kumaraswamy Breakage function........................................................... 63

3.3 BIOCHEMICAL MARKERS AND “FINGERPRINTS” .......................................................... 70

3.3.1 Microscopical methods....................................................................................................... 70

3.3.2 Fluorescence techniques..................................................................................................... 72

3.3.3 Wet chemistry and Infrared methods coupled with multivariate analysis.......................... 73

3.4 COMPOSITIONAL BREAKAGE EQUATIONS ..................................................................... 77

3.11 SUMMARY .............................................................................................................................. 80

CHAPTER 4 MODELLING FIRST BREAK MILLING OF DEBRANNED WHEAT ............. 81

4.1 INTRODUCTION ...................................................................................................................... 81

4.2 MATERIALS .............................................................................................................................. 82

4.3 EXPERIMENT PROCEDURES ................................................................................................ 82

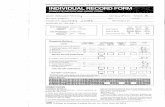

4.3.1 Characterisation of wheat by SKCS.................................................................................... 82

4.3.2 Conditioning of wheat......................................................................................................... 83

4.3.3 Debranning of wheat kernels.............................................................................................. 85

4.3.4 Milling of wheat.................................................................................................................. 86

4.3.5 Sieve Analysis of milled fragments.................................................................................... 87

Table of contents

4

4.3.6 Mathematical Analysis........................................................................................................ 88

4.4 RESULTS AND DISCUSSION ................................................................................................. 89

4.4.1 Bran removal....................................................................................................................... 89

4.4.2 Effect of debranning on the parameters of the DNKBF..................................................... 92

4.4.3 Parameter a......................................................................................................................... 93

4.4.4 Parameter α......................................................................................................................... 94

4.4.5 Parameters m1 and n1........................................................................................................... 95

4.4.6 Parameters m2 and n2........................................................................................................... 97

4.4.7 Overall effect of debranned wheat on the DNKBF............................................................. 98

4.4.8 Overall effect of roll gap................................................................................................... 101

4.4.9 The suggested nature of Type 1 and Type 2 particles...................................................... 106

4.5 SUMMARY .............................................................................................................................. 109

CHAPTER5 CHARACTERISATION OF TISSUES AND MILLED FRACTIONS ................ 110

5.1 INTRODUCTION .................................................................................................................... 110

5.2 MATERIALS ............................................................................................................................ 111

5.3 EXPERIMENTAL PROCEDURES ......................................................................................... 111

5.3.1 Dissection of wheat components into botanical tissues.................................................... 111

5.3.2 Moisture content................................................................................................................ 112

5.3.3 Sample preparation for FTIR analysis.............................................................................. 113

5.3.4 Fourier Transform Infrared (FTIR) spectroscopy............................................................. 115

5.3.5 Mathematical analysis....................................................................................................... 117

5.5 MANUAL ISOLATION OF WHEAT KERNEL TISSUES .................................................... 118

5.6 FTIR-ATR ANALYSIS OF GROUND BOTANICAL TISSUES ........................................... 120

5.7 PRINCIPAL COMPONENT ANALYSIS ON GROUND ISOLATED TISSUES ................. 121

5.7.2 Improving the separation of the clusters by using mathematical pre-treatment tools...... 129

5.7.3 PCA analysis of milled samples....................................................................................... 132

5.8 CALCULATING THE PROPORTION OF BOTANICAL TISSUES..................................... 135

Table of contents

5

5.9 SUGAR QUANTIFICATION BY HPLC ................................................................................ 139

5.9.1 Stock and standard solutions............................................................................................. 139

5.9.2 Sample preparation for chemical hydrolysis..................................................................... 140

5.9.3 HPLC analysis.................................................................................................................. 140

5.10 SUMMARY ............................................................................................................................ 146

CHAPTER 6 DEVELOPING A COMPOSITIONAL BREAKAGE EQUATION ................... 148

6.1 INTRODUCTION .................................................................................................................... 148

6.2 EXPERIMENT PROCEDURES .............................................................................................. 148

6.2.1 Sample preparation for FTIR analysis.............................................................................. 149

6.3 DERIVATION OF A COMPOSITIONAL BREAKAGE EQUATION .................................. 149

6.4 COMPOSITIONAL BREAKAGE FUNCTIONS .................................................................... 156

6.5 FINDING THE CONCENTRATION FUNCTIONS USING THE DNKB FUNCTIONS...... 160

6.6 SUMMARY .............................................................................................................................. 191

CHAPTER 7 CONCLUSIONS AND RECOMMENDATIONS ............................................... 193

7.1 INTRODUCTION .................................................................................................................... 193

7.2 PROGRESS MADE IN THE CURRENT THESIS.................................................................. 194

7.2.1 Modelling first break milling of debranned wheat using the DNKBF............................. 194

7.2.2 Characterisation of wheat botanical tissues and milled fractions with FTIR and sugar

profiles using HPLC.................................................................................................................. 195

7.2.3 Development of a compositional breakage equation for wheat milling........................... 196

7.3 RECOMMENDATIONS FOR FUTURE WORK ................................................................... 197

REFERENCES ............................................................................................................................... 201

APPENDICES ................................................................................................................................ 214

APPENDIX 1 .................................................................................................................................. 214

APPENDIX 2 .................................................................................................................................. 215

Table of contents

6

APPENDIX 3 .................................................................................................................................. 219

APPENDIX 4 .................................................................................................................................. 220

APPENDIX 5 .................................................................................................................................. 244

List of Tables

7

LIST OF TABLES

Table 2.1 Chemical composition of the whole wheat grain and its various components. ................ 41

Table 2.2 Main systems of the Mill flow sheet ................................................................................. 50

Table 2.3 Comparison among some existing debranning processes.. ............................................... 56

Table 4.1 Average and standard deviation (SD) values of SKCS kernel weight, diameter,

hardness and moisture content of Mallacca and Consort wheats. ............................................. 84

Table 5.1 Summary of the milled fractions analyzed. .................................................................... 114

Table 5.2 Moisture content of both wheat types and the botanical components.............................119

Table 5.3 Example of height data introduced in the spreadsheet to quantify the relative

proportion of each botanical component in the unknown sample..........................................137

Table 5.4 Sugars composition of two wheat grain tissues, two milled fractions from Mallacca

wheat and the results reported by Barron et al. (2007)............................................................143

Table 6.1 Particle size distributions and composition of size fractions following milling of

Mallacca and Consort wheats .................................................................................................. 161

Table 6.2 Fitted DNKBF parameters. ............................................................................................. 165

List of Figures

8

LIST OF FIGURES

Figure 2.1 Structure of the wheat kernel.. ......................................................................................... 32

Figure 2.2 Hyperspectral imaging of transversal cuts of Consort and Mallacca. ............................. 34

Figure 2.3 Ideal relation between botanical components and milled fractions.. ............................... 35

Figure 2.4 Scanning electron micrograph of Consort (soft) wheat.. ................................................. 37

Figure 2.5 Fluorescence micrograph of a transversal cut of Mallacca wheat.. ................................. 38

Figure 2.6 Micrograph of pure dissected germ tissue from Mallacca wheat.. .................................. 40

Figure 2.7 Average carbohydrate composition of whole mature wheat kernels. .............................. 43

Figure 2.8 Saddlestone. ..................................................................................................................... 45

Figure 2.9 A Quern stone from the Iron Age. ................................................................................... 46

Figure 2.10 Possible evolution of the milling devices. ..................................................................... 47

Figure 2.11 Simplified diagram of a typical flour milling process.. ................................................. 49

Figure 2.12 Flour milling process.. ................................................................................................... 51

Figure 2.13 Illustration of roll dispositions. ...................................................................................... 52

Figure 3.1 Non-cumulative and Cumulative form of the Double NKBF. ......................................... 68

Figure 4.1 Mallacca, hard wheat, Consort, soft wheat ...................................................................... 82

Figure 4.2 Single Kernel Characterization System. .......................................................................... 83

Figure 4.3 The Satake TM-05C (laboratory debranner).. ................................................................. 85

Figure 4.4 Satake STR-100AU Test Roller Mill. ............................................................................. 86

Figure 4.5 The Satake PLSB Series 2000 Laboratory Sifter. ........................................................... 87

Figure 4.6 Percentage of wheat mass removed at different debranning times and the rate of

wheat mass removal.. ................................................................................................................. 91

Figure 4.7 Malacca and Consort wheats at 0, 30 and 60 s of debranning. ........................................ 92

Figure 4.8 Values of collapsing parameter a at different debranning times. .................................... 94

Figure 4.9 Parameter α as a function of debranning time ................................................................. 95

Figure 4.10 Parameters m1 and n1 as a function of debranning time................................................. 97

Figure 4.11 Parameters m2 and n2 as a function of debranning time................................................ 98

Figure 4.12 PSD as described by the DNKBF from Mallacca and Consort wheats. ...................... 100

List of Figures

9

Figure 4.13 Experimental data, cumulative and non-cumulative DNKBF for Mallacca wheat

at 0 s and 60 s of debranning .................................................................................................. 102

Figure 4.14 Experimental data, cumulative and non-cumulative DNKBF for Mallacca wheat

at 0 s and 60 s of debranning. .................................................................................................. 103

Figure 4.15 Experimental data, cumulative and non-cumulative DNKBF for Consort wheat

at 0 s and 60 s of debranning. .................................................................................................. 104

Figure 4.16 Experimental data, cumulative and non-cumulative DNKBF for Consort wheat

at 0s and 60s of debranning. .................................................................................................... 105

Figure 4.17 Example of particles resulting from first break milling of Consort wheat. ................. 107

Figure 4.18 Effect of debranning on wheat breakage. .................................................................... 108

Figure 5.1 Hand dissections of wheat botanical tissues.. ................................................................ 112

Figure 5.2 Ball Mill used for grinding the botanical tissues. .......................................................... 113

Figure 5.3 Falling number hammer mill. ........................................................................................ 114

Figure 5.4 Spectrum two (FTIR-ATR) spectrometer. ..................................................................... 116

Figure 5.5 The four major wheat components dissected from Mallacca wheat. ............................. 118

Figure 5.6 FTIR-ATR spectra of milled Mallacca dissected wheat grain. ..................................... 120

Figure 5.7 PCA scores of the four botanical tissues. ...................................................................... 123

Figure 5.8 Loading vectors associated to PC1 and PC2 ................................................................. 124

Figure 5.9 Baseline corrected and normalised FTIR-ATR spectra and second derivative

computed for each botanical tissue .......................................................................................... 126

Figure 5.10 Baseline corrected and normalised FTIR-ATR spectra and second derivative

computed for each botanical tissue. ......................................................................................... 127

Figure 5.11 PCA scores of the four botanical tissues. Whole spectra (4000 to 550 cm–1

). ............ 129

Figure 5.12 PCA scores of the four botanical tissues. Spectral range from 810 to 1800 cm–1

. ...... 130

Figure 5.13 Spectra of different milled fractions.. .......................................................................... 132

Figure 5.14 Base line corrected and normalised spectral data and Second derivative

computed. Range (1800-810 cm-1

).. ........................................................................................ 133

Figure 5.15 PCA scores of wheat milled samples........................................................................... 134

Figure 5.16 Loading vectors associated with PC1. ......................................................................... 135

Figure 5.17 HPLC equipment used. ................................................................................................ 141

Figure 5.18 HPLC chromatograms of pericarp and endosperm after hydrolysis. ........................... 142

List of Figures

10

Figure 5.19 HPLC chromatograms of the sugars present in the two samples of Mallacca

wheat milled. ........................................................................................................................... 143

Figure 6.1 Contrived example. ........................................................................................................ 151

Figure 6.2 Non-cumulative form of the contrived example. ........................................................... 152

Figure 6.3 Broken wheat particle.....................................................................................................158

Figure 6.4 Cumulative particle size and component distributions for Mallacca (S-S). ................. 163

Figure 6.5 Non-cumulative particle size and component distributions for Mallacca (S-S). ........... 164

Figure 6.6 Concentration functions for Pericarp, Intermediate layer, Aleurone and starchy

endosperm. ............................................................................................................................... 169

Figure 6.7 Cumulative particle size and component distributions for Mallacca (D-D). ................. 171

Figure 6.8 Non-cumulative particle size and component distributions for Mallacca (D-D). .......... 172

Figure 6.9 Concentration functions for Pericarp, Aleurone, Endosperm and Intermediate layer... 173

Figure 6.10 Cumulative particle size and component distributions for Consort (S-S). ................. 175

Figure 6.11 Non-cumulative particle size and component distributions for Consort (S-S). ........... 176

Figure 6.12 Concentration functions for Pericarp, Intermediate layer, Aleurone and starchy

endosperm. ............................................................................................................................... 179

Figure 6.13 Cumulative particle size and component distributions for Consort (D-D). ................. 181

Figure 6.14 Non-cumulative particle size and component distributions for Consort (D-D). .......... 182

Figure 6.15 Concentration functions for Pericarp, Aleurone, Intermediate layer and Endosperm. . 183

Figure 6.16 Pericarp, Intermediate layer and Aleurone distributions for Mallacca and Consort.... 185

Figure 6.17 Pericarp, Intermediate layer, Aleurone and starchy endosperm distributions for

Mallacca and Consort. ............................................................................................................. 188

Figure A5.1 Typical data set for a PLS.. ......................................................................................... 244

Abstract

Silvia Galindez PhD Thesis August 2014 11

A COMPOSITIONAL BREAKAGE EQUATION FOR

FIRST BREAK ROLLER MILLING OF WHEAT

ABSTRACT

The particle size distribution produced from first break roller milling of wheat determines

the flows through the rest of the mill and hence the quality of the final flour, and is affected

by debranning and by the operation of the roller mill. The Double Normalised

Kumaraswamy Breakage function (DNKBF) gives a quantitative basis to describe

breakage during first break milling of wheat and to interpret effects. Previous work

developed and extended the breakage equation in order to understand and predict wheat

breakage based on distributions of the grain characteristics and the operating parameters of

the mill. However, broken particles vary in composition as well as size; therefore the

primary objective of the current work was to extend the DNKBF during first break milling

to include particle composition, using fingerprints of pericarp, aleurone, endosperm and

germ. Meanwhile, debranning is a technology that has enhanced flour milling in recent

years, leading to improvements in quality that are not well understood but that start with

the effect on milling. A second objective of the current work was therefore to apply the

DNKBF to describe and interpret the effects of debranning on wheat breakage and, in so

doing, to clarify the physical significance of the DNKBF parameters.

Samples of Mallacca (hard wheat) and Consort (soft wheat) were debranned for nine

different times, at three roll gaps and under S-S and D-D dispositions. The DNKBF

successfully described the normalised particle size distribution at different debranning

times. The DNKBF describes wheat breakage in terms of Type 1 and Type 2 breakage,

where Type 1 describes a relatively narrow distribution of mid-sized particles, whilst Type

2 describes a wide size range of predominantly small particles extending to very large

particles. The proportion of Type 1 breakage increased at longer debranning times, while

Type 2 breakage decreased, for both wheats under both dispositions. S-S milling tended to

produce more Type 1 breakage than D-D. A mechanism of wheat breakage is proposed to

explain the co-production of very large and small particles via Type 2 breakage, and hence

the effect of debranning. The proposed mechanism is that small particles of endosperm

arise from scraping of large flat particles of wheat bran under the differential action of the

rolls; removal of the bran reduces the production of the large bran particles and thus

reduces the opportunity for the scraping mechanism that produces the very small particles.

The composition of broken particles can be characterised considering the four major wheat

components, pericarp, aleurone, endosperm and germ. Kernels of Mallacca and Consort

wheats were manually dissected to isolate these components. FTIR spectroscopy was able

to distinguish the different components in milled fractions. However, attempts to quantify

the relative contribution of each wheat component in milled fractions (by measuring

specific peak heights and by Partial Least Squares, PLS) were compromised by technical

limitations. An alternative approach aimed to fingerprint the components using sugar

analysis by HPLC, with some success; however the technique was too complex and limited

by the detection limit of HPLC, in particular for arabinose and xylose.

Abstract

Silvia Galindez PhD Thesis August 2014 12

Instead, the botanical distributions within eight milled fractions of Mallacca and Consort

wheats milled under S-S and D-D dispositions were analyzed by PLS models developed by

Barron (2011). The concentration functions were then found by applying the DNKBF to

the particle size distributions and to the compositional distributions, the ratio of the

DNKBFs giving the concentration function. The DNKBF was able to describe the data

well for the four botanical components studied in both wheats: pericarp, aleurone,

intermediate layer and starchy endosperm. The analysis clarified the nature of the particles

produced on breakage, showing that for Mallacca wheat, the pericarp and aleurone layer

compositions mostly varied with particle size in similar ways. Intermediate layer showed

broadly similar results to those for pericarp and aleurone in the Mallacca wheat despite

being the least accurate component predicted. However, for Consort wheat, the

intermediate layer behaved differently from pericarp and aleurone, suggesting a different

breakage mechanism, perhaps associated with how the wheat hardness affects breakage of

the bran and the production of large flat bran particles. Creation of pericarp/intermediate

layer/aleurone dust during milling was notable, in particular for Mallacca wheat. The

relative uniformity of the Mallacca compositions in relation to pericarp, intermediate layer

and aleurone, which varied in consistent ways with particle size, was also notable. By

contrast, for Consort wheat, the relative proportions of these three components appear to

vary substantially in particles of different size, pointing to very different breakage origins.

It seems that in the hard wheat, the breakage patterns are dominated by the endosperm

physical properties, while for the soft wheat, the behaviour of the large bran particles

produced is dictated much more by the properties and structure of the bran layers than by

the hardness of the endosperm.

The approach presented is practical to describe, quantify and interpret the effects of

breakage on component distributions, in order to understand the fate of kernel components

during milling and hence the origins of flour quality.

Abbreviations

13

ABBREVIATIONS

AACCI American Association of Cereal Chemists International

AFM Atomic force microscopy

AG Arabinogalactan

ANOVA Analysis of Variance

Ara Arabinose

Asp Asparagine

ATR Attenuated Total Reflectance

AX Arabinoxylans

BG β-glucans

DB Dry basis

D-D Dull-to-Dull disposition

DEFRA Department of Environment, Food and Rural Affairs

DHD Ferulic acid dehydrodimers

DNKBF Double Normalised Kumaraswamy Breakage function

D-S Dull-to-Sharp disposition

ELSD Evaporative light scattering detector

FA Ferulic acid

FAO Food and Agriculture Organization of the United Nations

FE-SEM Secondary field emission scanning electron microscopy

FTIR Fourier Transform Infrared

Glc Glucose

Glu Glutamine

HI Hardness Index

HPLC High Performance Liquid Chromatography

ICP-OES Inductively Coupled Plasma-Optical Emission Spectrometry

INRA French National Institute for Agricultural Research

IR Infrared

MIR Mid-Infrared

NABIM National Association of British and Irish Millers

NKBF Normalised Kumaraswamy Breakage function

Abbreviations

14

p-CA Para-coumaric acid

PDF Probability Density Function

PC Principal Components

PCA Principal Component Analysis

PLS Partial Least Square

Pro Proline

PSD Particle Size Distribution

S-D Sharp-to-Dull disposition

SD Standard Deviation

SEM Scanning electron microscopy

S-S Sharp-to-Sharp disposition

SKCS Single Kernel Characterization System

SIMS Secondary ion mass spectrometry

SM Spectromicroscopy

STXM Scanning Transmission X-ray Microscope

t-SA Trans-sinapic acid

TEM Transmission electron microscopy

WB Wet basis

XPS X-ray photoelectron spectroscopy

Xyl Xylose

Nomenclatures

15

NOMENCLATURES

α Proportion of Type 1 breakage ()

a Collapsing parameter ()

ai, bi, ci, di Polynomial breakage function fitted parameters ()

Ai Height of peak i in the aleurone spectrum (cm)

Am,n Height of peak n in m botanical component (cm)

At Aleurone fraction (%)

Ch Height calculated for each peak (cm)

k Al-Mogahwi and Baker breakage function fitted parameter ()

D Kernel thickness (mm)

Ei Height of peak i in the endosperm spectrum (cm)

Et Endosperm fraction (%)

G Roll gap (mm)

Gi Height of peak i in the germ spectrum (cm)

Gt Germ fraction (%)

M Moisture content of sample (%)

Mi Initial moisture content before conditioning (%)

Mt Target moisture content for conditioning (%)

m1, n1 Type 1 breakage parameters from the DNKBF ()

m2, n2 Type 2 breakage parameters from the DNKBF ()

ρ Non-cumulative inlet particle size distribution to first break (m)

ρ2 Non-cumulative outlet particle size distribution from first break

(m)

P2 Cumulative outlet particle size distribution from first break (%)

Pi Height of peak i in the pericarp spectrum (cm)

Pmax Cumulative probability corresponding to the maximum particle size

(%)

Pmin Cumulative probability corresponding to the minimum particle size

(%)

Pt Pericarp fraction (%)

W Initial wheat weight before conditioning (g)

W1 Weight of empty container for Moisture content analysis (g)

Nomenclatures

16

W2 Weight of container plus sample before heating for Moisture content

analysis (g)

W3 Weight of container plus sample after heating for Moisture content

analysis (g)

xmax Maximum particle size (m)

xmin Minimum particle size (m)

Xi Mass proportions of botanical component i ()

Normalised output particle size (m)

max Maximum normalised output particle size (m)

min Minimum normalised output particle size (m)

yi Ratio between the mass of the botanical component i in particles in

the size range x and x + dx and the total mass in particles in the same

range ()

Yi Proportion (by mass) of each botanical component ()

Y* Ratio between the total mass of the botanical component i in

particles smaller than size x and the total mass of particles smaller

than size x ()

z Fully normalised output particle size ()

Declaration and Copyright Statement

17

DECLARATION

I declare that no portion of the work referred to in this thesis has been submitted in support

of an application for another degree or qualification of this or any other university or

institute of learning.

COPYRIGHT STATEMENT

1. The author of this thesis (including and appendices and/or schedules to this thesis)

owns any copyright in it (the “Copyright) and he has given The University of

Manchester the right to use such Copyright for any administrative, promotional,

educational and/or teaching purposes.

2. Copies of this thesis, either in full or in extracts, may be made only in accordance

with the regulations of the John Rylands University Library of Manchester. Details

of these regulations may be obtained from the Librarian. This page must form part

of any such copies made.

3. The ownership of any patents, designs, trademarks and any and all other intellectual

property rights except for the Copyright (the “Intellectual Property Rights”) and

any reproductions of copyright works, for example graphs and tables

(“Reproductions”), which may be described in this thesis, may not be owned by the

author and may be owned by third parties. Such Intellectual Property Rights and

Reproductions cannot and must not be made available for use without the prior

written permission of the owner(s) of the relevant Intellectual Property Rights

and/or Reproductions.

4. Further information on the conditions under which disclosure, publication and

exploitation of this thesis, the Copyright and any Intellectual Property Rights and/or

Reproductions described in it may take place is available from the Head of School

of Chemical Engineering and Analytical Sciences.

Dedication

18

DEDICATION

To my lovely fiancé and future husband Luis Gomez Palacin for all his unconditional love

and support along this nearly four years of relationship.

Acknowledgements

19

ACKNOWLEDGEMENTS

I gratefully acknowledge the National Council on Science and Technology of Mexico

(CONACYT), the Mexican Government and the Ministry of Public Education (SEP) for

financial support to undertake this project.

The Satake Corporation of Japan is gratefully acknowledged for its support in establishing

the activities of the Satake Centre for Grain Process Engineering.

I would like to express my gratitude to my research supervisor Dr Grant Campbell for his

support, guidance, friendship, cheerfulness and patience throughout these four years. For

always being available despite the massive amount of work that always had. For his

encouragement and help to overcome all the problems I was facing during my

experimental work and for helping me to improve my scientific writing skills. I know there

is still a long way to go with this, but at the end we have published one paper based on my

PhD project!, and the second one will come soon.

I would like to thank to Prof Colin Webb as my new supervisor for your guidance, help,

feedback and support during these last months as a PhD student. I’ve been enjoying our

meetings so much that I’m really going to miss them.

To Ben Perston and Kelly Palmer from Perkin Elmer for their technical assistance with the

Spotlight and Infrared systems and to Fred Warren from King’s College London and

Perkin Elmer for his kind help in the collaboration performed.

To Dr Cécile Barron and Dr Valérie Lullien-Pellerin from INRA, Montpellier, France, for

their kind help in the FTIR analysis of the milled fractions. Without your tremendous

effort, we could not have achieved the main objective of this PhD project.

To all the technicians working in The Mill, in particular to Liz Davenport, Roy, Shahla for

their kind support in the HPLC equipment and analysis, lab material and fixing equipment.

To my family, for all their love and support in these four years. I know it has been difficult,

but we did it! Thank you very much!! I love you so much!!!

To my friends and colleagues from the Satake Centre: Ruth, Nikolina, Stavrus, Amit,

Hosam. Thank you for your company and feedback. Ruth, I would like to acknowledge

you in particular because we have struggled together during these almost four years. Thank

you for all your help and collaboration in the hydrolysis and HPLC and for all the great

moments that we spent together in the office and in the lab.

To all my friends and colleagues in The Mill, for all the help, fun and great moments that

we spent together every day at lunch, parties and Conferences!

Chapter 1

20

CHAPTER 1

MODELLING OF WHEAT BREAKAGE

1.1 Wheat, an important cereal

Wheat is a unique seed closely linked with human food uses in the course of history.

Wheat has been the basic food for thousands of years of the major civilizations developed

in Europe, West Asia and North Africa and continues being the most important grain

source for humans. This importance has enabled wheat to be grown on more land than any

other crop (FAO, 2014).

Humans changed their hunter-gatherer life to settled agriculturalist life, which led to the

gradual development of agriculture and livestock equipment (Storck and Teague, 1952;

Evans, 1993). But what caused this shift in life style? Perhaps extreme forces such as

climate change, or cultural reasons, or maybe by population pressure or even the

combinations of these three events could answer this question (Evans, 1993). Many

historians have their own conclusions; for example, Childe (1934) based on historical

studies in the Near East and China, suggested that climate changes in the Pleistocene

occurred nearly at the same time as cultural changes that originated the “Neolithic

revolution”. Excavations in Oaxaca, Mexico shown that the transition to agriculture was

tremendously gradual, suggesting that agriculture has evolved gradually, irregularly and

independently in different regions (Adams, 1966). Boserup (1965) and others suggested

that maybe an increase of population in some areas led to more intensive and regular

cultivation, although there is still open the question if population pressure was responsible

of the development of agriculture.

A very important event that took place thousands years ago was crop domestication, which

earliest archaeological signs were found in Mexico, Near East and North China. Different

types of crops were domesticated in all these centres. The genetic changes that occurred in

crops perhaps from unconscious selection enabled their domestication (Evans, 1993;

Zohary et al., 2012). Wheat is a clear example of this, since only one tiny mutation in the

genetic makeup of the wild wheat einkorn allowed the cells between the stalk and the seed

to remain together, avoiding the seed to fall down after being ripened, as happens in the

Chapter 1

21

non-mutated wild wheat. With this new mutation, the collection of more grains was

possible, but even more important, its cultivation (Wrigley, 2009; Zohary et al., 2012).

Along other cereals, wheat provides important quantities of nutrients and energy to sustain

human and animal populations. However, among all the plants, wheat is the only grain

that contains gluten proteins. Their unique properties (i.e dough-forming for bread due to

its gas-retention ability) have enabled the production of a great variety of food products

(van Vliet et al., 1992; Decker et al., 2002; Dobraszczyk et al., 2000, 2003; Campbell,

2008; Hamer et al., 2009; Campbell and Martin, 2011). Nowadays, wheat has become for

humanity more than only a raw material for wheat-based products, it has become along

with other cereals a raw material for production of biofuels in order to cover the demand of

modern society to look for alternative energies to reduce the environmental impact.

The global population is now facing the increase of the demands of food supply in which

wheat plays an important role. Cereals in general and wheat in particular are required to

cover these needs and a non-food use (i.e biofuels) since the global population is

continuously growing and demands more food and energy (Dixon, 2007). On these bases,

wheat must be processed effectively in order to continue to make its central contribution to

meeting the world’s food needs whilst also leading the way towards sustainable production

of chemicals and energy based on biorefineries.

The processing of wheat begins with the separation of its botanical components. Flour

milling separates the wheat kernel into flour, hence an important component of the future

usage of wheat is the efficiency of the milling process to fulfil the different demands that

the modern society is increasingly facing.

1.2 Debranned wheat and modelling of wheat roller milling

Food products arising from cereals constitute a major part of the daily diet in the world´s

population. The wheat-food products are principally made from refined white flour from

which the outer layers of the wheat grain are removed. However, these layers (i.e pericarp,

the seed coat, the nucellar epidermis, aleurone), which are eliminated in the milling

fraction called by the millers as “bran”, contain most of the fibre, phytochemicals and

micronutrients of the wheat kernel that could contribute to increasing the nutritional quality

of human food if added in flours or used as food ingredients (Hemery et al., 2007).

Debranning process involves the removal of the peripheral layers of the cereal grain, by

abrasion and friction, using modified rice polishers. The debranned kernels are then

Chapter 1

22

recovered for being processed in successive stages. The removal of the bran before

grinding has resulted in increased flour and semolina extraction, as well as a considerable

reduction of steps in the sub-sequent milling process (Dexter and Wood, 1996). Several

advantages are associated with wheat debranning (or pearling), such as the removal of

contaminants that are present in the peripheral tissues of wheat grains (i.e mycotoxins,

pesticides residues and heavy metals) (Mousia et al., 2004; Laca et al., 2006; Bottega et al.,

2009; Posner, 2009; Delcour et al., 2012), or the removal of intrinsic components that are

detrimental to flour quality (e.g. instability of germ lipids) (Gys et al., 2004a,b; Beta et al.,

2005; Liu et al., 2008; Delcour et al., 2012; Sovrani et al., 2012; Sapirstein et al., 2013).

Flour produced from debranned wheat kernels exhibits different and better characteristics

and quality that results in a better bread in terms of organoleptic quality (soft texture, more

spongy and palatable taste) compared to flour produced from conventional milling (Mousia

et al., 2004; Singh and Singh, 2010; Delcour et al., 2012). More information about

debranning of wheat is detailed in Chapter 2. At least part of the effect of debranning on

flour quality arises through the effect of debranning on the milling process itself.

Therefore, to understand the process engineering consequences of debranning, in terms of

the interaction of debranned grains with the milling process, it is helpful to have models of

wheat kernel breakage. Such models have been developed and applied, so far, to

understand the breakage of whole wheat kernels.

As described in more detail in Chapter 3, the breakage equation that describes first break

roller milling was introduced by Campbell and co-workers using a breakage function. This

function considered and related kernel characteristics (i.e size, hardness, moisture content)

with processing parameters (i.e roll gap, roll disposition) (Campbell and Webb, 2001;

Campbell et al., 2001a; Fang and Campbell, 2003a,b; Campbell et al., 2007). The

polynomial breakage function enabled prediction of the particle size distribution obtained

by first breakage milling. Mateos-Salvador et al. (2011) introduced the Normalised

Kumaraswamy Breakage function (NKBF) in order to provide a simpler and more

meaningful breakage function. Campbell et al. (2012) formulated the Double Normalised

Kumaraswamy Breakage function (DNKBF), allowing two patterns of breakage to be

distinguished, with α indicating the proportion of Type 1 breakage. Fuh et al. (2014)

reformulated the DNKBF to account for the effect of roll gap more accurately whilst

retaining simplicity, with the function found adequate to describe breakage of a wide range

of wheats. However, in the current work, the simpler form of the DKNBF is applied to

Chapter 1

23

both sets of independent milled wheat fractions (debranned and whole wheats), for reasons

that are discussed in Chapter 4.

The breakage equation approach relates kernel properties and the mill operation to the

output particle size distributions. However, broken particles vary in composition as well as

size. In first break milling, the large particles produced are related to bran while the small

particles are associated to endosperm (Campbell, 2007). Therefore, a model of first break

milling that considers particle composition as well as size is required. However, it needs to

be remembered that the milling fraction called “bran” consist of several tissues that form

part of the whole wheat kernel, i.e the word “bran” is a practical milling term rather than a

botanical term.

The aim of the milling industry consists in separating and recovering flour relatively free

of bran. However, wheat milling generates many different fractions of imprecise origin that

can be remixed with flours in order to increase their nutritional content. To develop more

efficient milling processes, it would be useful to be able to monitor and determine the

histological composition of the milled fractions generated throughout the wheat milling.

The challenge to identify the botanical components contributing to particles of a given size

is considerable. In principle, this could be achieved by identifying specific biochemical

markers that are exclusively associated with particular botanical components in the kernel.

For example, Barron et al. (2007) developed a quantitative method based on carbohydrate

and phenolic acid content, leading to identification of potential biochemical markers to

monitor grain tissue proportions in fractions obtained from a conventional milling process.

Hemery et al. (2009) evaluated the grain tissue proportions in fractions of different

composition. Flour, bran and aleurone-rich fractions produced from milling and

debranning processes were analysed and good results were obtained although the germ

quantification did not enable the precise quantification of this tissue in milled fractions.

With these bases, Barron (2011) predicted the relative tissue proportion in wheat mill

streams by FTIR spectroscopy and Partial Least Square (PLS) analysis. PLS models were

developed to predict the proportion of the botanical tissues in the milled streams, achieving

a very good prediction for all botanical tissues.

Choomjaihan (2008) took a different approach to quantify the relative proportions of wheat

kernel components in size fractions following milling. Instead of identifying unique

markers, he aimed to demonstrate unique profiles or ‘fingerprints’ of minerals in the

Chapter 1

24

different kernel components. The mineral profile of a given milled fraction could thus, in

principle, be related to the distinctive profiles of the individual kernel components.

However, the mineral profiles were insufficiently distinct between components to allow the

proportion of each component in different size fractions to be deduced accurately.

Regression analysis consists on developing a model from a data set that would be able to

predict a desired response. There are plenty of regression methods that could be used for

quantitative analysis and Partial Least Squares regression is one of them. FTIR is a widely

used and non-destructive technique (the sample remains intact after analysis) that provides

a precise measurement without an external calibration (Esbensen et al., 2002). As

described in Chapters 3, 5 and 6, applying these techniques and appropriate analysis can

lead to accurate predictions, providing fast and easy bases for the analysis and

quantification of the large number of samples required for the extension of the breakage to

include composition.

A wide range of saccharides are present in all the wheat tissues but in different proportions

depending on the biochemical activities of each particular tissue (Barron et al., 2007; Stone

and Morell, 2009). By applying high performance liquid chromatography (HPLC), which

is a chromatographic technique that can separate a mixture of compounds (Fanali et al.,

2013) the identification and quantification of the sugar content in each wheat tissue and

milled fractions obtained can be possible. This technique is sufficiently rapid to construct

the basis for analysis and quantification of large number of samples.

Fistes and Tanovic (2006) defined a mathematical correlation in the form of a matrix

equation for predicting compositional properties of flour as well as their size distribution

following first break milling. Predicted results were compared with actual particle

compositional distribution obtained by experimental milling, and exhibited high accuracy

between them, showing the potential of the breakage matrix approach for predicting

compositional properties of flour stocks and their particle size distribution. However,

breakage matrices are discrete while continuous functions are more generally applicable

and more readily interpretable, thus yielding greater predictive power and greater

mechanistic insights regarding wheat breakage.

Knowing the botanical distribution in milled samples may help to divert certain flows in

the milling process to use them as a raw material for different processes or to enrich the

nutritional content of the final flour.

Chapter 1

25

The inclusion of composition in the breakage equation would make it more powerful in

general and it could make it particularly suited to understand, for example, the effects of

debranning.

The current work therefore aims to explore an alternative approach to that of Choomjaihan

(2008) for distinguishing grain components in milled fractions, and to find a suitable and

simpler function to describe not only the output particle size distribution from first break

milling, but also to describe compositional breakage functions. Infrared (IR) methods

alongside multivariate analysis, as well as sugar profile techniques are explored to find

specific fingerprints. Thus, the primary objective of the current work is to extend the

DNKBF during first break roller milling to include particle composition, characterized by

the fingerprints of pericarp, aleurone, endosperm and germ. This would help to indicate

and predict the distribution of these components within different size fractions obtained

during the roller milling operation. Equally, in the current work, the continuous equivalent

of the discrete compositional breakage matrices introduced by Fistes and Tanovic (2006) is

formulated and analyzed in wheat milled fractions. A second objective of the present work

is to apply the DNKBF to describe and interpret the effects of removal of bran on wheat

after first break milling and to determine the physical significance of the DNKBF

parameters.

1.3 Scope of the current work

The particles resulting from breakage during roller milling of wheat vary in size and in

composition. A breakage equation that includes composition would help to fully

understand the nature of wheat breakage and the fate of kernel components during milling.

The DNKBF is a flexible function that has given new insights into the nature of wheat

breakage in terms of the size of broken particles; the current work aims to address the issue

of particle composition through application of the DNKBF. Meanwhile, debranning is a

technology that has dramatically influenced wheat milling and flour quality in recent years.

The current work aims to understand the effect of debranning on first break milling, whilst

at the same time clarifying the physical significance of DNKBF parameters and hence the

nature of wheat kernel breakage and the origins of variations in particle composition.

Chapter 2 describes the general definition and uses of wheat, modern wheat milling and

debranning technologies. Chemical composition and location of nutrients within the wheat

Chapter 1

26

grain are reviewed.

Chapter 3 describes the development of the breakage equation and the recent introduction

of the Normalised Kumaraswamy Breakage function (NKBF), the Double NKBF and its

extended form. Biochemical markers and “fingerprints” used to identify tissues in milled

fractions are reviewed. The literature survey thus leads to the objectives of the current

work, to understand the effects of debranning on breakage within the framework of the

DNKBF, and to extend the breakage equation to include particle composition as well as

size.

Chapter 4 discusses the effect of debranning on wheat breakage; the wheat varieties used in

this work, their conditioning, debranning and milling procedures, the measurement of the

particle size distribution by sieve analysis, and the fitting of the DNKBF are described. A

mechanism of wheat breakage is proposed to explain the co-production of very large and

small particles via Type 2 breakage, and therefore the effect of debranning.

Chapter 5 discusses how botanical tissues were obtained by hand dissection of wheat

kernels, the collection of the FTIR spectra from the four major wheat components and

milled fractions followed by their multivariate analysis. Equally, it is explained how was

built up the calibration curve for sugar profiles and the HPLC analysis for both, botanical

tissues and milled fractions, as an attempt to the botanical composition of milled fractions.

Chapter 6 describes the extension of the breakage equation to include composition. The

mathematical formulation of the compositional breakage equation is derived.

Experimental data for the composition of different size fractions following milling is then

interpreted within this formulation, in order to find the form of the compositional breakage

function and to draw new insights regarding the nature of kernel breakage in terms of

particle composition.

Chapter 7 summarises the progress made in the current work and the conclusions drawn,

and points to recommendations for future research studies and industrial application.

Much of the current work has been presented at local and international conferences. Based

on the content of Chapter 4, a scientific paper has been accepted for publication in Cereal

Chemistry. The content of Chapter 6 is currently being prepared for submission as a

journal paper in Cereal Cereal Chemistry. The following list shows the Journal papers

accepted and in preparation, the conference works presented and the awards obtained.

Chapter 1

27

Journal papers

Galindez-Najera SP and Campbell GM (2014). Modelling first break milling of

debranned wheat using the Double Normalised Kumaraswamy Breakage

function. Cereal Chemistry (Accepted for publication). DoI: 10.1094/CCHEM-

02-14-0028-R.

Choomjaihan P, Galindez-Najera SP, Barron C, Lullien-Pellerin V and

Campbell GM. A compositional breakage equation for wheat milling. In

preparation for Cereal Chemistry.

Conferences

Galindez-Najera SP and Campbell GM. New insights from compositional analysis

and modelling. AACC International Annual Meeting, October 5–8, 2014 in

Providence, Rhode Island, US.

Galindez-Najera SP and Campbell GM. Milling of debranned wheat described with

the Double Normalised Kumaraswamy Breakage function (DNKBF). Particulate

Systems Analysis 2014, September 15-18, 2014 in Manchester, UK.

Galindez-Najera SP and Campbell GM. Milling of debranned wheat described with

the Double Normalised Kumaraswamy Breakage function (DNKBF).

ChemEngDayUK, April 7 - 8, 2014 in Manchester, UK.

Galindez-Najera SP and Campbell GM. Applying the Double Normalised

Kumaraswamy Breakage function (DNKBF) to describe the effect of debranned

wheat on first break milling. ChemEngDayUK, March 25 - 26, 2013 in London,

UK.

Galindez-Najera SP., Warren, F., Perston, B., Palmer, K., and Campbell GM.

Hyperspectral imaging of debranned wheat. Cereals and Europe Spring Meeting,

May 29 - 31, 2013 in Leuven, Belgium.

AACC International Annual Meeting, September 30 - October 3, 2012 in

Hollywood, Florida, US. Developing the compositional breakage equation using

FTIR spectroscopy to characterise wheat components and milled fractions.

Galindez-Najera SP and Campbell GM. Developing the compositional breakage

equation using FTIR spectroscopy to characterise wheat components and milled

fractions. Postgraduate research Conference, 2012, in Manchester.

Galindez-Najera SP and Campbell GM. Modelling first break milling of debranned

wheat using the Double Normalised Kumaraswamy Breakage function.

Postgraduate research Conference, 2011, in Manchester.

Travel and awards obtained

Travel award obtained for attending the AACC International Annual Meeting,

September 30 - October 3, 2012 in Hollywood, Florida, US.

Prizes and awards obtained

Second best Poster in the Postgraduate research Conference, 2012, in Manchester.

Chapter 2

28

CHAPTER 2

UNDERSTANDING WHEAT, MILLING AND DEBRANNING

2.1 Introduction

Wheat is an edible cereal grain that has fed human beings since ancient times, with milling

the key technology for releasing the nutrients in wheat and rendering them in a form

suitable for creating an array of staple food products. Meanwhile, wheat milling has

influenced other processing technologies that have contributed to the technology, cultural

and social evolution of Western civilisation, while debranning of wheat, adapted from rice

milling, is the latest technological development to impact on flour milling. The general

definition and uses of wheat, milling and debranning technologies are described in the

current chapter. Chemical composition and location of nutrients within the wheat grain are

reviewed. Modern wheat milling is an efficient process that economically fractionates the

wheat kernel to recover high quality flour. The use of debranning technology prior to

conventional roller milling is a key recent development. This fundamental understanding

of wheat leads into the specific focus of the current work, to enhance the process

engineering understanding of roller milling of wheat.

2.2 Wheat: a unique cereal grain

Wheat has accompanied mankind since ancient times, providing him with food and, along

with other cereals, enabling the transition from the hunter and gatherer nomad to the settled

agriculturalist (Storck and Teague, 1952; Wrigley, 2009).

In the regions of the ancient Eastern region of Egypt, Mesopotamia and the Levant it is

believed that wheat had its origins, around 7000 B.C., although the evidence is scarce

(Storck and Teague, 1952). There is indication that wild emmer, wild einkorn and durum

(related to emmer) are the oldest wheat types. Eventually, these species evolved to non-

brittle spike types, enabling their domestication (Storck and Teague, 1952; Wrigley, 2009).

Indeed, the evidence indicates that emmer and/or einkorn were first cultivated in

Mesopotamia, which is considered the birthplace of agriculture, and from there, the bread

wheats were quickly spread to Egypt, Iran (where they were somehow hybridized),

Chapter 2

29

China, Russia, India and Western Europe (Storck and Teague, 1952; Tainter, J., 1988;

Evans, L., 1993). The Durum variety was adopted many years later in comparison with the

other two types, which may be perhaps to the reduced agronomic adaptability and because

of the difficulty in milling the very hard Durum wheat grain (Wrigley, 2009).

After maize and rice, wheat is the third most cultivated cereal, with more than 700 million

tonnes harvested annually (FAOSTAT, 2014). The main world wheat producers are China,

India, USA, Russian Federation and France, which together contribute around 46% of the

total world wheat production (FAOSTAT, 2014). Most of the wheat used by UK millers is

grown in the UK, with an annual production of over 12 million tonnes in recent years,

while countries such as Canada, USA, France and Germany supply the majority of UK

imported wheat (NABIM, 2014; DEFRA, 2014). Although the UK has been recently a net

exporter of wheat, it requires import of higher protein wheats from these countries in order

to enhance the relatively poorer bread-making quality of the home-grown wheat. In recent

years, the amount of UK wheat exported has decreased as a result of the emergence of

wheat biorefineries producing fuel ethanol from lower protein wheat (for which the UK

climate is particular favourable) (Campbell, 2007).

Currently, in the UK, 31 companies are operating with 53 mills located throughout Great

Britain and Ireland (NABIM, 2014). In 2013, the flour production was around 5.1 million

tonnes, from which 49.2% was flour suitable for white bread-making, 11.6% for biscuits,

6.3% for wholemeal bread making, 2.4% for cakes, 2.9% for pre-packed household, 1.8%

for brown bread-making, 3.7% as food ingredients and the remaining 28.4% for other uses

(e.g starch manufacture) (NABIM, 2014). Wheat, as a traded commodity, is subject to

wide variations in price and quality due to different harvesting times around the world and

variations in grading systems (Carson and Edwards, 2009; Wrigley, 2009); part of the skill

of the miller is to yield a consistent quality product from a variable feedstock, while the

skill of the wheat trader and buyer is to maximise profits against a constantly changing

supply status.

Wheat is highly adaptable and has high yield potential, which contributes to making this

cereal so successful. Furthermore, wheat provides essential amino acids, vitamins,

minerals, antioxidants and dietary fibre components to the human diet. However, the

unique feature of wheat, that makes it pre-eminent among the cereals, is its ability to

produce raised bread (Belderok et al., 2000; Decker et al., 2002; Campbell, 2008).

Chapter 2

30

Wheat flour, when mixed with water, forms dough that is capable of retaining fermentation

gases produced by yeast in order to produce a highly aerated and palatable baked loaf

(Dobraszcyk et al., 2000; Campbell, 2008). No other cereal is able of doing this (with the

exception of rye, but its gas-retention ability is considerably inferior to that of wheat). This

unique ability comes from the gluten proteins of wheat flour which, on hydration, form a

strain hardening network that expands and contains inflating gas bubbles to produce bread

and other bakery products that are distinguished by an attractive aerated structure (van

Vliet et al., 1992; Hamer and van Vliet, 2000; Decker et al., 2002; Dobraszcyk et al., 2003;

Campbell, 2008; Hamer et al., 2009; Campbell and Martin, 2011).

The rheology involved in the breadmaking process is quite complex. For example, mixing,

sheeting, fermentation and baking are four critical steps in the breadmaking process.

During mixing, the viscoelastic properties of the wheat gluten protein are developed,

besides air is incorporated affecting the rheology and texture of the dough (Dobraszcyk et

al., 2000; Dobraszcyk and Morgenstern, 2003). The sheeting operation is different for each

product since its purposes depend on the desired product characteristics. In this context, for

bread dough for example, sheeting controls the bubble size distribution and shapes the

dough. The gluten network can be developed in bread dough by repeated sheeting.

Meanwhile for biscuit dough, sheeting is used for both to form the dough and to develop

the gluten network. During fermentation and baking, the gases produced by yeast are

trapped by the gluten network (Dobraszcyk et al., 2000; Dobraszcyk and Morgenstern,

2003; Campbell, 2008). The rheological properties of the bread dough affect the baking

quality. For example, if the dough fails to retain air and fermentation gases as a result of

the failure in the strain hardening properties and failure strain of cell walls (van Vliet et al.,

1992; Dobraszcyk et al., 2000; Dobraszcyk and Morgenstern, 2003), the resulting baked

bread has a very hard texture and not a particularly palatable taste.

Chapter 2

31

2.3 Classification of wheat

Although these days thousands of varieties of wheat are grown throughout the world,

currently, the two most prominent types of wheat are common wheat (Triticum aestivum

L.), used for bread-making and other bakery products, and for animal feed and industrial

(non-food) uses, and durum wheat (T. turgidum L. var. durum), a much harder wheat

suitable for pasta. Approximately 90-95% of the wheat crop is common wheat which is a

hexaploid and mainly selected by farmers for its superior properties. These species include

classes with spring and winter growth habitat (known as spring and winter wheats), hard

and soft endosperm, and red and white pericarp (seedcoat) (Dubcovsky and Dvorak, 2007;

Shewry, 2009). In fact, these three features, growth habit, kernel texture and bran colour,

are the most important criteria for classifying wheat (Gooding, 2009; Wrigley, 2009).

The uses of the varieties of common wheat are extensive. In general hard wheats have

higher protein contents and are more suited to breadmaking, while softer wheats are higher

yielding with lower protein contents that are more suited to cakes, biscuits, animal feed and

bioethanol production.

The grain of Durum is extremely hard and contains a high amount of protein, making it

suitable for pasta products (macaroni, spaghetti and other noodles) and semolina products

such as “couscous” and "bulghur", but in some localities it is also used for bread

(Pomeranz, 1988; Paulsen and Shroyer, 2004).

The oldest hulled wheat species einkorn (Triticum monococcum L.) (used for bread in

some regions), emmer (T. dicoccon Schrank) (bread and porridge uses), and spelt (T. spelta

L.) (used for bread) are now crops of minor economic importance and less frequently

cultivated (Stallknecht et al., 1996; Piergiovanni and Volpe, 2002). However, the interest

in these ancient species has been increasing again over the last years due to their high

adaptability to poor soils, attractive nutritional attributes, potential therapeutic properties,

to prepare alternative and new foods, and as a source of useful genes (Piergiovanni and

Volpe, 2002).

Plant breeders usually create new wheat lines more resistant to plagues or diseases and

equally to show yield improvements, so that commercial wheat types usually have a quite

short life cycle (NABIM, 2014). Therefore every year in the National Association of

British and Irish Millers (NABIM) web site, a list of both new and established wheat

Chapter 2

32

varieties is published. For example, currently there is one new winter variety that may be

suitable for bread-making (Chilton) and three new winter varieties that are appropriate for

biscuit and cakes (Delphi, KWS Croft and Monterey) (NABIM, 2014).

2.4 The structure of the wheat kernel

Figure 2.1 shows the structure of the wheat kernel, including its main components. Wheat

belongs to the grass family (Gramineae) that produces an edible caryopsis (Paulsen and

Shroyer, 2004). The embryo and endosperm are surrounded by seed coats and pericarp

(Dexter and Sarkar, 2004; Bechtel et al., 2009). The terms grain and kernel are commonly

used to describe the caryopses of cereals (Evers and Millar, 2002), hence both are used in

the current work.

Figure 2.1 Structure of the wheat kernel. Longitudinal (A) and transversal (B) view. Adapted and

modified from Dexter and Sarkar (2004), van der Kamp (2011) and Brouns et al., (2012).

Brush hairs

Endosperm (80-85%)

Aleurone layer (6-9%)

Nucellar tissue (Hyaline layer) Seedcoat (Testa 1%)

Tube cells Cross cells Hypodermis Epidermis

Inner pericarp

Outer pericarp

4-5%

Germ (3%)

Starch and

gluten

proteins

Alkylresorcionols

Insoluble & soluble

dietary fibre

(arabinoxylan,

β-glucan)

Proteins

Phenolic acids

Vitamin E

B vitamins

Minerals

Phytic acid

Enzymes

Lipids

Antioxidants

Vitamin E

B vitamins

Minerals

Sterols

Proteins

Insoluble

dietary

fibre

(xylan,

cellulose,

lignin)

Phenolic

acids

bound to

cell walls

Bran

Germ

Bran

Crease Endosperm

A

B

Pigment strand

Chapter 2

33

As Figure 2.1 shows, the wheat kernel has a lengthened oval form. Its length measures

from 4 to 10 mm, its width and depth from 2.5 to 4.5 mm and its average weight is around

30 to 35 mg. The wheat kernel is widest about the middle of its large axis (Evers and

Millar, 2002; Dexter and Sarkar, 2004; Shewry, 2009; Delcour and Hoseney, 2010). The

dorsal face is more rectilinear, and is traversed along its length by a broad and deep crease.

The grain resembles an oblate spheroid in shape, being incomplete as a result of the crease.

The crease is a deep furrow that runs almost the entire length of the kernel and extends the

bran layers deep into the kernel; this not only makes the separation of the bran from the

endosperm in milling difficult but also forms a perfect place for dust accumulation and

microorganism growth (Shewry, 2009; Bechtel et al., 2009; Delcour and Hoseney, 2010;

van der Kamp, 2011; Brouns et al., 2012). By contrast, the rice kernel does not exhibit a

crease, and bran and germ can be removed simply by polishing, such that rice endosperm

is eaten in a pure and intact form. Barley, oats and rye also have a crease, while maize,

sorghum and millet kernels do not have a crease. The presence of the crease in the wheat

kernel requires breaking open the kernel to separate bran from endosperm in the milling

process (Evers and Millar, 2002; Dexter and Sarkar, 2004; Shewry, 2009). The grain

shape, depth of the crease and the kernel size vary from one variety to another as well as

between kernels from the same variety. The higher end of the kernel is covered with small

hairs, called brushes. On the opposite end, on the dorsal (crease) side, is the germ area

where the embryo is covered with a folded membrane (Pomeranz, 1988; Bechtel et al.,

2009; Delcour and Hoseney, 2010; van der Kamp, 2011; Brouns et al., 2012).

Figure 2.2 shows hyperspectral images of transversal cuts of soft (Consort, A) and hard

(Mallacca, B) wheat types. On these images it can be observed some of the different

botanical constituents that make up the wheat grain, such as pericarp, aleurone and

endosperm. The spectra shown from each botanical component reflect their distinguishable

composition, enabling their identification.

Chapter 2

34

Figure 2.2 Hyperspectral imaging of transversal cuts of Consort (A) and Mallacca (B) wheats. Data

acquired with a Perkin Elmer Spotlight 400 ® system attached to a Frontier Spectrometer. Principal

Component Analysis (PCA) is carried out on the spectra collected; a false colour image is

generated from an overlay of each of the main principle components’ spatial locations. Image taken

by Silvia Galindez.

In practice, the milling industry aims to extract the nutritious components of wheat by

separating three fractions: flour (arising mainly from the endosperm), bran and germ; these

three main constituents comprise around 80-85, 12-18 and 2-3% respectively (Posner and

Benjamin, 2003; Campbell, 2007; Brouns et al., 2012). For this, roller milling is used

because it breaks the wheat kernel in a way that bran layers stay as large particles from

which the endosperm can be scraped by the differential action of the rollers (Campbell,

2007). Figure 2.3 presents the ideal relation between botanical components and the main

milled fractions obtained from roller milling (Bechtel et al., 2009). The typical “extraction

rate or yield” of white flour is 72% (Delcour and Hoseney., 2010), compared with a

theoretical maximum of up to 85%.

Waxy cuticle

Aleurone cell walls

Protein bodies

Starchy endosperm

Pericarp cell

walls

Aleurone cell walls

A

B

Chapter 2

35

Figure 2.3 Ideal relation between botanical components and milled fractions. Adapted from Bechtel

et al., (2009).

Inner pericarp

Intermediate cells

Cross cells

Tube cells (inner epidermis)

BEESWING

Pericarp (fruit coat)

Outer pericarp

Outer epidermis (pericarp)

Hypodermis

Thin-walled cells-remnants over most of grain; cell walls remain