Universal mag drive brochrue

-

Upload

eko-kiswanto -

Category

Business

-

view

245 -

download

0

Transcript of Universal mag drive brochrue

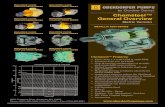

Sizes in Series: 5Capacity to 45 M³/Hr (200 GPM)Pressure to 14 Bar (200 PSI)Viscosity 1 to 55,000 cSt (28 to 250,000 SSU) Temperature -84°C to +260°C (-120°F to +500°F)

Viking® Mag Drive Pumps

Eliminates pump seal maintenance

Dimensionally interchangeable design eliminates repiping

Highest level of liquid containment available

Multiple port sizes, types & ratings available

■

■

■

■

Dimensionally Interchangeable, Sealless Mag Drive Pumps for Crucial

Liquid Containment Applications

� Viking Universal Mag Drive Series

Viking® AdvantagesPerformance▪ Nopackingormechanicalsealsmeansnosealfailureorreplacement▪ Easilyhandlesbothhighandlowviscosityfluids▪ Reducematerialloss,contaminationandgeneralhousekeeping▪ Simpledesign,easytomaintain▪ Provenreliability,100yearsofexperience

Technology▪ DimensionallyinterchangeablewithViking’sUniversalSealand

HeavyDutyBracketedpumps▪ Provenseallessdesign▪ Simplesolutionforupgradingexistingpumps▪ Short-term,dry-runcapabilitiesforeasylineclearingoremptyingtanks

withoutdamagingpump▪ Vikingdevelopedthe1stcommerciallyavailableinternalgear

magdrivepump

Productivity▪ Highestlevelofliquidcontainmentavailable▪ Eliminatesdowntimeduetosealreplacement▪ Localinventoryandsupportworldwide▪ Bi-directionalpumpdesignforenhancedapplicationflexibility▪ Lowerlifecyclecost▪ 3yearwarranty

Available Options▪ MultiplePortSizes,TypesandRatingsavailableIncludingThreaded,

Raised,andFlat-faceFlanged▪ JacketingOptionsavailableforCriticalAreasofpumpIncludingthe

Casing,HeadandReliefValve▪ Materialsofconstruction:steel,stainlesssteel,andcastiron▪ Specialconstructionoptionsforbushings,shaft,pin&clearancesavailable▪ Protectivedeviceoptionsinclude:powerloadmonitor,temperaturemonitor,

andlowflowdetector▪ Otheroptionsinclude:casingandcanisterdrains,andgaugeports

TheUniversalMagDriveprovidesadimensionallyinterchangeablefootprintwiththeViking'sUniversalSealandHeavyDutyBracketedpumps.Thisallowsfor an easy upgrade from packing or mechanicalsealstoseallessMagDrivetechnology,providingthe highestlevelofliquidcontainmentavailabletoday.

Performance Envelope

25 50 75 100 125 150 175 200

Capacity (GPM)

40302010

Capacity (M3/Hr)

50

100

150

200

2.5

5

7.5

10

12.5

Pres

sure

(PSI

)

Pres

sure

(Bar

)

15780 RPM 640 RPM

Stainless Steel

Cast Iron & Steel

KK L/LQ LL LSK

Viking Universal Mag Drive Series �

Applications

Model Number Key

L S 8 1 2 4 A-325 RField 1 Field 2 Field 3 Field 4 Field 5 Field 6 Field 7 Field 8 Field 9

Hard-to-Seal Liquids

Shaftsealleakageisthenumberonecauseofpumpdowntimeandmaintenance.Shaftsealswearfasterwhenliquid,airandheatcombineatthesealtocausechemicalreactions,like:• Crystallization (e.g.isocyanates).Abrasivecrystalscauseprematurewear.

• Sticking(e.g.adhesives,epoxyresins,paints).Sealfacesbondwhenpumpstops,andfailsatstartup.

• Varnishing(e.g.petroleumproducts).Layerbuildsuponsealfacescausing separation.

Typical Applications: • Isocyanates• Sodium Hydroxide• Adhesives• Epoxy Resins

Hazardous & Reactive Liquids

Shaftsealscanallowliquidsandvaporsout,causinghazardousexposure,andcanallowairin,causingunwantedchemicalreactions.Traditionalsealedpumps,includingthosethatrequireflushing,quenchingandbarrierfluids,aresubjecttothesamefailuresassingleseals,withtheadditionalcostandmaintenanceheadachesoftheassociatedequipment(pumps,pressurevessel,tubing/piping,filters,etc.).Whenthecostsofenvironmentalcontrolsareconsidered,thedimensionallyinterchangeableUniversalMagDriveSeriesisthemostcost-effectivealternative.

Typical Applications: • Volatile Organic Chemicals• Hazardous Chemicals• LPG and Ammonia• Reactive Chemicals

�4/7 Operations

Unplanneddowntimetofixaleakysealisunacceptableinfacilitieswithcontinuousprocesses,likerefineries,chemicalplantsandpapermills.Evenwhenpumping“safe”liquids,sealsaresubjecttomechanicalproblemslikelossofcompression,misalignmentofpumpanddriver,impropersealinstallation,shaftdeflectioncausingoff-centerfaces,suctionlift(vacuum)causingfaceseparation,andmanyothers.Ifyoucan’taffordpumpdowntime,theUniversalMagDriveSeriesoffersexceptionalup-timereliabilitythroughitsrobust,seallessdesign.

Typical Applications: • Refineries• Chemical and Polymer Plants• Paper Mills• Pipelines

Jacketing:1=Non-JacketedBracket

Shaft Sealing:8=Sealless

Material of Construction:3=SteelExternals4=CastIron7=StainlessSteel

Size:KKKLLQLLLS

Series Edition:A=OriginalDesign

Drive Configurations:__=StandardPumpD=DirectDriveR=ReducerDriveP=PurchasedReducer

Torque Specifications:K-KK=90Ft-lbK-KK=180Ft-lbL-LS=325Ft-lb

2=Bearing ShaftSupport

4 Viking Universal Mag Drive Series

Viking® BenefitsA

DV

AN

CE

D D

UR

AB

ILIT

YE

AS

Y I

NS

TALL

AT

ION

■ Dimensionally InterchangeableProven,dimensionallyinterchangeabledesignforViking'sUniversalSealandHeavyDutyBracketedpumpsaswellascompetitivepumpsthatduplicateViking'sfootprint.Provides simple solution for upgrading existing pumps, utilizing existing reducer, motor, coupling, guard, wiring and base.

■ Multiple Port ConfigurationsMultipleportsizes,typesandratingsareavailableincludingthreaded,raisedandflatfaceflanged(125#,150#,250#&300#). Provides easy solution to match customer requirements for quick, easy installation.

■ No Special Tools RequiredJackboltsforcouplingdisassemblyarestandardwiththepump.Simplifies maintenance and reduces planned downtime.

■ Lifting Lug IncludedAllowsforeasierpumphandlingwheninstalling,removingordisassemblingpump.Simplifies installation.

■ Drive OptionsMultipledriveoptionsareavailableincludingreducer,andvariablespeeddrive. Drive configurations provide easy solutions to match customer requirements for quick, easy installation.

■ Rotatable CasingUniversalSealpumpsareequippedwithcasingsthatcanbepositionedtomeetcommonpipingconfigurations,including90°andoppositeporting. Shortens and simplifies installation with no special tools required for quick installation.

■ Heavy Duty Bearings and BushingsProven,ruggedpumpdesignequippedwithheavy-dutybearingsandbushings.Provides enhanced shaft support extending pump and in-canister bushing life.

■ 3-Year WarrantyBestinclasswarrantythatcoversworkmanshipandmaterials.Warranty is � years longer than the competition for greater peace of mind.

■ Proven DesignPumphasonlytwomovingpartsproveninthousandsoftoughapplicationsaroundtheworld.Simple design minimizes service requirements while providing unmatched durability and reliability.

■ Innovative Magnet DesignInnermagnetisencapsulatedinalaserweldedstainlesssteelcanister.One-piece design extends pump life and eliminates maintenance.

Viking Universal Mag Drive Series �

■ Short-term Run-Dry CapabilityShort-termrun-drycapabilityispossibleduetostateoftheartdesignandmagnettechnology.Protects the pump during priming and accidental empty-tank situations.

■ Relief Valve, StandardPumpscomewithanadjustableinternalpressurereliefvalveonstandarddesign.Jacketedpressurereliefvalvesareavailableinsteelandstainless.Protects pump from over-pressure.

LOW

ER

CO

ST

OF O

WN

ER

SH

IPA

PP

LICA

TIO

N FLE

XIB

ILITY

■ Dual Thrust Control WashersPositivecontrolofrotorpositionformoreaccurateflow,alsoreducespumpwear.Provides lower life cycle costs and improves process control capability.

■ Externally Adjustable Relief ValveReliefvalvecanbeadjustedwhileinservicewhenprocessconditionschange.Provides maximum process up-time.

■ Adjustable End ClearanceAllowsthepumptobeadjustedfordifferentviscositiesandtemperaturesifprocesschanges,increasingproductivity.Single point adjustment maintains and maximizes pump efficiency, extending life.

■ Multiple Material OptionsWidearrayofpumpconstructionmaterialsavailableforinternalandexternalcomponentsallowbroadchemicalandtemperaturecompatibilityonlubricatingandnon-lubricatingliquidstomatchyourapplicationneed.Custom configured pumps lengthen life of pump for lower total cost of ownership.

■ Optimized EfficiencyProven,optimizedgearandpumpgeometrymaximizesoverallefficiency.Reduces product operating cost, providing a lower total cost of ownership.

■ Higher Pressure CapabilitiesThrustcontrol,enhancedshaftsupportandawideselectionofmaterialspermitshigherpressurecapabilities.Permits single pump standardization for multiple liquids and applications.

■ Bi-directional Pump DesignBi-directionalpumpingdesigneliminatescostofsecondpumpandpipingneededforloadingorunloadingorlinestripping.Provides application flexibility and reduces system costs.

� Viking Universal Mag Drive Series

UniversalMagDriveSeriesConstruction

Materials of Construction

Kalrez® is a registered trademark of DuPont Performance Elastomers.Viton® is a registered trademark of DuPont Performance Elastomers.

ComponentCast Iron

Series 81�4ASteel Externals

Series 81��AStainless Steel

Series 81�7A

Casing CastIronASTMA48,Class35B

SteelASTMA216,GradeWCB

StainlessSteelASTMA743,GradeCF8M

Head CastIronASTMA48,Class35B

SteelASTMA216,GradeWCB

StainlessSteelASTMA743,GradeCF8MCaseHardened

Bracket CastIronASTMA48,Class35B

CastIronASTMA48,Class35B

CastIronASTMA48,Class35B

IdlerStandard CastIron

ASTMA48Class35BCastIron

ASTMA48Class35BStainlessSteel

ASTMA743,GradeCF8MCaseHardenedOptional Material NA NA Non-GallingStainlessandPPSComposite

RotorStandard ①CastIron

ASTMA48,Class35B①CastIron

ASTMA48,Class35BStainlessSteel

ASTMA743,GradeCF8MCaseHardened

Steel Fitted SteelASTMA148,Grade80-50

SteelASTMA148,Grade80-50 NA

Rotor Shaft

Standard SteelASTMA108,Grade1045

SteelASTMA108,Grade1045 CoatedStainlessSteel

Steel Fitted HardenedSteel ASTMA108,Grade1045

HardenedSteel ASTMA108,Grade1045 NA

Idler Pin HardenedSteelASTMA108,Grade1045

Hardened SteelASTMA108,Grade1045 CoatedStainlessSteel

Idler Bushing

Standard CarbonGraphite CarbonGraphite CarbonGraphiteOptional Material HardenedCastIron HardenedCastIron SiliconCarbide

Internal Pressure Relief Valve CastIronASTMA48,Class35B

SteelASTMA216,GradeWCB

StainlessSteelASTMA743,GradeCF8M

Canister 316LStainlessSteel 316LStainlessSteel 316LStainlessSteel

Canister Bushing

Standard CarbonGraphite CarbonGraphite CarbonGraphiteOptional Material HardenedCastIron HardenedCastIron SiliconCarbide

Thrust Washers

Standard HardenedCastIron HardenedCastIron SiliconCarbideOptional Material SiliconCarbide SiliconCarbide NA

Coupling Magnets

Standard NeodymiumIronBoron NeodymiumIronBoron NeodymiumIronBoronOptional Material SamariumCobalt SamariumCobalt SamariumCobalt

O-ringsStandard BunaN BunaN PTFE(Derivative)Encapsulated

Optional Materials Viton®,PTFE(Derivative)Encapsulated,Kalrez®

Viton®,PTFE(Derivative)Encapsulated,Kalrez® Viton®,BunaN,Kalrez®

Adapter Plate CastIron ASTMA48,Class35B

Steel ASTMA216,GradeWCB

StainlessSteel ASTMA743,GradeCF8M

Adapter Bushing

Standard CarbonGraphite CarbonGraphite CarbonGraphiteOptional HardenedCastIron HardenedCastIron SiliconCarbide

① KKandLSsizeshaveductileironrotor,ASTMA536Grade60-40-18.

Footnotes for Specifications Table on Page 7:

① Formaximumrecommendeddischargepressuresseeperformancecurves. Ifsuctionpressureexceeds50PSIG,consultfactory.

②Extraclearancesarerequiredabove225ºF.Highertemperaturescanbehandledwithspecialconstruction,consultfactory.

③Portsaretappedforstandard(NPT)pipe.④Portsaresuitableforusewith125#ANSIcastironcompanionflangesorflangedfittings.⑤Portsaresuitablefor150#ANSIsteelorstainlesssteelcompanionflanges

orflangedfittings.⑥Consultfactoryforotherportsizeoptions.

Footnotes for Dimensions Table on Page 7:①Series8124Aportsaretappedforstandard(NPT)pipe.②Series8124A,sizesLQ,LLandLSportsaresuitableforusewith125#

ANSIcastironflangesorflangedfittings.③Series8123Aand8127Aportsaresuitablefor150#ANSIsteelorstainless

steelcompanionflangesorflangedfittings.④ SizesL,LLandLQ-couplingboremayrequiremodificationstofitshaftdiameter.

Viking Universal Mag Drive Series 7

Pump Model

⑥StandardPort Size

Capacity at Maximum Rated

Speed

Maximum Hydrostatic

Pressure

①Maximum Discharge Pressure

②Maximum

Recommended Temperature

ApproximateShipping Weight

mm in. M³/Hr. GPM RPM BAR PSI BAR PSI Deg. C Deg. F Kg. Lb.K8124A ③50 ③2

18 80 780 28 400 14 200 107 22588 195

K8123A ⑤50 ⑤2 93 205K8127A 10 150 93 205KK8124A ③50 ③2

23 100 780 28 400 14 200 107 22588 195

KK8123A ⑤50 ⑤2 93 205KK8127A 10 150 93 205L8124A ③50 ③2 30 135 640 28 400 14 200 107 225 127 280LQ8124A ④65 ④2 ½

30 135 640 28 400 14 200 107 225132 290

LQ8123A ⑤65 ⑤2 ½ 134 295LQ8127A 10 150 134 295LL8124A ④75 ④3

39 170 640 28 400 14 200 107 22593 205

LL8123A ⑤75 ⑤3 143 315LL8127A 10 150 143 315LS8124A ④75 ④3

45 200 640 28 400 14 200 107 225154 340

LS8123A ⑤75 ⑤3 159 350LS8127A 10 150 159 350

Model A B C D E F G H J K L M N O P S T ④ U V WK8124AKK8124A

mm 50 130 203 140 102 70 235 100 14 31 77 239 44 16 15 460 57 28.25x.12

133in. ① 2 5.12 8.00 5.50 4.00 2.75 9.25 3.95 .56 1.42 3.03 9.39 1.75 .62 .60 18.12 2.25 1.125 5.22

K8123AK8127AKK8123A KK8127A

mm 50 133 203 140 102 70 235 100 14 31 77 239 44 16 15 460 57 28.25x.12

133

in. ③ 2 5.25 8.00 5.50 4.00 2.75 9.25 3.95 .56 1.42 3.03 9.39 1.75 .62 .60 18.12 2.25 1.125 5.22

L8124Amm 50 165 260 178 112 102 254 137 14 65 86 231 44 16 16 499 86 36

.38x.19137

in. ① 2 6.50 10.25 7.00 4.38 4.00 10.00 5.40 .56 2.55 3.37 9.11 1.75 .62 .63 19.63 3.38 1.438 5.40LQ8124ALQ8123ALQ8127A

mm 65 183 260 178 112 102 254 137 14 65 86 231 44 16 16 499 86 36.38x.19

137

in. ②③2.5 7.19 10.25 7.00 4.38 4.00 10.00 5.40 .56 2.55 3.37 9.11 1.75 .62 .63 19.63 3.38 1.438 5.40

LL8124ALL8123ALL8127A

mm 75 183 260 178 112 102 254 137 14 65 86 231 57 16 16 511 86 36.38x.19

137

in. ②③ 3 7.19 10.25 7.00 4.38 4.00 10.00 5.40 .56 2.55 3.37 9.11 2.25 .62 .63 20.13 3.38 1.438 5.40

LS8124ALS8123ALS8127A

mm 75 183 260 178 112 102 254 137 14 65 120 231 62 16 16 551 86 36.38x.19

137

in. ②③ 3 7.19 10.25 7.00 4.38 4.00 10.00 5.40 .56 2.55 4.74 9.11 2.44 .62 .63 21.69 3.38 1.438 5.40

DimensionsforKthroughLSSizes-AllMaterialsofConstruction

Specifications & DimensionsUniversalMagDriveSeriesSpecifications

SeePage6forfootnotes.

SeePage6forfootnotes.

MIDDLE EASTIDEX Middle East FZEDubai, UAEPhone: +971-4-2257978Fax: +971-4-2259796www.idexapg.com

CANADAViking Pump of Canada, Inc.Windsor, OntarioPhone: (519) 256-5438Fax: (519) 256-5070www.vikingpumpcanada.com

LATIN AMERICAViking Pump (Latin America)D.F. Mexico C.F.Phone: +52 (5) 5255-1357Fax: +52 (5) 5255-1356

EUROPEViking Pump (Europe) Ltd.Shannon, IrelandPhone: +353 (61) 471933Fax: +353 (61) 475046www.vikingpumpeurope.co.uk

ASIA-PACIFIC GROUPSingaporePhone: +65-6763-6633Fax: +65-6764-4020www.idexapg.com

China - ShanghaiPhone: +86-21-5241-5599Fax: +86-21-5241-8339www.idexapg.com

China - BeijingPhone: +86-10-6522-7567/27Fax: +86-10-6522-7563www.idexapg.com

China - GuangzhouPhone: +86-20-3886-6156Fax: +86-20-3886-2776www.idexapg.com

India - MumbaiPhone: +91-22-6678-0048/53Fax: +91-22-6678-0055www.idexapg.com

Innovation and ExperienceVikingPumphasbeenapumpindustry leaderandinnovatorsinceitsfoundingin1911.Wecontinuetobuildonourevergrowingexperiencedeliveringinnovativenewpumpingsolutions,includingcustomdesigns,tomanythousandsofcustomerswhousemillionsofViking®pumpsinsomeoftheworld’stoughestapplications.

Broad Performance RangeCapacity:0.5to360M³/Hr(0.1to1600GPM)Pressure:0 to 172 Bar (0 to 2500 PSI)Temperature: -40°Cto370°C(-40°Fto700°F)Viscosity: 0.5to1,000,000cSt(28to4,500,000SSU)

Ultimate in Sealing SolutionsViking’sofferingofpacking,component mechanicalseals,cartridgeseals,and seallessMagDrivetechnologyprovidesthebestchoicesforsealingflexibilityneededtoprovideyourapplicationacustomizedsealingsolutioneverytime-savingyoumoney,time,andunplanneddowntime.

Material Options Matched to ApplicationViking'sdedicatedironandalloysfoundriesprovidepumpconstructionmaterialsfromcastirontoHastelloy®.Application-specificmaterialsofconstructionextendpumplifesignificantly,whilereducingmaintenanceandunplanneddowntime,whichenablesincreasedproductionandabetterbottomline.

Liquid Integrity ProtectionVikinghasdevelopedmultiplepositive displacementpumpprinciplestoprotectshear-sensitiveliquids,andlow-shearoptionstopreventdamagetofibers,polymers,andsolids.Full-jacketingoptionsprovideprecisetemperaturecontrolthroughoutthepump.TheVikingMagDrive®andothersealoptionspreventfluidcontactwithair,assuringliquidintegrity.

Local Applications and Engineering SupportOver245AuthorizedVikingPump Distributorsin 68countriesprovidelocalapplicationsupportandservice,backedbyVikingApplicationEngineersandVikingRegionManagersstrategicallylocatedaroundtheworld.

Quality ManufacturingVikingusesISO9001-2000,ISO14001,Six-Sigma,andLean/Kaizeninitsworldwidemanufacturingandassemblyprocessestoremovewaste,reducedevelopmentcosts,anddeliversuperiorproductsonschedule.DedicatedVikingfoundriesandmanufacturingfacilitiesutilizestate-of-the-artCNCequipment toassureunmatchedqualityisbuiltinto everypump.

Custom Designed SolutionsVikinghasprovidedcustomdesignedpumps toend-usersandOEMssinceitsfirstpump in1911,whenVikinginventedthegear-within-a-gearpumpingprincipletoremovewaterfromarockquarry.Today,enabledbyViking'sengineeringstaff,extensiveapplications experience,andin-housefoundries,more than20%ofViking'ssalesarenewVikingdesigns,orpumpsdesignsderivedfrommorethan1000Vikingcatalogpumpswithmorethan40,000activeconfigurations.So,whetheryouareanend-useroranOEM,Vikingcanprovidecustomdesignedpumpingsolutionstomeetyourspecificneeds.

©VikingPump,Inc.Copyright2007PrintedinU.S.A.01/2008Form No. ���-B

Worldwide Leader Since 1911 for Positive Displacement Pumping Solutions for Industrial, OEM, and Sanitary Applications.

VIKINGPUMP,INC.A Unit of IDEX Corporation406 State StreetCedar Falls, Iowa 50613-0008 U.S.A.Telephone: (319) 266-1741Fax: (319) 273-8157Email: [email protected] site: www.vikingpump.com

Formoreinformation,contactyourlocalauthorizedVikingPumpDistributororcontactVikingat:

A Unit of IDEX Corporation