Unit Operating Procedure

-

Upload

mukesh-kumar -

Category

Documents

-

view

231 -

download

1

Transcript of Unit Operating Procedure

-

8/10/2019 Unit Operating Procedure

1/60

-

8/10/2019 Unit Operating Procedure

2/60

UNIT OPERATING PROCEDURES

POST-TRIP PROCEDURES ...................................................................................................... 33

TURBINE PROTECTION UPON LOSS OF LOAD ..................................................................... 34

Master Fuel Trip ...........................................................................................................................34Low Waterwall Flow .....................................................................................................................38

High Waterwall Tube Temperature ............................................................................................. 38

Evaporator Inlet Sub-Cooling ...................................................................................................... 39

Loss of All Feedwater Pumps ..................................................................................................... 39

Low Airf low ...................................................................................................................................39

Furnace Pressure High/Low ........................................................................................................ 39

Separator Storage Tank Level High ............................................................................................ 40

Airheater Gas Outlet Temperature High ..................................................................................... 40

Both FD Fans Off or Both ID Fans Off ........................................................................................ 40

Both Secondary Airheaters Off ................................................................................................... 40

Load Run-Backs ........................................................................................................................... 40

Tube Failures ................................................................................................................................41WATERWALL TUBES................................................................................................................41

ECONOMIZER TUBES ..............................................................................................................41

SUPERHEATER AND REHEATER TUBES ............................................................................... 42

OPERATION WITHOUT BRP ............................................................................................................ 42General Remarks ..........................................................................................................................42

Cold Start Without BRP ............................................................................................................... 42

Shutdown Without BRP ...............................................................................................................43

Warm Start without BRP ..............................................................................................................43

Hot Start Without BRP .................................................................................................................43

APPENDIX A - FEEDWATER SPECIFICATIONS FOR ONCE THRU BOILERS .............................. 45

-

8/10/2019 Unit Operating Procedure

3/60

UNIT OPERATING PROCEDURES

LIST OF REFERENCES

TITLE LOCATION

Airf low Control and Distr ibut ion ....................................................... Part 6 Section 4

Boi ler Circu lating Pump Operating Procedures .............................. Part 2 Section 3 Tab 9

Recommended Burner Management System .................................. Part 7 Section 1

Pressure Part Connection and Expansion Movement Diagrams ... Part 2 Section 5 Tab 1

Process & Inst rumentation Diagrams .............................................. Part 2 Section 7

Pulverized Coal System ..................................................................... Part 6 Section 1

Pulverizer Operating Procedures ..................................................... Part 6 Section 2 Tab 2

Soot Blowing Philosophy .................................................................. Part 5 Section 4

Steam Line Blowing ........................................................................... Part 2 Section 3 Tab 8

Tilting Tangential Firing System ....................................................... Part 6 Section 4

Water Treatment................................................................................. Part 2 Section 3 Tab 3

SSC and Pulverizer Rejects System

-

8/10/2019 Unit Operating Procedure

4/60

UNIT OPERATING PROCEDURES

THIS PAGE INTENTIONALLY LEFT BLANK

-

8/10/2019 Unit Operating Procedure

5/60

UNIT OPERATING PROCEDURES

INTRODUCTIONThese procedures are intended to serve as a guide during the initialstages of operation. They include precautions, which must be observed,

and the proper operating sequences of the steam generator, fuel firingequipment and auxiliary equipment. Refer to the General ArrangementDrawings. The sequential procedures do not include all detailed refer-ence to equipment such as the feed pumps, condensate pumps, or theturbine.

Because the steam generator is only one part of a complex power sta-tion and all equipment must operate in unison, all specific proceduresand detailed values cannot be included in this manual. As operating ex-

perience is gained and the controls are fine-tuned, the characteristicsand operating requirements of the unit will become apparent.

Refer to the manufacturers instructions in the Maintenance and VendorManual for further operating details for specific equipment, includingpre-operational and operational procedures.

References to other sections included in these operating proceduresare listed in the Table of Contents.

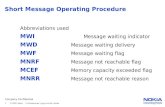

GLOSSARY OF COMMON

TERMS

BRP Boiler Recirculating Pump

-

8/10/2019 Unit Operating Procedure

6/60

UNIT OPERATING PROCEDURES

CCOFA Close-Coupled Overfire Air

SSC Submerged Scraper Conveyor

BMS Burner Management System

PRE-OPERATIONAL

PROCEDURES

CleanupThe furnace should be inspected and cleaned both internally and exter-nally before initial firing and prior to each subsequent cold start-up aftermaintenance. Remove all foreign material from the pressure parts.Clear any grating, pipe lines and electric conduit which may restrictnormal expansion of the steam generator. All personnel should be clear,and the access doors closed. A complete check list should be preparedby operating personnel.

Chemical CleaningSpecific pre-operational chemical cleaning procedures are includedelsewhere in this manual. The fuel firing and boiler circulating pump op-erating procedures, outlined under COLD START_UP, Lighting Off,should be used as a guide when operating the fuel firing equipment.

Steam Line BlowingPrior to starting up a new steam generator, or following a major pres-

sure part repair, the main steam and reheat steam lines should beblown out to remove scale and other foreign matter. Steam line blowing,which prevents damage to the turbine, should be done prior to chemicalcleaning. Refer to Steam Line Blowing Procedures for recommended

-

8/10/2019 Unit Operating Procedure

7/60

UNIT OPERATING PROCEDURES

Preparations for Lighting

Off

Before lighting off the steam generator, verify that the following stepshave been completed:

CAUTION: The differential temperature between thefeedwater and boiler metal must never exceed 200F(111C) (check the separator during initial filling or sepa-rator and superheater outlet header during filling for hy-drostatic test).

If the metal temperature is less than 100F (38C) andthe feedwater temperature is higher, a minimum fill rateshould be used.

1. The unit has been chemically cleaned, and the steam lines havebeen blown and safety valves have been set (before initial turbineoperation).

2. All control systems have been checked and are available for ser-

vice.All safety interlock systems should be checked prior to start-up toensure proper functioning. Exercise the systems by creating theactual interlock actuating conditions. Simulate the activating condi-tion if the actual condition cannot be created.

3. All instrumentation and associated mechanical equipment hasbeen checked out and is available for service.

4. The auxiliary fuel firing equipment has been checked out to en-sure it is properly functioning. Recheck the following items tomake sure that:

a Auxiliary fuel available at require pressure

-

8/10/2019 Unit Operating Procedure

8/60

UNIT OPERATING PROCEDURES

f. The pulverizer lube oil systems are available for service.

6. The windboxes have been checked for proper damper positioning

and the tilts are set at horizontal.

7. The feedwater system and at least one feedwater pump, includ-ing the instrumentation and equipment, has been checked outand is available for operation. During a start-up, the feedwaterflow should be controlled in automatic mode for best results.

8. The deaerator auxiliary steam supply is operational and deae-rated feedwater at 220F (104C) is available. To avoid oxygen

corrosion in the boiler, the use of deaerated feedwater with atemperature of greater than 215F (102C) is recommended. Re-fer to Water Treatment instructions.

9. The boiler recirculating pump (BRP) has been checked out, thesuction and discharge isolation valves are open, and all pump in-strumentation is available for service. The pump differential pres-sure monitoring must be in service. Ensure that the proper tripsettings have been made.

10. The steam generator start-up system valves are ready for opera-tion (MEFCV, HWL-1, HWL-2, WKFCV), with isolation valvesopen. The SST level control using HWL-1 and HWL-2 valves hasbeen checked and is available for service.

11. The Startup system drain transfer system is ready for operation.This system includes the flash tank, condensate receiving tank,and drain transfer pumps.

12. Auxiliary steam is available from another operating boiler orcommon system for supplying the deaerator, and feedwater tank.

13. Cooling water system is in operation.

-

8/10/2019 Unit Operating Procedure

9/60

UNIT OPERATING PROCEDURES

NOTE:It is assumed that the unit will be started with twoID fans, two FD fans, twoPA fans, and two SA air hea-

ters, and two PA air heaters in service. If the unit isstarted with only one ID and FD fan,one PA fanin ser-vice, the following damper positions apply to the equip-ment to be started. Dampers associated with the idleequipment should be closed. Refer to the fan manufac-turer's instructions for operating details.

14. All air and gas handling equipment has been checked out and isavailable for service. Air and gas duct dampers should be in thestart-up position as follows:

a. For the first draft group to be started (ID and FD fans), the fanoutlet shutoff dampers are closed and the flow control device isat minimum.

b. For the second draft group (opposite ID and FD fans), the out-let shutoff dampers are open to provide a flow path through theunit.

c. The PA fan outlet shutoff dampers and flow control device areclosed or at the minimum position.

d. The steam coil airheater inlet and outlet dampers are open andthe bypass dampers are closed. Alternately, if steam air-preheating is not desired, then the steam coil airheater inletand outlet dampers are closed and the bypass dampers areopen. Steam coil airheater usage should be based on main-

taining average cold end temperature of the airheaters abovethe recommended level for oil firing and coal firing. Refer to theairheater operating manual for recommended setpoints.

e The air heater gas inlet isolation gates gas outlet proportioning

-

8/10/2019 Unit Operating Procedure

10/60

UNIT OPERATING PROCEDURES

tracted and the main supply valve closed. Refer to the soot blow-er instructions.

17. All desuperheater spray water control and block valves areclosed.

CAUTION: Prevent possible water damage to the tur-bine by taking extreme care to eliminate all water fromthe main steam line(s), cold and hot reheat lines, andthe superheater and reheater elements and headers be-fore the turbine is rolled. Refer to the turbine manufac-

turer's instructions and the Valve Operating Diagram forproper drain valve settings.

18. Position superheater, and reheater and economizer drain valves,and vent valves in startup position. Refer to the Valve Operatingtable figure 6.

19. The auxiliary steam extraction line from superheater is isolated.

20. The warming-keeping system for the boiler start-up system is iso-

lated (supply is from economizer outlet links and discharge is toSH desuperheater).

21. The acoustic pyrometer or other measuring device for measuringfurnace outlet temperature is in working order and available forservice.

22. The HP and LP bypass stations are available for service, and hy-draulic stations are in operation. The water supply for desuper-

heating has been established.23. The condenser is available for service, with circulation water flow,

and vacuum has been established to accept water flow from thedrain transfer pumps and LP bypass (condenser has a pressure

-

8/10/2019 Unit Operating Procedure

11/60

UNIT OPERATING PROCEDURES

Warm Water Filling of the

Boiler

The entire economizer, furnace wall, and separator system must befilled with warm deaerated water (220 F (104C)) and be free of air.

The following procedure shall be carried out to ensure the water systemis free of air:

1. The economizer outlet vent valve and waterwall outlet vent valveis open.

2. BFPM is started at minimum setting and flow according to feed

pump operating procedures.

3. The drain transfer pumps between receiving tank and condenserare switched to automatic control in start-up position.

4. If the water system of the boiler is empty (economizer, furnacewalls, separators), then the system is to be filled with approx-imately 10% BMCR feedwater flow. Feedwater flow is preferablycontrolled using automatic feedwater control with a set point of

10% BMCR.5. Close the economizer outlet and waterwall outlet vent valve as

soon as a clear stream of water is discharged.

6. When the level in the SST reaches the high water level setpoint,the HWL-1 valve will begin to open. Increase boiler feedwaterflow to 30% BMCR and ensure that the HWL-1 valve reaches>30% open for more than 2 minutes. The water system is consi-dered full when:

a. The SST water level remains stable for 2 minutes with feedwa-ter flow at 30% BMCR

and

-

8/10/2019 Unit Operating Procedure

12/60

UNIT OPERATING PROCEDURES

tank and condensate drain pump back to the condenser (refer-ence figure 4 phase II).

3. Water flow circulation is continued through the entire pre-boilersystem, including the condensate polisher, to remove impurities.

4. During this time, constant boiler feedwater flow of 10% BMCR ormore is maintained.

5. The recirculation is continued until the water quality is within thespecified limits, based on samples taken at the HP feedwaterheater discharge and SST discharge.

Start of the BoilerRecirculation Pump

(BRP)1. It is assumed that the following preparatory work has been com-

pleted:

a. Feedwater quality within specified limits.

b. Boiler Feedwater flow setpoint at 10% BMCR.

c. Water SST level stable with HWL-1 at stable opening.

d. Cooling water flow to the hp cooler of the BRP adequate.

e. Suction valves and discharge valves are open.

2. Set the MEFCV valve at minimum (pump start) position, selectMEFCV to auto, and start BRP per pump operating instructions.

3. As soon as the BRP is running, SST level will decrease as theupper circuits are filled. Maintain 10% BMCR boiler feedwaterflow until SST level shows sustained increase. Monitor theMEFCV auto-action to establish economizer inlet flow at the no-minal flow sestpoint (40% BMCR) As SST level attains normal

-

8/10/2019 Unit Operating Procedure

13/60

UNIT OPERATING PROCEDURES

Superheat Steam

Temperature Contro l(Prior to Unit

Synchronization)The boiler will normally be started-up de-coupled from the turbine usingthe HP and LP bypass systems, which provide a steam flow paththrough the superheater, to the reheater, and to the condenser. Thisprovides additional flexibility for adjusting steam temperatures to matchturbine requirements at start-up. The primary methods for controllingsteam temperature will be firing rate and airflow adjustment.

Air Preheater Protection

During Unit Start-Ups On

OilIt is ALSTOMs strong recommendation to have the airheater soot blow-ing system continuously in service when firing oil to start up a boiler.This measure is intended to help avoid airheater fires due to accumula-

tion of oil vapor on heating surfaces or ash particles in the airheaterbaskets. A retractable soot blower is normally installed at the cold endof the airheater on the gas side, arranged close to the changeover of airto gas side when looking in direction of rotation, opposite the hot spotdetection device. This soot blower is primarily designed to reduceand/or control ash build-up in the airheater surface. It is not a cleaningdevice such as the stationary wash down nozzles.

Steam is the preferred soot blowing media. However, on some units

auxiliary steam sources are not available when starting a unit, and nor-mal sootblowing steam requirements are not reached until a later stagein the start-up process. In those cases, compressed air is an accepta-ble alternate blowing media, though less effective than steam. If neither

-

8/10/2019 Unit Operating Procedure

14/60

UNIT OPERATING PROCEDURES

For unit loads below 10% BMCR steam flow, excessive combustion air(more than the required 30% minimum air flow) or unnecessary high

furnace draft (more negative than -.062 kPa / -0.25w.g.) should beavoided. Burner tilts should not go above the horizontal position.

Changes in the firing pattern should be closely observed in respect to

possible carryover. Also, any steam that is available - including satu-

rated steam - can and should be used for airheater soot blowing aslong as sufficient steam pressure is available (at least 9 bar / 130 psig).When this minimum steam pressure has been reached, continuous coldend blowing should be initiated and continued until 10% BMCR steamflow is reached. After that airheater soot blowing can be reduced to in-

termittent operation, once every four to eight hours or as required, de-pending on the fuel being fired.

Once the unit is above 10% BMCR steam flow, normal soot blowing canbe followed using the units own auxiliary steam source as temperatureand pressure is built up.

WARNING: The greatest danger of developing an air-heater fire is in the initial stages of boiler operation, i.e.chemical cleaning and steam blowing. Experience hasshown that during these stages more than the normalprecautions need to be taken. Continuous plant obser-vations must be undertaken so the risk of a airheater firecan be kept to its very minimum. Airheater surfacesshould be waterwashed between these initial start-ups ifauxiliary steam was not available or used to clean theairheater prior to shutdown.

Once the unit has seasoned on coal, fly ash will havebeen deposited in various areas of the boiler (especiallyin the assemblies of the back pass). These ash depo-

-

8/10/2019 Unit Operating Procedure

15/60

UNIT OPERATING PROCEDURES

CAUTION: The ID fans may be capable of developingdrafts that exceed the furnace design pressure. There-

fore, an airflow path through the unit must be estab-lished and maintained before starting an ID fan and be-fore opening the ID fan flow control device by ensuringthat other dampers in the system are in the start-up po-sitions indicated in Preparations for Lighting Off, page 3.

The ID fan flow control device must be kept closed or atthe minimum open position until after the fan is started.This minimizes the possibility of developing excessive

negative pressure in the unit during the starting proce-dure.

Furnace draft must be maintained within safe limits at alltimes. Extreme care should be taken when draft and air-flow controls are in the manual mode. Be alert for possi-ble malfunctions of automatic control equipment result-ing in abnormal excursions, negative or positive, in fur-nace pressure.

2. Start the first draft group: Start one ID fan, then the correspond-ing FD fan. Open the outlet shut-off dampers. Adjust the ID fanfor proper furnace draft, and set furnace pressure control to au-tomatic. Adjust unit airflow to minimum 30%, and set unit airflowcontrol to automatic.

3. Start the second draft group: After closing the outlet shut-offdampers, start the other ID fan, then the corresponding FD fan.

Open the shut-off dampers and adjust the flow control device tobalance the draft groups, and place the second group into auto-matic.

4 St t th l t d /i it i f

-

8/10/2019 Unit Operating Procedure

16/60

UNIT OPERATING PROCEDURES

Excess Air Versus Load curve, and to Airflow Control and Distribu-tion in the Tilting Tangential Firing System section.

6. When the fans are started, the secondary air damper controlshould modulate the auxiliary air dampers to maintain a pro-grammed set point differential pressure between the windbox andfurnace.

7. Check that all other purge permissives are satisfied.

8. Place the thermoprobe into service to measure furnace exit gastemperature.

9. Initiate a furnace purge (timer in BMS).

10. Upon completion of the purge cycle, check that all firing prerequi-sites are satisfied, including the following control settings:

a. Boiler feedwater control setpoint is maintained at 5% to 10%BMCR with HWL-1 active and limiting SST level to continuous-ly purge the solids that may concentrate in the separator sto-rage tank during startup and thereby continuously cleans the

fluid in the furnace walls. If water quality is confirmed, this set-point can be reduced to zero to reduce water losses.

b. Start-up system (BRP and MEFCV valve) is on automaticmaintaining minimum economizer inlet flow setpoint.

CAUTION: It is extremely important that minimum eco-nomizer inlet (ie. Waterwall) flow be maintained at alltimes when firing the boiler to prevent tube damage due

to overheating. If waterwall flow falls below the low set-point, all fuel must be automatically tripped with a maxi-mum time delay of 10 seconds. Waterwall flow is meas-ured by flow element located at the economizer inlet.

-

8/10/2019 Unit Operating Procedure

17/60

UNIT OPERATING PROCEDURES

(1) Open LP bypass stop valve after establishing suffi-cient condenser vacuum and water supply for desu-

perheating.(2) Adjust to pre-set minimum position, and adjust pres-

sure setpoint of LP bypass valve to minimum (app. 30psig).

(3) Place control on automatic.

h. Open SH backpass drain valves, and RH outlet vent valves.

11. Start one seal air fan.

12. When the seal air to pulverizer underbowl pressure dfferential isadequate (>8 in.wg (203 mm.wg)), open the cold air gates to pro-vide a purge air flow path through the pulverizers and confirm thatthe cold air dampers are less than 5% open.

If the pulverizers are out of service, the pulverizer discharge gates must be fully open. The cold air inlet control dampers must be setto the minimum position. The pulverizer discharge gatesare onlyclosed during pulverizer maintenance, or when the pulverizers areidle and full of coal and other pulverizers are being started after aunit trip. Refer to EMERGENCY PROCEDURES, Master Fuel Trip.

13. For cold start-ups, the fuel startup sequence should follow this ta-ble (A elevation is the bottom elevation in the windbox):

Sequence Step Elevation Notes

1 AB warmup2 CD warmup

3 B coal If B coal not availiable, start A coal

4 C coal If C coal not availiable, start A coal

-

8/10/2019 Unit Operating Procedure

18/60

UNIT OPERATING PROCEDURES

sure/temperature at the desired rate (400F/hr max (222C/hr))and without exceeding the furnace exit gas temperature limitation

(1100F (593C)).17. To ensure stable operation of the water circulation system and to

ensure sufficient steam flow through the superheater, firing rateshould not be further increased until 100 psig (7 kg/cm2)is meas-ured in the water separator.

18. As the pressure is raised and saturation temperature increases,SST water level increase due to boiler water swell, and someHWL-1 and HWL-2 action may occur to limit SST water level. As

pressure further increases, the HWL-2 and then HWL-1 valveswill start to close as the water level (swell) decreases.

19. During all start-ups, control the firing rate to keep the maximumfurnace exit gas temperature below 1100F (593C), as meas-ured by the thermoprobe until approximately 10% steam genera-tion or the turbine is synchronized or flow is established throughthe HP/LP bypass system. Sufficient steam flow must be main-tained at all times to assure clearing the superheater and rehea-

ter elements of condensate. Do not close the startup drains com-pletely until steam flow through the HP/LP bypass is established.Once flow is established, progressively close startup drains andvents to transfer flow to the HP bypass.

20. The superheat backpass drain valve can be closed when separa-tor pressure reaches 75 psig (5.3 kg/cm2) (or before as desiredafter all condensate is removed).

21. Progressively increase LP bypass setpoint to 170 psig (12kg/cm2). As the HP bypass opens, the reheater will be warmedand pressurized as steam is passed through the LP bypass andreheat drains. In parallel, progressively throttle the reheat drains

-

8/10/2019 Unit Operating Procedure

19/60

UNIT OPERATING PROCEDURES

maintains a constant pressure during turbine rolling, synchroniza-tion, and initial loading.

28. After the required startup pressure is attained, the firing rate canbe adjusted to achieve the required steam temperature for turbinerolling. Refer to the start-up curves for the target steam condi-tions.

29. Do not exceed the furnace exit gas temperature limit of 1100F(593C) below 10% boiler load. Above 10% boiler load, automaticinterlocks provide protection from over-firing. If it is desirable tosupplement the warm up fuel, the pulverizer serving a lower ele-

vation of coal nozzles should be prepared for operation andstarted in accordance with Introducing Coal,. Adjacent warm-upfuel should be in service to supply the required ignition energy.The feeder should be set to keep the furnace exit gas tempera-ture from exceeding 1100F (593C).

The condition may exist when an upper elevation of coal will beplaced in service for start-up, with ignition provided by the asso-ciated elevation of warm-up fuel.Start-up by this procedure is al-

lowable, however, if utilized, care must be exercised not to exceedthe furnace exit gas temperature limitation of 1100F (593C) asapplicable, or the steam temperature values shown in the SteamTemperature Versus Load curve.

NOTE:The steam pressure should be increased slowlyduring the initial start of a new steam generator. Thisallows sufficient time for checking expansion move-

ments and permits the operators to become familiar withthe characteristics of the steam generator and auxiliaryequipment. Once these characteristics have been estab-lished, subsequent start-ups may be made at the fastest

-

8/10/2019 Unit Operating Procedure

20/60

UNIT OPERATING PROCEDURES

30. While the unit is heating up, check the boiler expansion move-ments frequently. Special attention should be given to expansion

of the boiler relative to the building steel. Expansion movementsshould be recorded for comparison with future start-ups. Refer tothe Pressure Parts Connection and Expansion Movement Dia-grams.

31. Maintain SST water level at normal setpoint via auto feedwaterflow control and check the water concentrations and constituentsas frequently as necessary to maintain proper boiler water condi-tions. Sample connections are located on the SST.

Rolling and

Synchronizing the

Turbine1. Confirm the steam conditions, pressure, temperature, and steam

purity, at the turbine are correct for turbine roll. (See turbine man-ufacturers recommendations and startup curves in figure 3).

2. Roll the turbine per the Turbine manufacturers procedures .3. SH and RH steam temperatures are maintained by adjusting fir-

ing rate and airflow.

4. When the turbine is warmed-up, synchronize the generator andput on initial load according to turbine/generator startup instruc-tions.

5. If the startup is done without the HP/LP bypass, the restriction on

furnace gas temperature must be maintained until the turbine issynchronized and RH flow is established.

6. After synchronization, all superheat and reheat vent and drainvalves should be confirmed closed

-

8/10/2019 Unit Operating Procedure

21/60

UNIT OPERATING PROCEDURES

CAUTION: Operators should be alert to detect thesymptoms of water carry-over from the boiler and intro-

duction of water into the turbine, such as:

a. A sudden, unexplained drop in steam temperature ineither the main steam or hot reheat line.

b. Vibration in the steam piping resulting from waterhammer.

c. Abnormal vibration and differential expansion read-ings from the turbine supervisory instrumentation.

Operators must be prepared to take necessary steps toprevent turbine damage upon detecting the introductionof water. Refer to the turbine manufacturers instructionsfor specific actions to be taken.

10. The firing rate should never exceed the rate necessary to matchthe total steam generation (steam to bypass plus steam to tur-bine).

If the unit is put on line before design operating pres-sure/temperature is reached, a further increase of firing rate shouldbe in accordance with a gradual rate of pressure/temperature in-crease consistent with increasing load. Do not allow steam tem-perature to exceed the values shown in the Steam TemperatureVersus Load curve.

11. If the unit was started with one set of fans in service, start thesecond set of fans as required. Refer to the fan manufacturer's

instructions for operating details.

Introducing Coal

-

8/10/2019 Unit Operating Procedure

22/60

UNIT OPERATING PROCEDURES

lowable, however, if utilized, care must be exercised not to exceedthe steam temperature values shown in the Steam TemperatureVersus Load curve.

5. Confirm that the pulverizer reject hopper is ready for service (dis-charge valve closed, loop seal full, and inlet valve open). Placethe pulverizer reject sluicing system in service (refer to SSC andPulverizer Reject System ..)

6. Check that the pulverizer start permissives are satisfied. Refer tothe Control System instructions. The coal fuel-air dampers shouldremain closed until ignition is established. Refer to Airflow Control

and Distribution in the Tilting Tangential Firing System section.Maintain the nozzle tilts at horizontal (+/- 10 degrees). At leastone PA fan must be in service.

If the unit start-up follows a master fuel trip, the pulverizer may notbe empty. Clear the pulverizer of excess coal per recommendedclearing procedures before starting the pulverizer. Refer to the De-sign and Operation manual, for the pulverizer clearing procedures.During this procedure, the pulverizer discharge gatesof all other

idle pulverizers must be closed. This prevents hot furnace gasesfrom entering the coal piping and the idle pulverizers. (See EMER-GENCY PROCEDURES,.) When the coal has been removed fromthe pulverizer, the feeder can be started at minimum speed andthen adjusted to a speed which provides the stable flame requiredto meet unit load requirements. Be sure the ignition energy in thefurnace is established before starting the pulverizer.

7. Start the pulverizer. Open the hot air shutoff gate. Place the pul-

verizer airflow and temperature control on automatic.and bringthe pulverizer up to the required operating temperature withoutcoal. When ready to fire coal, manually start the feeder at mini-mum rating Ignition of the pulverized coal should take place im

-

8/10/2019 Unit Operating Procedure

23/60

UNIT OPERATING PROCEDURES

9. Increase unit load as required by increasing the boiler inputs:feedwater, fuel, and air in coordinated automatic mode.

10. When the feeder rating of the first pulverizer has reached approx-imately 80%, place the second pulverizer, which supplies the ad-

jacent elevation of coal nozzles, in service in a similar manner.When the second adjacent pulverizer is proven in service, equa-lize the feeder rating of both. The warm-up fuel must remain inservice until both feeders achieve 50% rating.

If the adjacent pulverizer is not available for service, place the pul-verizer serving the next closest elevation of coal nozzles in service.

Do not remove the warm-up fuelfrom service until thetwo adjacentcoal elevations are in service with feeder ratings greater than 50%.

11. When the unit load reaches 30% of full load, the Burner Man-agement System and secondary air damper controls should closethe auxiliary air dampers which serve the compartments adjacentto the coal nozzles out of service. The Windbox to Furnace Diffe-rential Controller, provided in the Closed Loop Control Systemshould gradually increase the windbox-to-furnace differential

pressure to approximately 4 in. w.g.(102 mm H2O) as load is in-creased per the prescribed curve.

12. The airflow to the furnace must be sufficient for the firing rate. Au-tomatic control equipment is normally arranged to maintain sucha balanced condition. The operation of the O2measuring devices,often tied in with the airflow control, should be checked periodical-ly for proper operation.

Initial Load Increase to

40%1 Increase unit load as required by increasing the boiler inputs:

-

8/10/2019 Unit Operating Procedure

24/60

UNIT OPERATING PROCEDURES

6. Reduce warm up fuel firing to minimum. Warm up elevation CD isissued an elevation stop command.

7. At app. 40% BMCR, the firing rate matches the economizer inletflow. The steam temperature at the separator outlet will reach astable superheated condition, causing the level in the SST to de-crease, and the boiler will enter the once-through (dry) mode. Theboiler is proven in once-through (dry) mode when all the followingconditions exist:

a. Steam flow > 40% for 5 minutes.

b. Separator storage tank level < 39 inches (1 meter).c. Separator outlet temperature is superheated by >30F (17C).

d. The difference between economizer inlet temperature and feedwater temperature leaving the HP feedwater heater < 10F(6C).

When the controls swithch from wet to dry mode, FW flow controlwill be released from SST level control to FW-Firing Rate coordina-

tion to control separator outlet steam temperature, and the BRP willbe auto-stopped (note that BRP operation can continue with theunit is dry mode if desired).

8. When the BRP stops, the warm-keeping system for the start-upsystem should be put into operation. The warm-keeping systemmaintains the start-up system in a warm condition so that it canbe immediately put into service. This system uses water from theeconomizer outlet link as the source of heat. A wet-leg fluid level

is maintained in the startup system by automatically draining fluidto the superheat desuperheaters via the WKFCV valve.

9. Put into service additional BFPs per the manufacturer proceduresf h l d i d li l di b

-

8/10/2019 Unit Operating Procedure

25/60

UNIT OPERATING PROCEDURES

14. Place the feedwater-firing rate ratio control in auto. Place windboxtilts in auto control (RH temperature) at 30% load. Place combus-tion control on automatic when firing conditions are stable. Referto the control manufacturer's instructions for specific procedures.

15. Make frequent visual observations of furnace conditions to ensurethat no excessive slag build-up is developing. This is especiallyimportant when burning coal with low ash fusion temperatures.Operate the soot blowers as required to keep the steam tempera-ture control (nozzle tilts, desuperheaters)within operating range.If response to soot blowing is sluggish or insignificant, reduce unit

load or increase excess air to assist in lowering steam tempera-ture and take steps to eliminate the cause of the erratic steamtemperatures. Refer to Soot Blowing/Water Cannon Philosophy.

WARNING: The coutant bottom of the furnace is de-signed only to transfer ash to the bottom ash removalsystem and is not designed to store accumulated ash.

Under no circumstances should the level of ash in the

bottom ash hopper or submerged scrapper conveyor beallowed to reach the level of the coutant opening, thusblocking further removal of ash from the furnace.

Under no circumstances should ash or slag be allowedto bridge across the coutant opening.

If bridging starts to occur, load should be reduced in anattempt to shed the buildup.

If complete bridging across the coutant opening doesoccur, immediate steps should be taken to shut thesteam generator down to cold following normal shut-down procedures. The ash should then be removed by

-

8/10/2019 Unit Operating Procedure

26/60

UNIT OPERATING PROCEDURES

NORMAL OPERATION -

UNIT LOAD CHANGES

The normal load range under automatic control is 40% to 100%. Theboiler load change rates should not exceed 3% per minute (20 MW perminute) between 40% and 50% load, and should not exceed 5% perminute (33 MW per minute) above 50% load. These maximum loadchange rates can only be achieved if control actions are well coordi-nated and well tuned. Below 40% load, the change rates should not ex-ceed that shown on the prescribed start-up curves.

During normal operation, unit load changes may alter pulverizer loading

rate and/or the number of pulverizers in service. A wide range of loadcontrol can be achieved with the pulverizers on automatic.

During normal operation, the FD fans are modulated to supply the re-quired combustion airflow and excess air as a function of unit load. ThePA fans are modulated to supply the required airflow to the pulverizersthat are in service.

Decreasing LoadIf the unit load decreases to a point at which the feeder rating of thepulverizers in service is reduced to 40%, a pulverizer should be takenout of service. Normally the pulverizer serving the lower-most coal ele-vation is removed in order to maximize steam temperature by maintain-ing heat release higher in the furnace.

To remove the pulverizer from service, proceed as follows:

1. Ensure that pulverizer ignition energy is available in the furnace.

Start the warm-up elevation associated with the coal elevationserved by the selected pulverizer.

2. Select the feeder to manual and Gradually reduce the feeder rat-

-

8/10/2019 Unit Operating Procedure

27/60

UNIT OPERATING PROCEDURES

tions isnot recommended and is only permissible through the use of theassociated warm up fuel elevation(s) to provide support ignition energy.

If the unit load is reduced to a point at which only two pulverizers arerequired, the associated warm up fueladjacent to the coal nozzles inservice must be placed in service to ensure support ignition when thefeeder ratings drop to 50% or less. Auxiliary supporting fuel should beused whenever, in the operator's judgment, ignition stabilization is ne-cessary.

Increasing LoadIf, after several pulverizers have been taken out of service due to a loaddecrease, load increases again to a point at which the feeder rating ofthe pulverizers in service exceeds 80% of maximum, place an additionalpulverizer in service as follows

1. Establish the ignition energy required for the coal elevationserved by the selected pulverizer.

2. Start the pulverizer.

3. Open the hot air shutoff gate and place the Pulverizer Airflow andTemperature Control into automatic and bring the pulverizer up tooperating temperature (Refer to the Pulverizer and PulverizedCoal System sections of this manual).

4. Start the coal feeder. The feeder control should be on manualand at minimum feeder rating.

5. When the pulverizer is grinding and coal ignition has been estab-

lished, gradually increase the feeder rating until it equals that ofthe other feeders in service. Then, place the feeder on automaticcontrol.

-

8/10/2019 Unit Operating Procedure

28/60

UNIT OPERATING PROCEDURES

CAUTION:Exercise care to prevent water from enteringthe turbine through the main steam line(s), the hot re-

heat line(s), or the cold reheat line(s) during and afterthe shutdown process. This prevents water damage tothe turbine during a subsequent restart. Possible watersources are:

a. Overflow from the separator into the superheaterwhen a high water level exists.

b. Water entering the superheater or reheater throughthe desuperheaters due to open desuperheater con-trol valves or valve leakage with the feed pumpsrunning.

1. The rate at which load is reduced will be a function of the turbinerequirements. The operator determines the required trip load andthe rate of load decrease as input, then the control system will au-tomatically reduce boiler inputs at the required rate. Feedwater,air flow, fuel flow, and steam temperature should remain on au-

tomatic control during the shutdown for best coordinated control.2. Reduce the unit load to 60% Tmcr following the prescribed sliding

pressure vs. load curve (for a shutdown to hot, a higher pressuremay be desirable to preserve energy in the unit).

3. To maintain constant steam temperature while the turbine isshutdown, decouple the turbine and boiler using the HP/LP by-pass. Hold boiler load constant, transfer pressure control to theHP bypass, reduce turbine load at a rate prescribed by the turbinesupplier while transfering steam flow from the turbine to theHP/LP bypass.

4. Shutdown the turbine as prescribed by the turbine supplier.

-

8/10/2019 Unit Operating Procedure

29/60

UNIT OPERATING PROCEDURES

the spout and feeder are empty, and then stop the feeder. Makesure the pulverizer is completely empty by running it for at least 3minutes. Then, stop the pulverizer. Unless an emergency condi-tion exists, the pulverizer should always be emptied in this man-ner before being stopped. Refer to the shutdown procedures inthe Pulverizer and Pulverized Coal System sections in of this ma-nual.

8. As pulverizers are taken out of service, the secondary air dampercontrol system should close the associated windbox dampers andadjust the other dampers to compensate for the reduced firing

rate.9. Take the second pulverizer supplying the next highest elevation

of coal nozzles out of service when the feeder rating on all re-maining pulverizers reaches 40%. Continue taking additional pul-verizers out of service in the same manner. When only two pulve-rizers remain in service, the adjacent warm up fuel must beplaced in service prior to reducing the feeder rating of either pul-verizer to below 50%.

It is recommended that this consecutive elevation shutdown se-quence be followed. Firing coal at separated coal nozzle elevationswithout auxiliary supporting fuel is not permitted.

10. Overfire air will be reduced automatically as the unit load is re-duced per the prescribed control curves. Below approximately30% load, overfire will be closed to a minimum position. Keep theoverfire air dampers at minimum open position to prevent thenozzle tips from overheating.

11. Operate all soot blowers as load is reduced. Refer to the SootBlowing/Water Cannon Philosophy section and to the soot blowermanufacturers instructions.

-

8/10/2019 Unit Operating Procedure

30/60

UNIT OPERATING PROCEDURES

the SST. The boiler will now be returned to recirculation (wet)mode. The boiler is proven in recirculation (wet) mode when allthe following conditions exist:

a. Steam flow < 40%,

b. Separator storage tank level > 39 inches (1 meter)

c. Separator outlet temperature < saturation temperature + 30F(17C),

d. Difference between economizer inlet temperature and feedwa-ter inlet temperature >10F (6C).

When recirculation mode is logically proven, FW flow control willswitch from coordination of FW-Firing Rate controlling steam tem-perature to SST level control.

The BRP will be auto started to provide minimum waterwall flow.

16. Continue to reduce load to the predetermined load where the tur-bine will be taken off-line.

17. After the last pulverizer is shut down, remove the warm up fuelfrom service. All fires should be extinguished when the unit is offthe line.

With no pulverizers in service, the PA fans and the pulverizer sealair fans may also be shut down. The PA fans should not be shutdown if the air heater gas inlet temperature is above 400F (205C)

18. After all fuel firing is removed, close the HP and LP bypassvalves.

19. Immediately after closing the HP/LP bypass valves, open the su-perheater outlet vents and drains and all reheater vents anddrains Open other drains in the superheater system as required

-

8/10/2019 Unit Operating Procedure

31/60

UNIT OPERATING PROCEDURES

a. Complete a post trip purge of the unit by running the ID and FDfans for at least 5 minutes at 30% airflow after the fires are ex-tinguished.

b. If not already done, reduce the airflow through the unit to 30%minimum airflow. Keep the fans and air heaters in service untilthe unit has cooled to the desired temperature. Air heaters andfans should not be taken out of service until the air heater gasinlet temperatures have dropped below 400F (205C).

c. Keep the BRP in service until the boiler water temperature isreduced to the desired point. Keep the water level near normal

in the SST, adding makeup water as required.

26. If the cooling process must be accelerated to permit entry into thesteam generator for maintenance, proceed as in step 25, except:

a. Continue running the fans at the desired rate to cool the unit.The air heaters may be shut down when the gas entering tem-perature has dropped below 400F (205C). Refer to the airheater instructions.

With the air heaters stopped and the fans running, deposits offly ash may accumulate in the air heater and cause a rotor un-balance.

b. Keep the BRP in service to increase recirculation. Keep thewater level near normal in the separator storage tank. Shutdown the pump when the boiler water temperature is reducedto the desired level.

27. Do not shut down the scanner/ignitor air fan until the furnacetemperature has dropped to below 300F (149C).

28. If the boiler is to be laid up wet, refer to Lay-up Procedures.

-

8/10/2019 Unit Operating Procedure

32/60

UNIT OPERATING PROCEDURES

During a shutdown to hot standby, it is assumed that the unit will beshut down for a relatively short period of time and that the existing pres-sure and temperature conditions will be substantially maintained. A pro-cedure similar to that for normal shutdown should be used, with the fol-lowing exceptions:

1. Reduce steam pressure in line with unit load reduction, followingthe prescribed sliding pressure curve. To preserve energy in theboiler, maintain a higher pressure (approximately 2000 psig (141kg/cm2)) until the boiler is taken off line. After the boiler is off theline and fires removed and HP/LP bypass closed, the boiler maybe bottled up by closing all superheater drains and vents. Rehea-ter drains and vents should be opened to relieve pressure in thereheater.

2. It is not necessary to close the feeder inlet gates and run thespouts and feeders empty. As each pulverizer is taken out of ser-vice, close the hot air shutoff gate. Stop the feeder when thecoal/air temperature drops to 130F (54 deg C). Run the pulveriz-er for a 3 minute period until it is empty, and then stop the pulve-

rizer.3. The BRP should be kept in operation to ensure uniform boiler

metal temperatures. This will prevent possible local overheatingdue to hot slag deposits.

WARNING:If the fans are shut down with an air heatergas inlet temperature above 400F (205C), the air hea-ter must be kept rotating. However, running an air hea-

ter with the gas inlet temperature above 400F (205C)and no air flow through it will cause seal damage fol-lowed by excessive leakage during operation. (Refer toair heater instructions.) The decision to bottle up the

-

8/10/2019 Unit Operating Procedure

33/60

UNIT OPERATING PROCEDURES

CAUTION: The differential temperature between thefeedwater and boiler metal must never exceed 200F

(111C) (separator storage tank during initial filling orseparator storage tank and superheater outlet headerduring filling for hydrostatic test).

6. The operator should observe the SST level periodically so that heis always aware of the actual level and can take the appropriateaction to re-establish the water level when the unit is being res-tarted.

When the BRP is shut down, the water level will rise. As the unitcools and the water shrinks, makeup water should be added inter-mittently to prevent the water from dropping below normal level.

Adding relatively cold feedwater will establish a reservoir of coolerwater in the system. If the BRP is then started, this cooler water willproduce a cycle of cool and hot temperature transients to the pumpcasing and other pressure parts of the boiler. The BRP should beoperating when makeup water is added to minimize the tempera-ture stratification.

WARM START-UPAssuming that the unit has been down for a short period of time (lessthan approximately 36 hours), the unit can be re-started in a similar se-quence to Cold Start-up procedure as outlined below:

Warm Start Conditions

1. Boiler separator metal temperature > 212F (100C).

d

-

8/10/2019 Unit Operating Procedure

34/60

UNIT OPERATING PROCEDURES

2. Main steam pressure >= 1200 psig (84 kg/cm2).

and

3. Turbine requirements are met.

Preparations, Lighting

Off, and Load Increase1. Make a general inspection of the steam generator and check the

points outlined in the Preparations for Lighting Off for Cold StartUps.

2. The BRP should still be in service.

3. If the air heaters and fans were shut down at reduced tempera-ture (see NORMAL SHUTDOWN TO HOT STANDBY,), start theair heaters and fans as outlined under COLD START-UP, Light-ing Off. If the unit was bottled up hot with the air heaters still run-ning, start the fans in the normal sequence.

CAUTION: Prevent possible water damage to the tur-bine by using extreme care to eliminate all water fromthe main steam line(s), cold and hot reheat lines, andsuperheater and reheater elements and headers beforethe turbine is rolled. Refer to the turbine manufacturer'sinstructions and to the Valve Operating Diagram for theproper drain valve settings.

4. Open wide all superheater drains to allow complete draining of

superheater headers and/or elements. After draining, close alldrains except the superheater back pass lower header drains andthe start-up drains (main steam line vents and drains). Keep theback pass header drains open until only steam is discharged.

-

8/10/2019 Unit Operating Procedure

35/60

UNIT OPERATING PROCEDURES

7. Initiate a furnace purge and a normal light off sequence of thewarm-up fuel following the sequence noted above.

8. Set warm-up flow control to auto and increase fuel flow set pointto 5% of BMCR firing rate.

9. After a 5 minute stabilization period, Progressively increase firingrate to 10% BMCR. Increase separator pressure/temperature atthe desired rate (400 F/hr (222C/hr)) and without exceeding the

furnace exit gas temperature limitation (1100F (593C)).

10. When steam pressure at HP bypass begins to increase, the HP

bypass valve is released to pressure ramp mode. The valves willthen control the boiler pressure ramp-up to startup pressure or toexisting pressure if greater than startup pressure.

11. As the HP bypass opens, the reheater will be pressurized assteam is passed through the reheat vents and drains. Set the LPbypass station to minimum setpoint in auto mode. The LP bypasswill open in response to increasing reheat pressure. Progressivelythrottle the reheat vents and drains to transfer flow and pressure

control to the LP bypass station.12. Initiate an elevation start command for warm-up elevation EF.

13. Progressively increase firing rate to 15% BMCR.

14. Increase the firing rate, as prescribed, to raise the pressure andsteam production. The rate of pressure rise should follow the pre-scribed start-up curves.

15. When boiler pressure reaches startup pressure (or existing pres-sure), the HP bypass valve is released to pressure controlmode, and maintains a constant pressure during turbine rolling,synchronization, and initial loading.

-

8/10/2019 Unit Operating Procedure

36/60

UNIT OPERATING PROCEDURES

4. Synchronize the generator and put on initial load according to tur-bine/generator startup instructions.

5. During a hot restart, the turbine metal temperature will normallyrequire a rapid reloading of the unit.

6. After synchronization, all superheat and reheat vent and drainvalves should be confirmed closed.

7. As steam is transferred to the turbine, the HP/LP bypass willclose while maintaining main steam pressure and RH pressure at170 psig (12 kg/cm2).

8. As turbine conditions permit, put feedwater heaters into serviceper manufacturers instructions. Monitor the fluid condition enter-ing the evaporator to ensure that subcooled conditions are atleast 10 deg F (6C). The HP heater should be put into servicewhen load is above 20%.

9. Deaerator heating steam source is transferred from auxiliarysteam system to LP extraction when LP extraction pressure isadequate.

10. Commence coal firing as required to support load increase.

11. Coal firing and load increases generally follow the proceduresoutlined for cold start-ups and normal load changes.

EMERGENCY

PROCEDURES

-

8/10/2019 Unit Operating Procedure

37/60

UNIT OPERATING PROCEDURES

quick-opens and the balance of SG flow (70%Tmcr less SThouse load) is transferred to the bypass.

2. SG Load is held at 60%Tmcr for a stabilization period.

After stabilization, if desired the SG load and pressure can be reducedat a controlled rate of

-

8/10/2019 Unit Operating Procedure

38/60

UNIT OPERATING PROCEDURES

To permit firing during start-up, the initiating fuel trip circuits associatedwith the turbine must be disarmed before opening the turbine valves.They must then be rearmed at a suitable point in the start-up sequence,such as when synchronizing the turbine.

CAUTION: Operators should be alert to detect thesymptoms of water carry-over from the boiler and intro-duction of water into the turbine, such as:

a. A sudden, unexplained drop in steam temperature ineither the main steam or hot reheat line.

b. Vibration in the steam piping resulting from waterhammer.

c. Abnormal vibration and differential expansion read-ings from the turbine supervisory instrumentation.

Operators must be prepared to take necessary steps toprevent turbine damage upon detecting the introductionof water. Refer to the turbine manufacturers instructionsfor specific actions to be taken.

Extreme care must be taken following a trip of the turbine and boiler toprevent water from entering the turbine during a unit restart. Condensa-tion may cause water to collect in the main steam line(s) and cold re-heat lines. Water may be introduced into the superheater due to over-flow from the separator (inadvertent high water level). Water may be in-troduced into the superheater and/or reheater through the desuperhea-ters due to open or leaking spray water control valves.

Inadvertent introduction of water into the steam lines must be pre-

TURBINE PROTECTION UPON LOSS OF LOAD

-

8/10/2019 Unit Operating Procedure

39/60

UNIT OPERATING PROCEDURES

1. Maintain the unit airflow at the pre-trip value for at least 1 minuteand then gradually reduce the airflow to the purge rate (30% air-flow) and complete a unit post trip purge.

2. Procedure after Master Fuel Trip when all ID and FD Fans are off:

The ID and FD fans discharge dampers shall be opened to allownatural ventilation of the unit. Opening of fan(s) dampers shall betimed or controlled to avoid excessive furnace pressure excursionsduring fan(s) coast-down. The fans discharge dampers shall re-main open for a period of at least 15 minutes.

During this 15-minute period, the ID and FD fans shall not bestarted.

At the end of the 15-minute period, the ID/FD fans may be startedin accordance with ID/FD fan(s) start-up procedures.

If the unit will not be re-started for an extended time, a flow of airthrough the unit shall be maintained.

3. If warm-up fuel is in service when the fuel trip occurred, make

sure the warm-up header trip valve and individual nozzle shutoffvalves are closed.

4. If all auxiliaries are lost during a fuel trip, refer to the Boiler Circu-lating Pump Operating Procedures for handling the low pressurecooling water. The cooling flow must be maintained.

5. If all auxiliary power sources were lost during a trip, after complet-ing the 15 minute natural draft purge described above, start thefans and air heaters when power is restored, increase the unit air-flow to the purge rate and complete a 5 minute purge. Observethe hot restart precautions in the air heater instructions. The BRP,if available, should be placed in service during the purge, and theb il h ld b fill d (S B il Ci l i P O i

-

8/10/2019 Unit Operating Procedure

40/60

UNIT OPERATING PROCEDURES

9. Check that the startup system is ready for operation (HWL-1 iso-lation valve open, HWL-2 is interlocked to prevent opening at highpressure to protect the flash tank) and the drain transfer systemis ready for operation. Place the BFPM in service, stabilize deae-rator conditions, and establish feedwater flow of 10% BMCR tothe boiler to refill to normal SST level. Follow the same procedurefor boiler filling as outlined previously. When SST level is stablewith HWL-1 at stable opening and all BRP start permissives aresatisfied, start the BRP (Refer to Boiler Circulating Pump Operat-ing Procedures). Zero the feedwater flow as SST level recoversand attains the operational setpoint. If restart of the BRP is de-

layed, excessive HWL action will result in draining of water atpressure, oscillatory dump-feed action, with further reduction inboiler pressure and extension of startup time

10. The pre-firing furnace purge can be initiated once all purge per-missives are met.

11. If the boiler can be immediately restarted, then raise load to>20% on auxiliary fuel utilizing the HP/LP bypass and successive-

ly clear the pulverizers serving at least the 2 lower coal elevationsusing the steam transport system prior to re-synchronizing theturbine. The remaining pulverizers can be cleared using steamtransport before or after the turbine is synchronized. Refer to thepulverizer clearing procedure located in the steam inerting sectionof the Design and Operations manual for additional details:

a. Close the pulverizer discharge gateson all other idle pulveriz-ers containing coal during each steam transport procedure.

This prevents hot furnace gases from being carried back intothe pulverizers in the event of a furnace pressure rise when apulverizer is started.

b Start the lower elevation of warm up fuel and establish the igni

-

8/10/2019 Unit Operating Procedure

41/60

UNIT OPERATING PROCEDURES

procedure and returned to normal service or shut down in anormal fashion if not required for load regulation.

i. If the pulverizer will be retained in service, when the pulverizerhas completed the clearing process, open the hot air shutoffgate, bring the pulverizer up to normal operating temperatureand start the associated feeder

j. If the pulverizer will not be retained in service, stop it aftercompletely clearing the coal. The pulverizer discharge gatesshould remain open to allow a flow of cooling air through theempty pulverizer.

12. If, due to load conditions and/or requirements to the Burner Man-agement System, it is impossible to establish ignition permissivesto allow steam transport, inerting steam shall be maintained untileach pulverizer can be cleared of coal using steam transport orcooled to ambient

13. If the boiler cannot be re-started and the aurxiliary steam sourcecannot be continued indefinitely, then the pulverizers (those still

containing coal) must be switched to an alternate steam inertingsource or to an alternate inerting medium until they can be cooledto ambient and manually emptied. Refer to the clearing procedurelocated in the Pulverizer Inerting and Fire Fighting section of theDesign and Operations manual for additional details.

-

8/10/2019 Unit Operating Procedure

42/60

UNIT OPERATING PROCEDURES

Low Waterwall Flow

The flow entering the economizer is monitored continuously to directand alert the operator of abnormal flow conditions. Low flow could bethe result of a malfunction of BRP, MEFCV, feedwater pump, controls,or operator neglect. Low flow subjects the waterwall tubing to overheat-ing, and potential for failures. The minumum operational setpoint is 40%BMCR flow.

If the flow drops below the alarm setpoint of 39% BMCR, the operatormust investigate the above listed items.

If the flow continues to drop below the trip setpoint of 38% BMCR, au-tomatically trip the fuel following a maximum 10 second time delay. Thetime delay allows for momentary fluctuations due to valve transfers,etc.:

1. Trip all fuel immediately.

2. Shut off all steam being discharged from the unit (trip turbine,steam driven auxiliaries, and such).

3. Leave the BRP in service as long as it is operating normally.

CAUTION: The differential temperature between feed-water and boiler metal must never exceed 200F(111C) (separator during initial filling or separator andsuperheater outlet header during filling for hydrostatictest.)

4. If the problem is rectified, re-establish minimum waterwall flow.5. If the BRP cannot be kept in service, do not admit feedwater to

the unit.

-

8/10/2019 Unit Operating Procedure

43/60

UNIT OPERATING PROCEDURES

the operator to any abnormal condition of excessive heat absorption orlow fluid flow.

High waterwall tube temperatures are an indication of an imbalance be-tween firing rate and waterwall flow (over-firing, low waterwall flow, or acombination of both). Over-firing could be a result of extreme loadchange rates. Low waterwall flow could be a result of excessive SHspray flow, BRP trouble, MEFCV trouble, feedwater pump trouble, con-trol system trouble, or tube blockage.

If any spiral waterwall tube metal temperature exceeds the alarm set-point of 463C, then the operator should investigate the above listed

items.

If any 4 spiral waterwall tube metal temperatures exceed the trip set-point of 477C, automatically trip the fuel following a maximum 3-second time delay. This trip protects the tubes from overheating dam-age, and potential failure, and therefore immediate action is required.Investigate the above listed parameters and their control before re-firingthe boiler.

Evaporator Inlet Sub-

CoolingThe fluid condition entering the evaporator is monitored to alert the op-erator to abnormal conditions. If the fluid entering the evaporator is al-lowed to rise into the saturation region, the flow distribution in the eva-porator will be detrimentally affected, causing tube temperatures to in-crease.

If the fluid condition at the evaporator inlet is sub-cooled by less than10F (6C), an alarm is generated. The operator should take steps toreduce the temperature of feedwater entering the economizer or in-crease the flow of feedwater entering the economizer

-

8/10/2019 Unit Operating Procedure

44/60

UNIT OPERATING PROCEDURES

Separator Storage Tank

Level High If the SST level exceeds the high-high level setpoint 548 inches (13.9meters), then all fuel shall be tripped immediately. A warning alarm isgenerated at high setpoint of 509 inches (12.9 meters), at which timethe operator should check operation of the HWL valves, SST level con-trol, or the balance of feedwater and firing rate (possible that firing rateis too low for feedwater flow).

Airheater Gas OutletTemperature High

If the gas temperature leaving the airheater exceeds the high setpoint,all fuel shall be tripped immediately. This is to protect downstreamequipment from over-temperature.

Both FD Fans Off or Both

ID Fans Off

If at any time both FD or both ID fans are off while firing the boiler, thenall fuel shall be automatically tripped immediately.

Both Secondary

Airheaters Of fIf at any time both secondary airheaters are off while firing the boiler,then all fuel should be automatically tripper immediately.

Load Run-BacksUpon loss of the following equipment, load must be automatically re-

-

8/10/2019 Unit Operating Procedure

45/60

UNIT OPERATING PROCEDURES

Tube FailuresIf any water or steam carrying tube fails, the best shutdown method willbe dictated by the size of the failure, the ability to maintain a normal wa-ter flow (or level if the boiler is in the recirculation mode) and the de-mand for the unit to remain in service.

The following instructions are general since most of the conditions willrequire the judgment of the operators.

If a leak or tube failure does not involve a serious drain on the feedwa-ter supply, the water flow/level should be maintained and the unit takenout of service in the normal manner:

WATERWALL TUBES

1. Operate the soot blowers if conditions permit.

2. Switch the combustion control equipment to manual control andproceed to reduce the firing rate and air flow in a normal manner.

3. When all fires are extinguished continue the airflow through the

unit at a reduced rate to purge all combustible gases, vapors, etc.Shut down the fans when the unit is cooled sufficiently.

4. Feed water to the boiler by manual control. To speed cooling, boi-ler pressure can be reduced by opening the superheater outletdrains.

5. Allow the boiler to cool at least to 200F (93C) (separator metaltemperature); before draining.

If there is a serious water loss and the water flow/level cannot be main-tained with the feedwater supply available. Use the following method:

1. Trip all fuel.

-

8/10/2019 Unit Operating Procedure

46/60

UNIT OPERATING PROCEDURES

operation with known leaks should be made with this in mind. The unitshould be shut down in a normal manner.

A leak in a superheater or reheater element should be checked as soonas possible. Steam leaks in the superheater or reheater can cause con-siderable erosion damage to adjacent tubes. Any decision to continueoperation with known leaks should be made with this in mind. The unitshould be shut down in a normal manner.

A major superheater or reheater tube failure may require an emergencyunit shutdown. The operator must judge the degree of failure, its conse-quences, and then decide what type of shut down is required.

SUPERHEATER AND REHEATER TUBES

OPERATION WITHOUT

BRP

General RemarksStarting the boiler without the BRP is an unusual activity, and shouldtherefore be carried out in exceptional cases only.

The minimum economizer flow must be supplied by the BFPM, and inlieu of recirculation, water is drained through the start-up system HWLvalves to the flash tank, receiving tank, transfer pumps, and returned tothe condenser.

Because there is no water recirculation, heat and water losses will bemuch higher. So to compensate, additional make-up water should beavailable and additional heat input (both quantity and length of time) will

-

8/10/2019 Unit Operating Procedure

47/60

UNIT OPERATING PROCEDURES

7. When the pressure in the reheater reaches approximately 70 psig4.9 kg/cm2) with the HP/LP bypass system in operation, feedwa-ter heater no. 7 can be placed into operation to preheat the feed-

water and raise steam production. Care must be taken to controlthe steam flow to FWH no. 7 during this period such that the LPbypass valve does not close too much, disabling both the coolingflow through the reheater and LP pressure control. In addition,monitor the fluid condition entering the evaporator. If sub-coolingis less than 10 deg F (6C), then increase the economizer inletflow or decrease the feedwater temperature.

8. Roll and synchronize the turbine following the normal procedure.

9. Increase load to 40% following the normal procedure.

10. At approximately 40% load the boiler will enter the once-throughmode. When once-through mode is proven, the warm-keepingsystem should be put into operation.

11. Follow normal operation for unit load changes.

Shutdown Without BRP1. Reduce load in auto mode following the normal procedure.

2. At approximately 40% load, the boiler will transfer to the recircula-tion mode. With the BRP off, the feedwater flow setpoint will au-tomatically control the BFP loading to maintain the minimum eco-nomizer flow setpoint.

3. The HWL-1 will open in auto mode when the level in the SST

reaches the high setpoint. If additional drain capacity is needed,HWL-2 will open when HWL-1 reaches full open and level contin-ues to rise.

-

8/10/2019 Unit Operating Procedure

48/60

UNIT OPERATING PROCEDURES

fact that cold water will be fed to the economizer, instead of recirculatedwater from the SST via the BRP.

1. Prepare the unit for light-off following the normal procedure.2. Close the BRP suction and discharge isolation valves, and the

BRP bypass valve.

3. Set the feedwater flow setpoint to 40%. The HWL-1 and HWL-2will open in auto mode when the level in the SST reaches thehigh setpoint, and will drain the full capacity of 40%.

4. Note that the start up system valves (HWL-1, HWL-2) are inter-

locked to prevent opening above 2100 psig (148 kg/cm2) to pro-tect the flash tank, so pressure must be less than this value be-fore initiating the startup.

5. Light-off the boiler following the normal procedure. When the firstignitor is proven in service, the feedwater flow setpoint will auto-matically be controlled to 40%. Warm-up the boiler following thenormal procedure.

6. When the pressure in the reheater reaches approximately 70 psig(4.9 kg/cm2) with the HP/LP bypass system in operation, feedwa-ter heater no. 7 can be placed into operation to preheat the feed-water and raise steam production. Care must be taken to controlthe steam flow to FWH no. 7 during this period such that the LPbypass valve does not close too much, disabling both the coolingflow through the reheater and LP pressure control. In addition,monitor the fluid condition entering the evaporator and ensurethat this temperature is always sub-cooled at least 10 deg F. If

sub-cooling is less than 10 deg F (6 deg C), then increase theeconomizer inlet flow or decrease the feedwater temperature.

7. Roll and synchronise the turbine following the normal procedure.

-

8/10/2019 Unit Operating Procedure

49/60

UNIT OPERATING PROCEDURES

APPENDIX A -

FEEDWATER

SPECIFICATIONS FOR

ONCE THRU BOILERS

Refer to Water Chemistry Control for Once-Through Utility Boiler SYs-tems.

-

8/10/2019 Unit Operating Procedure

50/60

UNIT OPERATING PROCEDURES

Figure 1. Airflow Curve.

AIR FLOW CURVE

FOR COLD START-UP

0

10

20

30

40

50

60

70

80

90

100

0 10 20 30 40 50 60 70 80 90 100 110

BOILER LOAD - % OF MAX. DESIGN

AIRFLOW-

%OFMAX.DESIGN

PURGE

AIRFLOW

-

8/10/2019 Unit Operating Procedure

51/60

UNIT OPERATING PROCEDURES

Figure 2. Mill Operating Diagram

NTPC BARH II

PREDICTED PERFORMANCE

Mill Operating Diagram with Design Coal

0

10

20

30

40

50

60

70

80

90100

110

120

130

140

150

0 10 20 30 40 50 60 70 80 90 100 110 120

Mill Capacity - %

BoilerLoad-%BMC

R

One Mill

Two Mills

Four Mills

Five Mills

Three Mills

NOMAL OPERATING RANGE

40% TO 85% MILL CAPACITY

Alstom Power, Inc. Contract 00108Curve S-xxxx

Six MillsSeven Mills

NTPC BARH II

PREDICTED PERFORMANCE

Mill Operating Diagram w ith Worst Coal

150

NOMAL OPERATING RANGE

-

8/10/2019 Unit Operating Procedure

52/60

UNIT OPERATING PROCEDURES

Figure 3: Startup Curves

-

8/10/2019 Unit Operating Procedure

53/60

UNIT OPERATING PROCEDURES

-

8/10/2019 Unit Operating Procedure

54/60

UNIT OPERATING PROCEDURES

Figure 4: Boiler Cleanup Diagram

START-UP SYSTEM WITH RECIRCIRCULATION PUMP

WATER CLEAN-UP

1 ECONOMIZER

2 WATERWALLS

3 WATER SEPARATOR STORAGE TANK4 CONDENSER

5 CONDENSATE PUMPS

6 CONDENSATE DEMINERALIZ ER

7 LP HEATERS

8 FEEDWATER TANK WITH DEAERATOR

9 FEED PUMPS

10 HP HEATERS

11 RECIRCULAT ION LINE FORPRE-BOILER CLEAN-UP

12 FLASH TANK

13 RECEIVING TANK

14 MIXING PIECE / FILTER

16 CIRCULATING PUMP17 DRAIN TRANSFER PUMP

HWL-1 LEVEL CONTROL VALVE

HWL-2 LEVEL CONTROL VALVE

MEFCV MINIMUM ECONOMIZERFLOW CONTROL VALVE

M

M 9

10

2

17 6

5

4

13

12

16

14

MEFCV

HWL-

2

HWL-

1

8

M

17

PHASE II

PHASE III

3

-

8/10/2019 Unit Operating Procedure

55/60

UNIT OPERATING PROCEDURES

Figure 5: Recommended Startup, Shutdown, and Loading Guidelines

RECOMMENDED STARTUP, SHUTDOWN, and LOADING GUIDELINES and LIMITATIONS

Material Temperature Gradient Limitation

All Boiler Components Temperature 450F (232C)

increasing 600F (333C )//hr 150F(83C )//15 minutes

decreasing 600F(333C )//hr 150F(83C )//15 minutes

Startup Firing Rate Limitation

(to avoid overheating SH/RH tubing)

-

8/10/2019 Unit Operating Procedure

56/60

UNIT OPERATING PROCEDURES

THIS PAGE INTENTIONALLY LEFT BLANK

-

8/10/2019 Unit Operating Procedure

57/60

BARHII_00108_ UOP_REV02A.DOC-6/2/11 1

FIGURE 6 VALVE OPERATION FOR UNIT COLD START

Description/Location Valve Open Valve ClosedSeparator High Water Limit ValvesHWL-1, HWL-2

Open for SST high level control Closed all other times

Isolation Valves for HWL-1. HWL-2 Open for SST high level control Closed all other times

Minimum Economizer Flow Control Valve, MEFCV Open for control of minimum economizer flowwhen in recirculation mode

Closed when in once-through mode

Boiler Recirculation Isolation Open before starting BRP Closed when transfer to once-through mode is complete

BRP Suction Isolation Open before starting BRP Close if BRP trips

BRP Discharge Isolation Open before starting BRP Close if BRP trips

Warmkeeping System Supply Isolation Closed when in recirculation mode Open when in once-through mode

Warmkeeping System Control, WKFCV Closed when in recirculation mode Open for control of warm-keeping flow when in once-through

modeWarmkeeping System Discharge Isolation Closed when in recirculation mode Open when in once-through mode

Warmkeeping System Discharge Isolation Open at all other times Closed for maitaianance

SH Connecting Link Vents Open before lighting off Throttle as pressure increases, verify closed completely whenseparator pressure > 5 psig

SH Furnace Roof Inlet Header drain Open before lighting off Throttle as pressure increases, verify closed completely whenseparator pressure > 25 psig

SH Backpass lower rear Header Drains Open before lighting off Close immediately after synchronization of the unit. See note1.

SH Backpass lower front Header Drains Open before lighting off Operate in conjunction with SH Backpass lower front HeaderDrains

Link to steam inerting system

SH link from Desuperheater 1 vents Open before lighting off Throttle as pressure increases, verify closed completely when

separator pressure > 50 psigSH link to SH Platen Open before lighting off Throttle as pressure increases, verify closed completely whenseparator pressure > 25 psig

Main steam line vents Open before lighting off Throttle as pressure increases, verify closed completely whenseparator pressure > 75 psig

Main steam line drains Open before lighting off Throttle as pressure increases, close completely when turbineis under light load