UNEVEN BRAKEPADWEAR L - SIIA...L ast month in this space we concentrated on factors that can cause...

Transcript of UNEVEN BRAKEPADWEAR L - SIIA...L ast month in this space we concentrated on factors that can cause...

Last month in this space weconcentrated on factorsthat can cause uneven ve-hicle braking, or brakepull. A closely related top-ic concerns uneven brake

pad wear. This article will detail the pos-sible causes of uneven brake pad wearand discuss their remedies.

Ideally, we’d like to see all of thebrake pads that are removed during abrake service evenly worn, with eachpad having delivered its full measure ofservice. But this frequently is not thecase. One pad on one side of the vehi-cle may be worn much more than itsmate or the other two pads on the oth-er side of the vehicle. Pads may beworn at an odd angle or show evidenceof damage. To do a complete brake joband to make certain that the new pads

do not experience a similar fate, thecause of each of these conditions mustbe identified and corrected. What fol-lows are descriptions of uneven or oth-erwise abnormal brake pad wear symp-toms, and their cures.

In the best case, all of the front brakepads will have a nearly equal amount offriction material wear. This indicatesthat both brake calipers and all of therelated hydraulic components are oper-ating properly, and new brake pads canbe installed with confidence. Be sure toreplace the related brake hardware, in-cluding shims, abutment clips and anti-rattle clips. Clean the caliper mountingbrackets and service the caliper guidepins and slides.

One of the outboard brake pads mayshow greater wear than the inboardpad. This indicates that the outer pad

is continuing to press against the rotorafter the caliper has released. Thecaliper guide pins and bushings maybe seized. It’s also possible that the padmay be seized in its mounting bracket,due to corrosion.

Before installing new pads, servicethe caliper guide pins and bushings.Replace any worn parts as necessary.Clean and lubricate the caliper slides.Inspect the caliper for guide pinholedamage. Replace any parts that aredamaged or corroded.

If the inboard pad shows greater wearthan the outboard pad, this may indicatea worn caliper piston seal that’s not al-lowing the piston to return to the restposition. The caliper piston may alsohave damage or corrosion. The caliperguide pins and bushings may be seizedor the pad may be seized in the mount-ing bracket. Or there may be a problemwith the master cylinder that’s keepingthe caliper piston from fully releasing.

Before replacing the pads, inspectthe hydraulic brake system and checkfor residual brake pressure. Service thecaliper guide pins and bushings or re-place them if they’re worn or damaged.Clean and lubricate the caliper slides.Inspect the caliper for damage to theguide pinholes and piston boot. Replacethe caliper if it’s damaged or corroded.

The friction material may be worn ina wedge pattern. This is referred to astapered pad wear, and it can take placeacross the width of the pad as well asalong its length (horizontally or vertical-ly). Tapered pad wear may be caused bypads that were originally installed incor-rectly. Pads must be installed in their in-tended location for proper function.Worn caliper guide pin bushings mayallow a caliper to cock to one side, ex-erting uneven pressure across the pad’sfriction material. One of the caliper’s

UNEVENBRAKE PAD WEAR

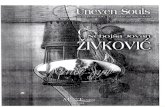

On a floating brake caliper, if the more heavily worn brake pad is on the outside ofthe caliper, this may be due to jammed or sluggish sliding caliper pins. After cleaningthe caliper pins and sleeves, apply the appropriate lubricant paste to the sleeves. Ifthe more heavily worn brake pad is on the piston side, this may be due to a jammedpiston or a piston that’s slow to retract when the brakes are released.

Illu

stra

tio

nco

urt

esy

Ben

dix

Bra

kes

Brake Pad on Outer SideIs More Heavily Worn

Brake Pad on Piston SideIs More Heavily Worn

Brake Pad Guide Guide Sleeve

Piston

SlidingSleeves

29February 2015

Pg_EDIT_Brake:Pg_EDIT_ 1/21/15 10:38 AM Page 1

guide pins or slides may be seized.Once again, this allows the caliper tomove at an angle, allowing it to applypressure on the pad unevenly.

Before replacing the pads, service thecaliper guide pins and bushings as de-scribed above, or replace them ifthey’re worn or damaged. Always re-place calipers in pairs. Mixing andmatching old and new components canresult in a braking imbalance or pull.

The friction material on one ormore of the pads may be damaged andshow signs of thermal distress. Exam-ples of this type of damage includecracking, glazing or lifted pad edges. Ifall front brake pads exhibit this kind ofdamage, the problem is not confinedto one caliper, and may be caused by adriver who has abused the brakes. Im-proper break-in procedures when thepads were installed may also be re-sponsible, or the brake pads simplymay be defective. Thermally damagedpads must be replaced.

If the damage is confined to onecaliper, check for evidence that the hy-draulic system is preventing pressurerelease at that caliper. A damaged flexi-ble brake hose may be responsible. Thecaliper also may not be capable of re-leasing due to seized components.

Before replacing the brake pads,make certain the correct pad material

for the application is selected and per-form the recommended break-in pro-cedure. Always inspect the friction sur-faces of the rotors. If only a partial sec-tion of rotor has been polished by thebrake pad and the rest is rusty, this in-dicates incomplete contact between thepad and the rotor. This may occurwhen one end of a pad is binding in its

mount at the abutment clip or a caliperslide is binding or frozen. Rotorsshould wear evenly.

In a worst case, one entire surface ofa rotor may be rough and rusty, indicat-ing the corresponding pad has not beenmaking contact with the rotor for a con-siderable length of time. Braking abilitywill be compromised in this instanceand uneven braking is very likely aswell. Before installing new pads and re-placing the rotor, identify the factorsthat are keeping the pads from makingfull contact with the rotor.

If the edge of a pad overlaps the topof a rotor, the wrong pads for the vehi-cle may have been installed. Alternately,worn guide pins, a worn caliper bracketor a worn caliper may have caused thepad to wear unevenly and extend overthe edge of the rotor. Before replacingthe pads, compare the rotor diameterwith OE specifications. If pads or a ro-tor have been worn past recommendedlevels, inspect the caliper piston bootand the piston. If the piston has been al-lowed to extend too far, it may not re-tract properly.—Karl Seyfert

30 February 2015

This article can be found online atwww.motormagazine.com.

A stuck caliper may cause significantly higher pad and rotor wear on one side of thevehicle. These rotors include integral wear indicator grooves, which have been com-pletely worn away on the inside surface of the rotor on the left. If any portion of thegroove is no longer visible, the rotor has reached the discard dimension.

The rusted and pitted surface on the inner diameter of this rotor indicates that thepad has not been making contact with a portion of the rotor for a significant periodof time. The diminished friction surface will reduce braking ability at that wheel andmay cause a brake pull. This type of uneven pad contact and rotor damage is mostlikely caused by the pad binding in the mounting bracket.

Pho

toco

urt

esy

ATE

Pho

to:K

arlS

eyfe

rt

Pg_EDIT_Brake:Pg_EDIT_ 1/21/15 10:39 AM Page 2