Unconfined compressive strength and micro-structural ...

Transcript of Unconfined compressive strength and micro-structural ...

Scientific Research and Essays Vol. 6(4), pp. 933-948, 18 February, 2011 Available online at http://www.academicjournals.org/SRE DOI: 10.5897/SRE10.1076 ISSN 1992-2248 ©2011 Academic Journals

Full Length Research Paper

Unconfined compressive strength and micro-structural properties of cemented sand and gravel materials

Tae-Hoon Kim1 and Yong-Seong Kim2*

1Civil Engineering Research Team, Institute of Construction Technology, Daewoo E and C, Suwon,

Gyeonggi-do 440-210 Korea. 2Department of Regional Infrastructure Engineering, Kangwon National University, Chuncheon,

Gangwon-do 200-701 Korea.

Accepted 19 January, 2011

The purpose of this study is to provide basic information for the utilization of the environmentally-friendly and economically outstanding CSG (cemented sand and gravel) construction method, which includes the physical and mechanical properties of CSG materials, such as the unconfined compressive strength, the microscopic structure and the freezing and thawing resistance given the volume and curing time of the CGS and the size of the specimen. In this study, specimens with four different cement contents of 4, 6, 8 and 10% of the total weight and three different sizes of φ50×100 mm, φ100×200 mm and φ150×300 mm were prepared to examine the characteristics of the sizes of the specimens and the features including the compressive strength, microscopic structure, freezing- thawing resistance and degree of wet-dry resistance. The results show that the larger the size of the specimen and the greater the content of cement in the specimen, the higher the compressive strength, freezing-thawing resistance, and wet-dry resistance. Moreover, the reactive products for each size of specimen were examined, and it was observed that some typical needle structured ettringite was generated due to the blending of cement through microscopic structural analysis, such as SEM and EDS analyses. Key words: Cemented sand and gravel, unconfined compressive strength, freezing and thawing, SEM, micro structure

INTRODUCTION With increasing research on the usage and development of environment friendly materials, many studies on mixed soils, where various compounds are mixed with a soil to improve its characteristics, have been conducted, and new construction methods have also been developed (Kong et al., 2001; Chae et al., 2003; Han and Oh, 2007; Youn et al., 2009). Many of the studies are focused on cement mixed soil because of its advantages of low construction cost and simple and fast construction (Cho, 1974; Kim and Kang, 1975; Suh and Koh, 1978; Do, 1980; Kim and Lee, 2005). Such soil is eco-friendly and able to provide a wide range of strengths similar to concrete. Recently, there have been focused on CSG (Cemented Sand and Gravel), which is similar to cement mixed soil but contains some gravels obtained in the *Corresponding author. E-mail: [email protected].

field. A few studies have been conducted to apply the CSG as a construction material to weirs, dams, roads and revetments (Kim et al., 2005; Bae, 2006; Yeon et al., 2010). Oie et al. (2003) performed research on temporary structure construction by CSG for the Dokuyama dam. Kongsukprasert et al. (2003) investigated the effects of deterioration on the viscosity of gravel mixed with cement. Bae (2006) designed a CSG mixture in both the laboratory and field and applied it to the Hwabook dam. Kim (2006) reported that the unconfined compressive strength of CSG is affected by moisture content, particle distribution, curing time, and unit cement volume. In the case of cement mixed soils, most studies have focused on the ratio of the cement mixture. However, Airey (1993) mentioned that the hardness of a cement mixture is also related to density, particle shape, mineral contents and so on. Gens and Nova (1993) reported that the behavior of cement mixture is affected by the geological and stress-strain history, the displacement rate, the

934 Sci. Res. Essays

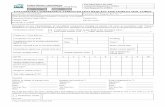

Table 1. Physical properties of normal Portland cement.

S.G Setting time (h-min) Compressive strength (MPa)

Initial Final 3 days 7 days 28 days

3.15 5-7 7-20 19.4 21.6 32.3

Table 2. Chemical compositions of normal Portland cement (Unit: %).

SiO2 Al2O3 CaO MgO SO3 K2O Na2O Fe2O3

21.09 4.84 63.85 3.32 3.09 1.13 0.29 2.39

Table 3. Physical properties of the specimens.

Specimens (mm) Gs D10(mm) D30(mm) D60(mm) Cu Cg USCS

φ50×100 2.65 0.06 0.25 0.92 15.3 1.13 GW-GM

φ100×200 2.65 0.14 0.85 3.8 27.1 1.36 GW-GM

φ150×300 2.65 0.14 0.92 10.05 75 0.6 GP-GM

temperature, and the direction of principal stresses. In addition, the behavior of cement mixtures is affected by the loading rate, stress path, micro-structure and cohesion between particles (Clough et al., 1979, Bressani and Vaughan, 1989; Reddy and Saxena, 1992, Chang and Woods, 1992).

In general, two sizes of specimens of φ50×100 mm and φ100×200 mm have been used for the tests of soil cement (Cho, 1974; Kim and Kang, 1975; Suh and Koh, 1978; Do, 1980; Kim and Lee, 2005). In contrast, a specimen of φ150×300 mm was adopted in the test for CSG (Kim et al., 2005; Bae, 2006; Yeon et al., 2010).

To investigate the effects of the particle distribution in the field on the strength of CSG, it is very important for laboratory tests to simulate the same particle distributions as in the field. Unfortunately, it is difficult because of the limitations of testing equipment. In other words, discrepancies in the mechanical properties between the real samples and the specimens are inevitable. Therefore, when applying the soil cement method or CSG method to construction sites, caution is required.

This study provides basic information about CSG, verifying the physical and mechanical properties according to the cement content, curing time and size of specimen. MATERIALS AND METHODS

Materials

Soils used for this study were sampled at the site at Kwangwon University. The soils were then divided into four groups by the particle size: 40 to 20, 20 to 10, 10 to 4.76 mm, and smaller than 4.76 mm. Portland cement was also used. The basic physical and

chemical properties of the Portland cement are shown in Tables 1 and 2. Table 3 shows the material properties of the specimens.

In general, there are several methods to match the similarity of the particle distribution between the field and the lab. One of them is the parallel grading method, which is the most frequently used method. In this method, the maximum particle size is first determined in accordance with the testing device, and then the particle distribution curve is moved in parallel so as to obtain the same coefficient of uniformity as the field one. Unfortunately, reducing the size of the particles is not so simple because the volume of finer material can be increased, which may have an effect on the strength, deformation and permeability of the ground. Therefore, extra caution should be necessary when using the parallel grading method. Sometimes the scalping and replacement method is adopted to overcome this limitation of the parallel grading method. In this method, a particle distribution curve is slightly adjusted so that the coefficient of uniformity becomes smaller than that of the original curve. By doing this, the volume of finer material can be constrained. In addition, there is an alternative, called the equal quantity replacing method, which takes advantage of both methods. In this method, the volume of the finer material remains the same as the original. This method is especially available where the permeability is the primary concern (Hou et al., 2004). Figure 1 shows the particle distribution curve of the material adjusted by the equal quantity replacing method. Specimens

Mixing The primary concern in mixing CSG materials is to determine the volume of the mixture to satisfy the designed strength and economical feasibility. In other words, the volume of the cement, water and aggregate should be carefully determined by means of laboratory tests, such as compaction and strength tests, and verified by pilot testing. As a matter of fact, there are no specific standards for CSG mixing. In general the mixing follows two standards. One is a geotechnical approach using compaction tests, and the other is the concrete mixing standard. In this study, a series

Kim and Kim 935

100 10 1 0.1 0.01 1E-30

20

40

60

80

100

D50 mm

D100 mm

D150 mm

Pe

rce

nt

fine

r b

y w

eig

ht (%

)

Grain size (mm)

Perc

enta

ge fi

ner b

y w

eigh

t (%

)

Figure 1. Grain size distribution curve.

Figure 2. Specimens for strength tests.

of unconfined compression tests, freezing-thawing tests and wet-dry tests were conducted on CSG mixtures with 4, 6, 8 and 10% cement.

Specimens

To obtain uniform specimens, three different moulds with sizes of φ150×300 mm, φ100×200 mm, and φ50×100 mm, as mentioned earlier, were used. However, similar to the mixing standard, no specific standards for the compaction tests for CSG materials. In the U.S.A., the standard compaction test (ASTM D 698) and the modified compaction test (ASTM D1557) are applied for RCC (roller compacted concrete), which is similar to CSG. In this study, compaction tests were conducted using the E method (φ150×300 mm) and A method (φ100×200 mm) as well as compaction by a rod. To investigate the unconfined compressive strength of CSG

according to the curing time, each group of specimens with different

volumes of cement was cured for 3, 7, 28 and 91 days. Figure 2 shows the mould and specimens. Tests Unconfined compression tests On the basis of KS F 2405, the unconfined compression tests were performed on the specimens of φ50×100 mm, φ100×200 mm, φ150×300 mm with curing times of 3, 7, 28 and 91 days. The loading rate was set to be 1 mm/min. Figure 3 shows the overall view of the unconfined compression test.

SEM

To investigate the hydration characteristics of CSG due to cement mixing the cross section of the specimen was examined by SEM

936 Sci. Res. Essays

Figure 3. Strength test view.

(scanning electronic microscopy), which is able to magnify as much as 10,000 times. Freeze-thaw tests Freeze-thaw tests were also performed based on KS F 2332. The loss rate of soil cement can be calculated by Equation (1) as

Loss rate (%) = (A/B) 100 (1) Where A = The initial mass of dried soil - the final mass of dried soil B = The initial mass of dried soil Dry - wet tests Dry-wet tests were conducted based on KS F 2330, and the loss rate was calculated similar to that of the freeze-thaw test. RESULTS AND DISCUSSION Compaction tests To analyze the optimum moisture content and the maximum dry unit weight of CSG according to cement volume, various compaction tests including A compaction and E compaction were conducted. The specimens were prepared with five different cement volumes of 0, 4, 6, 8 and 10%. Figure 4 shows the optimum moisture content and the maximum dry unit weight with respect to the cement volume. The maximum dry unit weight and the optimum moisture content obtained from A compaction appear to be 2.14, 2.05, 2.05, 2.02 and 2.04 g/cm

3 and 8,

10, 10.65, 11.38 and 10.29%, respectively, while E compaction gave 2.123, 2.105, 2.133, 2.121 and 2.12 g/cm

3 and 10, 10.2, 9.8, 10.1 and 10% for the maximum

dry unit weight and the optimum moisture content, respectively. Both tests showed a similar trend. Watanabe et al. (2003) conducted similar tests on the CSG with 2.5% of cement and reported that the optimum moisture content might vary according to the type of compaction by 5 to 8.7% and that the maximum dry unit

weights were 2.15 to 2.2 g/cm

3. These data appear to be

almost the same as what is reported here.

Unconfined compression tests The volume of the cement has a large effect on the strength of the CSG. In general, when the volume of cement is greater, the strength is higher. Figure 5 indicates the unconfined compression strengths with respect to the curing time, the volume of cement and the size of specimen. Table 4 shows the ratio of the strength to the curing time.

Figure 5(a) shows the compressive strength at the curing times of 3, 7, 28 and 91 days. There seems to be a remarkable strength development after 3 days of curing. However, after 28 days, the strength appears to increase smoothly. As shown in Table 4, the 28-day strength appears to develop about 60% of the 91-day strength. In addition, the strength ratio seems to be higher as the size of specimen increases. Figure 5(b) indicates the unconfined compressive strength with respect to the volume of cement. As shown in the figure, the larger the amount of cement the higher the unconfined compressive strength. From this observation, it may be clear that the strength of the CSG is highly affected by the volume of the cement.

The 91-day strengths of specimens with 10% of cement volume appear to be 13.8, 12.2, and 9.0 MPa for the sizes of φ150×300 mm, φ100×200 mm, and φ50×100 mm respectively. The 7-day strengths appear to be 7.0, 5.3, and 3.0 MPa for each specimen. In England and the U.S.A., a 7-day strength of 1.75 MPa is recommended for highway construction, and the US army Corps reports that no failure is expected when the strength is over 1.4 to 2.1 MPa. In addition, Soil cement over 2.1Mpa according to P.A.C., always satisfies the durability requirement (Cho, 1974). In Korea, the required strength for building materials is about 5.0 MPa, which means CSG with 10% cement is sufficient for block products such as shore protection. A relationship between the unconfined compressive strength and the size of the specimens is shown in Figure 5(c). As shown in Table 5, the unconfined compressive strength of the specimen size of φ100×200 mm appears to be about 85 to 88% of the specimen size of φ150×300 mm, while the specimen size of φ50×100 mm has strength 60 - 65% of the specimen size of φ150×300 mm.

As a matter of fact, few studies have focused on the effects of sizes of particle or specimens on the cement soil. In general, it is not easy to determine the effects of particle size on the shear strength of coarse materials and predict the real shear strength of the material (Varadarajan et al., 2003). Varadarajan et al. (2003) mentioned that, for materials that are easy to crush, the shear strength appears to decrease as the particle size increases. On the other hand, for materials that are hard to crush, the shear strength appears to be proportional to

Kim and Kim 937

1.80

1.85

1.90

1.95

2.00

2.05

2.10

5.00 6.00 7.00 8.00 9.00 10.00 11.00 12.00 13.00 14.00 15.00

Soil

Soil+cement4%

Soil+cement6%

Soil+cement8%

Soil+cement10%

(a) A compaction

1.960

2.000

2.040

2.080

2.120

2.160

4.00 5.00 6.00 7.00 8.00 9.00 10.00 11.00 12.00 13.00 14.00 15.00 16.00

Soil

Soil+cement4%

Soil+cement6%

Soil+cement8%

Soil+cement10%

(B) Modified E compaction Figure 4. Compaction curve by A and modified E compaction method.

Table 4. Average UCS ratio of the specimens.

Curing time Cement 4% Cement 6% Cement 8% Cement 10%

φ5 φ10 φ15 φ5 φ10 φ15 φ5 φ10 φ15 φ5 φ10 φ15

3 0 . 2 7 0 . 3 5 0 . 2 5 0 . 2 5 0 . 3 2 0 . 2 7 0 . 2 3 0 . 2 9 0 . 3 8 0 . 1 9 0 . 3 1 0 . 4 0

7 0 . 4 1 0 . 3 9 0 . 4 4 0 . 3 6 0 . 4 0 0 . 4 2 0 . 3 3 0 . 4 3 0 . 5 0 0 . 3 3 0 . 4 4 0 . 5 1

28 0 . 5 9 0 . 6 0 0 . 6 7 0 . 5 9 0 . 6 3 0 . 6 0 0 . 5 8 0 . 6 4 0 . 6 2 0 . 6 2 0 . 6 3 0 . 6 5

91 1 1 1 1 1 1 1 1 1 1 1 1

the size of the particles. From these findings, it may be concluded that the shear strength of a material is closely related to both particle size and material properties. Micro-structure of CSG In this study, an SEM (S-4300, Hitachi) was used to examine type and distribution of production due to hydration on the surface of a specimen. In addition, its constituents were analyzed by energy dispersive spectroscopy. Energy dispersive spectroscopy (EDS) is an analytical technique used for the elemental analysis or

chemical characterization of a sample. Figure 6 shows the micro structure of specimens. As shown in the figure, some productions due to the hydration of cement mixed in the CSG are observed.

In general, concrete generates little hydration production because of the large amount of cement. In contrast, the CSG generates less production, and the void of mixed soil is filled with this hydrate (Kellsen, 1996). Meanwhile, as shown in Figure 6, when the specimen size is larger and the volume of cement is greater, the generation of needle-shaped ettringite is greater.

As mentioned earlier, the hydration production is proportional to the volume of cement, which means it

938 Sci. Res. Essays

0 20 40 60 80 100 1200

5

10

15

Avera

ge U

CS

, q

u (

MP

a)

C uring tim e (day)

D 15 C -10%

D 10 C -10%

D 5 C -10%

D 15 C -8%

D 10 C -8%

D 5 C -8%

D 15 C -6%

D 10 C -6%

D 5 C -6%

D 15 C -4%

D 10 C -4%

D 5 C -4%

D 15 C -0%

D 10 C -0%

D 5 C -0%

Figure 5(a). Curing time vs. average UCS.

0 2 4 6 8 10 120

5

10

15

20

D150−91d, y=1.97+1.2X, R2=0.984

D100−91d, y=1.37+1.1X, R2=0.994

D50−91d, y=0.92+0.8X, R2=0.999

D150−7d, y=0.03+0.7X, R2=0.983

D100−7d, y=0.12+0.5X, R2=0.999

D50−7d, y=0.87+0.2X, R2=0.991

Avera

ge U

CS

, q

u (

MP

a)

Cement content (%)

Figure 5(b). Cement content vs. average UCS.

Kim and Kim 939

0 50 100 150 2000

10

20

Ave

rage U

CS

, q

u (

MP

a)

C10%-91d y=6.9+0.05X, R2=0.987

C8%-91d y=5.5+0.04X, R2=0.961

C6%-91d y=4.0+0.04X, R2=0.963

C4%-91d y=3.1+0.02X, R2=0.975

C10%-7d y=1.1+0.04X, R2=0.981

C8%-7d y=0.9+0.03X, R2=0.994

C6%-7d y=1.2+0.02X, R2=0.964

C4%-7d y=1.1+0.01X, R2=0.975

Specimen diameter (mm) Figure 5(c). Specimen diameter vs. average UCS.

Table 5. Average UCS ratio of the specimens due to specimen size.

Curing time 91 day 7 day

Cement content

Specimens (mm)mm)mm)mm) 10% 8% 6% 4% 10% 8% 6% 4%

φ50×100 0.65 0.63 0.60 0.65 0.43 0.42 0.52 0.60

φ100×200 0.88 0.86 0.85 0.86 0.76 0.74 0.82 0.76

φ150×300 1 1 1 1 1 1 1 1

could be one of the parameters affecting the compressive strength of the material. In addition, more needle-shaped ettringite was observed in the larger specimens, leading to a more comprehensive study of the relationship between hydration and specimen size. Figure 7 repre-sents the results of EDS on the specimens of φ50 mm (content 4%), φ100 mm (content 6%), φ150 mm (cement 10%). As shown in the figure, the major constituents of the first two specimens were O and Si. Meanwhile, the third specimen (φ150 mm) had O and Ca as the primary constituents. In addition, Si, C and S were found in the third specimen. In particular, sulfur was assumed to be ettringite. A small amount of aluminum (Al) was also detected. Freeze-thaw resistance

The relationship between the loss rate of CSG and the

volume of cement according to the cycles of freeze-thaw and dry-wet is shown in Figure 8. The loss rate appears to decrease with an increase of the volume of the cement. This phenomenon seems to be more obvious in wet and dry tests, perhaps because the moisture in the void of the specimens is expanded due to dry-wet cycling, which gives rise to a reduction of the density.

According to Figure 8, the loss rate appears to decrease as the size of the specimen increases. In particular, the specimens with 10% cement seemed to lose more weight. Catton (1959) mentioned that the weight loss due to freeze-thaw is dependent on the characteristics of the soil cement and that allowable ranges are less than 14% for a Groups A-1-a, A-1-b, A-3, A-2-4, and A-2-5; 10% for Groups A-2-6, A-2-7, A-4, and A-5; and 7% for Groups A-6, A-7-5, and A-7-6. In this study, the loss rates of due to dry-wet and freeze-thaw are 2.97, 2.02, 1.15% and 4.03, 3.02, 1.38% for the specimen sizes of φ50, φ100, φ150 mm, respectively.

940 Sci. Res. Essays

φ50 mm (cement content 4%)

φ50 mm (cement content 6%)

Kim and Kim 941

φ50 mm (cement content 8%)

(a) φ50 mm (cement content 10%)

942 Sci. Res. Essays

φ100 mm (cement content 4%)

φ100 mm (cement content 6%)

Kim and Kim 943

φ100 mm (cement content 8%)

5 µm

(b) φ100 mm (cement content 10%)

944 Sci. Res. Essays

5 µm

φ150 mm (cement content 4%)

φ150 mm (cement content 6%)

Kim and Kim 945

φ150 mm (cement content 8%)

(c) φ150 mm (cement content 10%)

Figure 6. Micro structure of CSG materials with different specimen sizes (×10000).

946 Sci. Res. Essays

0 5 10 150

200

400

600

800

1000

Inte

nsir

y

Energy (keV)

O

Si

Al

Mg

Ca

KFe

Element Weight% Atomic%

C K 12.16 21.13

O K 43.01 56.12

Al K 13.89 3.63

Mg K 0.61 0.53

Si K 16.20 12.04

K K 1.61 0.86

Ca K 6.93 3.61

Fe K 5.59 2.09

Ca

Inte

nsity

Figure 7a. EDS spectra of the CSG materials (φ 50 mm [refer to Figure 7 (a) cement content 4%]).

0 5 10 150

200

400

600

800

1000

Inte

nsity

Energy (keV)

O Si

Al

Ca

K Ca FeC

Element Weight% Atomic%

C K 17.59 27.09

O K 44.77 51.74

Mg K 0.76 0.58

Al K 6.58 4.51

Si K 12.56 8.27

K K 2.78 1.38

Ca K 11.36 5.24

Fe K 3.59 1.19

Figure 7b. EDS spectra of the CSG materials. (φ 100 mm [refer to Figure 7 (b) cement content 6%]).

That is, the loss rates of the specimen sizes of φ100 mm and φ50 mm are higher than that of φ150 mm by 1.8

times up to 2.9 times. However, these numbers make no big difference in engineering usage.

Kim and Kim 947

0 5 1 0 1 50

2 0 0

4 0 0

6 0 0

8 0 0

1 0 0 0

Inte

nsity

E n e r g y ( k e V )

O S i

A lC a

S KF e

C aM g

E l e m e n t W e i g h t % A t o m i c %

C K 1 0 . 7 4 1 7 . 2 1

O K 5 0 . 2 0 6 0 . 3 9

M g K 0 . 7 3 0 . 5 7

A l K 5 . 7 6 4 . 1 1

S i K 1 1 . 4 4 7 . 8 4

S K 0 . 9 7 0 . 5 8

K K 1 . 4 2 0 . 7 0

C a K 1 5 . 7 1 7 . 5 5

F e K 3 . 0 4 1 . 0 5

Figure 7c. EDS spectra of the CSG materials. (φ 150 mm [refer to Figure 7 (c) cement content 10%]).

0 2 4 6 8 1 0 1 20

1 0

2 0

3 0

Loss r

ate

(%

)

C e m e n t c o n t e n t ( % )

D 5 0

D 1 0 0

D 1 5 0

(a) Wet-dry test

0 2 4 6 8 1 0 1 20

1 0

2 0

3 0

Lo

ss r

ate

(%

)

C e m e n t c o n t e n t ( % )

D 5 0

D 1 0 0

D 1 5 0

(b) Freeze-thaw test Figure 8. Effect of cement content on the loss rate of CSG materials

Conclusion In this study, the physical and chemical characteristics, such as the unconfined compressive strength, stress-

deformation, micro-structure and freeze-thaw resistance of CSG, according to the cement volume, curing time, and specimen size were investigated. Based on the results of this study, the following conclusions can be derived.

948 Sci. Res. Essays (1) Unconfined compression tests were conducted on specimens of φ150×300, φ100×20, and φ50×100 mm, and the results showed that the unconfined compressive strength of the specimen with a size of φ100×200 mm was about 85 - 88% of that of the specimen with a size of φ150×300 mm, and the specimen with a size of φ50×100 mm had a strength 60 to 65% of that of the specimen with a size of φ150×300 mm. (2) SEM results showed that the greater the volume of cement, the greater the generation of needle-shaped ettringite. (3) The loss rates of the specimens with sizes of φ100 and φ50 mm were higher than that of φ150 mm by from 1.8 times up to 2.9 times, which means the loss rate appeared to decrease with an increase of the volume of cement. ACKNOWLEDGMENT This research was supported by grants from the Agriculture and Life Sciences Research Institute (ALSRI), and, in part, Institute for Advanced Construction Materials (IACM) of Kangwon National University. REFERENCES Airey DW (1993). Triaxial testing on naturally cemented carbonate soil.

J. Geotech. Eng. Div. ASCE., 119(11):1379-1398. Bae KU (2006). Laboratory and in-situ mix designs for applications of

the CSG method. Thesis for the Degree of Master, Chungnam National University.

Bressani LA, Vaughan PR (1989). Damage to soil during triaxial testing. Proc. of the 12th Int. Conf. on Soil Mech. and Found. Engrg., Rotterdam, The Netherlands, pp. 17-20.

Catton MD (1959). Farly soil-cement research and development. J. of the High-way Div., ASCE. pp. 1-15.

Chae KI, Kwon MN, Lee SH, Nam HS (2003). Permeability of soil-bentonite mixtures. J. Korea Soc. Agric. Eng., 45(1): 55-62.

Chang T, Woods RD (1992). Effect of particle contact bond on shear modulus. J. Geotech. Eng., ASCE., 188(8): 1216-1233.

Cho JG (1974). A study on the physical characteristics of soil-cement. J. Korea Soc. Agric. Eng., 16(3): 3533-3538.

Clough WG, Kuck WM, Kasali G (1979). Silicate-stabilized sands. J. Geotech. Eng. Div. ASCE., 105(1): 65-82.

Do DH (1980). Improvement of soil-cement with additives. J. Korea Soc.

Agric. Eng., 21(1): 63-77. Gens A, Nova R (1993). Conceptual bases for a constitutive model for

bonded soils and weak rocks. In Geotechnical engineering of hard soils-soft rocks, pp. 485-494.

Han JM, Oh YM (2007). Hydraulic characteristics of water affinity sea-wall block. J. Korean Soc. Coast. Ocean Eng., 19(2):179-182.

Hou YJ, Xu ZP, Liang JH (2004). Centrifuge modelling of cutoff wall for CFRD built in deep overburden. In Proc. of Int. Conf. of Hydropower, Yichan, China. pp. 86-92.

Kellsen KO (1996). Heat Curing and post-heat curing regimes of high-performance concrete: influence on microstructure and C-S-H composition. Cem. Concr. Res., 26(2): 295-307.

Kim JY, Kang YM (1975). A study on the effects of molding water content and cement content on unconfined compressive strength of soil cement mixtures. J. Korea Soc. Agric. Eng., 17(1):3685-3701.

Kim KY, Park HG, Jeon JS (2005). Strength characteristics of cemented sand and gravel. J. Korean Geotech. Soc., 21(10):61-71.

Kim KY (2006). The effect affecting the unconfined compressive strength of C.S.G materials. J. Korean Geotech. Soc., 22(10):33-45.

Kim SC, Lee SH (2005). Strength characteristics of cement-mixed soil, J. Korea Soc. Agric Eng., 47(3): 49-56.

Kong KY, Kim HT, Ro JK, Hong BM (2001). Study on the mechanical properties of low mix soil-cement. J. Korea Soc. Agric. Eng., 43(6): 127-134.

Kongsukprasert L, Tatsuoka F (2003). Viscous effects coupled with ageing effects on the stress-strain behaviour of cemented-mixed gravel. Deformation Characteristics of Geomaterials. pp. 569-578.

Oie M, Yamaguchi Y, Fujita K, Jikan S (2003). The construction of temporary structures by CSG method in Tokuyama dam project. Roller Compact Dams, pp. 499-510.

Reddy KR, Saxena SK (1992). Constitutive modelling of cemented sand. Mech. of Mat. 14(2):155-178.

Suh WM, Koh CK (1978). A study on the effects of molding pressure on the compressive strength and durability of soil-cement mixture. J. Korea Soc. Agric. Eng., 20(1): 4575-4591.

Varadarajan A, Shama KG, Venkatachalam K, Gupta AK (2003). Testing and modeling two rockfill materials. J. Geotech. Geoen. Eng. 129(3): 206-218.

Watanabe K, Tateyama M, Jiang GL, Tatsuoka F, Lohan TN (2003). Strength charateristics of cement mixed gravel evaluated by large triaxial compression test. Proc. 3rd Int. Symp. on Deformation Characteristics of Geomaterials. Di, B. ed., Lyon, pp. 683-693.

Yeon KS, Kim YI, Hyun SH, Kim YS (2010). Compressive strength properties and freezing and thawing resistance of CSG materials. J. Korea Soc. Agric. Eng., 52(1): 51-59.

Youn JN, Sung CY, Kim YI (2009). Physical and mechanical properties of porous concrete using waste activated carbon. J. Korea Soc. Agric. Eng., 51(2): 21-27.