Ultra Precision Machining Systems 140 GPM Glass Press ... · Ultra Precision Machining Systems...

-

Upload

duongthuan -

Category

Documents

-

view

247 -

download

0

Transcript of Ultra Precision Machining Systems 140 GPM Glass Press ... · Ultra Precision Machining Systems...

Ultra Precision Machining Systems

Courtesy of Fraunhofer-IPT

140140140 GPMGPMGPM Glass Press Molding Technology

Please see reverse side for more specifications

a PMT Group company

Moore Nanotechnology Systems, LLC 230 Old Homestead Hwy , Swanzey, NH 03446 USA Tel (603) 352-3030 Fax (603) 352-3363 [email protected] www.nanotechsys.com the group

Machine Features

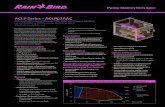

Single chamber precision glass molding machine with 140mm diameter capacity

Capable of utilizing multi-cavity mold inserts

Compatible with both fixed and floating mold sets

PC based motion controller that operates in either position or force

control mode with integrated heating and cooling loops

Windows based front end with user friendly touch screen

to program the machine

Capable of molding at temperatures up to 800 °C

Molding chamber capable of operating under

vacuum or an inert gas environment

Maximum pressing force of 25 kN

Glass Press Molding Cycle

Heating Stage

Soaking Stage

Pressing Stage

First Cooling Stage

Second Cooling Stage

GPMSim is an FEA software package designed to predict the be-havior of the molding process for glass optics. GPMSim’s unique capabilities include a simplified user interface to create molds with various aspheric profiles and model the glass molding process. It also comes with a built-in materials library. The software automati-cally generates a quadrilateral mesh and computes the FE results by going through the five stages of the glass molding cycle. Some of the results are - profile analysis, coefficients of the molded lens profile, thermal shrinkage, molding deformation, residual stresses, index change etc.

Form Accuracy

WC Mold 0.081m PV

Molded Glass Lens 0.122m PV

Surface Finish

WC Mold 1.27nm Ra

Molded Glass Lens 1.51nm Ra

Mold and Glass Mesh Model

Profile Deviation

Thermal Shrinkage

3D Render of Molded Lens

Results at the end of the Cycle

Residual Stresses

Electrical Machine Air Nitrogen

Machine: 230 VAC (+/- 10%); 3 Phase; 50/60Hz; 18kVA(45 amp.)

Chiller: 60Hz: 208-230 VAC; 3 Phase; 8kVA (20 amp.) 50Hz: 400-460 VAC; 3 Phase; 11kVA (16 amp.)

- 5.5-7.0 bar (80-100 psi) - 142 SLPM (5 SCFM) - Dry and pre-filtered to 10µm

- 6.9-10.3 bar (100 - 150 psi) - 283 SLPM (10 SCFM)

- 99.998% Pure Nitrogen containing less than 0.001% (10 parts per million) Oxygen

Utility Requirements

Note: In an effort to continually improve our product performance, specifications are subject to change without notice. (Please consult your Sales Representative for our latest specifications)

Rev.0914