Ultra compact air cooled coolers : A cool story?

-

Upload

elbrons -

Category

Technology

-

view

512 -

download

0

description

Transcript of Ultra compact air cooled coolers : A cool story?

28-1-2015Ultra compact air-cooled coolers

Ultra compact air-cooled coolers

on platforms: A cool story?

A Story about Design: by Johan van der

Kamp and Hans van Essen: source Engineer

Live. http://www.engineerlive.com/iog

28-1-2015Ultra compact air-cooled coolers

Brief introduction

linkedin.com/pub/johan-van-der-kamp/2a/848/424

nl.linkedin.com/pub/hans-van-essen/28/8b7/917

28-1-2015Ultra compact air-cooled coolers

Ultra compact air-cooled coolers

on platforms

• Johan van der Kamp and Hans van Essen explain how

• to design ultra compact coolers that fulfil the stringent

• space requirements on offshore platforms.

28-1-2015Ultra compact air-cooled coolers

Ultra compact air-cooled coolers

on platforms

• Air-cooled cooling has advantages compared to cooling with water.

• More and more freshwater cooling (rivers, lakes and below ground) is

• disallowed because of its potential thermal and bio-pollution. Sea and ocean water requires

the use of expensive materials because of

• its high corrosion potential.

• Air-cooled cooling also has one main disadvantage: it requires a lot of plot

• space so that on offshore rigs space might become a particularly big problem.

• The Litoral-A field is a big oil and gas field in the Gulf of Mexico. Since the accident in the

deep part of the Gulf of Mexico several years ago, Petroleos Mexicanos (Pemex) has been

developing fields in the

• shallow part of the Gulf.

• The Litoral-A field is in the Bay of Campeche where the local water depth is 26 metres.

• In order to boost the current oil and gas production, the platform design is aimed at

improving the flexibility of the Litoral Processing Centre and reduce flare gas using high

pressure compression.

28-1-2015Ultra compact air-cooled coolers

Ultra compact air-cooled coolers

on platforms

• The platform is to be capable of increasing the gas pressure to 85bar.

• The compressors for this platform were designed and supplied by a Houston-based

compressor supplier, in the USA. Air-cooled coolers were to be used for cooling.

• Bronswerk and this supplier have supplied exciting combinations of high pressure

compressors and coolers in various offshore projects.

• The Litoral-A Project required a design combining safe and reliable cooling in a

limited space.

• The supplier approached Bronswerk at an early stage with the challenge of the

project to find a solution for this situation and produce a design

• which would permit safe and reliable cooling in a tight space.

• Each of the compressors needs gas coolers for a 1st stage and a 2nd stage, a

recycle gas cooler and an oil cooler.

• For this project Bronswerk gave the supplier an initial indication of the size of the

coolers based on the gas composition, flow, temperature, pressure.

• It soon became evident that space, weight and absorbed fan power were

• critical points in the overall module designs.

28-1-2015Ultra compact air-cooled coolers

Ultra compact air-cooled coolers

on platforms

• The disadvantage of conventional air-cooled cooling now became apparent: there

was not enough space for common air-cooled coolers.

• Conventional designs:

28-1-2015Ultra compact air-cooled coolers

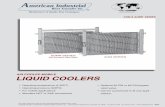

Fig. 1. A conventional design.

Ultra compact air-cooled coolers

on platforms

28-1-2015Ultra compact air-cooled coolers

• Increase the number of rows of finned tubes in combination with a conventional fan1).

Using more rows while maintaining the external pressure drop of the finned tubes

within acceptable level will reduce the flow of cooling air.

• Leading to higher outlet temperatures of the air and a lower temperature difference

between process flow and air.

• It became apparent that it would be impossible to meet the space requirements and

on top of that the absorbed power was over 30 per cent higher than permissible.

Furthermore, the noise level would be unacceptably high.

• Various tube diameter sizes were considered, butnone suited the specifications.

• To overcome the high airside pressure drop, one fan below the bundle (forced draft),

and one fan above (induced draft) was looked at.

• No improvement in the absorbed power and noise level was obtained.

• And, most importantly, this produced an unreliable design due to the unpredictability

of the conventional fan performance.

Ultra compact air-cooled coolers

on platforms

• On the process side no limitations or problems were encountered. Within the

specified maximum tube side pressure drop, several trial designs resulted in

acceptable heat transfer.

• The problem was to ensure that the required flow of cooling air could be ‘pressed’

through the finned tube bundle.

• Smaller bundle space means higher air velocity and whence a higher pressure drop

for a given air flow.

• An increased number of layers (to bring the required cooling surface area within the

limited plot area) also increases the pressure drop.

• The resulting pressure drop on the airside was far higher than is common in air-

cooled cooler applications and higher pressure drop means higher

• driving power and a higher noise level.

• The only feasible solution would be to employ a fan which delivered an optimal

volume flow and static head within the constraint of maximum permissible power (in

other words: highest efficiency).

• Also, the noise produced by that fan should stay below the maximum permissible

noise level.

28-1-2015Ultra compact air-cooled coolers

Ultra compact air-cooled coolers

on platforms

• The ultra-high efficiency, ultra-low noise fan, the Whizz-Wheel,

• was considered. This fan is capable of achieving:

• A 50 per cent reduction of absorbed motor power or

• For the maximum allowable motor power produce a higher airflow in

• combination with a higher static pressure head.

28-1-2015Ultra compact air-cooled coolers

Ultra compact air-cooled coolers

on platforms

28-1-2015Ultra compact air-cooled coolers

Fig. 3. Compact Header design

Ultra compact air-cooled coolers

on platforms

• The selection of this Whizz-Wheel fan in combination with the higher number of tube

rows lead to the result that all of the suppliers strict

• requirements regarding space, absorbed motor power and noise level could be

fulfilled.

• This placed the supplier in ‘pole position’ to win this job.

• Compared with the best (smallest) design of the coolers when fitted with conventional

fans1), the final Whizz-Wheel based design requires 40 per cent less space.

• In spite of this smaller space, the consumed motor power of the coolers is 25 per cent

below the maximum allowable level.

• With conventional fans1(even with the larger space) the permissible noise level was

exceeded by 5dB(A).

• In the final Bronswerk design, the noise level is within the permissible limit.

• Although the coolers have more rows of finned tubes, the total height of the coolers is

reduced by 0.6 metres.

28-1-2015Ultra compact air-cooled coolers

Ultra compact air-cooled coolers

on platforms

• Even the weight of the coolers is 15,000kg less than with the conventional fans1.

• The other main benefits are not only for the smaller cooler but also for the overall

project:

• The ability to provide a suitable module on an existing platform without modifying the

platform structure;

• Maintaining the weight of the module below the maximum crane lift capacity to avoid

the need for a heavier crane;

• Fewer fans, so fewer E-power connection points and cables, and fewer components

requiring maintenance;

• No self-induced vibrations from the fans to the structure.

28-1-2015Ultra compact air-cooled coolers

Ultra compact air-cooled coolers

on platforms

• The Whizz-Wheel design has led to several applications in which the space occupied by

the coolers could be brought to allowable ultra

• compact dimensions.

• Together with the two other advantages of these fans, ie strongly reduced power

consumption and strongly reduced noise generation, the result is that for many air-cooled

coolers or condensers, specifications can be met that were unimaginable before the

Whizz-Wheel.

28-1-2015Ultra compact air-cooled coolers

Triggered by Coolers?

• Triggered by Coolers?

• Read more on

• http://www.bronswerk.com/en/Air-Cooled-Cooler/PT6/

• http://www.bronswerk.com/en/Whizz-Wheel/PS68/

• http://www.bronswerk.com/en/Air-Cooled-Heat-Exchanger/PT38/

• http://www.bronswerk.com/en/Gas-extraction/C25/

28-1-2015Ultra compact air-cooled coolers

Coolers

• Interested?

• Ask our colleague nl.linkedin.com/pub/bram-marcus/11/24b/34b or contact our

company.

28-1-2015Ultra compact air-cooled coolers

Coolers

28-1-2015Ultra compact air-cooled coolers

• Like to know more innovations?

• Have a chat with Bronswerk people via our website or

• Visit our website: http://www.bronswerk.com/en/Organisation/In-the-press/P396/

• Meet us on LinkedIn.

• https://www.linkedin.com/company/bronswerk-heat-

transfer/products?trk=top_nav_products

28-1-2015

•Join our community!

•Join our community!

• Conversate with us on Facebook.

• http://www.facebook.com/Bronswerk.

Join our community!

• Follow us on Twitter.

• https://twitter.com/bronswerk

28-1-2015

Join our community!

• Share our content.

• http://www.slideshare.net/Bronswerk

28-1-2015

Thank you for your attention!

28-1-2015Ultra compact air-cooled coolers22