UG-crate status

description

Transcript of UG-crate status

UG-crate status

AMS TIM - CERN - 15/4/2008

A.Bartoloni, B.Borgia, F.R.Spada*

INFN Roma

F.R.Spada - UGcrate status - AMS TIM - 25/4/2008 2

UG-electronics in the TRD Gas System

F.R.Spada - UGcrate status - AMS TIM - 25/4/2008 3

UG electronics design history

EM QM

Aug 2004Design of control electronics from EM to QM updated after test session

Feb 2005Contract issued to G&A Engineering for construction and qualification of QM and FM

May 2005

Radiation test of few components performed at Karlsruhe, under the supervision of A.Kounine

Further modifications introduced because of gas circuit changes

No basic circuit modified (ADC, switches, serial link, …)

QM QM2

Jan 2007A list of 15 components in QM identified by Th.Siedenburg, that may be not be approved by the collaboration

Feb 2007 1 component rejected (linear regulator TPS73xx)

Jun – Sep 2007

Revision of the layout

Following the change of linear regulators, of power distribution scheme and several changes required by safe operation (short circuits on cables or components), design needs major modifications

Sep 11, 2007 Go-ahead for the QM2 construction

F.R.Spada - UGcrate status - AMS TIM - 25/4/2008 4

QM to QM2 modifications

Replace the TPSxxxx regulators with SEL free LP2989 (UGBS, UGBC, UGFV)

Put limiting resistor on Kulites and GP50 power supply lines (UGBS, UGBC)

Separate 12V power supply for UGPS and flipper valve (UGFV)

Introduce LP2953 regulator to generate 24V for pumps high speed (UGBP)

Introduce LP2953 regulator to generate 21V for analog mux (UGBP)

Eliminate 3.3V DC-DC converter generate 3.3V from 5V on backplane

Introduce Solid State Fuses (SSF) for short circuit protection on 5V, on each module

Introduce pull-down resistors on Mosfet gates

Introduce differential amplifier on Kulite inputs

Eliminate UHVG redesign of backplane

Eliminate 2 UGFV and reduce 8 multiple channels to 4 redesign of pcb

F.R.Spada - UGcrate status - AMS TIM - 25/4/2008 5

UG electronics test history

(1) since then, QM1-UG widely used for the TRD gas functional tests

(2) SlowControl software used on QM1-UG and for QM2-UG functional tests

(3) found a few problems in the FM gas circuit cabling (pumps and spirometer)

(4) found some anomalous behaviour in interaction with UGPD - solved

QM1 Jul 2006 UG functional tests at G&A Carsoli ok(1)

QM2

Feb 4-12, 2008 UG functional tests in Rome ok(2)

Feb 13-29, 2008 UG ESS + TVT qualification at SERMS ok

Mar 4, 2008 UG at CERN for functional tests with gas circuit ok(3)

Mar 12, 2008 UG in Rome waiting for UGPD

Mar 14, 2008 UGPD arrived in Rome

Mar 18, 2008 UG+UGPD functional test ok

Mar 25-27, 2008 EMC UG+UGPD test at SERMS ok(4)

FM Mar 2007 FM-UGPS installed at Aachen

F.R.Spada - UGcrate status - AMS TIM - 25/4/2008 6

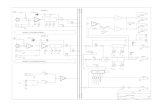

QM2 UG-electronics qualification test set-up

UG CRATE

TV / EMCCHAMBER

EPPCANBUS

POWER SUPPLIES A

POWER SUPPLIES B

29V 12V 5V

GASSYSTEM

SIMULATOR

ADC/DACNATIONAL

INSTRUMENT

TEST STATION

SLOW CONTROL

F.R.Spada - UGcrate status - AMS TIM - 25/4/2008 7

List of operations for qualification tests

1. UGSCM A and B are initialized; 2. all valves controlled by UGBS (V1a, V2a, V3a, V4a, V10a,

V20a, V1b, V2b, V3b, V4b, V10b, V20b, Sp1, Sp2) are enabled and opened for 5 s one at a time, and status is read, then disabled;

3. all pressure sensors controlled by UGBS (P1a, P2a, P1b, P2b, Pk1c, Pk2c, Pk1d) a re read out;

4. all heaters controlled by UGBS (H1, H2, H3, H4, H5) are enabled and started for 1 minute, then disabled, one at a time;

5. operations 2 to 4 are repeated 4 times: [UGSCM-A + UGBS-A], [UGSCM-A + UGBS-B], [UGSCM-B + UGBS-A], [UGSCM-B + UGBS-B];

6. all power supplies (25V, 12V, 5V, 8.5V) controlled by UGBC are enabled, and the status is read out;

7. all valves controlled by UGBC (V6a, V18a, V6b, V18b, V6a&V18a, V6b&V18b) are enabled and opened for 5 s one at a time, and status is read, then disabled;

8. all pressure sensors controlled by UGBC (P3, P4) are read out;

9. all circulation pumps controlled by UGBC (CP1, CP2) are enabled at H speed, started and stopped after 5 s, then enabled at F speed, started and stopped after 5 s then disabled, one at a time;

10. all UGBC serial ports (RS232_1, RS232_2, RS232_3, RS232_4) are enabled and the status is read, then disabled;

11. all power supplies (25V, 12V, 5V, 8.5V) controlled by UGBC are disabled;

12. operations 6 to 11 are rep eated 4 times: [UGSCM-A + UGBC-A], [UGSCM-A + UGBC-B], [UGSC M-B + UGBC-A], [UGSCM-B + UGBC-B];

13 . a ll po wer su pplies con trolled by UGFV (12VPS, 12VFV, 21V, MUX) are enab led;

14 . modu les 1 to 4 are se lec ted one at a time, and for ea ch modu le, va lves V1 to V5 a re op ened then closed afte r 5 s;

15 . multiplexers 1 to 4 are se lected one at a time, and for each multiplexer a ll press ure sen sors (P1 , P2, P3, P4, P5) are read o ut;

16 . a ll po wer su pplies con trolled by UGFV (12VPS, 12VFV, 21V, MUX) are d isab led;

17 . operat ions 13 to 16 a re re peated 4 times : [UGSC M-A + UGFV-A], [UGSCM-A + UGFV-B], [UGSC M-B + UGFV-A], [UGSCM-B + UGFV-B].

Time needed to perform all commands: 15 minutes

F.R.Spada - UGcrate status - AMS TIM - 25/4/2008 8

UG crate in the termal chamber

F.R.Spada - UGcrate status - AMS TIM - 25/4/2008 9

UG crate on the vibration plate

F.R.Spada - UGcrate status - AMS TIM - 25/4/2008 10

Termal test profile

Before vibration After vibration

F.R.Spada - UGcrate status - AMS TIM - 25/4/2008 11

UG crate being prepared for TV test

F.R.Spada - UGcrate status - AMS TIM - 25/4/2008 12

TVT temperature and pressure profiles

F.R.Spada - UGcrate status - AMS TIM - 25/4/2008 13

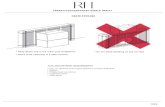

EMC test setup

F.R.Spada - UGcrate status - AMS TIM - 25/4/2008 14

EMC test setup

UG crate

UGPD 5.6V, 12V, 29V

from UGPD

F.R.Spada - UGcrate status - AMS TIM - 25/4/2008 15

EMC test setup

UG crate

UGPD

Marotta, pumps & flipper

simulator

F.R.Spada - UGcrate status - AMS TIM - 25/4/2008 16

EMC test setup

28V power supply for UGPD

F.R.Spada - UGcrate status - AMS TIM - 25/4/2008 17

Problems encountered during EMC test:

CE03: at 15kHz exceeded limit by ≈ 3db

Inserted a 500 µF capacitor on 29V line to the backplaneSolved

RS03: at 60V/m, 240MHZ lost LeCroy communication between UGSCM and UGPD (with UGSCM UG crate ok)

Elimination of one ground loop on LeCroy bus at UGPDShielded 12V and 29V power cables (originally, twisted)Solved

F.R.Spada - UGcrate status - AMS TIM - 25/4/2008 18

Conducted emission around 15 KHz with capacitor on 29V

F.R.Spada - UGcrate status - AMS TIM - 25/4/2008 19

Summary• QM2 was qualified at SERMS, Terni

• Both the ESS and the TVT showed full functionality of the electronics, with stability of sensor readings within 0.3-0.4 % in all temperature ranges

Full reports are under preparation by the test laboratories

• Only two modifications will be implemented to the FM electronics:1. one 470 µF capacitor on the backplane connected to the 29V A and 1 on the

29V B to comply with the EMC test2. 3K Ω pulldown resistors on RX0A and on RX0B on the backplane to avoid

feeding static 5V from UGSCM to RS232 components in the UGBC

The required ECO's will be issued

• No modifications required by the ESS or by the TVT test• No modifications required by the functionality test performed on the actual gas

circuit• The spirometer was correctly read, and the pumps were correctly operated when

correctly connected

We require that 1. on the UGPD FM controller S9011A, the grounding 0 ohm resistor for the

return line of the 3.3V be removed2. on the UGSCM FM the pull-up resistors on RX lines be removed 3. the power cables between UGPD and UG be shielded

F.R.Spada - UGcrate status - AMS TIM - 25/4/2008 20

UG-electronics schedule

QM2 21/01/08 QM2 boards ready functional tests

11/02/08 13/02 ready to start qualification tests (SERMS)

29/02/08 29/02 end of qualification tests (no EMC)

05/03 ready to start tests at CERN

14/03/08 07/03 end of tests at CERN

25/03/08 start EMC test

27/03/08 end EMC test

Go-ahead for FM with 2 weeks delay

FM 04/04/08 21/04 FM boards delivered by G&AStart acceptance tests @ SERMS

21/04/08 05/05 end of FM boards acceptance tests

F.R.Spada - UGcrate status - AMS TIM - 25/4/2008 21

BACKUP SLIDES

F.R.Spada - UGcrate status - AMS TIM - 25/4/2008 22

Radiated immunity loss of UGSCM UGPD communication

60 V/m

F.R.Spada - UGcrate status - AMS TIM - 25/4/2008 23

Conducted emissions

F.R.Spada - UGcrate status - AMS TIM - 25/4/2008 24

EM to QM modifications

Change power supply: 24V 30V supply for Kulite, Marotta valves, pumps, heaters

Pumps power supply: 12V directly from DC-DC converter24V with step-down circuit 30V 24V

Heaters on CO2, Xe vesselson/off switches identical to Marotta valves

Kulite gauges

Dallas T sensors replacing GP-50 T+ n. 2 dedicated links to USCM

No basic circuit modified (ADC, switches, serial link, …)