UF FLOATING 1116files4.webydo.com/29/291605/UploadedFiles/2f6b9628-a38e... · 2015. 3. 26. ·...

Transcript of UF FLOATING 1116files4.webydo.com/29/291605/UploadedFiles/2f6b9628-a38e... · 2015. 3. 26. ·...

-

...FBV 6.05

-

We cannot accept responsibility for any errors in this catalog, as technical advancements may result in improved designs and materials.

-

F1Universal Floww w w. u f v a l v e . c o m

Preface

Preface

Our mission at Universal Flow (UF), is to provide a quality product at a competitive priceand to meet the needs and requirements of our customers in a timely manner. UF valvesare designed, manufactured and tested under strict quality control to meet and exceedall industry standards to which they are constructed. UF valves are completely traceablewith chemical, physical and pressure test records.

Universal Flow offers a wide variety of industrial and commercial valves using carbon andalloy steels. Standard sizes range from 1/2” to 36” in diameter, with pressure ratings fromANSI class 150 to class 2500.

This catalog contains basic dimensions and specifications for UF valves. The designs andmaterials offered may vary in accordance with our continuing product developmentprogram.

F1

-

F3Universal Floww w w. u f v a l v e . c o m

Table of Contents

Ball Valve Figure Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F4

Specification Conformance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F5

F Series Floating Design Ball Valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . F6 - F11

Available Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F12

Torque Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F13

Material Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F14- F15

Terms and Conditions of Sale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F16

F3

-

F4 Universal Floww w w. u f v a l v e . c o m

epyT

)1(

troP

)2(

ssalC

)3(

ydoBlairetaM

)4(

mirTlairetaM

)5(

dnEnoitcennoC

)6(

taeSlairetaM

)7(

laeSlairetaM

)8(

evlaVnoitarepO

)9(

cp2-FllaBgnitaolF

evlaVcp1-U

llaBgnitaolFevlaV

yrtnEediS-AFnoinnurTdetnuoMevlaVllaByrtnEpoT-T

noinnurTdetnuoMevlaVllaBediScp3-P

yrtnEnoinnurTdetnuoMevlaVllaB

llamScp3-HgnitaolFeziS

evlaVllaB

decudeR.1troP &

trohSnrettaP

decudeR.2troP &gnoL

nrettaPtroPlluF.3

trohS&nrettaP

troPlluF.4gnoL&nrettaP

laicepS.5troP

ssalC.10051

ssalC.30003

ssalC.60006

ssalC.80008

ssalC.90009

ssalC.510051

ssalC.520052

BCW.10501A.20

8FC.30403F.40M8FC.50613F.60

3FC.70L403F.80

M3FC.90L613F.01

BCL.112FL.2115F.31

/W.S.C.10PNELIM1/W.S.C.20PNELIM3

woL.30.S.CpmeT

LIM3/WPNE

613F.40M8FC.50403F.60

8FC.70L403F.80

3FC.90L613F.01

M3FC.11rC31.21

lenoM.31yolletsaH.41

15F.51

FR.1JTR.2

WB.3WS.4

TPN.5FRxWB.6

JTRxWB.7

nirleD.1EFTP.2

EFTP-R.3nolyN.4

Peek.5)4TH(

Devlon.6

Buna.1Viton.2

MDPE.3Aflas.4

reveL.1raeG.2

detarepO/wreveL.3

gnikcoLeciveD

raeG.4detarepO

gnikcoL/weciveD

metSeraB.5detautcA.6

SpecialModifier

)x(

Ball Valve Figure Description

F4

Example: P 4 01 01 04 1 2 2 1(9) Valve Operation: Handle(8) Valve Seal Material: Viton(7) Valve Seat Material: PTFE(6) Valve End Connection: RF(5) Valve Trim Material: F316(4) Valve Body Material: WCB(3) Valve Pressure Rating: Class 150(2) Valve Port: Full Port and Long Pattern(1) Valve Type: Side Entry Trunnion Mounted

Notes: 1. Materials to NACE MR0175 on request.2. Design and construction details are subject to change without notice.3. Other materials available upon request.

How to OrderFigure numbers are designed to cover essential features.

-

Universal Floww w w. u f v a l v e . c o m

F5

Specification Conformance

API - American Petroleum Institute• API6D Specification for Pipeline Valves (Gate, Plug, Ball and Check Valves)• API6FA Specification for Fire Test For Valves• API598 Valve Inspection and Testing• API607 Fire Test for Soft-Seated Quarter-Turn Valves• APIQ1 Specification for Quality Programs for the Petroleum and Natural Gas Industry

ANSI - American National Standard Institute• B16.5 Steel Pipe Flanges and Flange Fittings• B16.10 Face to Face and End to End Dimensions of Valves• B16.25 Butt-Welding Ends• B16.34 Valves - Flanged, Threaded, and Welding End

British Standard• BS5351 Steel Ball Valves for the Petroleum, Petrochemical and Allied Industries• BS6755 Testing of Valves• BS5146 Inspection and Test of Valves• BS1503 Steels for Fired and Unfired Pressure Vessels• BS1560 Steel Pipe Flanges and Flanged Fittings for the Petroleum Industry• BS2080 Face-to-Face, Center to Face, End to End, and Center to End Dimensions

of Flanged and Butt-Welding End Steel Valves for the Petroleum,Petrochemical and Allied Industries

• BS4504 Flanges and Bolting for Pipes, Valves and Fittings

ISO - International Organization for Standardization• ISO9001 Quality Systems - Model for Quality Assurance in Design, Development,

Production, Installation and Servicing• ISO5211 Valve Actuator Attachment

MSS - Manufacturers Standardization Society• SP6 Standard Finishes for Contact Faces of Pipe Flanges and Connecting-End

Flanges of Valves and Fittings• SP25 Standard Marking System for Valves, Fittings, Flanges and Unions• SP72 Ball Valves with Flanged or Butt-Welding Ends for General Service

NACE - National Association of Corrosion Engineers• MR0175 Sulfide Stress Cracking Resistant Metallic Materials for Oil Field Equipment

UF ball valves are designed, manufactured and tested in accordance with API, ANSI,ASME, and BS requirements. The following list contains the most important applicablestandards for ball valves. UF valves may be produced in accordance with other international standards on request.

-

...

Universal Floww w w. u f v a l v e . c o m

F6

Series of Floating Ball Valves

The UF series of floating ball valves features a variety of material choices in alloy, carbon,or stainless steel and is available in sizes from 1” to 12” in ANSI classes 150 to 1500. NACEMR0175 specification can be fully satisfied if required. This valve series offers versatility,performance and reliability at a resonable cost, as well as the following functions:

• Field proven durability in demanding applications• Anti-blowout stem• Anti-static device• Full rated bi-directional shut-off• Full rated dead end service• Reduced port or full port• Fire safe design

The full port valves, ranging from 1” to 12”, provide maximum flow with minimum pressuredrop across the valve. All valves use FDA-approved non-silicon lubricant. Mounting dimensionsand parts are identical to the latest ISO Standard for interchangeability. Standard features ofthe F Series ball valve include:

• Fully machined mounting pad to easily convert from manual to actuated operation• Lockable handle• Adjustable packing gland• Graphite stem packing

Pressure-temperature Chart

Temperature

Pres

sure

(PSI

G)

LAIRETAM

)BCW(SC

051LCISNA

285

275

003LCISNA

740

720

0006LCISNA

1480

1440)M8FC(SS

Pressure Rating (PSIG)

Low Temperature LimitsLAIRETAM ºF ºC

BCW 02- 92-

BCL 05- 64-

-

Universal Floww w w. u f v a l v e . c o m

F7

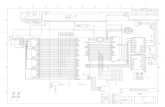

1”FP ~ 6”RP CL.150 F Series Ball Valve

EZISA B C D E U K L H TW

hcni mm hcni mm hcni mm hcni mm hcni mm hcni mm hcni mm hcni mm mm sbl gkPF"1 1 52 5 721 13.2 8.85 52.4 801 96.2 3.86 - - 88.5 051 - - 04.9/54.9 71 7.7PF"5.1 5.1 83 5.6 561 69.2 2.57 5 721 96.3 7.39 5.51 493 48.9 052 83.0 6.9 84.9/55.9 7.02 4.9

PR"2 5.1 83 7 871 51.3 08 6 251 96.3 7.39 5.51 493 48.9 052 83.0 6.9 84.9/55.9 9.32 8.01PF"2 2 15 7 871 20.3 7.67 6 251 15.4 511 5.51 493 48.9 052 44.0 2.11 84.9/55.9 1.03 7.31PR"3 2 15 8 302 00.4 201 5.7 191 15.4 511 5.51 493 48.9 052 44.0 2.11 20.71/11.71 4.14 8.81PF"3 3 67 8 302 5.3 98 5.7 191 60.6 451 02 805 8.51 004 44.0 2.11 20.71/11.71 5.65 6.52PR"4 3 67 9 922 52.4 801 9 922 60.6 451 02 802 8.51 004 44.0 2.11 78.12/79.12 8.58 9.83PF"4 4 201 9 922 4 201 9 922 42.7 481 02 805 8.51 004 26.0 7.51 78.12/79.12 5.79 2.44PR"6 4 201 5.01 762 52.5 331 11 972 42.7 481 02 805 8.51 004 26.0 7.51 78.12/79.12 511 9.15PR"6 4 201 5.51 493 57.7 791 11 972 42.7 481 02 805 8.51 004 26.0 7.51 78.12/79.12 431 16

Dimensional Data

15 16173

14

1312

18

7

11

6

2

1094 5

1

8

17

16

19

Standard Material Parts ListNO. DESCRIPTION MATERIAL NO. DESCRIPTION MATERIAL1 BODY WCB/CF8M 11 GROUND SPRING 316SS2 ADAPTER WCB/CF8M 12 STEM PACKING PTFE/GRAFOIL3 STEM CS+ENP/316SS 13 GROUNDING WASHER GRAPHITE4 BALL CS+ENP/316SS 14 GLAND FOLLOWER 316SS5 BODY GASKET 316SSW/GRAPHITE 15 PACKING RETAINER ASTM A351Gr. CF8M6 SEAT PTFE/R-PTFE 16 PACKING GLAND STUD ASTM A193Gr. B7/Gr.B87 THRUST BEARING PTFE 17 PACKING GLAND NUT ASTM A194Gr. 2H/Gr.88 STOP PLATE ASSY. SS 18 STEM WASHER 316SS9 HEX NUT ASTM A194Gr. 2H/Gr.8 19 HANDLE ASSY. CS/SS/DI10 STUD ASTM A193Gr.B7/Gr.B8

-

F8 Universal Floww w w. u f v a l v e . c o mF8

6”FP ~ 12”RP CL.150 F Series Ball Valve

EZISA B C D E H L G BB Y TW

hcni mm hcni mm hcni mm hcni mm hcni mm hcni mm hcni mm hcni mm hcni mm hcni mm sbl gk

PF"6 6 251 5.51 493 57.7 9.691 11 972 18.01 6.472 54.1 8.63 57.0 1.91 03 267 36.21 8.023 81 064 912 99

PR"8 6 251 5.11 292 21.5 031 5.31 343 18.01 6.472 54.1 8.63 57.0 1.91 03 267 36.21 8.023 42 016 802 49

PR"8 6 251 81 754 9 922 5.31 343 18.01 6.472 54.1 8.63 57.0 1.91 03 267 36.21 8.023 42 016 862 221

PF"8 8 302 81 754 9 922 5.31 343 52.41 0.263 72.2 7.75 26.0 7.51 - - 36.21 8.023 42 016 893 081

PR"01 8 302 31 033 52.6 951 61 604 52.41 0.263 72.2 7.75 26.0 7.51 - - 36.21 8.023 42 016 514 881

PR"01 8 302 12 335 5.01 762 61 604 52.41 0.263 72.2 7.75 26.0 7.51 - - 36.21 8.023 42 016 074 312

PF"01 01 452 12 335 5.01 762 61 604 14.71 2.244 60.3 7.77 26.0 7.51 - - 36.41 6.173 42 016 085 362

PR"21 01 452 41 653 7 871 91 384 14.71 2.244 60.3 7.77 26.0 7.51 - - 36.41 6.173 42 016 095 862

PR"21 01 452 42 016 21 503 91 384 14.71 2.244 60.3 7.77 26.0 7.51 - - 36.41 6.173 42 016 086 803

Dimensional Data

16 17

15

1

4 5 9 610

2

11

7

18

12

3

14

13

8

19

20

Standard Material Parts ListNO. DESCRIPTION MATERIAL NO. DESCRIPTION MATERIAL1 BODY WCB/CF8M 11 GROUND SPRING 316SS2 ADAPTER WCB/CF8M 12 STEM PACKING PTFE/GRAFOIL3 STEM CS+ENP/316SS 13 GROUNDING WASHER GRAPHITE4 BALL CS+ENP/316SS 14 GLAND FOLLOWER 316SS5 BODY GASKET 316SS W/GRAPHITE 15 PACKING RETAINER ASTM A351Gr. CF8M6 SEAT PTFE/R-PTFE 16 PACKING GLAND STUD ASTM A193Gr. B7/Gr.B87 THRUST BEARING PTFE 17 PACKING GLAND NUT ASTM A194Gr. 2H/Gr.88 STOP PLATE ASSY. CS/SS 18 STEM WASHER 316SS9 HEX NUT ASTM A194Gr. 2H/Gr.8 19 HANDLE ASSY. CS/SS/DI10 STUD ASTM A193Gr.B7/Gr.B8 20 HAND WHL/GEAR OP. CS/DI

-

Universal Floww w w. u f v a l v e . c o m

F9

1”FP ~ 6”RP CL.300 F Series Ball Valve

Standard Material Parts ListNO. DESCRIPTION MATERIAL NO. DESCRIPTION MATERIAL1 BODY WCB/CF8M 11 GROUND SPRING 316SS2 ADAPTER WCB/CF8M 12 STEM PACKING PTFE/GRAFOIL3 STEM CS+ENP/316SS 13 GROUNDING WASHER GRAPHITE4 BALL CS+ENP/316SS 14 GLAND FOLLOWER 316SS5 BODY GASKET 316SS W/GRAPHITE 15 PACKING RETAINER ASTM A351Gr. CF8M6 SEAT PTFE/R-PTFE 16 PACKING GLAND STUD ASTM A193Gr. B7/Gr.B87 THRUST BEARING PTFE 17 PACKING GLAND NUT ASTM A194Gr. 2H/Gr.88 STOP PLATE ASSY. CS/SS 18 STEM WASHER 316SS9 HEX NUT ASTM A194Gr. 2H/Gr.8 19 HANDLE ASSY. CS/SS/DI10 STUD ASTM A193Gr.B7/Gr.B8

EZISA B C D E U K L H TW

hcni mm hcni mm hcni mm hcni mm hcni mm hcni hcni mm hcni -mm hcni mm sbl gk

PF"1 1 52 5.6 561 5.3 98 88.4 421 9.2 86 - - 88.5 0.051 - - 073.0/273.0 04.9/54.9 0.22 0.01

PF"5.1 5.1 83 5.7 191 35.3 7.98 31.6 7.551 96.3 7.39 5.51 493 48.9 0.052 83.0 7.9 373.0/673.0 84.9/55.9 8.52 7.11

PR"2 5.1 83 5.8 612 52.4 0.801 5.6 561 96.3 7.39 5.51 493 48.9 0.052 83.0 7.9 373.0/673.0 84.9/55.9 3.82 8.21

PF"2 2 15 5.8 612 52.4 0.801 5.6 561 15.4 6.411 5.51 493 48.9 0.052 44.0 2.11 373.0/673.0 84.9/55.9 8.43 8.51

PR"3 2 15 31.11 7.282 65.5 2.141 52.8 6.902 15.4 6.411 5.51 493 48.9 0.052 44.0 2.11 373.0/673.0 84.9/55.9 5.25 8.32

PF"3 3 67 31.11 7.282 28.5 8.741 52.8 6.902 60.6 9.351 02 805 57.51 0.004 44.0 2.11 076.0/476.0 20.71/11.71 8.87 7.53

PR"4 3 67 21 503 6 251 01 452 60.6 9.351 02 805 57.51 0.004 44.0 2.11 076.0/476.0 20.71/11.71 8.401 5.74

PF"4 4 201 21 503 6 251 01 452 42.7 9.381 02 805 57.51 0.004 26.0 7.51 168.0/568.0 78.12/79.12 5.921 7.85

PR"6 4 201 88.51 304 49.7 202 5.21 813 42.7 9.381 02 805 57.51 0.004 26.0 7.51 168.0/568.0 78.12/79.12 5.261 7.37

-mm

Dimensional Data

15 17 16 3

14

1312

18

7

11

6

1

2

4 5 9 10

8

17

16

19

-

F10 Universal Floww w w. u f v a l v e . c o mF10

6”FP ~ 10”RP CL.300 F Series Ball Valve

EZISA B C D E H L G BB Y

hcni mm hcni mm hcni mm hcni mm hcni mm hcni mm hcni mm hcni mm hcni mm hcni mm sbl gk

PF"6 6 251 88.51 4.304 49.7 7.102 5.21 813 57.21 9.323 72.2 7.75 26.0 7.51 84 9121 36.21 8.023 42 016 352 511

PR"8 6 251 5.61 914 26.6 861 51 183 57.21 9.323 72.2 7.75 26.0 7.51 84 9121 36.21 8.023 42 016 492 331

PR"8 6 251 57.91 205 88.9 152 51 183 57.21 9.323 72.2 7.75 26.0 7.51 84 9121 36.21 8.023 42 016 633 251

PF"8 8 302 57.91 205 88.9 152 51 183 61 604 60.3 7.77 26.0 7.51 - - 36.41 6.173 42 016 425 732

PR"01 8 302 81 754 8.6 371 5.71 544 61 604 60.3 7.77 26.0 7.51 - - 36.41 6.173 42 016 345 642

PR"01 8 302 4.22 965 2.11 482 5.71 544 61 604 60.3 7.77 26.0 7.51 - - 36.41 6.173 42 016 516 872

WT

Dimensional Data

16 17

15

1

4 5 9 610

2

11

7

18

12

3

14

13

8

19

20

F10

Standard Material Parts ListNO. DESCRIPTION MATERIAL NO. DESCRIPTION MATERIAL1 BODY WCB/CF8M 11 GROUND SPRING 316SS2 ADAPTER WCB/CF8M 12 STEM PACKING PTFE/GRAFOIL3 STEM CS+ENP/316SS 13 GROUNDING WASHER GRAPHITE4 BALL CS+ENP/316SS 14 GLAND FOLLOWER 316SS5 BODY GASKET 316SS W/GRAPHITE 15 PACKING RETAINER ASTM A351Gr. CF8M6 SEAT PTFE/R-PTFE 16 PACKING GLAND STUD ASTM A193Gr. B7/Gr.B87 THRUST BEARING PTFE 17 PACKING GLAND NUT ASTM A194Gr. 2H/Gr.88 STOP PLATE ASSY. CS/SS 18 STEM WASHER 316SS9 HEX NUT ASTM A194Gr. 2H/Gr.8 19 HANDLE ASSY. CS/SS/DI10 STUD ASTM A193Gr.B7/Gr.B8 20 HAND WHL/GEAR OP. CS/DI

-

F11Universal Floww w w. u f v a l v e . c o m

2”RP ~ 6”FP CL.600 F Series Ball Valve

Standard Material Parts ListNO. DESCRIPTION MATERIAL NO. DESCRIPTION MATERIAL1 BODY WCB/CF8M 9 STUD ASTM A193Gr.B7/Gr.B82 ADAPTER WCB/CF8M 10 GROUND SPRING 316SS3 STEM CS+ENP/316SS 11 STEM PACKING PTFE/GRAFOIL4 BALL CS+ENP/316SS 12 GLAND A1055 BODY GASKET 316SS W/GRAPHITE 13 HANDLE ASSY. CS/SS/DI6 SEAT PTFE/R-PTFE7 THRUST BEARING PTFE8 HEX NUT ASTM A194Gr. 2H/Gr.8

Dimensional DataEZIS

A

2" RP

2" FP

3" RP

3" FP

4" RP

4" FP

6" RP

6" FP

1.5

1.97

1.97

3

3

4

4

5.91

38

50

50

76

76

102

102

150

11.5

11.5

14

14

17

17

22

22

292

292

356

356

432

432

559

559

B

6.5

6.5

8.25

8.25

10.75

10.75

14

14

165

165

210

210

273

273

356

356

D

5.91

6.5

6.5

7.48

7.48

8.47

8.47

10.83

150

165

165

190

190

215

215

275

E

17.72

17.72

17.72

27.56

27.56

35.43

35.43

47.24

450

450

450

700

700

900

900

1200

G WT

46

55

77

90

174

179

348

492

21

25

35

41

79

81

158

223

inch mm inch mm inch mm inch mm inch mm lb kg

F11

E

12

G

313

11

AD

7 11

1 6 4 5 8 9 2

-

F12 Universal Floww w w. u f v a l v e . c o m

Available Options

F12

Cryogenic ServiceUF can manufacture and supply ball valves for cryogenicservice with extended stems (customer specified lengths).

Sour Gas ServiceAll UF ball valves can be furnished to meet the requirementsof NACE MRO175 when required.

Operational ExtensionsUF ball valves will accept complete operational extensionsto include body bleed and sealant injection functions.

ActuationUF ball valves permit easy adaptation of manual, electric,hydraulic, or pneumatic actuators.

Live-Load Body BoltingBody to bonnet bolting can be live-loaded withbellevile spring washers for applications whererapid temperature fluctuations could cause possiblejoint leakage.

-

Universal Floww w w. u f v a l v e . c o m

Torque Factors

ledoM I II III VI V

oitaR 1:05 1:08 1:07 1:092 1:023

tuptuO.xaM)MN(euqroT

0021 0052 0054 0005 0007

Elements affecting the valve torque...The torque value of soft seated ball valves depends on the following main factors.

1. Valve design and material selection• Seat design and material selection

The “self compensation for swell” results in low torque and maximum flexibility.The friction force depends on the seat material.

• Floating ball design or trunnion mounted ball design:For trunnion mounted ball valve, the fluid load is carried by the trunnion bearing,which is PTFE lined. The PTFE lined bearings insure smooth long-life operationand result in an overall lower torque.

2. Service conditions• Pressure differential:

For size over 1” ball valve, the torque will increase substantially with any rise in pressure.• Operation frequency:

If a valve remains in the closed position under differential pressure for extended periods of time, the torque will increase due to cold flow of the resilient material.

• Fluid medium influence:The torque tends to be lower with oil medium.

• Temperature influence:Within the operating temperature range, the torque will remain constant except at low temperature levels, when the seat becomes more rigid.

• Operating limitation:Resilient materials such as PTFE and R-PTFE can be damaged by fast rotation of the ball while under pressure.

Actuator selection is based on torque value. Electric and pneumatic actuators can be sizedand mounted on valves on request.

Manual Gear Operators

Torque Ratings of Gear Operators

For operating torque over 2830 IN-LBS, UF recommends manual gear operators. The gearoperators are fully enclosed and equipped with anindicator to show the position of the ball. Handleextensions, chain sprockets or right angle drivesare available on request.

F13

-

F14 Universal Floww w w. u f v a l v e . c o mF14

Ball Valve Material Specification

LAIRETAMMTSA

.CEPS

NOITISOPMOCLACIMEHC SEITREPORPELISNET SSENDRAHBHXAMC

XAMnMXAM

PXAM

SXAM

iSXAM

rC oM iN rehtO RISK

SISK

IA%

C%

BCW 03.0 00.1 40.0 540.0 6.0 5.0< 2.0< 50.< 07 63 22 53

BCL 03.0 00.1 40.0 540.0 6.0 5.0 2.0 5.0 07 63 22 53

8FC 80.0 5.1 40.0 40.0 0.20.810.12-

5.00.80.11-

07 03 53

M8FC 80.0 5.1 40.0 40.0 5.10.810.12-

0.20.3-

0.90.21-

07 03 03

3FC 30.0 5.1 40.0 40.0 0.20.710.12-

50.00.80.21-

07 03 53

M3FC 30.0 5.1 40.0 40.0 5.10.710.12-

0.20.3-

0.90.31-

07 03 03

501A 53.006.050.1-

40.0 50.0 53.0 --- --- --- 07 63 03 03

403 80.0 0.2 40.0 30.0 0.10.810.02-

---0.80.11-

57 03 04 05

613 80.0 0.2 40.0 30.0 0.10.610.81-

0.20.3-

0.010.41-

57 03 04 05

L403 530.0 0.2 40.0 30.0 0.10.810.02-

---0.80.31-

57 03 04 05

L613 530.0 0.2 40.0 30.0 0.10.610.81-

0.20.3-

0.010.51-

57 03 04 05

014 51.0 0.1 40.0 30.0 0.15.115.31-

--- --- 001 08 51 54

024 51.0> 0.1 40.0 30.0 0.10.210.41-

--- ---

7B73.094.0-

56.001.1-

530.0 40.051.053.0-

57.002.1-

51.052.0-

--- 521 001 61 05

M7B73.094.0-

56.001.1-

530.0 40.051.053.0-

57.002.1-

51.002.1-

--- 501 08 81 05 532

H2 4.0> 0.1 40.0 50.0 40.0 --- --- ---

8B 80.0 00.2 540.0 30.0 00.10.810.02-

---0.85.01-

57 03 03 05 322

M8B 80.0 00.2 540.0 30.0 00.10.610.81-

0.20.3-

0.010.41-

57 03 03 05 322

8 80.0 00.2 540.0 30.0 00.10.810.02-

---0.85.01-

7L83.084.0-

57.000.1-

40.0 40.051.053.0-

08.000.1-

51.052.0-

--- 521 501 61 05

M7L83.084.0-

57.000.1-

40.0 40.051.053.0-

08.000.1-

51.052.0-

--- 001 08 81 05

-

Universal Floww w w. u f v a l v e . c o m

F15

Ball Valve Material Specification

Specifications for Seat MaterialsseitreporP nirleD nolyN EFTP EFTP-R )4TH(KEEP NOLVED

epyT rodedloM denihcaMtsaC,dedloM

denihcaMrorodedloM

denihcaMrodedloM

denihcaMrodedloM

denihcaMrotsaCdenihcaM

ytivarGcificepS 24.1-04.1 20.0±20.1 61.2 03.2-22.2 43.1-03.1 41.1ssendraH

)0422DMTSA(5±021-R**

stniop 5±57D 5±85D 5±06D 5±58D 1±97D

elisneT)isp(htgnertS 0057-0066 )nim(0008 0042-0012 )nim(0464 )nim(000,11 295,11

etamitlU)%(noitagnolE 032-091

)"6

-

F18

Contact Information

Universal Flow ValveCorporation