Typical lithium cell TPort Washington, N.Y.

Transcript of Typical lithium cell TPort Washington, N.Y.

MACHINE DESIGN www.machinedesign.com76 • JUNE 16, 2005

EMBEDDED SYSTEMS INDUSTRY FOCUSEdited by Leland Teschler

Sol JacobsTadiran BatteriesPort Washington, N.Y.

The world is going wireless.Currently, there are approx-imately 80 million wireless-monitoring systems in useworldwide, serving applica-

tions ranging from building automa-tion to vibration-monitoring systemsand mesh networks.

Oak Ridge National Laboratory re-cently outlined 12 top requirementsfor an ideal wireless sensor. Re-searchers there concluded that thenumber-one criterion was the needfor an adequate battery life, followedby the need to be self-powered andsmall. This study makes clear howimportant battery technology is forpractical wireless sensors.

Of all battery technologies cur-rently available, lithium is consid-ered the best choice for remote wire-less sensors. Household alkalinebatteries have low initial voltagesand high self-discharge. In contrast,lithium chemistries feature the high-est energy density (energy per unitweight and energy per unit volume)of all battery types.

To conserve power, wireless de-vices can be designed to remain in asleep mode, which requires littlebackground current (usually on theorder of hundreds of microamps orless). These devices then wake up totransmit or receive data.

The power dissipation qualities ofsome wireless sensors are that of lowpower consumption in sleep mode,followed by a large spike when active.

Lithium power sourcescan last 20 years, justthe thing for embeddedsensors that must workreliably for longperiods.

BatteriesFOR LIFE

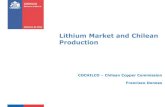

Positive terminal

Plastic cover

Welding seam

Insulator

Cell cover

Current collector

Lithium anode

Cathode

Separator

Insulating sleeve

Cell can

Negative terminal

Glass-to-metal seal

Typical lithium cell

The cross section of a typical bobbin-type lithium cell reveals details oftheir construction. The anode is typically lithium foil pressed onto theinner surface of the cell. The separator between the anode and cathodeis nonwoven glass that allows ions to move between the electrodes. Thecathode is porous Teflon-bonded carbon powder. Thyonyl chloridecathodic reduction takes place on the cathode surface when a load isconnected. The electrolyte is a solution of lithium aluminum tetrachloridein thionyl chloride. The current collector makes an electrical connectionbetween the porous carbon cathode and the positive terminal of thebattery. The can and cover are typically nickel-plated cold-rolled steel.The cell cover is welded to the cell can by a laser seam-welding process.

MACHINE DESIGN www.machinedesign.com78 • JUNE 16, 2005

EMBEDDED SYSTEMS INDUSTRY FOCUS

LITHIUM BATTERIES IN ACTIONInvocon Inc. in Conroe, Tex. (invocon.com), manufactures Multiple-Input, Tiny, EnhancedWireless Instrumentation Systems (MITE-WIS) devices used to monitor repaired concrete sectionsof the Westerschelde River Tunnel in the Netherlands. A MITE-WIS unit is embedded into the con-crete repair patch each time a concrete repair is made. Fireproofing maintains its integrity andthere is no need for large cables to pass through the concrete, which would otherwise create weakpoints for heat to reach the primary tunnel wall.

MITE-WIS units identify potential structural failures by sensing strain variations across theboundaries of concrete patches. Lithium batteries provide up to two years of service life for a sam-pling rate of three separate channels per minute. Each unit can store up to three months of data,which downloads during monthly maintenance procedures.

American Millennium Corp. (AMCi) in Golden, Colo. (amc-wireless.com) manufactures de-vices that interact with GPS/GEO satellites to monitor a variety of applications, including pipelinesand gas compressors. Alkaline batteries are problematic here because the SatAlarm-Sentry systems

would need 20 D-sized alkaline cells. Temperaturerange is also an issue because the capacity of an al-kaline cell drops by 60% at –10°C.

Instead, four D-sized lithium-thionyl-chloridecells plus four hybrid-layer capacitors (HLCs) sup-ply power. SatAlarm devices deliver high-currentpulses for short intervals and otherwise remain in apower-save stand-by mode. The hybrid lithium’s ex-tended temperature range of –40 to 85°C lets themonitoring devices perform continuously in severeclimates.

Hexagram Inc., Cleveland (hexagram.com),manufactures automatic meter-reading (AMR) sys-tems that handle gas, electric, and water meterreading remotely. STAR meter-transmitter units usenarrow-band radio signals to communicate with anetwork of data-collection units mounted on build-ings or utility poles. To conserve energy, a timerpowers up the unit and transmits data at pro-grammed intervals. Over 2 million units are now inthe field powered by lithium-thionyl-chloride bat-teries. Units installed 20 years ago are still operat-ing with over 75% of their original capacity. Lowself-discharge gives the batteries a proven 20-yearlife in this application, and their extended tempera-ture range is compatible with outdoor installations.

Oceantronics Inc. in Honolulu (oceantron-ics.net), manufactures GPS tracking/sensing de-vices. One of the applications for these tracking de-vices are in ice buoys used to track global climatechange on ice floating on the Arctic Ocean. The firstsuch buoys carried battery packs made from 380 al-kaline D cells. The batteries weighed 54 kg and op-erated for about a year. These have since been re-placed by battery packs containing 32 lithium-thionyl-chloride D cells and four hybrid layer ca-pacitors. The new batteries weigh about 90% lessthan the old ones. The logistics of shipping a muchsmaller and lighter unit are also simplified, which isextremely important to technicians working in frigidArctic waters. Several smaller lithium packs can beused in sequence to extend the operational life ofthe system.

Cross sectionGrout

Tunnel wallMITE-WIS

FireproofingNonformal sensor

Tunnel interiorRepaired area

A wireless MITE-WIS unit embedded in a concrete repairpatch enables fireproofing material to maintain itsintegrity by eliminating the need for large cables to passthrough tunnel-wall concrete, which would otherwisecreate weak points for heat infiltration.

Hexagram STAR meter-transmitterunits contain lithium cells that are stilloperating after 20 years in the field.

MACHINE DESIGN www.machinedesign.com79 • JUNE 16, 2005

EMBEDDED SYSTEMS INDUSTRY FOCUS

This is because they draw a high current in activemode, perhaps on the order of amps for periodsranging from a fraction of a second to a few minutes.

Such behavior is particularly true for devicestransmitting signals to receivers located some dis-tance away. One example is that of GPS-enabledbuoys. Buoys may periodically read their positionfrom GPS satellites, then report back via a burstradio transmission to a receiving station milesaway. Current draw can reach several amperes foras much as a few seconds in such cases. But thedelivery of these pulses presents technical chal-lenges even to some kinds of lithium cells.

These challenges are most applicable to bob-bin-type lithium cells. Such cells are particularlywell suited for remote use thanks to their high ca-pacity, small size, and an ability to withstandbroad fluctuations in pressure, temperature, andshock. Bobbin cells, for example, are well suitedfor wireless applications fielded under the Zigbeestandard. Wireless sensors following the Zigbeeformat can use single-chip transceiver chips thatoperate from under 20 mA in both transmit andreceive modes.

Nevertheless, the low-rate design that givesbobbin-type lithium cells a long life impedes theirability to deliver the large currents that somekinds of remote applications demand. Contribut-ing to this problem is a build-up of solid elec-trolyte interface (SEI) on the lithium anode,which is part of the internal battery. This reduc-tion becomes even more significant when the cellsare stored at elevated temperatures.

A few years ago, Tadiran developed a hybridbattery called PulsesPlus. It combines a bobbin-type cell with a patented high-rate, low-imped-ance HLC (hybrid layer capacitor). This hybridsystem delivers extremely high currents with agenerous safety margin. The HLC can supply acontinuous current of up to 2A with maximumpulses of up to 5A.

INSIDE THE CELLIt is useful to review how lithium cells are con-

structed. All lithium cells use a nonaqueous elec-trolyte. Their nominal open-circuit voltages(OCVs) range between 2.1 and 3.9 V. Lithiumcells also feature extended operating temperatureranges, with some lithium-based cells capable ofoperating at up to 150°C.

However, lithium batteries are not all alike. Pri-mary cells can employ a variety of l i thiumchemistries including: Li/CFx (lithium poly car-bon monofluoride); Li/MnO2(lithium manganesedioxide); Li/SO2 (lithium sulfur dioxide); andLi/SOCL2 (lithium thionyl chloride).

Lithium thionyl chloride is the chemistry foundin the bobbin-type cells often employed with wire-less applications. These 3.6-V cells feature the

highest energy density and voltage of all lithiumchemistries, with up to 20 years of service life.Bobbin-type lithium thionyl chloride cells offerextended temperature ranges of –55 to 85°C, withsome models going to 150°C. While the theoreti-cal service life of a lithium thionyl chloride cellcan exceed 20 years, the actual service life variesdepending on the manufacturer.

The combination of an HLC with a bobbin cellenables the PulsesPlus to exhibit qualities of botha battery and a capacitor. Specifically, the capaci-tor portion of the PulsesPlus cell eliminates thevoltage drop that would otherwise take placewhen loads draw significant pulse current. Thebattery portion of the cell supplies long-term, rel-atively low currents. Pulsed loads initially drawcurrent from the capacitor rather than the battery.The capacitor and the battery are electrically inparallel.

An alternative to using a PulsesPlus cell wouldbe to synthesize this behavior by using a discreetcapacitor with a separate primary cell. The prob-lem with using conventional capacitors in such arole is that they are necessarily bulky; it takes alarge capacitor to supply enough energy for timeperiods that can extend to minutes, as with somepulse-type loads. Moreover, the larger the capaci-tor, the larger the rate of charge leakage. So the

Converting toPulsesPlusbattery packslet GPS buoysreplace 380D-sizealkaline cellswith 32lithium D-cellsplus 4 AA-sizedcapacitors.

MACHINE DESIGN www.machinedesign.com80 • JUNE 16, 2005

EMBEDDED SYSTEMS INDUSTRY FOCUS

capacitor is constantly discharging the cell, albeitat a low rate.

Some designs also try handling pulses throughuse of what are often dubbed supercapacitors inparallel with the primary cell. Supercapacitorsare electrochemical capacitors. They store chargein a bulk electrolyte rather than on plates. Thisconstruction lets them be physically smaller thanconventional plate-type caps. The problem withsuch devices is that they generally exhibit high im-pedance, which may limit the magnitude of the in-stantaneous current they can supply for a pulse.Supercapacitors are made up of individual 2.3-Vunits which have balancing problems whenplaced in series for higher voltages. Leakage cur-rent can be a problem as well.

In contrast, the HLC uses a special structurethat eliminates the usual difficulties associatedwith supercapacitors. HLCs are made specificallyto work in the 3.6 to 3.9-V nominal range and aremade with only one unit.

CELL QUALITIESService life mainly depends on the cell’s self-

discharge rate, which is governed by the chemicalcomposition of the electrolyte, manufacturingprocesses, as well as mechanical and environ-mental considerations. Self-discharge can bemade worse by high levels of impurities in theelectrolyte. Extreme temperatures can also re-duce battery performance, affecting both voltageand self-discharge rate.

Lithium battery performance can also be hin-dered by the cell’s internal impedance. This internalresistance is developed by the electrolyte, the anode,and the cathode. Experienced battery manufacturers

know how to effectively control impedance byblending special additives with the electrolyte.

There are several other lithium chemistries thatare useful as primary cells and may be candidatesfor specific kinds of uses. Li/CFx cells have anOCV of 3.0 V and moderate energy density. Cylin-drical types use a spiral cathode for higher ratecapability and have crimped plastic seals. Thoughgenerally safe, the elastomer seal can break underconditions of extremely high temperature and hu-midity, causing cell failure.

LiMnO2 cells are 3.0-V devices that resembleLi/CFx cells both in construction as well as perform-ance related to high temperatures and humidity.Their energy density and voltage is slightly betterthan Li/CFx cells, especially at cold temperatures.

Li/SO2 cells are also 3.0-V devices that deliverhigh current, especially at cold temperatures.Their main drawback, for wireless devices, is highself-discharge and reduced capacity. The servicelife and energy density of Li/SO2 cells are typicallyhalf that of lithium-thionyl-chloride cells. ■

MAKE CONTACT:Tadiran, (516) 621-4500, Fax: (516) 621-4517,

www.tadiranbat.com

We want your feedback.Did you find this material interesting? Circle 701Do you want more information of this type? Circle 702Comment via e-mail to [email protected] related topics would you like to see covered? Whatadditional information on this topic would you find useful?

Bobbin-type Li/SOCl2 cellscombined with a HybridLayer Capacitor together

form PulsesPlus batteries thatcan handle applications

drawing ampere-level current pulses.