Types of gears

-

Upload

nilkanth-shirodkar -

Category

Documents

-

view

8.786 -

download

3

description

Transcript of Types of gears

Mechanical Engineering Dept. 1

Gears

Mechanical Engineering Dept. 2

Applications of Gears

• Control gears – long life, low noise, precision gears

• Aerospace gears – light weight, moderate to high load

• Power transmission – long life, high load and speed

• Appliance gears – long life, low noise & cost, low to moderate load

• Toys and Small Mechanisms – small, low load, low cost

Mechanical Engineering Dept. 3

Mechanical Engineering Dept. 4

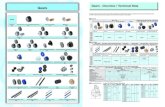

Types of Gears

Spur gears – tooth profile is parallel to the axis of rotation, transmits motion between parallel shafts.

Pinion (small gear)

Gear (large gear)

Internal gears

– teeth are inclined to the axis of rotation, the angle provides more gradual engagement of the teeth during meshing, transmits motion between parallel shafts.

Helical gears

Mechanical Engineering Dept. 5

Types of Gears

Bevel gears – teeth are formed on a conical surface, used to transfer motion between non-parallel and intersecting shafts.

Straight bevel gear

Spiral bevel gear

Mechanical Engineering Dept. 6

Types of Gears

Worm gear sets – consists of a helical gear and a power screw (worm), used to transfer motion between non-parallel and non-intersecting shafts.

Rack and Pinion sets – a special case of spur gears with the gear having an infinitely large diameter, the teeth are laid flat.

Rack

Pinion

7

Types of gears

Mechanical Engineering Dept. 8

Nomenclature of Spur Gear Teeth

= (tooth spacing)driven gear – (tooth thickness)driver , measured

on the pitch circle.

Backlash

Pitch circle gear diam.

Fillet radiusClearance

Base Circle

Mechanical Engineering Dept. 9

Useful Relations

P = N / d

P = diametral pitch, teeth per inch

N = number of teeth

d = pitch diameter (gear diameter)

m (module, mm) = d / N

Metric system

p (circular pitch) = πd / N

Pp = π

Mechanical Engineering Dept. 10

Standard Tooth SpecificationsPressure angle

Two mating gears must have the same diametral pitch, P, and pressure angle, φ.

Pitch line

Line of centers

Line of action

Base circle

Base circle

Pitch circle

Pitch circle

Pressure angle φ

Standard pressure angles, 14.5o (old), 20o, and 25o

11

Template for teeth of standard gears

12

Standard Gear Specifications

Parameter Coarse pitch (pd=N/d<20)

Fine pitch (pd=N/d>20)

Pressure angle, 200 or 250 (not common) 200

Addendum, a 1/pd 1/pd

Dedendum, b 1.25/pd 1.25/pd

Working depth 2.00/pd 2.00/pd

Whole depth 2.25/pd 2.2/pd+0.002

Circular tooth thickness 1.571/pd (circular pitch/2) 1.571/pd

Fillet radius 0.30/pd Not standardized

Clearance 0.25/pd 0.25/pd+0.002

Minimum width at top land

0.25/pd Not standardized

Circular pitch /pd /pd

Mechanical Engineering Dept. 13

Kinematics of Gear Trains

Conventional gear trains

ω3

ω2=

N2

N3

ω3 ω4= , ω5

ω4=

N4

N5

,

mV = e = train value

Speed ratio

ω5

ω2=

outputinput=

Reverted gear train – output shaft is concentric with the input shaft. Center distances of the stages must be equal.

14

Planetary (or Epicyclic) Gears

• Gears whose centers can move

• Used to achieve large speed reductions in compact space

• Can achieve different reduction ratios by holding different combinations of gears fixed

• Used in automatic transmissions of cars

15

Planetary gear

16

Planet

Carrier

Input shaft

Sun gearRing gear

Components of a planetary gear

17

A variant of a planetary gear

Carrier

18

EngineGear

Propeller, operates at about 100 RPM

Output flange

Engine operates at about 400 RPM

Connecting the main engine to the propeller through a reduction gear

19

Gear box

Synchronizers

Stick shift

The gear box is in first gear, second gear

20

Planetary gears

Planetary gears in automotive transmission

![HP Image Zone Print Job [4/7/2008 2:14 PM 2.343] …vibration.org/Presentation/Dec 2011/Part 2 Types of gears...Helical Gears If a gear was composed of innumerable staggered laminations](https://static.fdocuments.in/doc/165x107/5e817118bfac35181d752d8f/hp-image-zone-print-job-472008-214-pm-2343-2011part-2-types-of-gears-helical.jpg)