TWIN SCREW PRESS - Haarslev

Transcript of TWIN SCREW PRESS - Haarslev

data shee t _ ha arsle v _ 2 .0

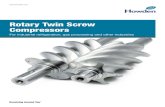

The Haarslev Twin Screw Press ensures efficient mechanical dewatering and reduction of the oil/fat content, which improves processing and increases the energy saving potential.The twin screw press attains a condition of high compression resulting in a low moisture and oil/fat content in the press cake. The Haarslev Twin Screw Press, can be delivered as a biconical or a cylindrical press. One of the advantages of the biconical type is that the flights of one screw reaches almost into the core of the other screw.Minimum slip in the press and a more uniform press cake.

OPERATIONThe twin screw presses are easy to operate, and the performance is easy to monitor through the advanced control system.

The closed design ensures effective deodorisation, and the combination of electronic control and instrumentation enables automatic safeguarding against overload. The variable screw speed provides for the flexibility necessary to cope with various raw materials and capacities.

The screw flights can be manufactured with stainless steel tips, which increase the operation time between maintenance works.

The Haarslev Twin Screw Press is used for pressing liquids from cooked fish or meat

in a wet rendering process.

TWIN SCREW PRESS

DESIGNThe press consists of two interlocking screws enclosed by a strainer shell and surrounded by a cover.The flights’ geometry can be cylindrical or biconical depending on the performance required and the type of material being processed. The screws rotate

in opposite directions, preventing the material from rotating with the screws. The strainer cage consists of perforated stainless steel plates surrounded by mild steel supporting plates, which are supported by heavy steel bridges.The strainer plate holes vary in size of the press from inlet to the outlet from 5 to 1.

DESIGN• Inspection doors on both sides of the cover

in its full length. • The cover and the inspection doors are made

of stainless steel.• The cover is equipped with a suction branch

for vapourisation.

The mild steel frame is supported on feet and is bolted to the gear housing.

Biconical Press are more energy efficient due to higher capacity at the same pm compared to cylindrical Press.

At the inlet end the press screws are supported by self aligning roller bearings. At the other end the shafts are flanged to the main gear shafts.

The twin screw press is supplied with an electric motor, V-belt drive, frequency converter for variable screw speed and a special helical reduction gear, which provides for a long life time.

t win scre w pres s

TYPEDIMENSIONS (mm)

SHIPPING WEIGHT(mt)

INSTALLED POWER(kW)

LENGHT (L) HEIGHT (H) WIDTH (W)

TP24 4400 1250 1030 4 7,5 - 11

MS35 5460 1800 1200 7 11 - 18,5

MS41 4600 2000 1500 9,5 30 - 37

MS49 5700 2400 1950 16 45 - 55

MS56 6700 2500 1870 23 55 - 75

MS64 7400 2800 2100 32 90 - 110

RS64 8350 2800 2100 34 90 - 110

XS88F 8400 2850 2165 46 90 - 132

TECHNICAL SPECIFICATIONS

We reserve the right to alter the specifications at any time without prior notice.

Inlet

OutletPress cake

OutletPress liquid

L

H

W

Inlet

OutletPress cake

OutletPress liquid

L

H

W

HEAD OFFICEHaarslev A/S • Bogensevej 85DK-5471 Søndersø • Denmark

Telephone: +45 63 83 11 00Email: [email protected]

www.haarslev.com

LOCAL EXPERIENCE - GLOBAL PRESENCEPlease contact us or visit our website

to locate the closest sales office.

MASTER YOUR PROCESS