TurningUpTheHeat - Land and Groundwater · 2018-06-22 · Feasibility Results Sample 1 Sample 2...

Transcript of TurningUpTheHeat - Land and Groundwater · 2018-06-22 · Feasibility Results Sample 1 Sample 2...

Turning Up The Heat

Applica2ons of In-‐situ and Ex-‐situ Thermal Remedia2on Techniques on Contaminated Sites

Indirect Thermal Desorption Plant

Andrew Race – Engineering Manager VIC

Veolia Indirect Thermal Desorption Plant

Vacuum distillation process designed to: • Dewater and decontaminate hydrocarbon affected PIW • Recover as much as possible

Important Points • Will not remove metals apart from Hg • Operates under vacuum and inert blanketing • Indirect heating of product using thermal oil jacketing • Potentially other wastes can be treated subject to EPA approval

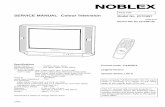

FEEDING UNIT THERMAL OIL HEATING UNIT

DRYER UNIT 1

DRYER UNIT 2

DISCHARGE UNIT

CONDENSER UNIT

COOLING WATER UNIT

DROPLET CATCHER

DUST FILTER VACUUM PUMP CHILLER ACTIVE CARBON

FILTER

DISCHARGE TO ATMOSPHERE

CHILLED WATER UNIT

INERT

CAT B, C NOT SUITABLE FOR

TREATMENT

CAT A NOT SUITABLE FOR

TREATMENT

TO COMPOST

TO LANDFILL

BACK TO EXISTING

TREATMENT PLANT

CAT A, B OR C DROPLET CATCHER

OIL / WATERBACK TO EXISTING TREATMENT PLANT

CLEAN OUTPUT MATERIAL

INERT REUSE OR DISPOSAL

TREATED SOLIDS

FILTER CAKE

LIQUID FLOWS

GASEOUS FLOWS

THERMAL OIL FEED/RETURN

COOLING WATER FEED/RETURN

SOLID FLOWS

WATER

FLAME IONISATION DETECTOR

INSTRUMENTATION

Process Flow Diagram

Vital Statistics

Process Temperature up to 370°C

Process Pressure 800 to 100 mbar (abs) Throughput 20,000 tonnes / annum

2.86 tonnes / hour

Inputs pH > 4.5 Grain size < 30 mm

Output Water with oil Oil with water Inert solid powder

Timeline

1/01/2008 1/06/2015

1/01/2008 -‐ 1/01/2009Pre Feasibility

1/01/2009 -‐ 1/01/2010Feasibility

1/01/2010 -‐ 1/01/2013Detailed Design

1/01/2013 -‐ 27/10/2014Construction

27/10/2014 -‐ 30/12/2014Commissioning

Feasibility Study

Feasibility Results

Sample 1 Sample 2 Sample 3 Sample 4

Totals (mg/kg) IW Cat C Cat B Input Output Input Output Input Output Input Output

TPH C6-C9 325 650 2600 0.023 0.01 14 2.64 1.136 0.486 1.378 0.2508

TPH C10-C36 5000 10000 40000 2020 164.6 166000 2400 51400 5400 32400 2656

Benzo(a)pyrene 5 5 20 19.6 0.546 5.54 0.038 0.34 0.046 0.306 0.048

Sum of PAH 50 100 400 318 5.18 1580 6.54 55.4 2.586 46.8 2.336

Di(2-ethylhexyl)phthalate 40 40 160 0.238 0.2 2.92 0.2 28.6 0.2 14.92 0.2

Detailed Design

Construction

Assembly

Assembly

Assembly

Presentation to ALGA Peter Mirkov – CEO

19 November 2014

Page 16

Agenda

Introduction to RENEX RENEX Project Overview Project Challenges Industry Interaction Regulatory Support and/or enforcement

Page 17

Introduction to RENEX

Project Background Victorian government mandate to eliminate high hazard waste to landfill by 2020 Contaminated soil represents the single largest source of hazardous waste sent to landfill Lack of existing treatment options for Contaminated Soils and other Prescribed Industrial Wastes Victorian Legislation focusing on Waste Management Hierarchy & Resource Recovery Although project was driven by Victorian legislation and market, treatment opportunities for wastes from across Australia exist and are expected to be utilised

Page 18

Introduction to RENEX

Who is RENEX A newly created business focusing on providing an Industrial Waste Treatment & Resource Recovery Facility (emphasis on Soils and Prescribed Industrial Wastes) Ownership

– Funds Managed by CleanTech Ventures • Victorian Clean Technology Fund • Cleantech Australia Fund

– Macquarie Bank – OPTrust – Private Investors

Page 19

RENEX Project Overview • Permanent facility for the treatment of up to 100,000 tonnes per annum of

contaminated soil and other PIWs (Other PIWs will include PCB oils, waste oils, as well as shredder floc from car recycling, tyres)

• 4 Ha site in Dandenong South

• 11,000 m2 under roof

• Storage capacity for up to 30,000 tonnes of contaminated soil

• Facility has complete mechanical pre-treatment capability – crushing, screening, metal removal - ability to receive concrete, bricks, rubble, plastic, tyvek suits, timber etc. “If it can be transported, we can accept it”.

• Modelled throughput at 10 tonnes per hour. • Materials pre-dried – full treatment capacity maintained, receive materials up to

sludge consistency (40+% moisture) • Facility is being commissioned in several major stages

Stage 1 – license to receive & store Soils & other PIWs (EPA approval 6th Nov 2013)

Stage 2 – EPA 30A approval to treat stockpiled soils – (EPA approval 3rd Nov 2014)

Stage 3 – EPA 20 Operating License – (Expect EPA approval Mar/Apr 2015)

Page 20

RENEX Project Overview

Insert RENEX site diagram

Page 21

RENEX Project Overview

What can RENEX treat? The facility can treat all organics (including volatile metals such as mercury) and at very high concentrations

– Phenols – Aromatic hydrocarbon – Petroleum hydrocarbons – Polychlorinated biphenyls (up to 6,000 mg/kg) – Chlorinated hydrocarbons – Organochlorine pesticides – All other organics – Mercury

Project Challenges

• Commenced in 2007 – over 7 years in the making

• So you want to build a Large Scale Thermal Soil & PIW Treatment Facility in Australia, here is what you need:

• Agreement from proven, global technology provider (1-3 years + $) • Identify and secure suitable land and location (1-2 years + $$$) • Local engineering exertise to produce EPA Works Approval Application (1 year + $) • Planning Permit, likely VCAT hearings (1-2 years + $$) • Project Funding, debt not an option as Banks wont talk to you, need expensive equity funding

(2 years + $$$$) • Local engineering, construction and operational capability (1 year + $$) • Build facility and transfer technology (2 years + $$$$$) • Receive largest EPA HazWaste fund of $1m 5 years after being promised (and yet still haven’t

received it all – but very grateful nonetheless)

• Above will take 7+ years and cost $70+ million

Page 22

Regulatory Support and/or enforcement

• EPA extremely supportive in technical management of project commissioning but lack of EPA enforcement commitment produces market uncertainty

• Regulations already gazetted (s.195) and hopefully will be enforced – timing issue with EPA

• Cat A and Cat B prices have reduced by 30%-40% (or more) since RENEX started receiving soil – obviously mostly driven by lowering of landfilling prices, and in some cases interstate movements. RENEX has dropped prices by similar amounts in this time. Is this sustainable? Is this good for our industry?

• Landfill can always be cheaper – but not the best environmental outcome

Page 23

Industry Interaction

• Consultants very supportive – but can create ‘conflict’ when assessing remediation options

• Ensuring that RENEX’s value proposition is communicated to a broad base within each firm

• Site owners have been very keen to look at RENEX as a potential solution – often wishing to contract directly with us

• Cartage companies have been willing to investigate RENEX as a viable solution to landfills where possible

• RENEX’s is not the solution for everything – but is a better solution than landfill

• What ‘value’ should be attributed to a solution that has a greater environmental benefit than landfill? OR What does EPA really mean by “Practically Accessible”

Page 24

Thermal Remediation Drivers for On Site Application

In-situ / Ex-situ By

Andrew Wollen, ERR Representing, GEO INC

What is Gas Thermal Remediation (GTR)? Ø Propane/Natural gas/Diesel Ø Closed heaPng system >> No VOC emissions Ø Soil and groundwater heated by thermal conducPon Ø Treatment temperatures from 50°C to >400°C Ø Treat sand, silt, CLAY, Bedrock, and Groundwater

Ø Vapor extracPon wells remove VOCs Ø VOCs treated by vapor treatment system

Steel Heater Wells

Outer tube

Inner tube

Technical Benefits of Heat

• Vapor pressure of organic materials increase

• Viscosity of separate phase liquids decrease

• Increases desorption • Diffusion rates increase • Solubility increases • Increases biodegradation • Rates of Hydrolysis increase • Thermal Oxidation

NAPL

VOLATILIZATION

Vapo

r&Pressure

DISSOLUTION

Henry’s&C

onstant

VOLATILIZATION

DISSOLUTION

DISSOLUTION

VOLATILIZATIO

N

DISSOLUTION

ADSORPTION������������

������������

Vapor&PressureADSO

RPTION

��������

GROUNDWATER

SOIL

SOIL1GAS

Thermal Conductivity varies by a factor of only 2-4 across all soil types

In-Situ GTR

Ex-Situ GTR

• 36 GTR TCHs • 36 Vapor Extraction Wells • Target Temperature: 200°C • Thermal Treatment Duration: 39 days • Treatment Goal: less than 100 mg/kg total petroleum hydrocarbons

Three Levels of Thermal Treatment

Level of Heating & Contaminant

Target Treatment

Temperature

(°C)

Heating Well

Spacing

(m)

Desiccation of Zone?

Range of Costs (all

inclusive)

($/m3)

1. VOCs: Gentle Heating (BTEX, CVOCs)

<100 4 – 6 No 40-200

2. VOCs (CVOCs, BTEX)

>100 2 – 4 Depends 60-300

3. SVOCs (PCBs, PAHs, BaP, dioxins)

200-300 1.5 – 3 Yes 150-600

Why in-situ Thermal Remediation? Challenging Goals • Rapid schedule • Low clean-up standards in

soil, GW or vapour intrusion • High probability of success • Source zone mass removal • Other options failed

Challenging Sites • Limited access - no

excavation possible • Depth of impacts precludes

excavation • Odour / noise / emissions • Transport risks/costs • Complex mix of COCs • DNAPL below the water

table • LNAPL smear zones • Fractured bedrock • Clay lithology- diffusion

limited condition

Dry Cleaner, Near Railway, Active

Form

er D

ry

Cle

aner

Former D

ry C

leaner

Equipment entry through 1m wide door

Compact Installation

Natural gas, propane, diesel, gasoline

Scalable equipment Site access

Flexibility is key Flexibility has been key for many

projects interna6onally!

• Refrigerated Cooling Compression and Condensation combined with regenerative adsorption

• Condenses VOCs into NAPL • NO UPPER LIMIT for influent

VOC concentration • NO DILUTION! • >99% Removal efficiency

Vapour Treatment C3 Technology or GAC

2014 Cleanup Project Excellence Award

Parsons Brinkerhoff / Huntsman

Thermal Conductive Heating Summary

1. Applicability: soil temperatures < 70C to > 325C 2. Access: where other approaches are constrained

3. Speed: Mobilize and commence operations in weeks not months, small footprint, & often minimal electrical installation required

4. Scalability: very small to very large projects

5. Economics: Very competitive in overall cost $/m3

6. Performance Guarantees are common

Questions?

PANEL SESSION