Turbo Glide

Transcript of Turbo Glide

..

2. Dragging low band.

Car Will Not Move In Reverse Only

1. Low band needs adjusting. 2. Clutch relief valve stuck. 3. Clutch plates binding in hub or

flange. 4. Clutch plates not properly installed. 5. Clutch piston stuck. 6. Reverse band strut broken .

Excessive Slip In All Ranges 1. Low oil level. 2. Manual con trol linkage improperly

adjusted. 3. Oil suction pipe damaged or not seat

ing properly, allowing air to be sucked into pumps.

4. Oil suction screen clogged. 5. Front oil pump worn or damaged. 6. Faulty pressure regulator valve or

gasket. 7. On 1950-52 units, free wheeling

stator rollers or secondary pump not properly assembled.

Excessive Slip In Drive Range Only ( 1950-52 )

1. Manual control linkage improperly adjusted.

2. Worn or burned clutch plates. 3. Defective clutch piston seals. 4. Defective clutch drum oil seals. 5. Defective clutch release valve.

Excessive Slip In Manual Low & First Gear In Drive Range

( 1953-59 ) 1. Improper linkage adjustment. 2. Improper low band adjustment or

broken band. 3. Modulator piston stuck (to 1954) . 4. Accumulator valve stuck. 5. Broken low servo piston ring. 6. Worn clutch drum. 7. Defective servo-to-case gasket. 8. Defective valve body gaskets.

Excessive Slip In Reverse Only 1. Improper linkage adjustment. 2. Improper reverse band adjustmen t,

or broken ban d.

TROUBLE SHOOTING 3. No oil pressu re due to stuck accumu

lator valve, s t uck modulator lever or piston (to 1954) .

4 . B rok en reverse servo piston rin g . 5. D efective valve body gaskets.

Car Creeps In Neutral 1. I mproper linkage adjustmen t. 2 . L ow ban d adju sted too tight. 3. Clutch in operative due to:

(a) Clutch p lates not properly as-sembled.

(b) Clutch plates sticking. (c) Clutch relief valve stuck closed. (d) Defective valve body gasket. (e) Con trol lever not attached t o

manual valve in side transmission.

Car Creeps Forward In Reverse or Backward In Low

1. I mproper manual linkage adjustmen t.

Low-To-Direct Shift Abnormally Rough

1. I mproper low ban d adjustmen t. 2. Worn clutch plates. 3. Clutch plates bin din g in drum or

f la n ge. 4. Modulator piston stuck (to 1954). 5. Inoperative accumulator dump valve. 6. Modulator vacuum line leaking

(1950-54 & 1958-59). 7. Vacuum modulator valve stuck

(1958-59) . 8. T hrottle linkage misadjusted (1955-

57 ).

Engine Races On Low-To-Direct Shift

1. Clutch plates worn or burned. 2 . Modulator spring weak (1950-54 &

1958-59). 3 . Oil passage to clutch restricted. 4. T hrottle lin kage misadjusted (1955-

57).

Rough Shift, Direct To Low 1. I mproper low ban d adjustment. 2. Modulator piston stuck (to 1954). 3. Vacuum modulator v a 1 v e stuck

(1958-59) .

4 . T hrottle linkage misadjusted (1955-57) .

No Upshift In Drive Range ( 1953-59 )

1 . D efective governor. 2. Stuck shift valve. 3. Clutch p lates worn or burn ed.

No Down Shift From Direct-To-Low With Accelerator Floored

( 1953-59) 1. T hrottle lin kage misadjusted. 2. Sticky shifter valve .

Rough Shift, Neutral to Reverse 1. Accum u lator piston stuck closed. 2. Improper reverse ban d adjustment. 3. Modulator piston stuck (to 1954). 4. E n gin e idlin g speed too high. 5. Excessive end play in tran smission .

mainshaft.

Chatter In Manual Low ( 1950-52 ) Chatter In Manual Low & First Gear Drive Range ( 1953-59 )

1. I mproper low ban d adjustmen t. 2. Worn low ban d or drum. 3 . Defective clutch plates. 4. Clutch piston stuck. 5 . Clutch relief valve stuck.

Chatter In Reverse 1. Improper reverse ban d adjustment. 2. Worn reverse ban d or drum. 3 . Worn or damaged reverse ring gear

bushin g . 4. Worn or damaged transmission case

rear bushin g.

Bu:z::z:ing In All Ranges 1. Low oil level. 2. Fron t andj or rear pump not fun c

tion ing properly .

Ringing Noise In Converter 1. Low oil level. 2. Oil suction pipe damaged or not

seating properly. 3. Defective pressure regulator valve. 4. Front oil pump worn .

Chevrolet Turboglide Troubles No Drive In Any Selector

Position. Cannot Load Engine 1. Front pump assembled backwards.

No Drive Except In Hill Retard. Cannot Load Engine

1. Both overrun clutches assembled backwards.

No Drive Except In Hill Retard & Reverse. Cannot Load Engine

In Drive 1. Outer overrun clutch assembled

backwards. 2. Forward a nd neutral clutch not ap-

plied due to severe leakage in f orward clutch hydraulic circuit.

Drive Is Poor At Low Speeds, No Reverse, Hill Retard Normal 1. Inner overrun clutch assembled

backwards.

Car Drives Very Slightly In Neutral, Reverse Normal

1. N eutral clutch not released.

Car Drives Normal In Neutral & Drive At Low Speeds, No Reverse 1. F orward clutch not released.

Transmission Will Not "Shift" to Performance Stator Angle

1. Stator control linkage out of adjustmen t.

2. Con verter charging pressure is low for one of the following reasons: a . L eakage which will reduce line

pressure enough to cause pressure regulator valve to shut off converter in line.

b. L eakage in con verter circuit. c . Stator control pressure leaking

to converter out across front oil seal ring or secon d oil seal ring on secon d turbine shaft.

21

TROUBLE SHOOTING

Unable To Push Start 1. Rear oil pump drive pin broken

or missing.

Clutch Slippage On Wide Open Throttle Starts

1. Low oil pressure due to leakage. Especially check forward pressure tube "0" ring.

2. Mechanical interference which will prevent forward or neutral piston to fully apply.

3. Neutral or forward clutch facing bond failure .

Second Turbine Seal Ring Lands Interfering With I.D. of Stator

Shaft 1. Case locating dowels on engine or

dowel holes in case mislocated.

Check by indicating front pump bore in case from crankshaft.

Hill Retard Slow to Apply 1. Control linkage out of adjustment,

preventing manual valve getting into hill retard position.

2. Leakage to hill retard clutch. Check pressure tube "0" ring seals and other sources.

3. Mechanical interference of hill retard piston.

4. Glazed hill retard plates (check neutral clutch for release ) . If neutral clutch does not disengage during hill retard, hill retard plate may be destroyed.

No Drive, Reverse Normal, No Hill Retard

1. Reverse clut ch not disengaged.

Hill Retard Brakes Violently. Stator Checking Pressure Reads

High 1. Vacuum hose disconnected.

Shifts From Standstill Very Slow 1. Check linkage to asqertain that

shift lever is positioned by transmission detents.

2. Accumula tor control valve stuck closed.

3. Leakage in hydraulic system. Check pressure tube " 0" rings and other seals and gaskets.

Shifts From Standstill Very Fast & Harsh

1. A ccumula tor control valve spring too strong or valve stuck open.

Chrysler Semi-Automatic Transmission Troubles In diagnosing trouble with this trans

mission, the main thing to remember is that the transmission electrical system is used to keep the transmission in third or first speed gear, depending on the position of the gear shift lever, and that the hydraulic control mechanism is used to keep the transmission in second or fourth speed gear, depending on the position of the gear shift lever.

No Upshift 1. Low oil level. 2. Wrong grade of oil. 3. Low oil pump pressure. 4. Solenoid washer left off. 5. Engine idling too fast.

Slow Upshift 1. Engine speed too fast due to stick

ing throttle linkage or idle speed adjustment.

2. Low oil pump pressure. 3. Wrong grade of oil.

22

Engine Misfires During Upshift Caused by resistance in ignition cir

cuits due to loose or dirty wiring connections, or spark plugs which are fouled or gapped incorrectly.

No Downshift Inoperative governor, solenoid, inter

rupter switch, circuit breaker, or resistor. Loose or dirty wiring connections.

No Kickdown Inoperative kickdown switch due to

faulty switch or incorrect throttle adjustment. Inoperative solenoid or interrupter switch. Loose or dirty wiring connections or broken resistor .

Kickdown At Other Than Recommended Speeds

Caused by malfunction of kickdown switch upper limit control piston in carburetor.

- -

Engine Stalling Ca used by points in the interrupter

switch being held in closed position, or faulty switch. Stalling on deceleration possibly due to anti-stall dashpot on carburetor not operating or out of adjustment.

Shuttling Transmission In Neutral and Car Coasting

This is a normal condition caused by mainshaft driving the countershaft which makes the governor function.

Jumps Out of Gear, 4th to 3rd Speed

Loss of oil pressure, possibly due to scored pump rotors or housing. Misalignment of transmission with flywheel housing.

Excessive Creeping Engine idle speed set too high.

- . ~- .... -.~~· -FfJ:..# -

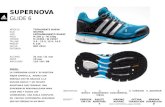

TURBOGLIDE

Fig. 1 Turboglide transmission

CONTENTS Description ........ ..............•... .. 345

Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . 21

Maintenance

Adding Oil .•••••••••••...•... ..• .. .... 346

Changing Oil •••••••••••••.••......... . 346

"In Car" Repairs

Air Pressure Checks ..••••.•.. .. .• .. ..... 346

Oil Pressure Tests . .... . ... ... ...... ..... 34 7

Rear Oil Pump ...•••.••• , •••••••••.••• • . 347

Valve Body .• , ••••••••••••••••.•••..... 349

DESCRIPTION The Turboglide automatic transmis

sion, Fig. 1, consists of a five-element torque converter and two planetary gearsets providing two reduction ratios, direct drive and reverse. Although three forward ratios are provided, there is no shifting of gears. Starting from rest with a maximum torque ratio of 4.3 to 1, there is a gradual transition to direct drive as speed increases. Fig. 2 illus-

Repairs Requiring Transmission Removal

Transmission, Disassemble ......... .... .. . 350

Torque Converter .... .. .... ..... ....... . 350

Rear Planet Carrier .......... . .......... . 351

Front Planet Carrier ..... ................ 352

Front Pump and Reverse Piston .... . ....... 352

l'ront Sun Gear Freewheel Assembly .. . .... 352

Neutral Clutch and Ring Gear .. .. ........ 354

Forward and Brake Piston and Support ..... 355

Transmission, Assemble . .. ..... ... . ...•.. 355

trates the operational phases. Each of the three turbines can drive

the transmission output shaft. As the car starts, the pump, driven by the engine, directs most of the oil in the converter against the vanes of the first turbine, which drives the sun gear of the rear planetary. A one-way roller clutch holds the ring gear, causing the rear planet carrier and output shaft to be driven at increased torque and reduced speed.

As car speed increases, a greater por-

tion of the oil strikes the vanes of the second turbine. The first turbine gradually fades out of the picture, and the second turbine takes over, driving the output shaft through the front ring gear and planet pinions, which walk around the sun gear, held stationary by its oneway clutch. Reduction in this range is less than in the starting range because the front planetary has a lower gear ratio than the rear.

As the car approaches cruising speed, oil flow is concentrated against the third turbine, which drives the output shaft directly, with no gear reduction. From this point on, action is similar to a conventional converter. When a speed is reached when the unit can no longer provide torque multiplication, the stator free wheels and the converter becomes a simple fluid coupling. The stator is provided with variable pitch vanes. When the accelerator is floored past the detent, the pitch is increased, giving greater torque multiplication and allowing the engine to turn at a speed where it can develop more power.

The five positions on the quadrant are: Park, Reverse, Neutral, Drive and Hill Retarder. A separate low range is unnecessary because maximum torque multiplication is available in Drive. When the car is descending a steep grade, the selector can be placed in the Hill Retarder position to obtain more effective braking through the engine and transmission. Under this condition, a

345

TURBOGLIDE

'VARIABLE PITCH STATOR ENGINE

DRIVEN PUMP

NOMENCLATURE

THIRD TURBINE

THIRD TURBINE SHAFT CONNECTED DIRECTLY TO TRANSMISSION OUTPUT SHAFT THROUGH PLANET CARRIERS

FINAL DRIVE (THIRD TURBINE PHASE)

1

4

disc clutch holds the rear ring gear, permitting the rear wheels to drive the first turbine at 2.67 times the speed of the output shaft. This high turbine speed creates turbulance in the converter, changing the kenetic energy of the descending car into heat. Engine speed is also increased, providing further braking effect.

Cone clutches are used for neutral, forward and reverse. Service on this transmission is easier becattse all bands have been eliminated. And since there is no automatic shifting, no governor is necessary, and the throttle linkage is simplified.

MAINTENANCE Adding Oil

In order to check oil level accurately,

FIRST TURBINE PHASE

FIRST TURBINE

REVERSE

FIRST TURBINE SHAFT DRIVES REAR PLANETARY GEARSET WHICH PROVIDES REVERSE BY REACTION TORQUE FROM FRONT PLANETARY GEARSET

Fig. 2 Turboglide oper ation phases

2

5

the engine should be running at idle speed with the transmission oil hot and the control lever in Drive position.

It is important that the oil level be maintained no higher than the "FULL" mark on the oil level dipstick. Do not overfill, for when the oil level is at the full mark on the dipstick, it is just slightly below the planetary gear unit. If the level is above the full mark, the planetary unit will run in the oil, causing the oil to foam and aerate. This aerated oil may cause malfunction of the transmission, resulting in cavitation noise in the converter and improper action of pistons or spewing from the filler pipe or breather.

Changing Oil Every 25,000 miles the transmission

"In Car" Repairs AIR PRESSURE CHECKS Five air checks can be made on this

transmission which are of value in determining the cause of a complaint prior to overhaul or as a means of checking clutch applications and seals during transmission overhaul. In order to perform the checks an air source of 100 lbs. pressure is required as well as an adapter (T ool 4353-1) to apply the air pressure.

To make the following checks with the transmission in the car, drain the oil,

346

then remove the converter cover pan , transmission oil pan and the main valve body. The oil pressure tubes shown in the Forward Clutch and Grade Retarder apply ports, Fig. 3, must be installed to make the checks.

Caution- If the checks are being performed during transmission overhaul, rebuild to the stage shown in Fig-. 3 and install Converter Holding Tool (No. 5384) to prevent the possibility of the converter being blown out of the transmission.

NEUTRAL CLUTCH ENGAGED

SECOND TURBINE PHASE

FIRST TURBINE

HILL RETARDER

FIRST TURBINE SHAFT DRIVEN AT 2.67 TIMES OUTPUT SHAFT SPEED THROUGH REAR PLANETARY GEARSET

3

6

should be drained and refilled. The transmission should be warmed up before it is drained.

1. Remove transmission oil pan plug.

2. After draining, install drain plug.

3. Pour in 3% quarts of automatic transmission fluid. (3% quarts will not be adequate if transmission has been setting for a long period without operating due to partial draining of converter.)

4. Start and allow engine to idle for a few minutes in Neutral until oil is hot or at operating temperature. Then, with selector lever in Drive, check to see that the oil level is at the full mark on the dipstick. Add oil as required but do not overfill.

Reverse Clutch Apply air to the reverse clutch port,

visually check that the reverse cone moves rearward, and check for air leaks.

If the reverse cone does not move, determine whether the front pump-totransmission case gasket is incorrectly positioned and blocking oil passages or if the reverse piston is cocked or bound.

If air leaks are heard, check for a damaged front pump-to-transmission case gasket or for damaged seals in the reverse piston.

FORWAR D CLUTCH PORT

GRADE RETARDER

PORT

Fig . 3 Air check points

Stator Piston Apply air tc;> the stator piston port and

listen for air leaks. If air leaks are detected, check for a mispositioned or damaged front pump-to-transmission case gasket, broken or warped seal rings on second turbine shaft, defective stator piston seal, or damaged or worn brass seal in the inside diameter of the stator support. If the brass seal is at fault, the stator support must be replaced as the brass seal cannot be serviced separately.

Neutral Clutch With air applied to the neutral clutch

port, listen for application of the clutch and for air leaks.

If no clutch application is heard, determine if the front pump-to-transmission case gasket is incorrectly positioned and blocking oil passages. If not, disassemble the neutral clutch and check for a locked-up or binding condition.

Possible causes if air leaks are heard are a torn or distorted front pump-totransmission case gasket, worn or broken seal rings on second or third turbine shafts, defective seals in the neutral clutch piston, or defective brass seal in inside diameter of second turbine shaft. If the brass seal is faulty, replace the front ring gear hub and shaft assembly.

Forward Clutch With the oil transfer tube installed as

shown in Fig. 3, apply air to the tube, observe that the forward clutch applies, and listen for air leaks.

Failure of the clutch to apply can be the result of a wedged forward piston or Grade Retarder piston, probably caused by cocked piston "0" rings. A blockage of the oil feed orifice in the forward and brake piston support could also prevent clutch application.

The first place to check if air leaks are

found is the "0" ring seals on the oil pressure tube in the forward clutch port; otherwise check the forward piston-tosupport seals.

Grade Retarder Piston Apply air to the Grade Retarder port

with the oil pressure tube installed. Check the Grade Retarder application by watching for the movement of the Grade Retarder reaction plate which will occur as the brake plates are forced against it by the piston moving rearward.

If the Grader Retarder piston does not move, check for cocked "0" ring seals in both the Grade R etarder and forward pistons or check for blocked orifice in piston support.

Leakage could only occur at either the oil pressure tube "0" ring seal or the brake piston "0" ring seal.

OIL PRESSURE TESTS 1. Connect pressure gauge to test point

on left side of transmission, Fig. 4. 2. Connect vacuum gauge and tacho

meter to engine. 3. Warm up transmission and engine

and check transmission fluid level. 4. With selector lever in "D" and then

in "R" range, pressure gauge should read 50-60 psi at 18" engine vacuum.

5. With selector lever in "D" range and at car speed of about 30 mph, push on accelerator to wide-open throttle condition. The pressure should rise to 195-210 psi at 2" engine vacuum. At any car speed, with foot off the throttle, pressure gauge should read 50-60 psi with 18-25" engine vacuum.

6. With selector lever in "D" range and a road speed of 45 mph, and foot off throttle, pressure gauge should read 50-60 psi.

7. Place selector lever in "GR" range at 45 mph and pressure should drop to

TURBOGLIDE

Fig. 4 Oil pressure test plug

Fig . 5 Removing rear pump drive pin

PARKING PAWl SPRING

Fig. 6 Transmission with oil pan removed

0 psi. The engine speed will drop momentarily (during manual shift from "D" to "GR") and then the grade retarder clutch will set down and engine speed will increase.

Cau tion- Due to rapid temperature rises of the fluid within the transmission, stall tests must not be performed on the turboglide transmission as serious damage to the transmission can result.

REAR PUMP Removal

Remove oil pan. Remove capscrew and retaining clip holding speedometer gear

TURBOGLIDE

._ -~ ----·-3 -- s·

0~ ~ 6

4

8 10

Fig. 7 Valve body components. 1957

1. Valve screws 2. Vacuum modulator screws 3. Front valve body gasket 4. Rear valve body gasket 5. Pressure tube "0" rings 6. Oil pressure tubes

7. Ditch plate 8. Ditch plate gasket 9. Transfer plate

1 '

1P

\ SCREWS

1 COVER

. 1 COVER GASKET

10. Transfer plate gasket 11. Hydraulic modulator valve 12. Pressure regulator valve

spring 13. Main valve body 14. Valve body screen 15. Screen screw 16. Gasket 17. Vacuum modulator valve

BODY

BASE GASKET

Fig. 9 Vacuum modulator valve

~HYDRAULIC MODULATOR VALVE SCREW I SC~EEN SPRING

TRANSFER PLATE

""'

MAIN VALVE BODY

348

y GASKET

GASKET

VACUUM MODULATOR VALVE

Fig. 8 Valve body components. 1958

BODY

VACUUM MODULATOR VAl

Fig. 10 Removing accumulator valve retaining ring

HYDRAUliC MODUlATOR PRESSURE VAlVE REGULATOR

_!.~SPRING

SEAT WASHER

ACCUMUlATOR VAlVE

lOWER RETAINER dRlNG

Fig. 11 Hydraulic modulator valve

GASKET

BOLT

l. "O''RINGS

~~ ~.- SCREWS

"O"RINGS PRESSURE \\.._ GASKET TUBES \......-..

5

8

6

· r

7

13

12 ~ ~

10~11

Fig. 12 Main valve body. 1957

housing in extension. Unfasten a nd remove extension from transmission case. Use puller to remove speedometer drive gear. Unfasten and remove pump body and seal ring from transmission. Remove pump driven gear, drive gear a nd drive pin. Fig. 5.

Inspection Blow out all oil delivery holes a n d in

spect all parts for visible damage. I nstall gears and check a ll clearances. All clearance measurements are the same as for comparable parts of the front pump. If a new bushing is required in the pump body, install it so it is flush with the neck of the body.

Installation

Wlliillllill r.

····T····/7=~'~ SPR~~GSHER /1 INNER tRING \

ROLL PIN OUTER SPRING

STATOR DETENT VALVE ~

TURBOGLIDE

1. Roll pin 2 . Detent spring 3 . Detent ball 4 . Retaining pin 5. Plug 6 . Spring 7. Accumulator control valve 8 . Lube relief valve 9. Spring

10. Rear check valve 11 . Spring 12. Front check valve 13. Spring 14. Main valve body 15. Manual control valve 16. Stator detent roll p in 1 7. Stator detent valve spring 1 8 . Stator detent valve 19. Pressure regulator valve 20. Spring seal washer 21. Pressure regulator spring 22. Accumulator valve 23. Inner spring 24. Outer spring 25 . Washer 26. Ring

ACCUMULATOR CONTROL VALVE

I I-ROLL PIN .-~

MANUAL CONTROL VALVE Q---DETENT BALL

After assembling the pump, install it in the transmission in the reverse order of its removaL

ROLL PIN '-DETENT SPRING

VALV£ BODY Removal

Take down the oil pan. Remove parking pawl spring, Fig. 6. Unfasten and remove valve body from tran smission. All three units of the valve body will come off as an assembly. Bolts are two different sizes. R ear bolt is hollow to permit oil pressure to valve body.

Disassemble Refer to Figs. 7 to 13, observing the

following: When removing the hydraulic accumulator valve from the hydraulic modulator, hold the unit in a vise or with a "C" clamp as the accumulator springs are under 90 lbs. pressure. T hen remove snap ring and take out seat, springs and piston.

Inspection Wash all parts in cleanin g solven t, air

dry and blow out all passages. Then inspect as follows: 1. Check detent valve spring for dis

tortion or damage.

Fig. 11A Oil passage pipe plugs

2. Inspect deten t valve for nicks, burrs, scoring or galling. Also check valve for freedom of operation in its bore.

3. Inspect lands of manual valve for wear or scratches.

4. Inspect modulator valve housing for galling or scorin g. Check retaining ring grooves.

Fig. 13 Main valve body. 1958

5. Inspect modulator valve and housing.

6. Inspect all pistons for freedom of operation in their respective bores.

7. Inspect springs for distortion or damage.

8. Clean sump screen thoroughly. Inspect rubber by-pass valve.

Assemble

R efer to Figs. 7 to 13, observing the following: Do not confuse the pressure regulator spring with the accumulator outer spring. T he pressure regulator is the heavier with a free length of 314".

Install stator detent valve spring in valve body, then install detent valve with hollow end indexing over spring. Hold valve in and press roll pin to engage in groove in end of valve. Do not install pin too deep; end of pin should not touch bottom of groove. Check freedom of assembly by strokin g valve.

The accumulator spring is the lightest spring of the valve body and the check valve has a hole in the center.

349

TURBOGLIDE

Repairs Requiring Transmission Removal

TRANSMISSION DISASSEMBLE

1. With transmission r emoved from car and mounted in holding fixture, proceed as follows:

2. Remove converter assembly. 3. Remove oil pan. 4. Remove capscrew and retaining clip

holding speedometer gear housing in extension.

5. Remove transmission extension. 6. Remove speedometer drive gear 3:nd

rear oil pump. When pump dnve gear is removed, drive pin, Fig. 5, can fall out if hole is on bottom of shaft.

7. Remove parking pawl spring, Fig. 6. 8. Remove valve body. 9. Remove two oil pressure tubes, Fig.

14. 10. Place transmission with input shaft

facing upward and remove front pump capscrews.

11. Remove front pump, stator support and reverse piston assembly, noting two threaded holes to mount puller, Fig. 15. .

12. Remove reverse cone and spnng. Then place transmission horizontal with bench.

13. Remove neutral clutch and front ring gear assembly, which includes turbine shaft, neutral shaft and neutral clutch piston.

14. Remove reverse cone ring (tanged to case) with soft drift and hammer.

15. Remove front planet carrier. 16. Remove front sun gear and freewheel

assembly (gear section forward). 17. Remove forward cone retaining ring,

Fig. 16. 18. Remove forward cone ring and for

ward cone. By exerting slight pressure on output shaft, both ring and cone can readily be removed.

Fig. 14 Valve body and oil pressure tubes

Fig. 1 S Removing front pump with pullers

19. Remove forward and brake piston and support as an assembly.

20. Remove rear unit ring gear and output shaft and rear planet carrier as a unit.

21. Remove both brake clutch plates and aluminum separator.

22. Disassemble rear ring gear from rear planet carrier by removing retaining ring and remove two races and needle bearing from extension in carrier. Remove caged needle bearing from output shaft.

23. Remove detent control lever, Fig. 17. 24. Remove manual selector lever. 25. Remove parking brake bracket and

parking lock actuator assembly. 26. Remove parking brake pawl, pin and

"0" ring. Pin is removed by driving its front end.

27. Remove by-pass valve. Spring under cover in v alv e is under tension and care should be used when cover i s r er emoved, Figs. 18 and 19.

28. Remove vacuum diaphragm, Fig. 20.

Fig. 16 Removing forward cone retaining ring

..

by holding valve body and removing retaining nut from inside of transmission case. Valve strut will come off with retaining nut.

CONVERTER Refer to Figs. 21 and 22 when disas

sembling and assembling the converter. Before disassembling, mark the cover and housing for alignment and balance upon reassembly. When disassembling the turbine assembly, note that the first turbine inner ring and turbine shell are marked to assure correct relationship of parts for balance on reassembly.

When disassembled, wash and air-dry all parts. Then inspect the following parts for scoring or galling: Converter hub outer surfaces, converter hub thrust washers, turbine hubs and thrust washers, converter cover bushing, stator race and cam rollers. Check converter

PARKING BRAKE • BRACKET AND SCREWS

Fig. 17 Valve body controls (typical)

pump vanes and turbine vanes for looseness or damage. Inspect cam springs for distortion. Check stator blades for excessive wear or damage.

When reassembling, refer to Figs. 21 and 22. When installing the stator blades, the trailing or sharp edges of the blades should point downward after installation in stator. Neck of stator piston must be pushed fully through rear carrier to install stator blades. When installing the turbines, align the balance marks. Then install first turbine inner ring with inner flat surface facing up in turbine shell.

REAR PLANET CARRIER 1. Wash planet carrier and gears, blow

out all oil passages and air-dry. 2. Inspect planet pinions for nicks or

other tooth damage. Check pinion shafts for pitting or irregular bearing surface, Figs. 23 and 24.

3. Check end clearance of planet gears, measuring between gears and output shaft flange thrust washers. This clearance should be .006" to .030". Check thrust washer for looseness and wear on rear planet carrier.

4. Check sun gear for tooth damage. Also check planet needle thrust bearing for damage.

5. Inspect output shaft bearing surface for nicks or scoring and output shaft bushing.

6. Inspect output shaft splines for nicks and damage and check fit to transmission case. Also check fit of rear carrier to front carrier output shaft.

7. Inspect bearing surface of speedometer gear on output shaft. Speedometer drive gear is pressed on shaft and looseness will result in driven gear failure.

When disassembling, mark the carrier and output shaft for correct relationship on reassembly. The separation of the carrier from the output shaft will enable all parts of the rear carrier assembly to be removed. The carrier pinion shafts will remain in either the carrier or the output shaft, depending on which piece has the closer fit. Do not attempt removal of pinion shafts by breaking four way stake. Pinion shafts must be removed by disassembling the planetary carrier only. Damaging the stake marks will ruin the retaining qualities of the carrier or output shaft and necessitate

Fig. 19 By-pass valve. 1958

TURBOGLIDE

VACUUM DIAPHRAGM

il NUT STRUT

RETAINER

DIAPHRAGM

RELIEF SPRING

THERMAL BY-PASS VALVE

RETURN RING SPRING SEAL

Fig. 1 8 Thermal by-pass valve and vacuum diaphragm. 1957

TURBINE AND CONVERTER PUMP

STATOR

BOLTS

FIRST TURBINE RING

SECOND TURBINE

Fig. 21 Exploded v iew of torque converter

replacement of the carrier and output shaft assembly. The output shaft bushing is precision bored in place during assembly; this bushing is not replaceable.

1 STRUT DIAPHRAGM

COVER

Metal sometimes is shaved from carrier pinion shafts during reassembly when shafts are entering holes in hardened carrier. If shavings are not removed, false clearance readings can be obtained, Fig. 25. Pinian end clearance should be checked between washer and pinion as shown. Checking clearance between washer a nd carrier (location of shavings) will give false clearance readings. Fig. 20 Vacuum modulator. 1958

351

TURBOGLIDE Align alignment marks on carrier to

marks on output shaft and insert dowels of carrier into respective holes in output shaft. While installing carrier to output si1aft, align tangs of thrust washers to lock holes in carrier. To accomplish mating of the carrier and output shaft, install the assembly in an arbor press, Fig. 25.

FRONT PLANET CARRIER Due to the similarity between the front

planet carrier, Figs. 26 and 27, and the rear planet carrier, inspection and service procedures are almost identical. The front planet carrier is different inasmuch as it is minus the sun gear and sun gear thrust washers. All gear clearances for the rear planet carrier apply to the front planet carrier. The carrier bushing is precision bored in place in the carrier during assembly and is not replaceable.

FRONT PUMP & REVERSE PISTON

When disassembling and reassembling, refer to Fig. 28. When disassembled, wash all parts, blow out all oil passages and air-dry parts. Then inspect as follows:

1. Pump gears for nicks or damage. 2. Stator support pump face for nicks

or being scored. 3. Pump body for nicks or scores. 4. If pump body oil seal shows excess

ive wear, hardness, damage or evidence of leakage, pry it out and press in a new seal.

5. Splines of stator shaft for wear. 6. Both ends of stator shaft inner dia

meter for wear. 7. If square seal ring (rubber) is dam

aged, install a new one. 8. Facing material on reverse piston

and ring for cracks or flaking; questionable clutch facings should be replaced.

9. If reverse cone shows evidence of excessive heat, replace it.

10. Inspect pump bushing for scoring or galling. Check clearance between bushing and converter pump hub; clearance should be .005" maximum.

~ . ;;;;.o e

()CJ \ STAt

PISTON PISTON SEAl RETAINING

STATOR RING PISTON

e o e.., STATOR BlADE REAR CARRIER

RACE <:;;\ \ FREE WHEEL

SPRINGS STATOR SLADE ROUERS FRONT CARRIER

FRONT THRUST PAD

\ STATOR fREE WHEEl CAM

Fig. 22 Exploded view of stator

OUTPUT SHAFT

Fig. 23 Rear planetary carrier and output shaft. 1957

11. Install pump gears and check: Clearance between outside diameter of driven gear and body should be . 0025" to .0055". Clearance between internal gear and crescent should be .003 to .009". With scale and feeler gauge check gear end clearance, which should be .0005" to .0015".

Assemble Remove gears from pump body, oil

generously and replace in pump body. The drive gear is installed in the pump

body with the lug toward the body. The lug mates with the slot in the converter housing. If drive gear is installed improperly the pump will not operate .

FRONT SUN GEAR FREE WHEEL ASSEMBLY

When disassembling and reassembling, refer to Fig. 29. The sprag assembly should not be disassembled. An arrow stamped on the outer cage of the sprag

NEEDLE THRUST PINION PINION PIN LOCK PLATE

SUN GEAR REAR THRUST WASHER

NEEDLE BEARINGS

~/~~ ~ i

BEARING THRUST WASHER

=\ RETAINER . \ I 0;

352

OUTPUT SHAFT

~0 ~0~ Oo

REAR SUN GEAR

=

=

PINION GEAR

0 = Co ot r 1 H

PINION SHAFT

NEEDLE THRUST BEARING RACE

Fig. 24 Rear planet gearset. 1958

CARRIER

Fig. 25 Installing rear carrier to output shaft

assembly designates front of transmission.

When disassembled, wash all parts, air-dry and inspect for damage as follows: 1. Inspect inner race of cam for exces

sive scoring or burning. Also check Jugs on outer perimeter of cam for nicks or burrs.

2. Check bushings in sun gear for looseness or bushing scoring. Bushings must be replaced in pairs and while sun gear is removed from freewheel unit. Before installing bushings, note position of oil grooves in bushings. Grooves must point outward to maintain oil reservoir in sun gear.

3. Inspect sun gear teeth for nicks and burrs. Check sun gear for fit into front planetary unit.

4. Inspect internal and external races of sun gear for excessive scoring or burning.

5. Inspect sprag bearing for excessive wear.

6. If sprag wear is indicated, replace sprag assembly.

When reassembling, the sprag is in-

DRIVE PLATE HUB OIL SEAL RING

I /

//r PLANET PINION SPACER

//

./} c ~~ I

""G! PINION THRUST WASHER

TURBOGLIDE

PLANET CARRIER

Fig. 26 Front p lanet carrier assembly. 1957

SEAL DRIVE GEAR

SQUARE Oil RING

I

7

STATOR SUPPORT SEAL RING REVERSE

PISTON, SEAL RING

DRIVEN GEAR

STATOR SUPPORT REVERSE

PISTON GASKET

Fig. 28 Front pump and reverse piston assembly

stalled with the stamped arrow on its outer cage toward front of transmission. Sprags are assembled correctly if they will slip while holding outer cam stationary and turning sun gear clockwise as viewed from the front.

When installing the sun gear retainer, index the tang of the new retainer into the hole in the rear of the sun gear a nd

clamp in a vise, using the fixture shown in Fig. 30. Use care when staking not to bend the retainer due to the close tolerance between the retainer and sprag bearings.

Index the sun gear in the forward cone sprag, twisting counterclockwise to enable cams to twist, allowing sun gear race to seat under sprags while twistmg.

WASHERS NEEDLE BEARINGS ( 17 EACH)

PINION GEARS WASHERS

PINION THRUST WASHERS

)* ·;:1~ PINION THRUST PINION ~ ~

BOLTS FLANGE WASHERS SHAFTS WASHERS

Fig. 27 Front planet gearset. 1958

NEEDLE BEARINGS (17EACH)

353

TURBOGLIDE

Q RETAINER RING ~ SUN

GEAR SUSHING ~ ~

REAR RING REAR RING

FORWARD CONE SPRAG BEARING

FORWARD CONE SPRAG

FORWARD CONE SPRAG SEARII-IG

SUN GEAR

GEAR SPRAG GEAR SPRAG RETAINER BEARING BEARING RING

REAR RING GEAR SPRAG

SUN GEAR RETAINER

Fig. 29 Front sun gear freewheeling assemb ly

NEUTRAL CLUTCH & RING GEAR

When disassembling and assembling, refer to Figs. 31 and 32. The gear thrust washer (3) is available in different thicknesses to give proper clearance within the transmission. To a id in r emoving the neutral clutch piston, apply air pr essure into the ball check hole in the hub. The piston is doweled to the hub and therefore will not rota te independent of the hub. The ball check in t he hub is not removable. Wash all parts and air-dry. Then inspect for the following conditions:

1. Splines in hub for nicks and burrs.

v~O • ~ OOOQ:J I 2 3 ""' 5 6 7 8 9

• I<)

Check hub for fit in third turbine. 2. Ball check in hub for looseness. If

leakage is suspected, hub may be checked by filling cavity with oil and observing check ball.

3. Inspect inner race of hub for excessive scoring or burning. Surface on which piston moves must be micro smooth to eliminate possibility of oil ring breakage.

4. Check all ring lands for nicks or burrs which may hamper freedom of ring movement.

5. Check bushing in center of hub. If bushing is scored or loose, or hub inner race is damaged, replace hub and shaft assembly.

6. Check neutral clutch piston for

COD 0 12 13 14 IS 16 17 18 19

Fig. 31 Neutral clutch and ring gear. 1957

1. Converter oil seal ring 11 . Inner seal 2. Turbine shaft oil seal rings 12. Neutra l clutch piston ' 3. Gear thrust washer 13. Outer seal 4. Front ring gear hub 5. Ri ng gear hub bushing 6. Race 7. Needle bearing 8 . Race

14. Piston spring 15. Clutch cone 16. Cone ring 17. Cone ring retainer

9. Oil rings 18. Ring gear 10. Clutch hub 19. Ring gear retaining ring

PISTON SPRING

Fig. 30 Staking sun gear reta iner to sun gear

burred or nicked groove for piston outer seal or inner race being scored or pitted. Any surface r oughness in contact with rubber seals will cause seal failur e.

7. Inspect neutral clutch inner and outer facings for cracks or flaking. Questionable clutch facing damages should be repaired by replacement.

8. Check all tangs and keyways for proper engagement. The smallest burr will hamper assembly and possibly accelerate wear.

9. If neutral cone surface (1957) indicates excessive heat, replace.

10. Inspect driven pla.te facings (1958) for cracks or flaking. Questionable clutch facings should be replaced.

11. Inspect front ring gear teeth for wear and chips.

Before assembling any part to or with an "0" type r ound or square seal, lubricate all contacting parts with automatic transmission fluid . Assemble all parts except items 1, 2 and 3, Figs. 31, 32. These parts are not installed at this time due to their being removed during selective washer checking operation.

REAR DRIVE PLATE SNAP RING

( 16 USED) DRIVE PLATES

01o~00d ~ SEAL /sNAP RING\

FRONT RING GEAR HUB NEUTRAL CLUTCH HUB RETAINER DRIVEN PLATES FRONT RING GEAR Fig. 32 Neutral clutch and front ring gear. 1958

354

FORWARD & BRAKE PISTON & SUPPORT

Refer to Fig. 33 when servicing this unit. When disassembled, inspect for the following conditions:

1. Inspect splines of hub for nicks or burrs. Check hub of brake piston for fit in to hub or forward piston.

2. Inspect all surfaces con tacting "0" rings or square seal rin gs for scoring or burning. All surfaces must be micro smooth to preven t seal failures.

3. Inspect piston a nd con e ring facing material for cracks or flaking. R eplace facings if at all questionable.

4. If forward cone surface shows signs of excessive heat, replace cone.

5. Inspect Hill Retarder composition plates. If facings are at all questionable, replace them.

When assembling, lightly lubricate all "0" ring seals and square seals to insure proper mating of parts to seals to prevent damage of seal during assembly.

1957 TRANSMISSION, ASSEMBLE

1. Install parking pawl and shaft with "0" ring in case, Fig. 34.

2. Index manual control lever into manual control rod and park pawl lock rod (bullet type) and secure with bolt and nut (see Fig. 17).

3. Install stator lever through control lever and install detent control lever plate, securing with hairpin clip.

4. Install parking lever bracket. 5. Install rear race and needle bearing

assembly on front of output shaft carrier, then install front race over shaft.

6. Install caged needle thrust bearing on rear of output shaft, using grease sparingly to hold bearings in place.

7. Install rear ring gear onto rear planet carrier and output shaft. Use grease sparingly to hold bearing in place.

8. Install output shaft and rear ring gear into case from front.

9. Install brake drive plate (composition) by indexing ring gear. Then

Fig. 34 Installing stator control lever

0 I

RETU RN SPRING

FORWARD PISTON

SUPPORT ·o·· RING

TURBOGLIDE

BRAKE PISTON ··o· RING

BRAKE PISTON

RETAINER RING

Fig. 33 Forward and brake piston and support

index brake reaction plate (aluminum) to case a nd follow up with the other brake drive plate.

10. In stall forward cone on piston . 11. I nstall forward cone ring over spr

ing on forward piston, making sure notches of ring fully engage outer tangs on edge of spring.

12. I nstall forward a n d brake pistons and support in case. Index outer support and forward cone ring to case a nd the six lugs on brake piston to case, being careful not to remove cone ring from over spring. K eep taper section of forward piston to front of transmission.

13. I nstall forward cone ring retainer to secure unit to case. Outer forward cone ring may have to be tapped gently to compress spring in piston to provide enough space to install retainer. Be sure retainer is firmly seated in its groove.

14. Install needle thrust bearing race over extension of front planet carrier and install needle bearing over race.

15. Install tanged washer onto front end of front planetary, using a small amount of grease to keep washer located.

16. Holding neutral clutch assembly with one hand with shaft pointing up, lift front planetary with tanged washer installed a nd index keyways on front planetary housing to cone lugs in neutral clutch assembly.

17. After planetary is installed, rest shaft of neutral clutch on bench and install freewheeling sprag over rear extension of planetary. Twist sprag to mate sun gear to planetary gears.

18. Install needle thrust bearing over extension of front planetary gear extending through freewheel unit.

19. Install unit in case, twisting shaft to engage lugs of freewheeling outer cam to forward cone in forward clutch mounted in case. Forward cone is loose and may be turned to align with lugs of freewheeling cam.

20. T urn transmission so input shaft is facing up.

21. Install reverse cone ring in case with tapered portion forward. T a ng fits in case and drain back notch should be at bottom of case.

22. At this time the end play of the transmission should be checked, using equipment shown in Figs. 35 and 36. With gauge mounted as shown in Fig. 35, note highest reading as indicated at several points on pump mounting. Then install gauge as shown in Fig. 36 and note the highest reading. Subtract the reading obtained with Fig. 35 with that of Fig. 36. T his difference will give the thickness of the thrust washer to install. Allowable clearance is .008" to .028". Install the thrust washer which will give the proper clearance. Washers are available in thicknesses of .068", .085" and .103".

23. Install four oil seal rings to extension on front ring gear hub.

24. Install reverse cone into case, meshing tangs with slots in neutral clutch and front ring gear.

25. Install reverse cone spring into case. 26. Install two guide studs in case to

guide pump to avoid damage to oil seal rings on front ring gear hub shaft.

Fig. 35 Dial gauge mounted on rear of front pump

355

TURBOGLIDE

27. 28.

29.

30.

31.

32. 33.

34.

35.

36. 37.

38. 39. 40. 41. 42. 43.

Fig. 36 Dial gauge Installed in transmission case

Install stator support gasket. Install square seal ring on outer lip of stator support. Align tang of oil pump drive gear to bottom of pump housing. It is important that transmission be in vertical position with front end facing up. The installation of pump over oil seal rings on second turbine shaft is accomplished by sliding pump down easily and centering pump over guide studs. Also, this will enable converter to be installed without damaging oil seal rings. Pump housing may have to be tapped to fully seat in case. Remove guide studs and install pump ·attaching screws. Install converter driving lug of pump to mate with keyway of front pump drive gear. Converter may be rotated to complete mating of splines. A minimum measurement of %, " from front of case to front of converter must be present, assuring that all parts are properly engaged. Install converter holding tool, Fig. 37. Place transmission parallel to floor. Turn output shaft to locate drive pin hole to top of output shaft and install drive pin (see Fig. 5). Position pump on output shaft, indexing drive gear to drive pin. Install pump attaching bolts. Then install square ring seal over pump. Converter mttst be assembled to transmission before oil pump can be tightened. Install by-pass valve. Install vacuum diaphragm outside of case along with vacuum modulator strut and attaching nut. Install oil pressure tubes. Install valve body. Install speedometer drive gear. Install rear extension. Install speedometer driven gear. Install transmission oil pan.

1958 TRANSMISSION ASSEMBLE

1. Install parking pawl and shaft with "0" ring in case.

356

2. Index manual control lever into manual control rod and parking lock pawl rod and secure with bolt and nut.

3. Install stator lever through control lever, Fig. 34.

4. Install parking lever bracket and torque bolts to 15-18 lb. ft.

5. Install rear race, needle bearing and front race on front of output shaft carrier.

6. Install caged needle thrust bearing on rear of output shaft.

7. Install ring gear on rear planet carrier and output shaft.

8. Install output shaft and rear ring gear into case from front.

9. Install grade retarder members in following order: Thin reaction plate (steel) Brake plate (lined) Thick reaction plate (steel) Brake plate (lined) Thick reaction plate Brake plate Thin reaction plate

10. Install forward and brake piston support in case with forward piston toward front. Check that this unit is fully seated in case by seeing that the oil transfer tube holes in case and piston support line up.

11. Install forward cone (steel) and forward cone ring.

12. Install forward cone ring retainer. Outer forward cone ring may have to be tapped gently to compress spring in forward piston to provide space to install retainer.

13. Install needle thrust bearing and race over extension of f:-ont planet carrier.

14. Install tanged washer onto front of front planetary.

15. Holding neutral clu~ch assembly with one hand with shaft pointing up, lift front planetary with tanged washer installed and index keyways on front planetary housing to driven plate lugs in neutral clutch.

16. After planetary unit is installed, rest shaft of neutral clutch on bench and install front sun gear freewheeling unit over rear extension of planetary. Twist sprag assembly to mate sun gear to planetary gears. Install needle thrust bearing over extension of front planetary gear extending through freewheel unit.

17. Install unit in case, twisting shaft to engage lugs of freewheeling unit outer cam to forward cone in clutch unit mounted in transmission case. Forward cone is loose and may be turned to align with lugs.

18. Turn transmission so input shaft is facing up.

19. Install reverse cone ring in case, tapered portion forward. Oil return grove should be at bottom of case.

20. Install reverse cone ring in case and reverse cone. Mesh tangs of cone with slots in neutral clutch and front ring gear.

21. Install reverse cone spring in case with rounded ends forward.

22. Install two guide studs in case to guide front pump to avoid damaging oil seal rings on front ring gear hub shaft.

23. Install stator support gasket to case. 24. Install square seal ring on outer lip

25.

26.

27.

28.

29.

30.

31.

32.

Fig. 37 Installing converter holding tool

of stator support. Align tangs of oil pump drive gear to top and bottom of pump housing. It is important that transmission be in vertical position with front end up. The installation of pump over seal rings is accomplished by sliding pump down easily and centering pump over guide studs. Also, this will enable converter to be installed without damaging oil seal rings. At this time, check for correct thickness of selective thrust washer to be used as follows: a. Install four of front pump-to

case bolts. b. Rotate transmission so that

transmission output shaft is down.

c. Mount dial indicator so that plunger is resting on end of neutral clutch hub. Then zero indicator.

d. Push upward on output shaft and observe total indicator movement.

e. Indicator should read .008" to .028". If within limits front pump bolts should be coated with sealer and installed.

f . If clearance is not within limits, the selective thrust washer must be changed to obtain the specified clearance.

Torque front pump bolts to 15-18 lb. ft. and remove the guide studs. Install converter assembly. Lift converter up and down while turning slightly to engage pump lugs. This engagement will be indicated when the converter drops an additional %". A minimum measurement of %, " from front of case to front of converter must be made to insure all parts being properly engaged. Install converter holding tool, Fig. 37; then turn transmission parallel to floor. Turn output shaft to locate drive pin hole to top of output shaft; then install wear plate and rear pump drive pin. Position rear pump on output shaft, indexing drive gear to drive pin; then install bolts and torque to 7-9 lb. ft. Install square seal ring over pump. Install thermal by-pass valve and torque to 7-9 lb. ft. Screw vacuum diaphragm into case; then insert strut into vacuum modulator.

33. Install two "0" rings on each oil pressure tube and install tubes in support (tapered end into support) through case, making sure oil seal rings are seated.

34. Perform the air checks outlined at the beginning of this chapter before installing valve body to check assembly of the transmission up to this point.

35. Install valve body, guiding detent plate into groove, manual valve lever to manual valve detent valve, and carefully pick up manual valve, oil

pressure tubes and vacuum modulator strut.

36. Install special drilled · bolt at rear of valve body to rear case. Hole in bolt carries lube pressure to drilled passages in case to output shaft from valve body. Torque this hollow bolt to 18-21 lb. ft.

37. Install remaining bolts in valve body and torque to 8-10 lb. ft.

38. Index spring in parking lock pawl; then index into bracket on rear bolt of valve body.

TURBOGLIDE 39. Install speedometer gear on output

shaft. When fully installed, distance from forward edge of gear to rearmost surface of rear pump should be 14 ".

40. Install rear extension housing and torque to 23-26 lb. ft.

41. Install universal joint yoke and rotate freely. If yoke is tight, remove extension housing and tap rear pump body to center output shaft with extension bushing and seal.

42. Install speedometer driven gear. 43. Install transmission oil pan.

TWIN ULTRAMATIC~ 1955-56 For Linkage Adjustment See Car Chapter

CONTENTS Description ..... ... . .... ... ....... ..... 357 Trouble Shooting . . . . . . . . . . . . . . ...... 30

Adding Oil Changing Oil

Maintenance

.................. 358 ........ . ..... •.• ... 358

"In Car" Repairs

Bands, Adjust ..........•.••.••••••••••. 358 Control Valve ....•.••••••• , , , , , , , , , ••.. 358

Throttle Pressure, Adjust . . ... ....... ..... 359 Governors . ... ........................ . 359

Repairs Requiring Transmission Removal

Transmission, Disassemble ... .. .... .. ..... 360 Torque Converter ..•.••••.•.•........ .. 360 Reverse Brake .........•••••••••..•.... . 361

low Range Brake .... ........ , ......... .. 361

High Range Clutch ... ................... 362

Planetary Unit . .... ....... .............. 363

Transmission, Assemble ......... . . ....... 364

DESCRIPTION This transmission, Fig. 1, incorporates

(1) a torque converter, (2) a direct drive clutch, (3) a high range clutch, (4) low range and reverse brakes and bands, (5) a compound planetary gear system, and (6) an hydraulic control system.

Torque Converter

The torque converter provides maximum torque multiplication by the use of a pump (driving member), a two-stage turbine (driven member) and a stator

Fig. 1 Sectional view of Twin Ultramafic Transmission. 1954 (late), 1955-56

357

CHEVROLET 7. Disconnect engine rear mount on

transmission extension, then remove transmission support crossmember.

8. Remove flywheel cover and flywheelto-converter attaching bolts.

9. Lower rear of transmission slightly so that three upper transmission attaching bolts can be rea ched; use universal socket and a 39-inch extension. Care must be taken not to lower transmissi on too far as the dist1·ibutor housing may be forced agai nst the dash causing damage to the distributor.

10. Support engine at oil pan rail with a suitable jack capable of supporting weight of engine when transmission is removed.

11. Remove remaining transmission attaching bolts.

12. Move transmission slightly to the rear and downward. Do not tip front of trq,nsmission downward as the conv eTteT cottld fall out as transmission is r emoved. Secure converter in place with a suitable holding tool to prevent it falling out.

13. Reverse removal procedure to install transmission.

Removal, 1952-57 1. Remove toe pan plate and, on models

prior to 1955, remove transmission hole cover.

2. Remove spark plugs. 3. On V8s, disconnect ground strap

from battery and wires from starter solenoid.

4. Disconnect oil cooler lines at transmission and speedometer cable from driven gear fitting. Unclip cooler lines and tie them to right frame side rail.

5. Disconnect transmission control rods from levers.

6. On 1955-57 models, split rear universal joint and remove propeller shaft and front universal joint.

7. On models prior to 1955, disconnect emergency brake rod from cross shaft and drop cross shaft, cables and spring. Unfasten and slide universal ball and collar back on propeller shaft housing. Split the front universal joint and lower front end of propeller shaft.

8. Drain transmission. 9. Remove filler tube and dip stick and

tape filler tube opening. 10. On V8s, remove starting motor. 11. On V8s, disconnect exhaust pipe

from cross-over pipe. On 6-cylinder models, disconnect exhaust pipe from exhaust manifold.

12. Disconnect muffler from its bracket. Then move exhaust pipe and muffler to the left and tie to left frame side member.

13. Remove flywheel inspection cover. 14. Using a suitable tool to turn engine

over, remove three flywheel-to-converter attaching bolts through opening in flywheel housing that is adjacent to the starting motor on V8s. On 6-cylinder models, the opening is on left side of engine.

15. Remove all converter housing-to-flywheel housing bolts except the upper most three.

16. On models prior to 1955, remove transmission support.

490

Fig. 30 Shift linkage adjustment. 1958 Turboglide

Typical of 1959

17. Install engine support bar or cradle to support engine.

18. Position hydraulic jack under transmission; raise and fasten handling equipment to transmission.

19. Remove rear engine mountings. 20. Remove three remaining attaching

bolts through toe pan opening. 21. Move transmission to rear slightly

and install a suitable converter holding tool.

22. Lower transmission on jack and remove from under car.

23. Reverse the order of removal procedure to install the transmission.

TURBOGLIDE For details on this transmission see

the Turboglide Chapter.

TURBOGLIDE LINKAGE 1959 Adjustments

Shift Linkage--1. Check transmission shift linkage for

proper adjustment as follows: With engine stopped, move range selector lever to the position where Drive detent is felt. Slowly release lever to feel if lever lock pin freely enters lock plate. Check Reverse range in similar manner. If lock pin does not enter lock plate freely in both ranges, adjust as follows:

2. Position selector lever in "D". Disconnect shift control rod at its swivel attachment to the shift control lever on the lower end of the mast jacket by loosening clamp nut.

3. Place transmission shift control outer lever in Drive Position. (Drive detent in transmission is the first clockwise detent position from the fully counterclockwise detent or "GR" position, Fig. 30.)

4. Hold shift control lever (at lower end of mast jacket) against the Drive stop of the range selector lock plate while at the same time adjusting the length of the swivel on the shift control rod for free entry into the shift lever on the mast jacket. With the linkage held in this position, carefully retighten the swivel clamp nut.

5. Test transmission shifts in all ranges.

Throttle Detent Linkage--1. Disconnect transmission throttle rod

from carburetor throttle lever and accelerator rod from carburetor throttle lever.

2. Pull throttle valve rod toward front of car its full limit of travel, then adjust TV rod swivel for free entry into ca rburetor throttle lever with lever in wide open throttle position. Secure swivel to lever.

3. Check adjustment by placing carburetor throttle lever in wide open position, then pushing downward (counterclockwise) on transmission throttle valve lever and noting if transmission throttle valve rod attached to carburetor throttle lever deflects (transmission not on internal stop). If rod deflects or carburetor throttle lever will not reach wide open position, repeat adjustment.

4. Position carburetor throttle lever at wide open throttle and with an assistant depressing the accelerator pedal to hold the accelerator . pedal lever in contact with the lever stop, adjust swivel on accelerator rod to permit free entry into carburetor throttle lever. Secure swivel to lever.

5. Check for detent feel by depressing accelerator pedal by hand. Detent should be felt before accelerator pedal rod strikes carpet or floor mat.

Neutral Safety Switch-1. Place gearshift lever in neutral. 2. Loosen screws securing switch re

tainer. Then while holding ignition switch in "Start", adjust position of switch until engine turns over.

3. Hold switch in this position and tighten screws.

4. Check adjustment by cranking in both neutral and park.

1958 Adjustments Shift Linkage--Follow instructions as outlined for 1959 models.

Throttle Linkage-

1. Disconnect transmission throttle valve (TV) rod at throttle bellcrank on carburetor.

2. Place wood block %" thick beneath accelerator pedal rod and carpet · or floor mat and have an assistant hold accelerator pedal fully down to block.

3. Pull transmission TV rod toward front of car its full limit of travel (through detent) and adjust rod swivel for free entry into hole in throttle bellcrank.

4. Connect TV rod swivel to throttle bellcrank with clip, remove block from beneath accelerator pedal rod and check for detent "feel" by depressing accelerator pedal by hand. Transmission detent should be felt before pedal rod strikes carpet or floor mat.

5. Road test and adjust to insure that stator high angle is obtained at full throttle.

Neutral Safety Switch-This adjustment is obtained in the same manner given for 1959.

1957 Adjustments Shift Linkage-1. Loosen shifter tube lever clamp nut

to allow upper control rod to move freely on the swivel.

2. Move selector lever on transmission toward fron t of car to Neutral position (3rd position forward).

3. Place hand control lever in Neutral. 4. Tighten shifter tube swivel clamp

nut. 5. Check operation of linkage.

Throttle Linkage-1. Referring to Fig. 27, remove rod A

from throttle lever B. 2. Place lever B in wide open position

and pull rod A forward until stator control valve spring tension is overcome and lever is bottomed.

3. Adjust swivel on rod A for easy entrance in lever B before fixing swivel in lever B.

Neutral Sa.fety Switch-1. Loosen switch mounting screws. 2. Place selector lever in neutral. 3. Install cotter keys into two holes in

switch on each side of pointer. Switch may be rotated to place pointer between holes.

4. Tighten mounting screws and remove cotter keys.

5. If engine does not turn over after adjustment is made, loosen screws and rotate switch in the direction necessary until it does. Be sure selector lever is in neutral when performing this operation.

TURBOGLIDE, REPLACE

1957 1. Remove toe pan plate. 2. Remove spark plugs. 3. Disconnect battery ground strap

from battery and wires from starter solenoid.

4. Remove starter. 5. Remove oil filler pipe. 6. Disconnect oil cooler lines at ther

mal by-pass valve, remove hose from diaphragm and remove speedometer cable. Tie cooler lines to right frame side rail.

7. Disconnect linkage rods from transmission levers.

8. Remove propeller shaft and front universal joint.

9. Drain transmission fluid. 10. Disconnect muffler from its support

bracket and move muffler and exhaust pipe to the left and tie to left frame side member.

11. Remove converter underpan. 12. Support rear of engine with a jack. 13 .. Unfasten flywheel from converter. 14. Place separate jack under trans

mission.

CARBURETOR SWIVEL

15. Remove both rear engine mounts. 16. Unfasten transmission from engine. 17. Move transmission to rear slightly

and install a suitable converter holding tool.

18. Lower transmission from under car. 19. Reverse foregoing procedure to in

stall the transmission.

1958 1. Drain oil and remove filler pipe. 2. Disconnect oil cooler lines and speed

ometer drive cable fitting at transmission. Tie lines out of the way.

3. Disconnect body ground strap. 4. Disconnect shift control rods from

transmission. 5. Remove propeller shaft. 6. Attach a suitable transmission lift

ing device. 7. Disconnect engine rear mount on

transmission extension an d remove transmission support crossmember.

8. Remove flywheel cover a n d flywheelto-converter attaching bolts.

9. Lower rear of transmission slightly so that three upper transmission-toengine attaching bolts can be reached (use a universal socket and a 39" extension ). Care must be used not to lower the transmission too far as the distributor housing may be forced back against the dash causing damage to the distributor.

10. Support engine at oil pan rail with a jack capable of supporting engine when transmission is removed.

11. Remove remaining attaching bolts. 12. Move transmission slightly to rear

and downward and out beneath car. Do not tilt front of transmission downward as the converter may fall out.

13. To install, reverse removal procedure.

1959 1. R emove drain plug (early) or filler

tube (late) to drain oil. 2. Disconnect oil cooler lines a nd speed

ometer cable. 3. Remove crankcase ven tilation clamp

from tran smission.

CHEVROLET

Fig. 31 Throttle linkage adjustment. 1958 Turboglide

4. Remove hose from vacuum modulator and from clamped attachment at side of transmission .

5. Disconnect rods from levers at transmission.

6. Disconnect propeller shaft from transmission.

7. Install suitable transmission lifting rig or other lifting device.

8. Disconnect engine rear mount on · transmission exten sion , then remove transmission support crossmember. If shims are present, be sure to reinstall exactly the number present as these effect drive line angles.

9. Remove transmission underpan. 10. Mark flywheel-to-converter relation

ship for assembly. T hen, using a jumper to turn over engine, remove flywheel-to -converter attaching bolts. The "light" side of converter is denoted by a "blue" stripe painted across the ends of the converter cover and housing. This marking should be aligned as closely as possible with the "white" stripe painted on the engine side of the flywheel outer rim to maintain balance during assembly.

11. Lower transmission slightly so that 3 upper transmission attaching bolts can be reached for removal. Do not lower transmission too far as there is danger of the ignition distributor housing being forced against the dash.

12. Support engine with jack at oil pan rail while transmission is removed.

13. Remove remaining attaching bolts and remove transmission from vehicle.