TS790 & TS900 - RS Components...

Transcript of TS790 & TS900 - RS Components...

TS790 & TS90010 - 56 Zone Intruder Alarm

Control Panels

Installation & Programming

Manual

1 2 3

4 5 6

7 8 9

ENT 0 ESC

A B COMIT AREA

POWER BUSY

1 2 3

4 5 6

7 8 9

ENT 0 ESC

A B COMIT AREA

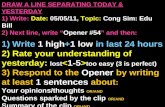

Engineers menu 1Select Option :-

1 2 3

4 5 6

7 8 9

ENT 0 ESC

A B COMIT AREA

POWER BUSY

1 2 3

4 5 6

7 8 9

ENT 0 ESC

A B COMIT AREA

POWER FUNCTION

Contents

OverviewIntroduction . . . . . . . . . . . . . . . . . . . . . . . . . 1System Architecture . . . . . . . . . . . . . . . . . . . 1Control Panel . . . . . . . . . . . . . . . . . . . . . . . . 1Remote Keypads . . . . . . . . . . . . . . . . . . . . . 2

32 Character LCD (TS900.REM). . . . . . . . . 28 Character Starburst (TS790.STAR) . . . . . . 24 Character LED (TS700.REM) . . . . . . . . . . 2Remote Arming Station (TS700.ARM) . . . . 2

TS900 NODE . . . . . . . . . . . . . . . . . . . . . . . . . 2ID Node (TS900.IDNODE). . . . . . . . . . . . . . . . 2TS700 LEC . . . . . . . . . . . . . . . . . . . . . . . . . . . 2Specifications . . . . . . . . . . . . . . . . . . . . . . . . 2

General. . . . . . . . . . . . . . . . . . . . . . . . . . . 2Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . 2Physical . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

System InstallationCable Routing . . . . . . . . . . . . . . . . . . . . . . . 3Node Network Wiring (TS900 Only) . . . . . . . . 3Remote Network Wiring . . . . . . . . . . . . . . . . 4Combined Network Wiring (TS900) . . . . . . . . 4Control Panel Installation . . . . . . . . . . . . . . . 5Control Panel PCB Layout. . . . . . . . . . . . . . . 6Connection Terminals & Indicators . . . . . . . 7Mains Connection . . . . . . . . . . . . . . . . . . . . 8Battery Connection . . . . . . . . . . . . . . . . . . . 8Remote Keypads . . . . . . . . . . . . . . . . . . . . . 8

TS900 LCD Remote Keypad . . . . . . . . . . . 8TS790 Star Remote Keypad . . . . . . . . . . . 8TS700 LED Remote Keypad . . . . . . . . . . . 9TS700 Remote Arming Station . . . . . . . . . 9Installation Procedure. . . . . . . . . . . . . . . . 9

Engineer’s Keypad . . . . . . . . . . . . . . . . . . . . 10TS900 Node Installation (TS900 Only) . . . . . . 10TS900 Node Layout. . . . . . . . . . . . . . . . . . . . 11TS700 Lec Installation . . . . . . . . . . . . . . . . . . 12Wiring Detection Circuits . . . . . . . . . . . . . . . 12

Double Pole . . . . . . . . . . . . . . . . . . . . . . . 12End Of Line . . . . . . . . . . . . . . . . . . . . . . . . 13

External Sounder Connections . . . . . . . . . . . 13Installing an External Sounder from a Node14

Auxiliary Tamper. . . . . . . . . . . . . . . . . . . . . . 14Extension Loudspeakers. . . . . . . . . . . . . . . . 14Digicom/RedCARE Installation . . . . . . . . . . . 15Plug-on Digicom Installation . . . . . . . . . . . . 15Plug-on digi-Modem Installation . . . . . . . . . 15Output Modules Installation (CPA6.OM) . . . 16Connecting a Printer . . . . . . . . . . . . . . . . . . 16

Using the CPA6 Printer . . . . . . . . . . . . . . . 16Using the DATAC / RS232 Printer . . . . . . . . 16

Programmable Outputs. . . . . . . . . . . . . . . . 17Control Panel Outputs . . . . . . . . . . . . . . . 17Node Outputs . . . . . . . . . . . . . . . . . . . . . 17Remote Keypads & TS700.LECs. . . . . . . . 17

Installing a Monitored Power Supply . . . . . . 18Pre Power-Up Checks . . . . . . . . . . . . . . . . . 18Initial Power-Up . . . . . . . . . . . . . . . . . . . . . . 18Power-Up Checks . . . . . . . . . . . . . . . . . . . . 19NVM Defaults . . . . . . . . . . . . . . . . . . . . . . . . 19

Engineer’s Menu 1Introduction . . . . . . . . . . . . . . . . . . . . . . . . . 21

Menu contents . . . . . . . . . . . . . . . . . . . . 21Panel Outputs . . . . . . . . . . . . . . . . . . . . . . . 22Digicom Outputs . . . . . . . . . . . . . . . . . . . . . 22Digicom Channels . . . . . . . . . . . . . . . . . . . 22Programmable Output Types . . . . . . . . . . . 22Program Circuits . . . . . . . . . . . . . . . . . . . . . 25

Circuit Types. . . . . . . . . . . . . . . . . . . . . . . 25Circuit Attributes . . . . . . . . . . . . . . . . . . . . 26

System Timers . . . . . . . . . . . . . . . . . . . . . . . 27Setting Modes . . . . . . . . . . . . . . . . . . . . . . . 30Do System Print . . . . . . . . . . . . . . . . . . . . . . 30Remote Reset Algorithm . . . . . . . . . . . . . . . 31Configuration. . . . . . . . . . . . . . . . . . . . . . . . 31Goto User Menu 1 . . . . . . . . . . . . . . . . . . . . 33

Menu contents . . . . . . . . . . . . . . . . . . . . 33View Location Text (LCD Only) . . . . . . . . . . . 34

Engineer's Menu 2Introduction . . . . . . . . . . . . . . . . . . . . . . . . . 35

Menu Contents . . . . . . . . . . . . . . . . . . . . 35View Circuits. . . . . . . . . . . . . . . . . . . . . . . . . 36Set System Time. . . . . . . . . . . . . . . . . . . . . . 36

Set System Date. . . . . . . . . . . . . . . . . . . . . . 36Change Passcode . . . . . . . . . . . . . . . . . . . 36Chime Circuits . . . . . . . . . . . . . . . . . . . . . . . 37Alter 24Hr Group . . . . . . . . . . . . . . . . . . . . . 37Print System Log . . . . . . . . . . . . . . . . . . . . . . 37Configure Wards . . . . . . . . . . . . . . . . . . . . . 37Log Event Codes . . . . . . . . . . . . . . . . . . . . . 38View System Log . . . . . . . . . . . . . . . . . . . . . 38Log Event Codes . . . . . . . . . . . . . . . . . . . . . 39Log Event Codes . . . . . . . . . . . . . . . . . . . . . 40Reset User Code 1. . . . . . . . . . . . . . . . . . . . 40Start Call Back . . . . . . . . . . . . . . . . . . . . . . . 40

Engineers Menu 3Introduction . . . . . . . . . . . . . . . . . . . . . . . . . 41

Menu Contents . . . . . . . . . . . . . . . . . . . . 41Time Switches . . . . . . . . . . . . . . . . . . . . . . . 42Part Set Groups . . . . . . . . . . . . . . . . . . . . . . 43

Part Set Group Operation . . . . . . . . . . . . 43Code Set Groups. . . . . . . . . . . . . . . . . . . . . 43

Code Set Group Operation . . . . . . . . . . . 43Engineers Name (LCD Only) . . . . . . . . . . . . 44Part Set Text (LCD Only) . . . . . . . . . . . . . . . . 44Circuit Text (LCD Only) . . . . . . . . . . . . . . . . . 44Custom Text Menu (LCD Only) . . . . . . . . . . . 44

Reset Message . . . . . . . . . . . . . . . . . . . . 44Banner Message . . . . . . . . . . . . . . . . . . . 44Location Text . . . . . . . . . . . . . . . . . . . . . . 45Printer Header . . . . . . . . . . . . . . . . . . . . . 45Part Set Banner. . . . . . . . . . . . . . . . . . . . . 45

Node Outputs . . . . . . . . . . . . . . . . . . . . . . . 45Built In Tests . . . . . . . . . . . . . . . . . . . . . . . . . 45

Current Consumption . . . . . . . . . . . . . . . 45Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . 46View Circuit Resistance (LCD Only) . . . . . 46Test Digi Outputs . . . . . . . . . . . . . . . . . . . 46

View Inactive Circuits . . . . . . . . . . . . . . . . . . 46Custom Outputs A & B. . . . . . . . . . . . . . . . . 47

Custom Output - Example 1 . . . . . . . . . . 47Custom Output - Example 2 . . . . . . . . . . 47Custom Output - Example 3 . . . . . . . . . . 47

Modem Options (LCD Only). . . . . . . . . . . . . 48Call Back No.1 . . . . . . . . . . . . . . . . . . . . . 48Call Back No.2 . . . . . . . . . . . . . . . . . . . . . 48Call Back No.3 . . . . . . . . . . . . . . . . . . . . . 48Modem Password . . . . . . . . . . . . . . . . . . 48Modem Site No.. . . . . . . . . . . . . . . . . . . . 48Program Digicom . . . . . . . . . . . . . . . . . . 48

Reset Digicom . . . . . . . . . . . . . . . . . . . . . 50

AppendicesPoint ID Extended Reporting . . . . . . . . . . . . . 51Resetting the Engineers passcode . . . . . . . . 51Domestic Part-Set Application Example . . . . 53

Defining Part-Set buttons to Omit a Ward . 53Defining Part-Set buttons to Arm a Ward(s) 54

Commercial Part-Set Application . . . . . . . . . 56Key Point Application Example. . . . . . . . . . . 56Time Switch Application Example. . . . . . . . . 57Alarm Abort & Confirmation . . . . . . . . . . . . . 57

Alarm Abort Operation . . . . . . . . . . . . . . . 57Sequential Confirmation Operation . . . . . 57

Text Editing Keys . . . . . . . . . . . . . . . . . . . . . . 58Cursor Types . . . . . . . . . . . . . . . . . . . . . . . 58Common Key Sequences . . . . . . . . . . . . 58

Setup New Users . . . . . . . . . . . . . . . . . . . . . . 59User Types . . . . . . . . . . . . . . . . . . . . . . . . . 59

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61Engineers Menus. . . . . . . . . . . . . . . . . . . . . . 62User Menus . . . . . . . . . . . . . . . . . . . . . . . . . . 62

OverviewIntroductionThe TS790 and TS900 alarm control systems havebeen designed to suit medium to large installationsites. The TS900 system can be expanded from 10to 56 zones, whereas the TS790 is expandablefrom 10 to 16 zones. Both systems feature “up” and“down” line loading, allowing the system to beremotely programmed or interrogated via thetelephone line and a P.C.

Complex site requirements such as multi-wardsetting can be achieved, as both systems arecapable of being broken down into 4 separatelycontrolled areas (Wards) so that the premises orparts of the premises can be control ledindependently.

System Architecture

Control PanelThe control panel is the controlling unit for thesystem, it has a power supply and connections fora standby battery. It has the following facilities:

l 8 programmable detection circuits

l Bell and strobe outputs

l 4 programmable outputs (1 x Voltage freecontacts and 3 high current transistorised)

l 8 programmable digicom/RedCARE outputs

l A connector for a Menvier plug-on digicom ordigi-Modem

l Extension loudspeaker output

l All system program information and the 700event log is stored in a removable non-volatilememory (NVM)

TS900NODE

2 Outputs

8 Zones

TS900NODE

2 Outputs

8 Zones

TS900NODE

2 Outputs

8 Zones

TS900NODE

2 Outputs

8 Zones

TS900NODE

2 Outputs

8 Zones

CONTROLPANEL

TS900 NODENETWORK

TS900 ID NODETS900NODE

2 Outputs

8 Zones30 ID Zones

8 Outputs(Two Options)

REMOTEKEYPADor LEC

1 Outputs

2 Zones

REMOTEKEYPADor LEC

1 Outputs

2 Zones

REMOTEKEYPADor LEC

1 Outputs

2 Zones

REMOTEKEYPADor LEC

1 Outputs

2 Zones

REMOTENETWORK

(8 Zones)

Printer

Speaker

CPA6.OM

AUX 12V

Plug-onDigicom/Modem

Bell output

Strobe output

Digi outputs 1 - 8

Outputs 1 - 4

Figure 1. TS790 & TS900 System Architecture

TS790 & TS900 Installation Manual Overview

1

Remote KeypadsUp to 4 remote keypads can be connected to thecontrol panel. Each remote keypad has twodetection circuits and a single switched -veoutput. There are four types of remote keypadsthat can be used:

32 Character LCD (TS900.REM)The TS900 remote keypad has a backlit 32character super-twist Liquid Crystal Display (LCD)and a backlit tactile rubber keypad. When usingthe LCD Keypads the text for user codes, partsetting modes and circuit identification can beprogrammed to make the operation andprogramming of the system easier.

8 Character Starburst (TS790.STAR)The TS790 remote keypad has a backlit 8character starburst display (LCD) and a backlittactile rubber keypad.

4 Character LED (TS700.REM)The TS700 remote keypad has a 4 character LEDdisplay and backlit tactile rubber keypad. Whenusing the LED remote keypads, text can not beprogrammed but all other system functions areavailable.

Remote Arming Station (TS700.ARM)The Remote Arming Station only allows setting andunsetting of the system. The unit has two indicatorLEDs, the “Power LED” and a programmable“Function LED” (the “Function LED” may beprogrammed as “Fault” or “Area Set” etc.).

TS900 NODEThe TS900 Node provides eight programmabledetection circuits and two programmable outputs(Can only be used on the TS900).

ID Node (TS900.IDNODE)The TS900 ID NODE can be used as an alternativeto the standard TS900 Node. It provides a single IDDetector Loop for connection to 30 ID devices and8 programmable outputs. Several configurationoptions allow it to be used on its own or with existingTS900 Nodes. (Can only be used on the TS900.)

TS700 LECThe Local Expansion Card (LEC) provides twoprogrammable detection circuits and oneprogrammable output.

Specifications

GeneralZones TS790 - 10 to 16

TS900 - 10 to 56Expansion 2 zone LECs and/or Keypads

8 zone Nodes (TS900 only)30 zone ID Nodes (TS900 only)

Outputs (Panel) 12 + 8 via plug-on digicomKeypad types 32 Character LCD

8 Character Starburst LCD4 Character 7-segment LEDLED Arming station

ElectricalMains Input 230 ±10% 50Hz ±5%Control Panel 220mA (normal)

300mA (alarm)Battery 12V 7Ah Sealed Lead AcidPower Supply TS790 - 1.0A

TS900 - 1.5ALCD keypad 40mA (normal) 50mA (alarm)Starburst keypad 50mA (normal) 60mA (alarm)LED keypad 60mA (normal) 70mA (alarm)Arming Station 30mA (normal) 40mA (alarm)TS900 Node 60mA (normal) 60mA (alarm)ID Node 80mA (with 1 device)

160mA (with 30 devices)TS700 LEC 30mA (normal) 30mA (alarm)

PhysicalControl panel 335(W) x 265(H) x 85(D)mm

4.7KgRemote Keypads 130(W) x 130(H) x 30(D) mm

280gNodes (all types) 128(W) x 182(H) x 34(D) mm

370gTS700 LEC 142(W) x 82(H) x 36(D) mm

213gEnvironment -10 to 55°C

Overview TS790 & TS900 Installation Manual

2

System InstallationCable RoutingWhen installing cables, the following should benoted:

+ Screened cable may prove necessary if theNetwork is run adjacent to cables thatproduce R.F. or are switching high currentloads, e.g., mains, telephone, computer.

+ Ensure that all Network and detection circuitcables are kept clear of mains supplycables, telephone cables, R.F. cables andcables supplying bells or sounders.

+ Mains power supply cables to the systemmust be connected to an un-switchedfused spur that cannot be accidentallyswitched off, and must enter the housing viaits own cable entry point.

+ In larger installations it may prove necessaryto fit remote power supplies to overcomeexcessive voltage drops in the cable runs. Itis recommended that the Menvier 519XB isused in these instances as it can be faultmonitored by the control panel.

Node Network Wiring (TS900 Only)Nodes require a 4 core cable for interconnection,and may be connected in a “daisy-chain” or “star”configuration. The distance between each Nodemust not exceed 100 metres. Power for detectorsis provided by the Aux +/- terminals. Oninstallations that utilise the Node outputs to drivesounders and strobes it may be necessary to fit aremote power supply (Figure 2) to prevent overloading of the control panel power supply.

Control PanelNode

Node

NodeNetwork

Node Node

IN OUT

AUX

IN OUT

AUX

AUX

AUX12V

-+

IN OUT

AUX

IN OUT

AUX

Node

100m

I/D=1 I/D=2

Power ForDetectors

Power ForDetectors

Power ForDetectors

Power ForDetectors

Remote PSU(519 XB)

Power ForDetectors

I/D=3

I/D=5

I/D=4

ABFG

ABFG

ABFG

ABFG

ABFG

ABFG

ABFG

ABFG

ABFG

ABFG

ABFG

100m 100m 100m

Figure 2. TS900 Node Network Wiring

TS790 & TS900 Installation Manual System Installation

3

Remote Network WiringDevices on the “Remote Network” require a 6 corecable for in te rconnect ion, and may beconnected in a “s tar” or “daisy-chain”configuration. The distance to the furthest devicefrom the control panel must not exceed 100metres. Power for detectors are provided by the Aand B terminals (Figure 3).

Combined Network Wiring (TS900)On some installations it may be desirable to havea remote keypad connected after the Nodes. Thiscan be achieved by using an eight core cablefrom the control panel and connector strips withinthe Node and remote keypads (Figure 4).

RemoteNetwork

Spare Core

Control Panel

Power ForDetectors

Power ForDetectors

Power ForDetectors

Power ForDetectors

I/D=2I/D=1 I/D=3 I/D=4RemoteKeypador LEC

A B C D E

RemoteKeypador LEC

A B C D E

RemoteKeypador LEC

A B C D E

RemoteKeypador LEC

A B C D E

ABCDE

100 Meters (Max.)

Figure 3. TS790 & TS900 Remote Network Wiring

RemoteKeypador LEC

NodeNetwork

RemoteNetwork

Control Panel

Power ForDetectors

Power ForDetectors

Power ForDetectors

CDE

IN OUT

AUX 12V

NodeI/D=2

ABFG

ABFG

IN OUT

AUX 12V

Node

A B C D EI/D=1

ABFG

ABFG

ABFG

IN OUT

AUX 12V

NodeI/D=3

ABFG

ABFG

100 Meters (Max.)

100mConnector Strips

Figure 4. TS900 Combined Network Wiring

System Installation TS790 & TS900 Installation Manual

4

Control Panel InstallationProceed as follows:

1. Open the control panel by removing twoscrews from the front cover. Remove the coverby sliding it up slightly to disengage the bottomclip, disconnect the earth bonding cable fromthe spade connection on the front cover, thenlift clear.

2. Note the position of the cable entries as follows:

(a) Plastic cable entries and 20mm knock-outstop and bottom for trunking.

(b) Eight 20mm cable entries for detection,alarm and remote keypad cables.

(c) A 20mm cable entry for mains (240V)above the mains input terminal block onthe right hand side of the control panelback box.

+ The mains cable must enter the controlpanel through its own cable entry andmust not be mixed with other cables.

3. Hold the control panel back box in the requiredposition (keyhole to the top) and mark thecentre of the keyhole position. Remove theback box, drill and plug the hole.

4. Screw a No 10 screw into the plugged hole.Re-position the back box and mark theremaining four securing holes. Remove theback box, drill and plug the holes.

5. Re-position the back box and pass all cablesinto the base via the trunking holes orknockouts, grommeting as appropriate.

6. Secure the back box using not less than 30mmx No 10 screws through the four dished 5mmholes.

7. If required install and connect the following:

(a) Stand alone digicom or RedCARE STU.

(b) Plug-on digicom type DC54, DC58 orDC58M.

(c) Output modules type CPA6.OM.

(d) Printer type DATAC or serial RS232 via aprinter adapter (MPA).

(e) Relay module type RM.3A.

+ When replacing the cover, alwaysensure that the earth bonding lead isconnected to the spade connectionon the front cover.

Key-hole mounting Lid tamper Mains cable entry

Mains fusedterminal block

Mainstransformer

Printed Circuit Board (PCB)Earth bonding lead(connected to front cover)

Space for a 7 Ahlead acid battery

20mm cableentries

Figure 5. TS790 & TS900 Control Panel Layout

TS790 & TS900 Installation Manual System Installation

5

Control Panel PCB Layout

OUTPUT MODULE PRINTER

1 AMPNODE SUPPLY

REMOTEKEYPAD

JP3

DIGI-MODEMFACTORYRESET

Node Networkconnection terminals(TS900 Only)

Auxiliary 12V

Auxiliary 12V

RemotekeypadNetworkconnections

ProgrammableDetectionCircuits 1 - 8

Digicom OutputsProgrammable @ 100mA

12V Digicom Power

Line Fault Input (12V = Fault)

Auxiliary Tamper

Extension loudspeaker

External sounderconnections

21V A.C. from mainstransformer

Earth connection

Panel OutputsO/P 1 = Change over contactsO/P 2 = Switched -ve @ 500mAO/P 3 = Switched +ve @ 500mAO/P 4 = Switched +ve @ 500mA

Z1

Z2

Z3

Z4

Z5

Z6

Z7

Z8

T1

T2

T3

T4

T5

T6

T7

T8

CIR

CU

IT1

CIR

CU

IT2

CIR

CU

IT3

CIR

CU

IT4

CIR

CU

IT5

CIR

CU

IT6

CIR

CU

IT7

CIR

CU

IT8

RRJP5

JP6

SPEAKERVOLUME

NOVRAMS

AUX 12V

BELL 12V1 AMP

BATTERY FAULT

POWERON

EA

RT

HT

RG -

ST

B -T

R-

H/O -

H/O +

SP

K+

AU

XTA

MP

LIN

EF

LT+

DC

12

34

DIG

ITA

LC

OM

MU

NIC

AT

OR

56

78

AU

X

ARE

MO

TE

NE

TW

OR

KB

CD

E

+4

+3

-2A NO

DE

NE

TW

OR

KO

UT

PU

T1

--O

UT

PU

TS

--B

GF

N/O

N/C

CO

M0V

12V

0V12V

PO

WE

RA

. C.

V

1 AMPFS3

FS4

JP1JP4

JP2 EN

GIN

EE

RS

RE

MO

TE

U2 U3

Figure 6. TS790 & TS900 Main PCB

System Installation TS790 & TS900 Installation Manual

6

Connection Terminals & IndicatorsThe main PCB has the following “Jumper Plugs” (JP)and indicator LEDS:

JP1 PRINTERThis 6-pin plug is used for connecting toeither a CPA6.P printer or a standard RS232printer via the MPA printer adaptor.

JP2 ENGINEERS REMOTEAn Engineers remote keypad may betemporally connected to this 6-pin plug toallow programming and testing to becarried out at the control panel.

JP4 DIGI-MODEMA plug-on digicom or digi-Modem may beconnected to this 7-pin plug to allow panelalarm information to be transferred to acentral station. The digi-Modem is used forremote communication and programmingvia a P.C. The PCI lead also connects to thisplug when using the P.C. for directcommunication with the control panel.

JP4 OUTPUT MODULEOutput Modules type CPA6.OM may beconnected to this 5-pin plug, and are usedto prov ide switched -ve outputs toLEDs/relays etc. The outputs may beprogrammed such that they will mimiccircuit activations or activate only when acircuit causes an alarm condition.

JP5 RRIf the panel is programmed as “EngineerReset”, shorting the “Remote Reset” (RR) pinsafter an alarm condition will cause the panelto reset. These pins could be connected tothe “Control” output on a RedCARE STU sothat the central station may provide a“Remote Reset” facility.

JP6 FACTORY RESET)If these pins are shorted during power-up allsystem parameters are reset to their factorydefault settings. If the engineer’s passcodeis lost or forgotten it can be reset to 1234without loosing any other program data. Theprocedure for resetting the engineer’spasscode is described on page 51.

VR1 SPEAKER VOLUMEWhen an extens ion loudspeaker isconnected to the control panel terminalsthe volume of the advisory tones may beadjusted using this control.

+ Alarm tones are always at full volume.

U2/3 NOVRAMSA removable non-volatile memory (NVM)device that stores all system programparameters and the 700 log events. Theevent log can be expanded to 1800 eventswhen the second NVM(U2) is fitted. Ordercode PP5.MEMKIT (5 x NVMs).

LED1 POWER ONThis LED indicates that the system power(mains or battery) is healthy.

LED2 BATTERY FAULTIf the system battery is incorrectly connectedto the control panel or the battery voltagelevel is below 4 Volts then the “Battery Fault”LED will illuminate. The fault LED will onlyextinguish when the battery has beencorrectly connected or replaced.

V SYSTEM CURRENT CONSUMPTIONThe system current consumption may becalculated by measuring the Voltage acrossthis test point on the main PCB. Using aVoltmeter set to a low Voltage rangemeasure the Voltage across the test pointand multiply the reading by 10 to give theTotal system current consumption i.e., areading of 70mV = 700mA.

TS790 & TS900 Installation Manual System Installation

7

Mains ConnectionThe mains supply is connected to a 3 way "EuroType" fused terminal block, which is fitted with a315mA fuse. All electrical connections should becarried out by a qualified electrician and mustcomply with the current IEE regulations.

+ To comply with european regulations thesupply should be fed from a readilyaccess ib le disconnect device, e.g.un-switched fused spur fitted.

+ When making mains connections it shouldbe ensured that if the cable slips in such away as to place a strain on the conductors,the protective earthing conductor will bethe last to take the strain.

Battery ConnectionA 7Ah battery must be fitted to the system to allowit to function during a mains fail condition. TheTS790/TS900 is equipped with a “Battery Protection”circuit so that if a battery is accidentally reverseconnected or its voltage is below 4V, the “BatteryFault” LED illuminates. To clear the fault simplyreconnect or replace the battery as appropriate.

Remote KeypadsFour types of remote keypads can be used on thesystem, however, only the TS900 remote keypadcan be used for programming text information.Any combination of remote keypad may be usedon the same system if desired.

TS900 LCD Remote KeypadThe TS900 remote keypad has a 32 characterback-lit Liquid Crystal Display (LCD).

TS790 Star Remote KeypadThe TS790 remote keypad has a 8 characterback-lit starburst Liquid Crystal Display (LCD).

L

E

N

To transformer

FUSE 315mA

Figure 7 Mains Supply Connections

2 Detectioncircuits

Programmable outputswitched -ve

@100mA

I/DSelector

TamperSwitch

A B

REMOTEI/D1

23

4ENG

C D E O/P-

CIR

CU

ITB

CIR

CU

ITA

ZB

ZA

TB

TA

Remote networkconnections

LCD Module

DIS

AB

LED

WA

RD

SO

UN

DE

RC

ON

TR

OL

Figure 8 TS900 Remote Keypad Layout

Programmable outputswitched -ve@ 100mA

Remote networkconnections

= Disabled

2 Detectioncircuits

'ENT'Key

Disable

WARD SOUNDERCONTROL

DISABLE

I/DSelector

TamperSwitch

A B

REMOTEI/D1

23

4ENG

C D E O/P-

CIR

CU

ITB

CIR

CU

ITA

ZB

ZA

TB

TA

LCD Module

Figure 9 TS790 Star Remote Keypad Layout

System Installation TS790 & TS900 Installation Manual

8

TS700 LED Remote KeypadThe TS700 remote keypad has a 4 character LEDdisplay.

TS700 Remote Arming StationThe TS700 remote arming station only has twoindicator LED's, a power LED and a programmablefunction LED which follows the programmableoutput.

Installation Procedure.

+ Always ensure that all power (mainsand battery) is removed beforemaking any connections to theremote keypad.

1. Separate the cover and base by using ascrewdriver to push 2 of the clips (top orbottom) inward from the base indents, then liftthe cover assembly, noting that the PCB is fixedto the under side of the cover.

2. Hold the base in position (keyhole to the top)and mark the three securing holes, drill andplug the wall as required. Pass all the cablesinto the base via the cable entry points asappropriate and secure the base to the wall.

3. Connect “Remote Network” and detectioncircuit cables to the appropriate terminals, seeFigure 8.

4. Set the I/D selector jumper link to the requiredposition:

I/D Selector Circuit A Circuit B PanelOutput

1 09 10 5

2 11 12 6

3 13 14 7

4 15 16 8

ENG/NULL N/A N/A N/A

l No two remote keypads or LECs shouldhave the same I/D.

l If the I/D is set to “ENG” the remote keypadwill function as an Engineer’s keypadallowing it to be plugged onto the controlpanel so that system programming andtesting may be carried out (see Engineer’sKeypad).

5. I f the remote keypad has a "ENT" keyenabled/disable link it can be used to limit thefunctionality of the remote keypad. If the "ENT"key is enabled the remote keypad can beused to set/unset and access all user menus.If the "ENT" key is disabled the remote keypadcan only be used to set and unset the system.

6. If the remote keypad has a “Ward SounderControl” link it can be used to make the remotekeypad sounder follow the programmableoutput. When the link is set to the disabled

2 Detectioncircuits

Programmable outputswitched -ve

@100mA

I/DSelector

TamperSwitch

A B

REMOTEI/D1

23

4ENG

C D E O/P-

CIR

CU

ITB

CIR

CU

ITA

ZB

ZA

TB

TA

Remote networkconnections

LED Module

DIS

AB

LED

WA

RD

SO

UN

DE

RC

ON

TR

OL

DISABLED

'ENT' KEY

Figure 10 TS700 Remote Keypad Layout

TamperSwitch2 detection

circuits

Programmable outputswitched -ve

@100mA

I/DSelector

A B

REMOTEI/D1

23

4

DISABLED

DISABLED

WARD SOUNDERCONTROL

'ENT' KEY

ENG

C D E O/P-

CIR

CU

ITB

CIR

CU

ITA

ZB

ZA

TB

TA

Remote networkconnections

Figure 11 TS700 Arming Station Layout

TS790 & TS900 Installation Manual System Installation

9

position the sounder responds as normal.When the link is set to the enabled position thesounder is only enabled when the remotekeypad programmable output is active. Forexample, to make the keypad ward respectivefor ward A, program the output on the remotekeypad to "Sounder Control A" (type 064) andset the "Ward Sounder Control" link to theenabled position.

7. Finally clip the remote keypad cover onto thebase being careful not to trap any cables or toobstruct the tamper switch.

Engineer’s KeypadNormally all system programming will be carriedout from one of the installed remote keypads,however sometimes it may be more convenientto program the system at the control panel. Thiscan be achieved by using an “Engineers Keypad”which is temporarily plugged on to the controlpanel (JP2). To convert a standard remote keypadto an “Engineers Keypad” an Engineer’s interfacelead is required which can be obtained from yoursupplier (P/No. NETEKI).

TS900 Node Installation (TS900 Only)The TS900 NODE allows the facility to add an extraeight programmable detection circuits and twoprogrammable outputs . The Nodes areconnected on the “Node Network” and up to fivemay be connected to the TS900 system.

+ Always ensure that all power (mainsand battery) is removed beforemaking any connections to the Node.

1. Separate the cover and base by using ascrewdriver to push 2 of the clips (left or right)inward from the base indents, then lift the coverclear.

2. If the Node is being fitted inside the controlpanel you may remove the Node PCB from itsbase and secure it to base of the control panelusing self adhesive feet. If required, the tamperswitch may also be disabled by fitting thejumper link across JP2, see Figure 13.

3. If the Node is being fitted outside the controlpanel, hold the base in position and mark thefour securing holes. Drill and plug the wall asrequired, then pass all cables into the base viathe cable entry points as appropriate. Securethe base to the wall using the appropriate fixingscrews.

4. Connect “Node Network” cables anddetection circuit cables to the appropriateterminals, see Figure 13.

5. Set the I/D selector jumper link to the requiredposition:

Node I/D

1 2 3 4 5

CIRCUITS

A 17 25 33 41 49

B 18 26 34 42 50

C 19 27 35 43 51

D 20 28 36 44 52

E 21 29 37 45 53

F 22 30 38 46 54

G 23 31 39 47 55

H 24 32 40 48 56

OPs+A 1 3 5 7 9

-B 2 4 6 8 10

l No two NODES should have the same I/D.

l The NODE I/D selector DOES NOT have tobe set sequentially but it is advisable so asto aid fault finding and programming.

6. Finally clip the Node cover onto the basebeing careful not to trap any cables or toobstruct the tamper switch.

Control Panel

To TS900RemoteKeypad

A (Red)A

AU

X12V

0V

EN

GIN

EE

RS

RE

MO

TE

JP2

C (Yellow)B

B (Black)CD (White)DE (Blue)E

7 Way 0.1" Molexconnector

Figure 12 Engineer's Keypad Connections

System Installation TS790 & TS900 Installation Manual

10

TS900 Node Layout

A B F G A B F GAUX 12V

AUX 12V500mA

NODE I/D

JP2ZA

ZH

ZG

ZF

ZE

ZC

ZD

ZB

CIR

CU

ITA C

IRC

UIT

HC

IRC

UIT

GC

IRC

UIT

FC

IRC

UIT

E

CIR

CU

ITC

CIR

CU

ITD

CIR

CU

ITB

TA

TH

TG

TF

TE

TC

TD

TB

JP2 FITTED = NO TAMPER

Fit jumper-link to disabletamper switchTamper switch

I/D selector

Programmabledetection

circuits A - D

From previousNode

Mains power indicatorOn = mains onFlashing = mains off

Auxiliary 12V output(for powering detectors)

Programmable outputs:[A+] = switched +ve @100mA[B -] = switched -ve @100mA

To next Node

Programmabledetectioncircuits E - H

Auxiliary 12Vfuse (500mA)

12345

A BO/P

NETWORK IN NETWORK OUT

+ + - - -+

Figure 13 TS900 Node Layout

TS790 & TS900 Installation Manual System Installation

11

TS700 LEC InstallationThe TS700 LEC (Local Expansion Card) isconnected to the “Remote Network” and providestwo additional programmable detection circuitsand a programmable output. The “RemoteNetwork” may have up to three LECs connected,as the system will always require at least oneremote keypad.

+ Always ensure that all power (mainsand battery) is removed beforemaking any connections to the LEC.

1. Remove the cover from the base and carefullyremove the PCB.

2. If the LEC is being fitted inside the control panelyou may remove the LEC PCB from its baseand secure it to base of the control panel usingself adhesive feet. If required, the tamperswitch may also be disabled by fitting thejumper link across JP2, see Figure 14.

3. If the LEC is being fitted outside the controlpanel, hold the base in position and mark thetwo securing holes. Drill and plug the wall, thenpass all cables into the base via the cable entrypoints. Secure the base to the wall using theappropriate fixing screws.

4. Connect “Remote Network” cables anddetection circuit cables to the appropriateterminals, see Figure 14.

5. Set the I/D selector jumper link to the requiredposition:

I/D Selector Circuit A Circuit B PanelOutput

1 09 10 5

2 11 12 6

3 13 14 7

4 15 16 8

NULL N/A N/A N/A

l No two LECs or remote keypads shouldhave the same I/D.

l DO NOT set the I/D selector to the “NULL”position.

6. Finally clip the LEC cover onto the base beingcareful not to trap any cables or to obstruct thetamper switch.

Wiring Detection CircuitsAll detection circuits may be wired as "End Of Line"(EOL) or "Double Pole" (DP). Both methods can beused on the same equipment.

Double PoleThe DP method requires the following:

l The detector alarm and tamper contacts areconnected to the zone and tamper terminalsrespectively.

l The combined alarm and tamper loopresistance must be less than 100 Ohms.

l The maximum number of detection devicesallowed in a circuit is ten.

l Normally open devices such as pressure padsand exit terminator buttons are connectedbetween the zone and tamper terminals.

l If the detection circuit is not used links can befitted across the zone and tamper loops orprogrammed as Not Used.

Networkconnections

Programmableoutputswitched -ve@100mA

Tamper switch

Fit jumper-link todisable tamper switch

CABLE ENTRY

CABLE ENTRY

Programmabledetection circuits

I/D selector

CC

TB

ED

CB

LEC

I/D

A

12

34

NULL

JP2TAMPER = JP2 NOT FITTEDNO TAMPER = JP2 FITTED

CC

TATA

TB

ZA

ZB

O/P

Figure 14 TS700 LEC Layout

System Installation TS790 & TS900 Installation Manual

12

End Of LineThe EOL method requires the following:

l The detector alarm contacts must have a 4K7shunt resistor fitted.

l A 2K2 End of Line (EOL) resistor must be fittedat the point in the circuit furthest from thecontrol panel.

l Loop resistance with the EOL resistor shortedmust be less than 100 Ohms.

l The maximum number of detectiondevices allowed in a circuit is ten.

l Normally open devices such as pressurepads and exit terminator buttons areconnected across outer terminals

l If the detection circuit is not used links canbe fitted across the zone and tamper loopsor programmed as Not Used.

External Sounder ConnectionsThe following terminals have been provided toallow connections to an external sounder:

H/O - This is used to provide a permanent -vehold off to external sounders, strobes etc.

H/O + This is used to provide a permanent +vehold off to external sounders, strobes etc.It is protected by a 1 Amp fuse (Bell 12V).

TR - This is the negative tamper returnconnection from the siren or bell.

STB - This is the strobe output which will switch to0V on alarm and is rated at 500mA.Connect the other side of the strobe to theH/O +.

TRG - This is the bell trigger output which willswitch to 0V on alarm and is rated at500mA. This output can be programmedfor SAB or SCB operation, as follows:SAB: TRG - will switch to 0V on alarm andwill provide a maximum of 500mA.

SCB: TRG - will provide a negative holdoff (500mA), which is removed on alarm.

Alarm

TamperCIR

CU

ITAZ

ATA

CIR

CU

ITAZ

ATA

CIR

CU

ITAZ

ATA

Alarm

Tamper

Max. 10 devices per circuit

Wiring N.O. devices (Exit Terminators)

Alarm

Tamper

500 meters or 100 Ohms

Figure 15 Double Pole Wiring

500 meters or 100 Ohms

Alarm

Alarm

Tamper

Max. 10 devices per circuit

Wiring N.O. devices (Exit Terminators)

Tamper

4K7 = Yellow, Violet, Red2K2 = Red, Red, Red

Alarm

Tamper

4K74K7

4K7

2K2

2K2

2K2

CIR

CU

ITBZ

BT

BC

IRC

UIT

BZB

TB

CIR

CU

ITBZ

BT

B

Figure 16 End of Line Wiring

TS790 & TS900 Installation Manual System Installation

13

Installing an External Sounder from a NodeThe TS900 Node has two programmable outputs,these can be utilised to drive an external sounder.However, it is recommended that a remote powersupply is fitted next to the Node in order to providesufficient power for the external sounder. A relaymodule such as the Menvier RM3A is also requiredto drive the external sounder. The figure belowshows the connection details.

Auxiliary TamperThese two terminals provide tamper protection toauxiliary devices such as power supplies, extensionloudspeakers etc. If they are not used they mustbe linked out.

Extension LoudspeakersUp to two extension loudspeakers can beconnected across the [SPK+] and [H/O-] terminalson the control panel PCB. The volume for theloudspeaker is controlled by VR1"SpeakerVolume".

Aux12V

RLY 2COIL -

COIL -

SPARE 1

SPARE 2

TAMPER

RM3ASAB

MODULE

REMOTEPOWERSUPPLY

NODESPARE 3

SPARE 4

STROBE-

STROBE +

TAMPER OUT

TAMPER IN

TRIGGER

+12V

0V

TAMPER

CIRCUIT X

Program circuitas: NIGHT

ZX

TX

COIL +

COIL + RLY 2

COM

COM

N/O

N/O

N/C

N/C

RLY 1

RLY 1

12V0V

+-

A+B-

Figure 17 External Sounders Connection - Node

1 x 16 Ohm Loudspeaker

2 x 16 Ohm Loudspeakers

SPK+H/O -

SPK+H/O -

Figure 18 Loudspeaker Connections

TypicalExternal Sounder

ControlPanel

H/O + 12V +

H/O - 0VTamper InTR -

STB - Tamper Out

TRG - Strobe +veStrobe -veTrigger -ve

Figure 19 External Sounder Connections

System Installation TS790 & TS900 Installation Manual

14

Digicom/RedCARE InstallationA stand alone digital communicator, RedCARE STUor Paknet interface card can be connected to thecontrol panel using the following connections:

Digicom Outputs 1 to 8These are the programmable digicom outputconnections. They are normally at +12V andswitch to 0V when active. The outputs can beinverted so that they switch from 0V to +12V whenactive (see System Configuration on page 31).Each output will source 5mA in the +12V conditionand sink 100mA in the 0V condition.

+DC POWERThis provides the +12V power to the digicom. Thisoutput is un-fused and therefore should only beused if the digicom is fitted inside the controlpanel. The 0V supply for the digicom/STU can bepicked up from any of the auxiliary 0V terminals.

LINE FLTWhen this input is switched to +12V, a “Line Fault”condition is generated. A “Line Fault” condition Inthe unset mode will cause a “Chime” type tone tobe generated every minute, which can besilenced by entering any valid passcode. A “LineFault” condition In the set mode will cancel the“Bell Delay”.

Plug-on Digicom InstallationA plug-on digital communicator DC54 or DC58may be fitted inside the control panel to allowalarm status information to be transferred to adedicated central station. The unit should be fittedin accordance with the installation instructionssupplied with it and connected to the controlpanel plug DIGI-MODEM (JP3) using the leadprovided with the unit, see Figure 21. The NVMwithin the digicom can be programmed via thecontrol panel, see page 48.

Plug-on digi-Modem InstallationA plug-on digi-modem DC58M may be fittedinside the control panel to allow remoteinterrogation and programming via a personalcomputer (PC). It will also function as a standarddigicom (if required). The unit should be fitted inaccordance with the installation instructionssupplied with it and connected to the controlpanel plug DIGI-MODEM using the lead providedwith the DC58M. The NVM within the digi-modemcan be programmed via the control panel, seepage 48. The modem data is also programmedvia the control panel.

ControlPanel

3GSTU

1

1+DC POWER

ProgramAs:-Open (060)Alarm (005)PA (006)Fire (007)

LINE FLT

AUX 0V

2

2

3

3

4

4

5

TB

1

Channel Inputs areProgrammed asPositive Removed

TB

2T

B3

TB

4

Control

LineF

aultR

PS

5

6

6

7

7

0VNO

NONO

NCNC

NC8

8

CC

CA+

A+A+

A+V+

Figure 20 3GSTU RedCARE Connections

Connect to JP7DIGI-MODEM

Plug-on digicom / digi-modem

AB

BC

B.T. master jack ( Type NTE5user accessible connections )

A(5) = White / Blue ring

BC(3) = Blue / White ringB(2) = Orange / White ring

Telephone cable(Type 1/0.5mm CW1308)

665544

332211

Figure 21 DC54/DC58 Connections

TS790 & TS900 Installation Manual System Installation

15

Output Modules Installation (CPA6.OM)Output Modules (CPA6.OM) can be used toprovide a set of outputs to LEDs or relays to indicateeither circuit alarm activations or circuit mimicactivations. The first output module connected tothe system will indicate circuits 1 to 8, the nextmodules will indicate circuits 9 to 16 etc. Outputmodules are normally fitted inside the equipmentthey are controlling and may be positioned up to500 metres away from the main panel. The outputmodule should be used and connected inaccordance with the instructions provided with it.

Connecting a PrinterThe TS790/900 supports two type of printers, theCPA6 printer (no longer available) and anystandard RS232 printer. When using a RS232 printera DCI/MPA printer adaptor will be required. MenvierSecurity supply a DATAC printer kit which consists ofa portable RS232 printer, charger unit andDCI/MPA adaptor.

Using the CPA6 Printer1. Plug the CPA6 printer directly on to the PRINTER

plug (JP1) on the main control panel PCB.

2. The printer will print-out a header, when finishedthe system program details and event log canbe printed.

3. When finished unplug the printer. If the printeris left connected events will be printed as andwhen they occur.

Using the DATAC / RS232 Printer1. Plug the DCI/MPA on to the PRINTER plug (JP1)

on the main control panel PCB.

2. Plug the other end of the DCI/MPA into theDATAC or RS232 printer.

3. In order for the printer to work correctly ensurethe printer is set to the following:

Baud rate = 4800Parity = NoneStart bits = 1Stop bits = 2Data bits = 8DTR = Normal

4. When set-up correctly the system programdetails and event log can be printed.

5. When finished unplug the MPA/DCI. If the printeris left connected events will be printed as andwhen they occur.

PL1

1k Resistors

LED's

1 2 3 4 5 6 7

+12

VIN

+12

VO

UT

+12

VO

UT 8

PL2

To next OM

Connect to pluglabelled OUTPUTMODULE

100m

Figure 22 Output Module Connections

DC58M

TelephoneNetwork

V21.Modem

Alarm ReceivingCentre

TS790/900 ControlPanel

Figure 23 DC58M Digi-modem Schematic

System Installation TS790 & TS900 Installation Manual

16

Programmable OutputsThe TS790/900 has many programmable outputswhich can be used to drive relays, LED’s etc. Eachoutput can be programmed for a differentfunction, see "Programmable Output Types" onpage 22.

Control Panel OutputsThe control panel has four programmable outputs:

[1] Set of voltage free change-over contactsrated at 1 Amp.

[-2] Switched -ve output rated at 500mA.

[+3] Switched +ve output rated at 500mA.

[+4] Switched +ve output rated at 500mA.

Node OutputsEach TS900 Node has two programmable outputs:

[+A] Switched +ve output rated at 100mA.

[-B ] Switched -ve output rated at 100mA.

Remote Keypads & TS700.LECsEach remote keypad and TS700 LEC has oneprogrammable output:

[O/P] Switched -ve output rated at 100mA.

RelayRelay

SmokeDetector

SmokeDetector

Relay available fromRS componentsP/No. 346-946.Capable of switchingmains voltages

Relay available fromRS componentsP/No. 346-946.Capable of switchingmains voltages

+ 12 V + 12 V

Aux 12 V

Aux 0V -ve O/P

+ve O/P

(Programmed as Alarm / Bell / etc)

(Programmed as Alarm / Bell / etc)

(Programmed as Detector Reset)

(Programmed as Detector Reset)

Aux 0V

Aux 0V

Aux 0V

+ve Outputs -ve Outputs

1K0 Ohm Resistor

12V BuzzerRS Part No. 245-051

12V BuzzerRS Part No. 245-051

1K0 Ohm Resistor

LED (Light Emiting Diode) LED (Light Emiting Diode)

-Ve O/P

-Ve O/P

-Ve O/P

+ve O/P

+ve O/P

+ve O/P

Aux 12V

Aux 12V

Aux 12V

0V 0V

Diode (IN418)Diode (IN418)

Figure 24 Output Examples

MPAor DCI

DATAC or RS232 printer

CPA6 Printer

RS232 Data

Connect to JP1PRINTER

Connect to JP1PRINTER

11

CPA6 PCPA6 P

DATA INPOWER

PAPER FEED

Figure 25 Printer Connections

TS790 & TS900 Installation Manual System Installation

17

Installing a Monitored Power SupplyThe TS790/TS900 can be configured to monitor the519XB power supply unit using the 519FM faultmonitor PCB. The 519FM plugs directly onto the519XB PCB plug labelled JP1.

The 519FM PCB monitors any combination of:

l Supply Failure (mains)

l Low Battery Voltage

l 12V Failure (fuse failure)In order to monitor the above fault conditions, theoutputs on the 519FM must be connected to adetection circuit.

If required, the PSU battery can be “load tested”periodically by connecting a switched +ve outputto the 519FM BATT TEST terminal. The battery testoccurs every hour on the hour for one minute, ifduring this time the battery voltage drops below10.6V a “Battery Fault” indication wil l begenerated.

Pre Power-Up ChecksOnce the system is installed, but prior topowering-up give the system one final check toensure that:

1. The wiring conforms to the requirementsdetai led in th is manual and that al linterconnections are correct (A to A, B to B etc.).

2. All system cables are kept clear of mainssupply cables, telephone cables and R.F.cables. It is recommended that cable ties beused to keep cables separated.

3. Verify that maximum cable lengths andresistances are not exceeded.

4. Mains power supply cables to the system areconnected to an un-switched fused spur.

5. Grommets are used where cables enter metalhousings to ensure that insulation is notcompromised.

Initial Power-UpTo power the system for the first time:

1. Place a small screwdriver blade between thepins on the control panel PCB, marked“FACTORY RESET”. This will ensure the factorydefault parameters are set, see page 19.

2. Switch on the 240V mains supply and removethe screwdriver blade.

3. Check that the power LED on the control panelPCB is illuminated.

4. Check that the LED remote keypads display“LT” (Panel Lid tamper) and LCD remotekeypads display “Panel Lid tamper”. Theremote keypad sounders and extensionloudspeakers will operate.

5. Enter the engineers passcode (default 1234) tosilence the sounders.

6. Connect the standby battery.

PSU. Power

PSU. Batt

PSU. Fuse

SupplyFailBatteryLow

12VFail

Batt Test0V

Aux 0V

O/P A+

TC

TB

TA

ZC

ZB

ZA

CIR

CU

ITC

CIR

CU

ITB

CIR

CU

ITA

Battery Test (045)

Program As:-

NODE

519 FM

Figure 26 Monitored Power Supply Connections

System Installation TS790 & TS900 Installation Manual

18

Power-Up ChecksWhen the initial power-up checks have beencompleted, check the following:

1. Switch off the 240V mains supply and measurethe DC voltage at each Node and remotekeypad and ensure the voltage is greater than11V whilst the system is powered from itsstandby battery.

2. Switch on the 240V mains supply and measurethe DC voltage between the mains earthconnection and AUX +12V. Then measure theDC voltage between the mains earthconnection and AUX 0V. In both cases themeasurement should be 1V or less. If thevoltage is greater than 1V, the system has an“Earth Fault” and all cables should be checkedfor isolation to Earth.

3. Using a voltmeter measure the DC voltageacross the control panel PCB test points (V) andcalculate the system current consumption(see page 7). Ensure that the reading is notgreater than 1.0A for the TS790 and 1.5A for theTS900.

4. Repeat test (3) with the system in an alarmcondition and ensure that the reading is notgreater than 1.0A for the TS790 and 1.5A for theTS900.

+ The TS790 & TS900 have an overloadprotection circuit. If the power supply isoverloaded, the display will show: “PSUOVERLOAD ! ! !” and sounder will sound.

NVM Defaults

Section Option Default

User CodesUser 00 Engineer 1234

User 01 Master 5678

User 02 - 31 Not Used

PanelOutputs

Panel Output 1 Walk Test

Panel Output 2 Courtesy Light

Panel Output 3 Switch 12V

Panel Output 4 Detector Reset

Panel Output 5 Code Accepted

Panel Output 6 Code Accepted

Panel Output 7 Code Accepted

Panel Output 8 Code Accepted

DigicomOutputs

Digicom Output 1 Fire

Digicom Output 2 PA

Digicom Output 3 Alarm

Digicom Output 4 Set

Digicom Output 5 Engineer on Site

Digicom Output 6 Bell

Digicom Output 7 Tamper

Digicom Output 8 Second Alarm

DigiChannels

Digi Channel 1 Fire

Digi Channel 2 PA

Digi Channel 3 Alarm

Digi Channel 4 Set

Digi Channel 5 Engineer on Site

Digi Channel 6 Bell

Digi Channel 7 Tamper

Digi Channel 8 Second Alarm

NodeOutputs

Node Output 1 Walk Test

Node Output 2 Courtesy Light

Node Output 3 Switch 12V

Node Output 4 Detector Reset

Node Output 5 Code Accepted

Node Output 6 Code Accepted

Node Output 7 Code Accepted

Node Output 8 Code Accepted

Node Output 9 Code Accepted

Node Output 10 Code Accepted

CircuitsCircuit 01 Final Exit

Circuit 02 Night (Access)

Circuit 03 - 06 Night

TS790 & TS900 Installation Manual System Installation

19

Section Option Default

Circuits

Circuit 07 Exit Terminator

Circuit 08 PA Audible

Circuit 09 Final Exit

Circuit 10 PA Audible

Circuit 11 - 56 Not Used

System Timers

00 ACPO Delay 000 seconds

01 No of Re-arms 000

02 Settle Time 007 seconds

03 Part Set Coms Dly 000 seconds

04 Exit Time 030 seconds

05 Entry Time 015 seconds

06 Bell Duration 020 minutes

07 Bell Delay 000 minutes

08 D-Knock Delay 000 seconds

09 Test Time 014 days

10 Second Entry 015 seconds

11 Service Time 000 weeks

12 Payment Time 000 weeks

13 Part Set Bell Delay 030 seconds

14 Courtesy Duration 030 seconds

15 Access Code Dur. 030 seconds

16 Modem Rings 000

17 Point ID Alarm 005

18 Ward Menu Dur. 000 seconds

19 Test Call 000 days

20 2nd Alarm Duration 060 seconds

21 Part Set Codes 021

22 Line Fault Delay 000 minutes

23 Mains Off Delay 000 minutes

24 No. Remote Resets 005

25 Monitor Duration 010 minutes

26 Activity Duration 024 hours

27 Part Set Entry Time 015 seconds

28 Abort Delay 180 seconds

SettingModes

Full Set Final Exit Setting

Part Set A Timed Exit

Part Set B Timed Exit

Part Set C Timed Exit

Rem Reset Algorithm 004

Configuration00 Bell is an SAB Yes

01 User 1 Limited No

Section Option Default

Configuration

02 Fire Signals All No

03 Silent 24hr Circuits No

04 Enable Duress Yes

05 Invert Abort No

06 Set With Line Fault Yes

07 User Reset Yes

08 Constant Exit Tones Yes

09 Hi Security Engineer No

10 O/M's Mimic Ccts Yes

11 Do Battery Test No

12 Final Exit is Night No

13 Audible Time Switch No

14 Show P.Set Info. Yes

15 Deferred Set No

16 Set with AC Off Yes

17 Loud Chime Tones No

18 Invert Output 1 No

19 Invert Digi Outputs No

20 On-Line Keypad Yes

21 Restore Point ID Yes

22 User Authorised No

23 Mimic Alarm & Fault No

Part SetGroups

Part Set Group A Ward A

Part Set Group B Ward B

Part Set Group C Ward C

Code SetGroups

Code Set Group A Ward A

Code Set Group B Ward B

Code Set Group C Ward C

Full Set Group Wards SABC

Custom Text

Reset Message CALL ENGINEER TORESET SYSTEM

Banner Message Blank

Location Text Blank

Printer Header Blank

Part Set Banner Blank

ModemOptions

Call Back No 1 Blank

Call Back No 2 Blank

Call Back No 3 Blank

Modem Password Blank

Modem Site No. Blank

System Installation TS790 & TS900 Installation Manual

20

Engineer’s Menu 1IntroductionEngineers menu 1 is the first of three engineersmenus, which is selected when the engineer’spasscode is entered. The engineer may leave“Engineer menu 1" by pressing the [ESC] key. Thesystem will return to the unset condition but theremote keypads will show ”Engineer-on- site". Thismessage will be cleared the next time a valid userpasscode is entered or by exiting the engineer'smode via user menu 1.

Menu contents

Hotkey Option Page

1 Program Panel Outputs 22

2 Program Digicom Outputs 22

3 Program Digicom Channels 22

4 Program Circuits & Attributes 25

5 Program System Timers 27

6 Program Setting Modes 30

7 System Print-out 30

8 Remote Reset Number 31

9 Program Configuration 31

0 Goto User Menu 1 33

B View Location Text 34

Engi neer s menu 1Sele ct Opti on :-

Engi neer s menu 2Sele ct opti on :-

Panel outp ut ?Ente r Number >-

Di gi outp ut ?Ente r Number >-

Di gi ch annel ?Ente r Number >-

Pr ogra m ci rc ui tsEnte r CCT No.> --

Syst em Ti mersEnte r Number >- -

Sett in g Modes ?Ente r Group >-

Syst em Pr in t OutLi ne Number 001

Remote Rese tAl gori th m >004

Conf ig ur at io nEnte r Number

User menu 1Sele ct Opti on:-

Engi neer on Si te12:1 9 Wed 22 AUG

1

2

3

4

5

6

7

8

9

0

ENT

ESC

ESC

1 2 3 4

Enter Engineer'sPasscode

PANEL IS INRECEPTIO N CLOSETB

Engineers Menu 1

TS900 Installation Manual Engineer's Menu 1

21

Panel OutputsOutputs 1 - 4 on the the control panel and remotekeypad outputs 5 - 8 can be programmed to anyof the output types shown on page 22 .

Digicom OutputsThe 8 digicom outputs on the control panel PCBcan be programmed to any of the output typesshown on page 22. In addition, all outputs can beinverted, see “Configuration option 19” on page32.

Digicom ChannelsThe 8 plug-on digicom channels can beprogrammed to any of the output types shown onpage 22.

Programmable Output Types

No/Type Description

000Bell On

Activates when the main Bell trigger ison and deactivates at the end of theBell Duration time or when the alarm iscancelled by the user.

001Strobe On

Activates when the Strobe trigger is on,and deactivates when the alarm iscancelled by the user.

002Switch 12V

Activates when the system is set anddeactivates when an alarm occurs orthe system is unset. This output isnormally used for latching detectors.

003Detector Reset

Normally active at all times anddeactivates for 3 seconds when a validpasscode is entered prior to setting thesystem. This output is normally used fordetector that required power to beremoved in order to reset them, e.g.,smoke detectors.

004Walk Test

Activates when the “Walk Test” option isselected and deactivates when the“Walk Test” option is finished.

005Alarm

Activates when an intruder alarm isdetected and deactivates when thealarm is reset or aborted.

Panel Outp ut ?Ente r Number > -

Panel Outp ut 1is ty pe > 004

Panel Outp ut 1is ty pe > 021

Enter new output type

Type No.

1

Enter output No. 1 - 8e.g. 1

ENT

e.g. 021

Engi neer s menu 1Sele ct Opti ons :-

StarburstLCD LED

E1 -ENGR 1 -

PAN.-PANEL -

004004

021021

Panel Outputs Flowchart

Di gi Outp ut ?Ente r Number > -

Di gi Outp ut 7is ty pe > 020

Di gi Outp ut 7is ty pe > 071

Enter new output type

Type No.

2

Enter output No. 1 - 8e.g. 7

ENT

e.g. 071

Engi neer s menu 1Sele ct Opti ons :-

StarburstLCD LED

E1 -ENGR 1 -

DIG.-DIGI OP -

020020

071071

Digi Outputs Flowchart

Di gi Channel ?Ente r Number > -

Di gi Channel 8is ty pe > 011

Di gi Channel 8is ty pe > 055

Enter new output type

Type No.

3

Enter channel No. 1 - 8e.g. 8

ENT

e.g. 055

Engi neer s menu 1Sele ct Opti ons :-

StarburstLCD LED

E1 -ENGR 1 -

Dc5.-DIGI CH -

011011

055055

Digi Channels Flowchart

Engineer's Menu 1 TS900 Installation Manual

22

No/Type Description

006P.A.

Activates when a PA alarm is detectedand deactivates when the alarm isreset.

007Fire

Activates when a Fire alarm is detectedand deactivates when the alarm isreset.

008System Set

Activates when any ward is set anddeactivates when the system is fullyunset.

009Code Accepted

Activates for 10 seconds following entryof any valid passcode.

01024 Hour

Act ivates when a 24Hr alarm isdetected and deactivates when thealarm is reset.

011Second Alarm

Activates when a different detectorcauses an alarm and remains activefor the duration of the “2nd AlarmTime”. This output is normally used foran ALARM CONFIRMATION signal.

012Courtesy Light

Activates during entry and when anyremote keypad is used. The duration ofthis output is controlled by the settingof the “COURTESY DUR” timer.

013Engr On Site

Act ivates when the engineer ’spasscode is entered and deactivateswhen a user passcode is entered.

014Ccts Omitted

Activates when any circuit is omittedand deactivates when all circuits arereinstated.

015Auxiliary

Activates when an Auxiliary alarm isdetected and deactivates when thealarm is reset.

016Ward A Armed

Activates when “Ward A” is in exit modeand when “Ward A” is set. Deactivateswhen “Ward A” is unset.

017Ward B Armed

Activates when “Ward B” is in exit modeand when “Ward B” is set. Deactivateswhen “Ward B” is unset.

018Ward C Armed

Activates when “Ward C” is in exit modeand when “Ward C” is set. Deactivateswhen “Ward C” is unset.

019Ward S Armed

Activates when “Ward S” is in exit modeand when “Ward S” is set. Deactivateswhen “Ward S” is unset.

020Tamper Fault

Activates when a Tamper alarm isdetected and deactivates when thealarm is reset.

021Line Fault

Activates when a telephone line fault isdetected and deactivates when thefault is cleared.

022Mains Off

Act ivates when mains power isremoved and deactivates when themains power is restored.

No/Type Description

023Exit / Entry

Activates when the panel is in the exitor entry mode.

024Test Fail

Activates when a circuit fails test,deact ivates when reset by theengineer.

025First Knock

Activates when a double knock circuiti s act ivated for the f i r s t t ime.Deact ivates when the circuit isactivated for the second time or whenthe system is reset.

026Comms Failed

Activates for 5 seconds when theplug-on digicom fai ls tocommunicate.

027Comms Success

Activates for 5 seconds when theplug-on digicom communicatessuccessfully.

028Comms Active

Activates when the plug-on digicom isactive and deactivates when theplug-on digicom is inactive.

0292nd Entry

Activates when the second entry timeris started and deactivates when thesecond entry timer expires.

030Entry

Activates when the panel is in the entrymode.

031Exit

Activates when the panel is in the exitmode.

032Ward A Set Fail

Activates when “Ward A” fails to setand deactivates when the set failcondition is reset by the user.

033Ward B Set Fail

Activates when “Ward B” fails to set anddeactivates when the set fail conditionis reset by the user.

034Ward C Set Fail

Activates when “Ward B” fails to set anddeactivates when the set fail conditionis reset by the user.

035Ward S Set Fail

Activates when “Ward S” fails to set anddeactivates when the set fail conditionis reset by the user.

036Ward A Alarm

Activates when a night or final exitcircuit in “Ward A” causes an alarm(not tamper) and deactivates whenthe alarm in “Ward A” is reset.

037Ward B Alarm

Activates when a night or final exitcircuit in “Ward B” causes an alarm (nottamper) and deactivates when thealarm in “Ward B” is reset.

038Ward C Alarm

Activates when a night or final exitcircuit in “Ward C” causes an alarm(not tamper) and deactivates whenthe alarm in “Ward C” is reset.

039Ward S Alarm

Activates when a circuit in “Ward S”causes an alarm and deactivateswhen the alarm in “Ward S” is reset.

TS900 Installation Manual Engineer's Menu 1

23

No/Type Description

040Time Switch A

This output is controlled by the settings of“Time Switch A” (see Engineers Menu 3)

041Time Switch B

This output is controlled by the settings of“Time Switch B” (see Engineers Menu 3)

042Time Switch C

This output is controlled by the settings of“Time Switch C” (see Engineers Menu 3)

043Access Code

Activates when an “Access” passcodeis entered. The duration of this output iscontrolled by the sett ing of the“Acc.CODE DUR” timer (see SystemTimers).

044General Fault

Activates during battery fault or whenthe system is prevented from being set.Deactivates when al l faults arecleared.

045Battery Test

Activates for 1 minute on the hour everyhour. This output is used to test the batteryin remote PSU using a 519FM monitorPCB).

046Service Call

Activates when the system is on-linewith a remote PC and Lineloadsoftware.

047System Full Set

Activates when all areas within thesystem are set and deactivates whenany area is unset.

048Custom O/P A

Th i s output i s act ive when acombination of output conditionsoccur . The combinat ions areprogrammed in Engineers Menu 3 (seepage 47).

049Custom O/P B

Th i s output i s act ive when acombination of output conditionsoccur . The combinat ions areprogrammed in Engineers Menu 3 (seepage 47).

050PC output 1

This output can be switched on or offvia the PC and “Lineload” software.

051PC output 2

This output can be switched on or offvia the PC and “Lineload” software.

052Sounder Control

Normally used as the 0V connection foran extension loudspeaker so that onlysystem alarm tones are generated.Only suitable for Panel Outputs 1 and2.

053Service Required

Act ivates when the “SERVICEREQUIRED” message is displayed anddeactivates when the engineerpasscode is entered.

054Call Engineer

Activates when the system requires an“Engineer Reset”, deactivates whenthe system is reset by the engineer or“Remote Reset”.

055Always Off

Never activates.

No/Type Description

056Duress

Activates when a duress passcode isentered and deactivates when theduress alarm is reset.

057System Part Set

Activates when the system is part set,deactivates when the system is fullyunset or fully set.

058Battery Fault

Activates when a battery fault occursand deactivates when the battery faultis cleared.

059Set Fail

Activates when any ward fails to set,deactivates when the set fail conditionis reset.

060Open/Close

Activates when the system is unset,deactivates when the system isset/part-set.

061ID Alarm

Activates for 2 seconds when anycircuit causes a new alarm condition.

062Random

Activates randomly (min = 5 minutes,max =60 minutes)

063Modem lockout

Act ivates when the modem islocked-out (four failed attempts).Deactivates when a master userpasscode is entered or after 4 hours.

064Sndr Control A

Activates when “Ward A” is in entry, exit,alarm or set fail.

065Sndr Control B

Activates when “Ward B” is in entry, exit,alarm or set fail.

066Sndr Control C

Activates when “Ward C” is in entry, exit,alarm or set fail.

067Sndr Control S

Activates when “Ward S” is in entry, exit,alarm or set fail.

068Chime

Activates for 2 seconds when a circuitthat is programmed as “chime” isactivated.

06924hr Ccts Omit

Activates when one or more 24 Hourcircuits are omitted.

070Timed Output

Activates when a “Monitored” circuit istriggered and remains active for theduration of the “Monitor Dur" seeSystem Timers.

071Abort

Activates for 5 seconds after an alarmis aborted by the user. The period inwhich the alarm may be aborted is setby the “Abort Delay” see System Timers.

100 - 155Circuit Mimics

Will mimic (active when circuit is active)circuits 01 to 56 respectively

200 - 255Circuit Alarms

Active when a circuit causes an alarm,for circuits 01 to 56 respectively .

Engineer's Menu 1 TS900 Installation Manual

24

Program CircuitsThe TS790 can monitor up to 16 detection circuits,whereas the TS900 can monitor up to 56 detectioncircuits. Each circuit must be programmed in orderfor the system to respond correctly.

Circuit TypesThe circuit type defines how the circuit will respondwhen it is triggered. The following circuit types areavailable:

0 Not UsedA circuit that will never generate any alarm.

1 NightA circuit that will generate a full alarm when thesystem is set.

2 24hrA circuit which is monitored at all times. Whentriggered in the unset condition a local alarmis generated and when triggered in the setcondition a full alarm is generated.

3 PA SilentA circuit which is monitored at all times. Whentriggered it will activate any outputs that areprogrammed as P.A.

4 PA AudibleA circuit which is monitored at all times. Whentriggered it will activate any outputs that areprogrammed as P.A. and generate a full alarmcondition.

5 FireA circuit that is normally connected to a smokedetector. When triggered it will generate a firetone on the internal sounders, the externalsounders are pulsed for the bell duration andany outputs programmed as fire will beactivated.

6 AuxiliaryA circuit which is monitored at all times. Whent r iggered i t w i l l act ivate any outputsprogrammed as Auxiliary.

7 Final ExitThis must be the first detector or door contactthat is triggered when entering the protectedarea. When the setting mode for the system isprogrammed for Final Exit setting, opening andclosing of this circuit during the exit procedurewill cause the system to set. Once set,activation of this circuit will start the entry timer.

8 Exit TerminatorA circuit that is normally connected to a pushbutton outside the protected premises, whichcan be used to finally set the system or area.

9 KeypointA circuit that may be connected to a keyswitchto allow setting and/or part-setting of thesystem.The Key Point circuit has two groups ofattributes. The first group of attributes controlthe wards that are set/unset when the circuit isswitched between “Healthy” and “Active”. Thesecond group of attributes control the wardsthat are set/unset when the circuit is switchedbetween “Healthy” and “Shorted”.When programming the Key Point circuit theeight standard attributes are not available,instead the attributes are used to select the KeyPoint operation as follows:

[1] Full Set Group - “Healthy” to “Active”.[2] Code Set Group A - “Healthy” to “Active”.[3] Code Set Group B - “Healthy” to “Active”.

[4] Code Set Group C - “Healthy” to “Active”.[5] Full Set Group - “Healthy” to “Shorted”.

[6] Code Set Group A - “Healthy” to “Shorted”.[7] Code Set Group B - “Healthy” to “Shorted”.[8] Code Set Group C - “Healthy” to “Shorted”.

If the “Key Point” is not assigned to any of theabove options, the circuit becomes a“Monitored” circuit. A “Monitored” circuit ismonitored at all times. When triggered it willactivate any outputs that are programmed asTimed Output and log the event.

A PSU-BatteryThis circuit may be connected to the 519XBpower supply via the 519 FM PCB to allow themonitoring of the standby battery. See“Monitoring a Power Supply” on page 18.

B PSU-FuseThis circuit may be connected to the 519XBpower supply via the 519 FM PCB to allow themonitoring of the standby battery. See“Monitoring a Power Supply” on page 18.

C PSU-PowerThis circuit may be connected to the 519XBpower supply via the 519 FM PCB to allow themonitoring of the mains power failure. See“Monitoring a Power Supply” on page 18.

TS900 Installation Manual Engineer's Menu 1

25

Circuit AttributesEach circuit type can have one or more attributesassigned to it to alter its operation. The followingcircuit attributes can be programmed:

1 AccessCircuits programmed with this attribute areautomatically isolated during the entryprocedure to allow a “walk through” route forthe user to access the remote keypad. The“Access” attribute can only be assigned toNight and Final Exit circuit types.

2 Double KnockCircuits programmed with this attribute will onlycause an alarm condition if:

a) The circuit is activated twice within theDouble Knock window (this time may be set inthe System Timers menu).

b) The circuit remains active for the wholeduration of the Double Knock window. The“Double Knock” attribute can only be assignedto Night, 24hr and Auxiliary circuit types.

3 TestCircuits with this attribute will be disabled fromthe system for the period set by the “Test Time”(see System Timers). If the circuit is activatedduring this period the activation will be loggedand the user is informed of the circuit failurewhen trying to set the system. The test failmessage may only be cleared with theEngineers passcode. If at the end of the testperiod no activations have occurred the circuitis automatically removed from test andbehaves as normal. The test period is initiatedby entering the Engineers passcode. The “Test”attribute can only be assigned to Night, 24hr,PA Silent, PA Audible, Fire, Auxiliary, PSU Battery,PSU Fuse and PSU Power circuit types.

4 OmittableCircuits with this attribute are allowed to beomitted by the user when setting the system.The “Omit” attribute can only be assigned toNight, 24hr, Auxiliary, PSU Battery, PSU Fuse andPSU Power circuit types.

5 ResetThis attribute is normally assigned to a circuitthat is connected to a vibration or smokedetector, so that during the “Detector Reset”period the circuit is not monitored. The “Reset”attribute can only be assigned to Night, 24hr,Fire and Auxiliary circuit types.

6 FlaggedCircuits with this attribute are monitored duringthe unset condition so that when they activatethe circuit activation is stored. When the userdecides to set the system, any circuits thathave not been activated during the “ActivityDur” period are reported to the user, indicatingthat the detector may be obstructed. Anexample of this feature would be to assignmovement detectors within a warehouse areawith this attribute. This would report to the userat the time of setting any detectors that havebecome obstructed by pallets etc. The“Flagged” attribute can only be assigned toNight, Final Exit and Exit Terminator circuit types.

7 EntryCircuits with this attribute will initiate the entryprocedure when the system is part-set andrespond as normal when full set. This attributemust be assigned to all circuits that arerequired to initiate the entry procedure in thepart-set condition. The “Entry” attribute can onlybe assigned to Night, 24hr and Final Exit circuittypes. When assigned to a 24 Hour circuit type,the circuit can be used to initiate the entryprocedure. Once the system is unset the 24hour will revert to normal operation.

8 ChimeCircuits with this attribute will cause the internalsounders and remote keypad sounders togenerate a two tone “chime” sound if thecircuit is activated. The users may enable ordisable the chime feature, or select it tooperate when the system is unset or part-set.The “Chime” attribute may only be assigned toNight, 24hr, Auxiliary, Final Exit and ExitTerminator circuit types.

Engineer's Menu 1 TS900 Installation Manual

26

System TimersThe system timers are as follows:

00 ACPO DelayFor ACPO requirements this timer normally setto 90 seconds. If during the entry procedurethe user deviates from the entry route andgenerates an alarm, the communication ofthe alarm signal to the central station isdelayed by this timer. This timer has a workingrange of 000-199 seconds.

01 No of Re-ArmsAt the end of the bell duration time the systemre-arms all circuits that are healthy. Circuits thatare still in an alarm are isolated until theychange to a healthy condition. This countercontrols the number of times that a "circuit" willre-arm before it is locked out of the system. Thiscounter has a working range of 000-199.

02 Settle TimeWhen setting the system by “Final Exit” or “ExitTerminator”, detectors that are on the exit routesometimes take 3-4 seconds to settle afteractivation. The delay programmed in this timeris used to allow these detectors to settle beforethe system or area is set. This timer has aworking range of 000-199 seconds.

03 Part Set Comms DelayWhen the system is part -set thecommunication of an alarm signal to thecentral station can be delayed by the valueset in this timer. If the timer is set to 199 thepart-set communications are disabled. Thistimer has a working range of 000-199 seconds.

04 Exit TimeThis timer sets the delay between the userinitiating the exit procedure and the system (orarea) actually setting. If during the exit time an“Exit Terminator” circuit is activated the exit timeis cancelled and the system sets immediately.This timer has a working range of 000-199seconds.

05 Entry TimeWhen the system is set or part-set, and the entryprocedure is initiated, the entry timer starts tocount down. If a valid user passcode has notbeen entered when the timer reaches zero,the internal sounders are activated and the“2nd Entry. . .” timer is started. This timer has aworking range of 000-199 seconds.

06 Bell DurationThis controls the duration of the externalbell/sounder. If the timer is set to 199 the belloutput is continuous. This timer has a workingrange of 000-199 minutes.

Pr ogra m ci rc ui tsEnte r CCT No.> --

CCT 04 NI GHT

CCT 04 F. EXIT>* * * * * * * *

CCT 04 F. EXIT>* * * * * * * C

Enter circuit type:

= Not Used= Night= 24hr= PA Silent

Circuit No.

Attributes

Circuit Type

4

0

1

2

3

ENT

Enter circuit No.e.g. 04