TRP 700 / 900

Transcript of TRP 700 / 900

High Performance Rotary Presses

TRP 700 / 900

Synonymous for flexibility, power

and performance

The TRP Series: Superior Performance

Machines of the TRP series are double-rotary presses, ex-tremely sturdy and stable machines with two pre and main pressing stations and optionally 23-67 punch stations de-pending on the pressing format. Thanks to the unique modu-lar machine concept, customised TRP-presses are available in a number of different versions. This high level of flexibility

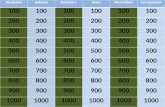

Number oftool stations

780 mm 23 31 33 35 37 39 47 55

1,000 mm 29 39 43 45 47 49 59 67

Number of compression stations

2 2 2 2 2/3 2 2 2/3/4/5

Description for all models N / N2S / 2S / 3S – 5S / NM / 2U / 2UM

TRP 700

Max. compression pressure kN 100 100 100 100 100 100 100 100

Max. pre-compression pressure kN 40 40 40 40 40 40 40 40

TRP 900

Max. compression pressure kN 200 200 200 200 200 200 200 200

Max. pre-compression pressure kN 60 60 60 60 60 60 60 60

Max. tablet diameter mm 64 59 54 49 44 39 34 27

Max. filling depth mm 40 (60) 40 (60) 40 (60) 40 (60) 40 (60) 40 (60) 40 (60) 40 (60)

Rotor speed min-1 5-30 5-30 5-30 5-30 5-30 5-30 5-30 5-40

Production ofsingle-layer tablets

780 mm pcs/hr 82,800 111,600 118,800 126,000 133,200 140,400 169,200 264,000

1,000 mm pcs/hr 104,400 140,400 154,800 162,000 169,200 176,400 212,400 321,600

Pitch diameter mm 780/1,000 780/1,000 780/1,000 780/1,000 780/1,000 780/1,000 780/1,000 780/1,000

Die diameter / Shoulder mm 80/92 70/76 64/70 59/65 56/62 46/54 45/51 38/44

Max. tablet height for a compression ratio of 1.6:1

mm 25/37 25/37 25/37 25/37 25/37 25/37 25/37 25/37

Shaft / Head diameter mm 65/75 60/70 55/65 50/60 45/50 40/50 35/45 28/40

Upper-punch insertion depth mm 5/17 5/17 5/17 5/17 5/17 5/17 5/17 5/25

TRP 700

Machine height mm 2,240 2,240 2,240 2,240 2,240 2,240 2,240 2,240

Footprint mm 1,400/1,400 1,400/1,400 1,400/1,400 1,400/1,400 1,400/1,400 1,400/1,400 1,400/1,400 1,400/1,400

Weight kg approx. 7,500 7,500 7,500 7,500 7,500 7,500 7,500 7,500

Total connected load kVA 35 35 35 35 35 35 35 35

TRP 900

Machine height mm 2,555 2,555 2,555 2,555 2,555 2,555 2,555 2,555

Footprint mm 1,500/1,500 1,500/1,500 1,500/1,500 1,500/1,500 1,500/1,500 1,500/1,500 1,500/1,500 1,500/1,500

Weight kg approx. 10,000 10,000 10,000 10,000 10,000 10,000 10,000 10,000

Total connected load kVA 90 90 90 90 90 90 90 90

KORSCH TRP 700/900 Technical Data

Technical modifications reserved.

The maximum compression force varies as a function of the tablet/

punch size and output. The maximum output varies as a function

of the material, tablet/punch size and compression force.

KORSCH TRP 700/900 presses comply with applicable safety regu-

lations as well the guidelines applicable in the German chemical

industry. They have been tested in accordance with EMV guide-

lines and are delivered with required EC certificate.

in the industrial tableting field is only provided by KORSCH. Likewise, permanent further development of the TRP-sys-tems is a matter of course. Thanks to the latest control and regulation equipment, fully automatic, electronically monitored and operator-free per-manent production is possible.

for Every Application.

Unique technical features and unprecedented versatility combine to make the KORSCH TRP Series the clear choice for reliable, high-speed, continuous tablet production.

Production Capabilities:✓ Alkaline Batteries✓ Lithium Batteries✓ Dishwasher Tablets✓ Laundry Detergent Tablets✓ Multi-Layer Detergent Tablets✓ Salt-Tablets✓ Magnets✓ Cleaning Tablets

✓ Fertilizer Tablets✓ Catalysts✓ Sintered Metals Components✓ Ceramic Oxide Components✓ Blanks for Electronic Industry✓ Effervescent Tablets✓ Food Supplement Tablets✓ Deep-Fill Pharmaceutical Tablets✓ Multi-Layer Pharmaceutical Tablets

ConfectionaryIndustry

Ph

arm

aceutical

Industry

Chemical IndustryTech

nical Industry

Food

Proc

essi

ng

Ind

us t

ry

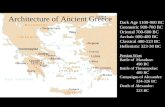

The TRP 700/900: Unique Design ...

The new machine design features five completely separate zones. The stand-alone control cabinet contains all electrical components and instrumentation required for operation and comes with a heat exchanger as standard equipment. Peripherals include a tablet deduster, metal-detection unit, tablet collection system and a tablet sampling unit.

Control cabinet

Touch Screen Operator Interface

Siemens or Allen-Bradley PLC Platform

PharmaControl®

Press Force Control Module

Single Tablet Rejection Module

Product Recipe Module

Equipment Diagnostic Module

Printer Interface

Head piece

Sealed housing for mechanical and electrical components. GMP execu-tion for Pharmaceutical applications

with smooth, paint free surface surrounding the compression zone.

Intermediate Shrouds

Insure an isolated and contained compression zone.

Compression Zone

Includes the main rotor, press tools, upper cam track, upper compression

stations, feeding units, and discharge chutes – designed with

quick-disconnect for efficient cleaning and changeover.

Lower Cam Track

Fully isolated from the compression zone with stainless steel shrouds,

includes the lower cam track, lower compression stations, and precision

adjustment motors.

Machine Base

This isolated zone includes the main drive, lubrication pump, hydraulic

components, electrical connections, and base plate with vibration

dampening footpads.

... Features for Superior Performance.

KORSCH TRP double rotary presses feature two pre- and main-compression stations and 23 to 67 punch stations depending upon the format of the blanks. The unique modular design of TRP presses makes it possible to configure installations to meet specific customer needs. KORSCH is the only manufacturer to offer such unprecedented versatility for industrial tablet production. KORSCH customers will also appreciate the fact that the TRP system will be regularly enhanced.

700/900-3S/5S

Dedicated multi-layer configuration for the production of three, four, and five layers. First layer filling depth of 40/60 mm, and filling depth to 25 mm on each subsequent layer provides ex-treme versatility. Low tamping force measurement and control capability - from 100 N to 20 kN, and a final compression force of 50 kN. Fully automated controls provide independent control of each layer weight.

700/900-NM

Dedicated tablet press for the high-speed production of rings – utilized extensively for the production of alkaline batteries. The TRP 700 is utilized for production of LR03 (AAA), LR06 (AA) rings, and the heavy tonnage TRP 900 is especially ideal for LR14 (C-size) and LR20 (D-size) configurations. Precompression ca-pability of 40-60 kN, and final compression force of 100-200 kN. Specially designed ejection system permits forces to 60 kN.

700/900-2U/2UM

Specialized configuration with two independently controlled lower punches for special shapes. Utilized primary for ceramics and sintered metals, this configuration offers extreme flexibility for the high-speed production of a wide variety of components. Available with a center pin in the lower punch for ring produc-tion.

700/900-2S

Dedicated bi-layer configuration with low tamping force mea-surement and control capability - from 100 N to 20 kN, and a final compression force of 50 kN. First layer filling depth up to 40/60 mm, and first layer insertion depth to 25 mm pro-vides maximum flexibility for first and second layer weight. Fully automated controls provide independent control of each layer weight.

700/900-N2S

Standard TRP 700/900-N with optional conversion kit for high-speed bi-layer tablet production. Conversion kit includes change parts for cam track and insertion depth adjustment to permit both single and bi-layer tablet production on the same machine for maximum flexibility.

700/900-N

Standard double-sided tablet press for high-speed production of single layer tablets. Precompression capability of 40/60 kN and main compression capability of 100/200 kN.

The Compression Zonefeatures exceptional accessibility

The compression zone has been completely redesigned for optimal cleaning and changeover, and features the exten-sive use of quick-disconnects for all components.

The Pharmaceutical model features a fully GMP-compliant compression zone, with stainless steel shrouds, and clean, smooth surfaces. The large rotor offers a range of 23-67 press stations, and the machine can produce a tablet to 60 mm in diameter. The maximum output is 321,600 tablets per hour at 40 RPM. The TRP 700/900 is clearly intended for continuous, high-speed production, and is designed to operate a minimum of 160 hours without any significant maintenance or service.

The Principle – Perfection.

The Press Toolsoffer a variety of options to eliminate picking and sticking

Picking and sticking – or the adherence of material to the punch surface can be a major issue for many technical and pharmaceutical products.

The TRP 700/900 offers the unique TWIST option, in which the upper and lower punch are twisted in opposite direc-tions just after compression – a system that has an extensive track record of success in many applications. In addition, in extreme cases, the machine can be equipped with rotary brushes that clean the punch surfaces, and if required, a spray lubricant system to facilitate tablet ejection.

In any case, these options permit the long-term continuous production of extremely difficult products.

The Sealsinsure exceptional dust containment and extended run durations

KORSCH machines feature a unique seal design between the rotor and the machine housing. A special labyrinth seal has no contact with the moving parts and is therefore wear-free. The seal requires absolutely no maintenance, provides optimal dust containment, and permits easy access for machine disassembly and cleaning. A similar sealing system is used on the four panels of the lower cam track, which features a quick-disconnect design. All machines offer an isolated and encapsulated compression zone as standard equipment and the noise level is limited to a maximum of 85 dB.

The Motorfor versatility and high performance

A new feature of the TRP 700/900 is the frequently drive on the main motor, in combination with a precision FLENDER DUPLEX worm gear transmission. This system provides high torque at all speeds, and a special high-speed control sys-tem provides immediate compensation of load variations between punches – to insure smooth, continuous produc-tion. The main motor has been rated to permit the start of the machine at any speed, under maximum load – without any difficulty.

The Controlssuperior capability in a user-friendly format

A new feature of the TRP 700/900 is the remote electri-cal cabinet and a user-friendly operator touch screen. The cabinet complies with IP54 and features a closed-loop heat exchanger. The TRP 700/900 features a modular control system design, on a Siemens or Allen-Bradley PLC platform. A press force control system with fuzzy logic control, and a single tablet rejection system can be installed for virtually any product. For pharmaceutical applications, the control system features an electronic event log. capability to track machine adjustments, alarms, and product recipes.Option: SCADA systems Win CC or Wonderware.

The Feeding Systemconsistent filling and dosing at high speed

The TRP 700/900 can be provided with a gravity feed frame, or if required, a variable speed force feeding system. These feeding systems are designed to eliminate the effect of head pressure to insure consistent filling throughout the batch. A level control system is provided for gravity feed systems to insure reproducible filling in a wide variety of technical applications.

The KORSCH TRP: Unique Capabilities.

Presses designed for maximum precision

The KORSCH TRP Series offers a extreme range of capability and performance for a wide variety of technical and phar-maceutical applications:

✓ Heavy Tonnage Main Compression Capability, 100-200 kN✓ Heavy Tonnage Recompression Capability, 40-60 kN✓ Ejection Force Capability to 60 kN✓ Punch Shafts with TWO Robust Guide Rollers✓ Hardened, Polished Guide Bushings for Precision Tool Alignment✓ Precision Tolerances on Press Tools✓ Tablet Diameter to 60 mm✓ Filling Depth to 60 mm✓ Upper Punch Insertion Depth to 25 mm✓ Center Pin Holder for Ring Shapes✓ GMP Compliant Execution for Pharmaceutical Applications✓ Stainless Steel Shrouding✓ Automatic Punch Lubrication System✓ Hydraulic Press Force Overload System✓ Frequency Controlled Main Drive with Precision Worm Gear✓ Optimal Dust Sealing for Efficient Service and Cleaning✓ Heavy Duty Construction for Long-Term Performance✓ Specifically Designed for Unattended and Continuous 3-Shift Production✓ Multi-Layer Capability (2, 3, 4 and 5 layer design)

Constant Monitoring of Machine Functions and Faults

The TRP Series is specifically designed for unattended operation, and features a comprehensive fault diagnostic system to insure maximum reliability. Monitored functions and faults include the following:

✓ Main Drive Motor✓ Compression Zone Sealing✓ Machine Windows and Panels✓ Precompression Force Limits (option)✓ Main Compression Force Limits✓ Ejection Force Limits (option)✓ Lubrication System Performance✓ Punch Removal Cam✓ Upper Punch Tightness✓ Lower Punch Tightness✓ Tablet Sticking to Upper Punch✓ Punch Breakage✓ Center Pin Breakage✓ Low Material Level✓ Lower Punch Removal Cam✓ Filling Cam✓ Dosing Cam✓ Press Force Control Limits (option)✓ Tablet Counter✓ Fuse Blown✓ Feeding System Blocked (option)✓ Compressed Air✓ Tablet Jam in Discharge (option)✓ Temperature in Main Bearings

An Overview.

✓ Performance

✓ Economy

✓ Long Service Life

✓ Controls

Efficient.

The TRP 700/900 Series offers an extensive array of signifi-cant advantages for a diverse range of product applications. For technical and pharmaceutical applications, this machine offers unprecedented versatility for high-speed production single layer, multi-layer, ring, and special shaped products. The TRP 700/900 represents the most advanced technology, and a commitment to continued improvement and innova-tion insured continued success in the future.

The KORSCH TRP Series is especially robust, and the press tool system provides extreme flexibility and reliability. This machine is ideal for continuous production over three shifts, and can be operated in an unattended and fully automated configuration.

Qualified.

Product DocumentationAt KORSCH, machine documentation, equipment qualifica-tion and validation services are treated with an extremely high level of importance. Detailed and comprehensive validation has been developed for all modules of the TRP machine for pharmaceutical ap-plications that require the highest standard of qualification. This documentation includes complete information pertain-ing to the machine hardware, software, calibration, and functional performance.

Process DocumentationThe KORSCH control system provides the opportunity for a wide range of process documentation and reports, includ-ing information pertaining to product recipes, press force trending, single tablet rejection, and tablet sampling data. In addition, the KORSCH system offers an electronic audit trail capability to provide comprehensive documentation of process adjustments and machine faults over the course of batch production.

CertificationKORSCH PRESSEN AG is ISO 9001 certified and maintains comprehensive internal procedures for quality management in all phases of machine design, development, and fabrication.

Reliable.

Continued Dialog with Customers for Quality ServiceFor over eight decades, KORSCH has been a committed and reliable partner to the pharmaceutical, technical, and chemical industries. Our clear corporate goal is to continue to meet the demands and requirements of these markets, through the continued development of innovative products – to reinforce our position as a global leader in tablet com-pression technology.

In addition, KORSCH has a commitment to pursue working partnerships with customers worldwide, for the develop-ment of special products for unique requirements, and we have an extensive track record of success in providing innovative solutions for challenging applications.

KORSCH maintains the highest level of technical service to support installations throughout the world. Highly trained and highly qualified, our service engineers are available at all times to insure that downtime is minimized and that machines are maintained and operated to insure peak performance. KORSCH offers a comprehensive Training Certification Program, and a Preventative Maintenance and Calibration Program. In addition, KORSCH offers an extensive spare parts support program, with fast delivery and dedicated inventories for partner customers.

Proprietary technology.

The creativity of any company is reflected in its proprietary technology and commitment to innovation.

KORSCH PRESSEN holds more than 100 patents, and many of these advancements are offered in the TRP 700/900 Series, as follows:

• Special Punch Head Design for Heavy Tonnage• Fuzzy Logic Press Force Control Module• Real-Time Moving Average Press Force Calculation• PUNCH TWIST Capability

KORSCH 24/7 Service Hotline: +49 30 43576-300 • E-Mail: [email protected]

97

00

01

56

–1

1/2

00

7

The KORSCH Philosophy

KORSCH is the only true specialist in tablet compression technology, and tablet compression equipment has been our core competency

for almost 90 years. KORSCH offers the most complete line of tablet compression equipment, ranging from small-scale feasibility, to fully

automated production, to specialised multi-layer technology, to wash-in-place (WIP) and high containment technology.

Our production concept reflects an extreme level of flexibility, where key components are utilised in different machine models to provide

efficiency and scalability. Precision manufacturing and assembly ensures a stable and robust design, combined with user friendly opera-

tions and a minimum number of parts, for easy cleaning and changeover.

KORSCH equipment is designed to operate reliably in even the most demanding 24/7 production environments, and immediate access

to service support is critical. The KORSCH Service Hotline offers instant and qualified technical assistance.

KORSCH AG

Breitenbachstraße 1

13509 Berlin

Deutschland/Germany

Tel. +49 30 43576-0

Fax +49 30 43576-350

E-Mail: [email protected]

KORSCH Schweiz GmbH

Untere Dünnernstraße 31

P.O. Box 117

4612 Wangen

Schweiz/Switzerland

Tel. +41 62 21282-92

Fax +41 62 21282-94

E-Mail: [email protected]

www.korsch.de

KORSCH America Inc.

18 Bristol Drive

South Easton, MA 02375, USA

Tel. +1 508 238-9080

Fax +1 508 238-9487

E-Mail: [email protected]

Hotline: +1-800-KORSCH-1

KORSCH UK

Tel. +44 (0)151 427 8909

Fax +44 (0)151 427 8909

Mobile: +44 (0)7780 708 788

E-Mail: [email protected]

PT. KORSCH Asia Pacific

German Centre Building

Jl. Kapt. Subijanto Dj., BSD

15321 Tangerang,

Indonesien/Indonesia

Tel. +62 21 5376-216/-217/-218

Fax +62 21 5376-219

E-Mail: [email protected]

KORSCH France

Tel. +33 (0)4 72 71 48 34

Mobile: +33 (0)6 31 10 79 96

E-Mail: [email protected]