Triple/S Dynamics Presentation - Belt Conveyor vs. Horizontal Motion Conveyor

-

Upload

grand-view-media -

Category

Engineering

-

view

5.865 -

download

0

Transcript of Triple/S Dynamics Presentation - Belt Conveyor vs. Horizontal Motion Conveyor

The purchase of capital equipment is a significant decision and often requires the involvement of many

internal professionals including engineering, purchasing, maintenance, finance, and Quality Control.

Hitting The

Target

• Equipment that Delivers

Many times the purchase price is just the tip of the iceberg. Therefore it is important to consider

all of the cost elements.

Developing an Understanding of “TOTAL COST OF OWNERSHIP” and how that impacts

“RETURN ON INVESTMENT” for industrial minerals processors.

METRIC #1

RETURN ON INVESTMENT (ROI)

A performance measure used to evaluate the savings and/or revenue increase credited to the equipment after initial and ongoing costs are considered.

Simple ROI = Amount of Financial Gain Total Investment Amount

METRIC #2

TOTAL COST OF OWNERSHIP (TCO)

A performance measure meant to uncover all the lifetime costs associated with the equipment both before and after it is purchased.

Currently, there is no broadly accepted formula for computing TCO. The main objective is to make sure all relevant costs are considered when evaluating equipment ROI.

CAPEX + OPEX = TCO Capital Operational Total Cost of Expenditures Expenditures Ownership

Purchase price and installation costs often times account for a very small

percentage of the Total Cost of Ownership.

10%

90%

Capital Expen-ditures

Operational Expenditures

TCO COMPONENTS

Equipment Costs Installation Costs Engineering Costs Shipping Cleaning/Spillage/Waste Environmental Costs/Impact

Energy Costs Training Operating Labor Maintenance Spare Parts Controls Disposal Costs Unscheduled Maintenance/Downtime

METRIC #3

OVERALL EQUIPMENT EFFECTIVENESS (OEE)

A performance measure that determines actual production performance against expected production performance.

OEE = Availability X Performance X Quality

Availability – Takes into account downtime loss which can be defined as any event that halts planned production.

Performance – Takes into account Speed loss which can be defined as any event that causes a process to produce less than its expected rate.

Quality – Takes into account production loss which can be defined as equipment performance that contributes to material not meeting Q & A standards.

Why is OEE important to TCO and ROI

Calculating OEE can help identify “downtime loss” and “material waste” which can be a major contributor to total cost of ownership and have

a major impact on return on investment.

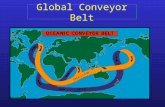

Material handling equipment (conveyors) play an important role in the mining, processing, transporting,

and storage of bulk materials.

While it is usually difficult to identify and quantify the benefits associated with material handling

equipment, it is much easier to identify and quantify the costs.

Conveyor downtime can have a major impact on plant

production which leads to lower revenues and

profitability.

Cost/Benefit analysis of belt conveyors compared to horizontal differential motion conveyors.

Belt Conveyors have always been an essential component of the mining and processing of

industrial minerals.

Horizontal Differential Motion Conveyors are beginning to find there place in the world of mining and industrial minerals processing.

ROI Analysis – Total cost vs. benefit analysis

Projected Costs

Direct – One Time Cost Direct – Ongoing Cost Indirect – Ongoing Cost

1) Engineering2) Procurement3) Equipment4) Installation5) Shipping6) Controls7) Existing Equip.

Removal8) Start-Up Assistance

1) Maintenance2) Operating Labor3) Spare Parts4) Utility Costs5) Engineering

1) Unscheduled downtime

2) Material Spillage (Waste)

3) Contamination4) off-spec material5) Equipment Cleaning6) Clean-up

Projected Benefits

ROI Analysis – Total cost vs. benefit analysis

Direct/Indirect Benefits

1) Revenue Increase - Higher Capacity - Better Product Quality2) Labor Savings - Reduced Attention - Reduced Staff3) Reduced Spare Parts

4) Reduced Maintenance5) Reduced Engineering -Redesign6) Reduced Material Waste7) Reduced Unscheduled Downtime8) Reduced Clean-up9) Improved Employee Satisfaction

100 foot conveyor – year 1 cost/installationApplication – 60 TPH Lime

Belt & Roller Conveyor

Triple/S Slipstick Conveyor

Equipment Cost $60,000.00 $125,000.00

Installation Cost $25,000.00 $45,000.00

Drive System Drive System

Motor Motor

Belt N/A

Idlers N/A

Total Initial Cost $85,000.00 $170,000.00

10-year Lifecycle Cost Comparison

Lifecycle Costs Failure Ratio-Annually Failure Ratio-Variable

Lost Bearings/Supports 5 per/yr. 5th & 10th year-typicalCost of Bearings/supports $150 X 5

($750.00)$800 X 2

($1,600.00)

Cost for Labor $35 hr. X 2 hrs. X 5($350.00)

$35 hr. X 2 hrs. X 2($140.00)

Downtime Hours 10 hours 4 hoursCost of Downtime per hour (60 tons X $200/ton) $15,000.00 (60 tons X $200/ton)

$15,000.00

Annual Cost $151,100.00 N/AYear 1 Capital + Operating Costs $85,000 + $151,100 = $236,100.00 $170,000.00

Year 1 Savings $66,100.00

Year 10 Operating Costs $1,511,000.00 $61,740.00

Year 10 Savings $1,359,900.00

10-year Lifecycle Cost Comparison

Rate of Return on Replacing Belt Conveyor with

Slipstick Horizontal Motion

Conveyor

$175,000 (equipment cost)/ $151,100 (annual maint.) = 1.16 X 12 = 13.9 months (ROI)

When purchasing equipment, many processors tend to focus on achieving a competitive

purchase price and will often overlook opportunities to increase their bottom line.

Vendor 1 Vendor 20

50

100

150

200

250

12560

45

25

6 1503.5

1.1

Purchase price InstallationUnscheduled Downtime Spare Parts

The Slipstick Conveyor

![1 SERIES Belt Conveyor System B090 - Bett Sistemi Srl€¦ · CONVEYOR BELT DEVELOPMENT CALCULATION FORMULA Conveyor belt length = 300 + {[(L-94)-(2• Conveyor belt thick. )]•2}](https://static.fdocuments.in/doc/165x107/5ad3c4047f8b9a48398b7ae4/1-series-belt-conveyor-system-b090-bett-sistemi-conveyor-belt-development-calculation.jpg)