Triple Sensor Operator Manual TM 11361A-Or1 REV E

Transcript of Triple Sensor Operator Manual TM 11361A-Or1 REV E

OPERATOR’S MANUAL FOR

360 DEGREE CAMERA SYSTEM (TRIPLE SENSOR)

NSN 5836-01-545-0098

S/N

Manufactured by Gyrocam Systems, LLC

995-3102-000

GYROCAM SYSTEMS, LLC TM 11361A-OR/1 REV E

2

Document Revision History The Document Revision History table provides a record of changes to this document.

Release Date Revision/Author Description of Change( s)

June 2006 Rev A / M. Kornblum Initial Release

August 2006 Rev B / M. Kornblum Startup and Pneumatics

September 2006 Rev C / M. Kornblum Laser Safety

June 2007 Rev D / G. Moreland Reformatted and Expanded

March 2008 Rev E / G. Moreland Minor Corrections Made

U.S. export law as contained in the International Traffic in Arms Regulations (ITAR) or Export Administration Regulations (EAR) may be applicable to the information contained in this document. This technical information is not to be placed in the public domain, exported from the U.S., given to any foreign person in the U.S., or re-exported without the specific authorization of Gyrocam Systems, LLC and the Department of the Army of the United States. This information will be used for military purposes only, and individual or corporate rights originating in the information, whether patented or not, will be respected, and the recipient will report promptly to the United States, any known or suspected compromise, and the information will be provided substantially the same degree of security afforded it by the Department of Defense of the United States. Also, regardless of any other markings on the document, it will not be downgraded or declassified without written approval of the originating United States agency.

This document is the property of Gyrocam Systems, LLC. Copyright for Government use associated with this manual is granted to the Government. Possession of this document conveys no rights implicit or explicit to service, modify, or operate Gyrocam products.

© Copyright 2008 by Gyrocam Systems, LLC.

GYROCAM SYSTEMS, LLC

TM 11361A-OR/1 REV E

3

WARNING SUMMARY This section and all other sections in this manual should be thoroughly read and understood before any attempt is made to start and operate the 360 Degree Camera System. Operating the Camera System without training or ins truction may result in personnel injury or damage to Camera System. GENERAL PRECAUTIONS The following operational procedures must be follow ed to ensure maximum protection:

all doors and hatches must be securely closed and l atched Camera System must be turned off prior to starting the vehicle Camera System must be turned on prior to vehicle mo vement mast must be raised 12 inches (30.48 cm) when vehic le is in transit mast area must be free of personnel and mechanical obstructions all electrical cables must be undamaged and properl y terminated any transit tie-downs on the payload must be remove d prior to operation

Extreme caution must be used when the Camera System mast is extended and the vehicle is in motion. Care must be taken to avoid c ontact with electrical power lines, low hanging tree branches, bridges, and other overh ead obstructions. Personnel injury, vehicle damage, Camera System damage, and death can result from failure to observe safety precautions when mast is extended and vehicl e is in motion. Moving parts can cause personnel injury. Ensure all personnel are clear of moving parts while operating the mast. Mast tip-over can result in equipment damage, perso nnel injury, or death. Avoid extending the mast and operating the Camera System in high wind conditions. CLEANING PRECAUTIONS Cleaning solvents can cause eye and skin irritation when improperly used to clean the gimbal and mast. Read and follow all safety instruc tions for cleaning solvents used for Camera System maintenance. ELECTRICAL PRECAUTIONS Mast and gimbal contact with sources of high voltag e can result in equipment damage, personnel injury or death. Do not extend the mast o r operate the Camera System near high voltage power lines or in weather conditions w here lightning is present.

GYROCAM SYSTEMS, LLC TM 11361A-OR/1 REV E

4

WARNING SUMMARY – Continued LASER PRECAUTIONS Camera System operator must not aim the Camera Syst em gimbal at the gunner on the vehicle, due to the presence of laser radiation whe n the night vision camera is in use. The gunner must not look directly at the 360 Degree Camera System during night vision camera and laser operation. Even though the laser light is invisible to the nak ed eye, the eye can be permanently damaged by sustained, direct exposure to the infrar ed laser. The unaided, eye safe distance of the laser is 2 meters and the aided (bi noculars), eye-safe distance is 17 meters. An image area of about 20 square inches is considered eye safe for a laser of this type and power level. Care should be taken ope rating the laser around personnel within 2 meters of the gimbal. Personal Protective Equipment (PPE) must be worn by personnel inside the eye-safe laser distance. Approved PPE are the Ballistic Las er Protective Spectacles (NSN 8465-01-416-3207), which are rated at two wavelengths (B LPS 2WL). PNEUMATIC PRECAUTIONS Over-pressurizing the mast will cause a pneumatic s afety valve to activate. Do not exceed the maximum pneumatic operating pressure of 35 psi (241 kPa) for the mast. Mast disassembly prior to depressurization can rele ase a jet of pressurized air. Lower the mast completely, depressurize the mast, and shu t down the vehicle power prior to performing maintenance on the mast. LIFTING PRECAUTIONS The mast is designed to lift a specific payload int ended for lighting, surveillance, and communication use only. Any other use may cause equ ipment damage, personnel injury, or death. Do not use the mast to lift perso nnel. Do not exceed the specified payload capacity.

GYROCAM SYSTEMS, LLC

TM 11361A-OR/1 REV E

5

OPERATOR OVERVIEW

The 360 Degree Camera System is manufactured by Gyrocam Systems, LLC, at its production facility in Sarasota, Florida. The 360 Degree Camera System is a remotely controlled, telescope-equipped, broadcast-quality camera system that contains color, night vision, and infrared imaging equipment. A unique optical system allows one telescope to gather light both a color and a night vision camera. An infrared camera can be used to locate targets in day or night time conditions. A Video Tape Recorder (VTR) is included to record and play back images seen through the camera(s). The 360 Degree Camera System is primarily used to locate and identify enemy combatant and insurgent activity, as well as the presence of improvised explosive devices (IEDs).

HOW TO USE THIS MANUAL

This manual:

A. Contains information for safe and efficient operation of the 360 Degree Camera System, manufactured by Gyrocam Systems, LLC. These instructions provide the user with a general knowledge of the equipment, its characteristics, along with usual and unusual operating procedures.

B. Provides troubleshooting and maintenance procedures for crew and organizational maintenance levels to keep the 360 Degree Camera System mission-ready.

C. Provides the best possible operating instructions for most circumstances that may be encountered during mission operations. Multiple emergencies, severe adverse weather, or combat conditions may require modifications to these procedures.

D. Describes the 360 Degree Camera System and principles of operation in Chapter 1. Chapter 2 lists Camera System operating controls. Chapter 3 describes operating procedures. Chapter 4 covers operator maintenance instructions, including maintenance checks and services (PMCS), cleaning, and lubrication procedures. Chapter 5 describes demolition to prevent enemy use.

E. Provides references in Appendix A, and Basic Issue Items (BII) are listed in Appendix B.

F. Includes a glossary and an alphabetical index located in the back.

G. Attempts to cover all areas of operation which the 360 Degree Camera System is designed to handle. Operators and maintenance personnel should have completed 360 Degree Camera System training courses for their assigned duties. Before attempting any questionable operations which are not covered in this manual or in training courses, clearance must be obtained from your commanding officer.

GYROCAM SYSTEMS, LLC TM 11361A-OR/1 REV E

6

TABLE OF CONTENTS CHAPTER 1 – INTRODUCTION…………………………………………..………..……..11

Section I – GENERAL INFORMATION…………………………...…………….…….11 1-1. SCOPE………………….…………………………………………….……..………11 1-2. FORMS AND RECORDS.…………………………………………….….……….11 Section II – CAMERA SYSTEM DESCRIPTION………………………..….………..12 1-3. DESIGNATIONS………………………………………………………..….………12 1-4. CHARACTERISTICS, CAPABILITIES, AND FEATURES………..…….……..12 1-5. CAMERA SYSTEM DESCRIPTION………………………………….…..………12 1-6. SPECIFICATIONS…………………………………………………….…..……….14 1-7. BREAK-IN SERVICE…………………………………………………....…………15

CHAPTER 2 – OPERATING CONTROLS……………………………………… ...……..16

Section I – GENERAL……………………..………………….…………………..…….16 2-1. SCOPE………………….……………………………………..…………….………16 Section II – CAMERA SYSTEM EQUIPMENT…………………..…………….……..16 2-2. GENERAL………………...……………………………………….……….……….16 2-3. GIMBAL………….………………………………………………..…………………16 2-4. KNEEBOARD…………………………………………………….………….……..16 2-5. INTERFACE UNIT (IFU)……………….………………………….………………17 2-6. VIDEO MONITOR…………………………………………………….……………17 2-7. VIDEO TAPE RECORDER (VTR)………………………………………….…….17 2-8. MAST……………………………………………………………………..………….17 2-9. NYCOIL……………………………………………………………………..……….17 Section III – SYSTEM CONTROLS……………..…………………………..…………18 2-10. SCOPE………………...………………………………………………….……….18 2-11. POWER SWITCH……………………………………………………….………..18 2-12. JOYSTICK…………………………………………………………….…….……..18 2-13. STICK ZERO INDICATOR…………………………………………….….……..19 2-14. STOW/OPERATE BUTTON…………………………………………….……….19 2-15. STOW MODE INDICATOR…………………………………………….…..……19 2-16. OPERATE MODE INDICATOR………………………………………...….……19 2-17. SENSITIVITY BUTTON…………………………………………….…………….20 2-18. AZIMUTH TRIM POTENTIONMETER…………………………….……………20 2-19. ELEVATION TRIM POTENTIOMETER…………………………….…………..20 2-20. AUTO TRIM BUTTON……………………………………………….…...………21 Section IV – CAMERA CONTROLS……………..……………………….……….…..23 2-21. SCOPE……………………………………………………………….…………….23 2-22. COLOR CAMERA SELECTOR BUTTON……………………….……..………23 2-23. NIGHT VISION CAMERA SELECTOR BUTTON………………….………….23 2-24. INFRARED CAMERA SELECTOR BUTTON……………………….…………23 2-25. ON SCREEN DATA ENABLE SWITCH…………………………….…...……..24

GYROCAM SYSTEMS, LLC

TM 11361A-OR/1 REV E

7

Section V – COLOR CAMERA CONTROLS……..………………….……...………..25 2-26. SCOPE………………………………………………………………......………...25 2-27. ZOOM SWITCH………………………………………………………...…………25 2-28. FOCUS KNOB………………………………………………………….....………25 2-29. EXTENDER BUTTON……...…………………………………………………….25 2-30. IRIS LEVEL KNOB………………………………………………………………..26 2-31. CAMERA GAIN KNOB……...……………………………………………………26 2-32. MASTER BLACK KNOB……………………………………………..…………..26 2-33. DETAIL/MANUAL BUTTON...……………………………………….…………..27 2-34. WHITE BALANCE BUTTON………...…………………………………..………27 Section VI – NIGHT VISION CAMERA CONTROLS……..…………...…………….28 2-35. SCOPE……………………………………………………………………..………28 2-36. NIGHT VISION READY INDICATOR…………...……………………...………28 2-37. LASER ILLUMINATOR SWITCH………………………………………..………28 Section VII – INFRARED CAMERA CONTROLS……..…………..…………………29 2-38. SCOPE……………………………………………………………………..………29 2-39. IR STATUS INDICATOR…………………………………………………………29 2-40. IR FIELD OF VIEW INDICATOR……………………………………….……….29 2-41. IR ZOOM BUTTONS………..……………………………………….…...………30 2-42. GAIN CONTROL KNOB……………………………………………….…………30 2-43. MANUAL LEVEL CONTROL KNOB……………...……………….……………30 2-44. FOCUS KNOB………………………………………………………..…...………31 2-45. IR POLARITY BUTTON……………………………………………..…...………31 Section VIII – PNEUMATIC MAST CONTROLS……..…………..………..…...……32 2-46. SCOPE…………………………………………………………………….….……32 2-47. MAST TOGGLE SWITCH………………………………………………..………32 2-48. MAST HEIGHT LASER………….…………………………………….…...…….32 Section IX – LASERDYNE VIDEO MONITOR CONTROLS………...…...…………33 2-49. SCOPE……………………………………………………………………..………33 2-50. VIDEO MONITOR FUNCTION BUTTONS………………………...…..………33 2-51. MENU BUTTON………………………………………………………..…………33 2-52. LAYOUT BUTTON………………………………………...…………...…………33 2-53. ENHANCE BUTTON……………………...……………………………...………33 2-54. ZOOM BUTTON…………………………………………………...…...…………33 2-55. FREEZE BUTTON…………………………………………………...…...………33 Section X – AVALEX VIDEO MONITOR CONTROLS……….……...…...…………34 2-56. SCOPE……………………………………………………………………..………34 2-57. VIDEO MONITOR FUNCTION BUTTONS………………………...…..………34 2-58. MAP BUTTON…………...……………………………………………..…………34 2-59. VIDEO BUTTON…………...……………………………...…………...…………34 2-60. FREEZE/ZOOM BUTTON……………………..………………………...………34 2-61. UP ARROW BUTTON………….………………………………...…...…………34 2-62. DOWN ARROW BUTTON……………..…………………………...…...………34

GYROCAM SYSTEMS, LLC TM 11361A-OR/1 REV E

8

Section XI – VIDEO TAPE RECORDER (VTR) CONTROLS..……..…..……….…35 2-63. SCOPE………………………………………………………………..……………35 2-64. VIDEO TAPE RECORDER CONTROLS………...………………….…………35 Section XII – INTERFACE UNIT (IFU) CONTROLS..………..…...………...………36 2-65. SCOPE……………………………………………………………………..………36 2-66. INTERFACE UNIT CONTROLS…………………...……………………………36

CHAPTER 3 – CAMERA SYSTEM OPERATION…………………… ...………..….…..38

Section I – BASIC OPERATIONS……………..…...……………………………….…38 3-1. PRE-OPERATIONAL CHECKS………………….………………………….……38 3-2. WALK AROUND INSPECTION…………………….……………………….……38 3-3. EXTERIOR PRE-MISSION CHECKS………………...…………………….……38 3-4. INTERIOR PRE-MISSION CHECKS……………………………………….……38 3-5. STARTING THE CAMERA SYSTEM………………………………………….…39 3-6. OPERATING THE MAST…………………………………………….……………40 3-7. OPERATING THE GIMBAL………………………………………….……………40 3-8. CHANGING THE GIMBAL STOW POSITION…………….………….…………41 3-9. OPERATING THE VIDEO MONITOR……………………...……...….…………41 3-10. OPERATING THE VIDEO TAPE RECORDER (VTR)………….…….………41 3-11. LOCATING A SURVEILLANCE TARGET……………………….…….………41 3-12. TRACKING A TARGET USING THE COLOR CAMERA……………….……42 3-13. TRACKING A TARGET USING THE NIGHT VISION CAMERA…...….……43 3-14. TRACKING A TARGET USING THE INFRARED CAMERA…………...……45 3-15. POWERING DOWN THE SYSTEM…………………………………….………46 3-16. INTERIOR POST-OPERATIONAL CHECKS……………………….…………46 3-17. EXTERIOR POST-OPERATIONAL CHECKS……………………..….………46

CHAPTER 4 – MAINTENANCE INSTRUCTIONS…………………………… .....……..48

Section I – CLEANING……………..………………………………….………….…….48 4-1. GENERAL…………………………………………………………….……..………48 4-2. CLEANING PRECAUTIONS………………………………………..…….………48 4-3. CLEANING INSTRUCTIONS………………………………………….….………48 4-4. LUBRICATION INSTRUCTIONS……………………………………..…..………48 Section II – PREVENTIVE MAINTENANCE CHECKS AND SERVICES….…...…50 4-5. MAINTENANCE NOTES……………………………………………………..……50 Section III – OPERATOR TROUBLESHOOTING……………………………………52 4-6. GENERAL…………………………………………...………………………………52

CHAPTER 5 – DEMOLITION TO PREVENT ENEMY USE…………………......……..57

Section I – DESTRUCTION OF CAMERA SYSTEM………………………..………57 5-1. GENERAL…………………………………………………………………..………57 5-2. DESTRUCTION OF CAMERA SYSTEM………………………………..………57 APPENDIX A – BASIC ISSUE ITEMS………………………………………....…..…58 GLOSSARY……………………………………………………………...………….……60 INDEX…………………………………………………………………….…….…………61

GYROCAM SYSTEMS, LLC

TM 11361A-OR/1 REV E

9

NOTES

GYROCAM SYSTEMS, LLC TM 11361A-OR/1 REV E

10

NOTES

GYROCAM SYSTEMS, LLC

TM 11361A-OR/1 REV E

11

CHAPTER 1 – INTRODUCTION

Section I – GENERAL INFORMATION 1-1. SCOPE

A. This manual contains operator instructions for the Gyrocam Systems, LLC, 360 Degree Camera System, Figure 1-1.

CAUTION

These procedures are provided to give instructions in safe and efficient camera system operation. However, personnel assigned as operators of the 360 Degree Camera System should have successfully completed the operator’s training course as prescribed by the camera system manufacturer. B. The purpose of this manual is to provide the operator with information and procedures to operate and maintain the 360 Degree Camera System under all mission operating environments.

C. The following information is included in this technical manual:

1. A description and use of the 360 Degree Camera System.

2. Camera System specifications.

3. Description and function of operating controls and indicators.

4. Operator preventive maintenance checks and services (PMCS).

5. Operator troubleshooting procedures.

1-2. FORMS AND RECORDS

A. Equipment Improvement Recommen-dations (EIR). The 360 Degree Camera System has been designed to meet operating requirements for projected missions. The key to any successful mission rests on the equipment performance and reliability. Your training and first hand experience provide excellent resources for observing areas that need improvement, noting discrepancies, and offering tips to fellow crew members and support personnel. Your feedback is appreciated. To provide feedback, please send an email with your comments to [email protected].

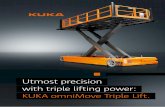

Figure 1-1 360 Degree Camera System

Gimbal Interface Unit (IFU) Kneeboard Video Tape Recorder (VTR)

Video Monitor

GYROCAM SYSTEMS, LLC TM 11361A-OR/1 REV E

12

Section II – CAMERA SYSTEM DESCRIPTION 1-3. DESIGNATIONS

A. There are two 360 Degree Camera System variants:

1. 360 Degree Camera System for U.S. Army deployment.

2. 360 Degree Camera System for U.S. Marine Corps deployment.

1-4. CHARACTERISTICS, CAPABILITIES, AND FEATURES

A. The 360 Degree Camera System is designed to support general armored personnel carrier (APC) mission requirements. B. The 360 Degree Camera System is typically designated for the location of enemy insurgent activity and improvised explosive device (IED) clearance activities. A single operator mans the Camera System, and maintains an active dialogue with the crew of the APC with regard to the images and activities captured by the Camera System to determine any necessary mission activities. C. The 360 Degree Camera System will operate under all climates and environmental conditions, day or night. Refer to paragraph 1-6 for Camera System specifications. D. The 360 Degree Camera System is equipped with day, night, and infrared vision cameras and can magnify visual targets up to 100 times what the unaided human eye can see. E. The Camera System is mounted on a 25 foot (7.62 m) pneumatically operated, extendable mast on the back of the APC. F. The Camera System includes a separate Video Tape Recorder (VTR) that can be used to record and play back images viewed through the Camera System previously. G. The Camera System provides On-Screen Data (OSD) that shows the current azimuth and elevation positions of the camera in relation to the front of the APC.

1-5. CAMERA SYSTEM DESCRIPTION

NOTE Right-hand (RH) and left-hand (LH) sides of the gimbal are determined by facing in the direction of forward travel. A. All 360 Degree Camera Systems consist of a round gimbal, mounted on a 25 foot (7.62 meter) telescoping mast, that houses the cameras and camera positioning motors, a Nycoil cable that is connected to the interface unit (IFU), a video monitor for viewing images, and a video tape recorder (VTR) for recording and playing back images. B. Camera system gimbals are composite fiber and injection-molded, plastic covered units that contain a color, night vision, and infrared camera. C. The mast and gimbal, when fully retracted, are housed in an armored closet at the rear of the APC.

GYROCAM SYSTEMS, LLC

TM 11361A-OR/1 REV E

13

Figure 1-2 360 Degree Camera System Dimensions

21.53 in. (54.69 cm)

Collapsed Height 70.5 in. (179.07 cm) Extended Height 300.0 in. (762.0 cm)

7.91 in. (20.1 cm)

11.35 in. (28.83 cm)

3.69 in. (9.37 cm)

14.51 in. (36.86 cm)

8.12 in. (20.62 cm)

7.68 in. (19.51 cm)

GYROCAM SYSTEMS, LLC TM 11361A-OR/1 REV E

14

1-6. SPECIFICATIONS Dimensions Gimbal – 15.10 x 15.10 x 21.53 in. (38.35 x 38.35 x 54.69 cm)

Interface Unit (IFU) – 7.68 x 8.12 x 14.51 in. (19.51 x 20.62 x 36.86 cm)

Kneeboard – 11.35 x 7.91 x 3.69 in. (28.83 x 20.1 x 9.37 cm)

Mast Specifications Collapsed height is 70.5 inches (179.07 cm)

Extended height is 300.0 inches (762.0 cm)

Time to extend, less than 60 seconds

Time to retract, less than 40 seconds

Fused at 5 Amps

Video Tape Recorder (VTR) Specifications 4-inch (10.16 cm) LCD screen

Requires mini-DV tapes

60 minutes of recording time per tape

NTSC output

Video Monitor Specifications 12.1-inch (30.73 cm) LCD screen

High brightness, daylight readable

1024 x3 horizontal pixels by 768 vertical lines (2.36 mega pixels)

18 bit color depth

Camera System Power Requirements 28 VDC, negative ground

Fused at 20 Amperes

Nominal operating current is 6 Amps

Transient operating current is 12 Amps

Operational from 22 VDC to 33 VDC

Weights Gimbal…………………….....…..66.0 lbs (29.94 kg)

Interface Unit (IFU)……….….…..10.0 lbs (4.54 kg)

Kneeboard…………………....……4.0 lbs (1.81 kg)

Performance Operating temperature range from -38.0° F (-38.9° C) to 142° F (61.1° C)

Maximum operating speed is 400 knots (740.8 km/hr)

Maximum transit speed is 400 knots (740.8 km/hr)

Service ceiling is 30,000 feet (9144.0 m)

Shock and Vibration 6 g’s non-operating, sinusoidal 15 minutes per each axis, no degradation in performance

15 g’s one time, 1 millisecond sinusoid, each axis, unit intact

Gimbal Stabilization Characteristics Vibration attenuation @ 7 Hz better than 30 dB

Vibration attenuation @ 21 Hz better than 20 dB

Vibration attenuation @ 60 Hz better than 12 dB

Vibration attenuation @ 120 Hz better than 6 dB

Typical stabilization between 5 and 10 micro radians, dependent on vehicle

Color Camera Specifications Three-chip color iris

NTSC color output

800 TV line resolution

379,000 pixels, 768 horizontal by 494 vertical per chip

16 Lux sensitivity at f/2 and 18 dB gain

62 dB signal-to-noise ratio

Wide horizontal field of view 26° (2.7x magnification)

Narrow horizontal field of view 1.47° (47x magnification)

Extender in narrow HFOV (95x magnification)

Clear aperture 2.5 inches (6.35 cm)

Night Vision Camera NTSC output

Shares color camera lens

Wide horizontal field of view 52° (1.4x magnification)

Narrow horizontal field of view 3.0° (24x magnification)

Extender in narrow HFOV 1.5° (48x magnification)

GYROCAM SYSTEMS, LLC

TM 11361A-OR/1 REV E

15

Infrared Camera f4, diffraction limited optics

Long life sterling cycle cooler

320x240 pixel InSb Array

Three fields of view, 31° horizontal (2.3x magnification)

Medium HFOV 9.2° horizontal (7.6x magnification)

Tight HFOV 2.7° horizontal (25.4x magnification)

Noise equivalent delta temperature (NE∆T) of 40 milliKelvin

1-7. BREAK-IN SERVICE

A. The 360 Degree Camera System does not require break-in operating restrictions when new.

NOTES

GYROCAM SYSTEMS, LLC TM 11361A-OR/1 REV E

16

CHAPTER 2 – OPERATING CONTROLS

Section I – GENERAL 2-1. SCOPE

_________ WARNING

This section and all other sections in this manual should be thoroughly read and understood before any attempt is made to start and operate the Camera System. Operating the Camera System without training or instruction may result in personnel injury or damage to the Camera System.

CAUTION

This chapter provides instructions in safe and efficient Camera System operation. Personnel assigned as crew members should have successfully completed the Operator’s training course as prescribed by the Camera System manufacturer.

NOTE Before you attempt to operate the Camera System, be sure you are familiar with the location and function of all controls and indicators. A. This chapter identifies and explains the use of all instruments and controls for operating the Camera System. B. Section II provides a description and function of Camera System components.

C. Section III describes the operation and function of switches, indicators, and knobs.

D. Section IV describes how to select the specific camera for the current viewing conditions and mission requirements.

E. Section V describes how to operate the color camera controls.

F. Section VI describes how to operate the night vision camera controls.

G. Section VII describes how to operate the infrared camera controls.

Section II – CAMERA SYSTEM EQUIPMENT

2-2. GENERAL

A. This chapter identifies and explains the use of all instruments and controls for operating the Camera System.

2-3. GIMBAL A. The gimbal contains the color, night vision, and infrared cameras.

B. Also contained in the gimbal are azimuth and elevation motors, image stabilization sensors, and laser illuminator for use with the night vision camera.

C. The gimbal is covered with a hard shell, watertight plastic cover that protects the electronics and cameras from dust, dirt, weather, and moisture.

2-4. KNEEBOARD

A. The kneeboard is the primary interface between the Camera System and the operator.

B. All gimbal and interface unit (IFU) controls are located on the kneeboard.

C. Controls and indicators for all three cameras are located on the kneeboard.

GYROCAM SYSTEMS, LLC

TM 11361A-OR/1 REV E

17

2-5. INTERFACE UNIT (IFU)

A. The interface unit is the main connection point for the gimbal, kneeboard, video monitor, and video tape recorder. B. There are no operator controls on the interface unit. C. Fuses and circuit breakers are located on the interface unit.

2-6. VIDEO MONITOR A. The video monitor displays the images gathered by the gimbal cameras inside the vehicle. B. The operator can configure several settings for optimal image viewing on the video monitor. C. The Camera System is equipped with one of two different brand video monitors:

1. Avalex video monitor 2. Laserdyne video monitor

2-7. VIDEO TAPE RECORDER (VTR) A. The video tape recorder (VTR) records and plays back video images gathered by the gimbal cameras inside the vehicle. B. Video tapes can be played back at normal, real-time speed or at a slow speed for greater scrutiny.

2-8. MAST _________ WARNING

Extreme caution must be used when the Camera System mast is extended and the vehicle is in motion. Care must be taken to avoid contact with electrical power lines, low hanging tree branches, bridges, and other overhead obstructions. Personnel injury, vehicle damage, Camera System damage, and death can result from failure to observe safety precautions when mast is extended and vehicle is in motion. A. The mast is a telescoping, pneumatically operated pedestal that raises and lowers the gimbal. B. The mast is raised and lowered by the introduction and egress of compressed air that is supplied by the vehicle, controlled by a toggle switch inside the vehicle.

2-9. NYCOIL A. The Nycoil is a flexible cable that is the main link between the gimbal and the interface unit (IFU).

B. The Nycoil contains cables for the three cameras inside the gimbal and the gimbal positioning motors, and links the mast height laser, gimbal, and mast height display to the IFU.

NOTES

GYROCAM SYSTEMS, LLC TM 11361A-OR/1 REV E

18

Section III – SYSTEM CONTROLS 2-10. SCOPE

A. This section describes the operation and function of switches, knobs, and indicators for operating the camera system gimbal, Figure 2-10. B. Controls and indicators for operating the gimbal are located on the kneeboard and include the following:

1. Power switch 2. Joystick

3. Stick zero indicator

4. Stow/operate button

5. Stow mode indicator

6. Operate mode indicator

7. Azimuth trim potentiometer

8. Elevation trim potentiometer

9. Auto trim button

2-11. POWER SWITCH

A. The power switch, Figure 2-1, is a two-position toggle switch that is used to turn the 360 Degree Camera System on and off.

Figure 2-1 Power Switch

B. With the power switch set to the OFF position (facing left), move the switch to the ON position (facing right). With the switch in this position, all Camera System electrical components will be powered.

CAUTION

The Camera System must be powered up prior to vehicle movement to prevent mechanical damage to the system.

1. To power up the Camera System, move the power switch from the left hand position to the right hand position. 2. The red LED to the right of the power switch will illuminate in red when the Camera System is powered up.

3. To power down the Camera System, move the power switch to the left hand position from the right hand position.

2-12. JOYSTICK

A. The joystick, Figure 2-2, is a 360-degree rotational handle that is used to control the azimuth and elevation physical movements of the gimbal.

Figure 2-2 Joystick B. With the camera system powered up, the joystick moves the gimbal in the following positions:

1. To move the gimbal so the field of view is lower, move the joystick forward.

2. To move the gimbal so the field of view is higher, pull the joystick backward.

3. To move the gimbal so the field of view is to the left, move the joystick to the left.

4. To move the gimbal so the field of view is to the right, move the joystick to the right.

Joystick

GYROCAM SYSTEMS, LLC

TM 11361A-OR/1 REV E

19

2-13. STICK ZERO INDICATOR A. The stick zero indicator, Figure 2-3, is illuminated in green when the joystick is in the centered position on the kneeboard and there is no physical input.

Figure 2-3 Stick Zero Indicator

B. When there is joystick movement, the stick zero indicator is not illuminated.

2-14. STOW/OPERATE BUTTON

A. The stow/operate button, Figure 2-4, is a two-position toggle button used to switch between position and stabilize modes.

Figure 2-4 Stow/Operate Button

B. Position mode is active when the following conditions are true:

1. The Camera System is powered up.

2. The stow mode indicator, to the left of the stow/operate button, is illuminated in red.

3. The stow/operate button is pressed when the stow mode indicator is illuminated in green.

C. Stabilize mode is active when the following conditions are true:

1. The joystick is moved.

2. The stow mode indicator is illuminated in green.

3. The stow/operate button is pressed when the stow mode indicator is illuminated in red.

NOTE After approximately three minutes of inactivity while in stabilize mode, the gimbal will automatically default to position mode.

2-15. STOW MODE INDICATOR

A. The stow mode indicator, Figure 2-5, located to the left of the stow/operate button, indicates one of the two modes that the camera system is currently in.

Figure 2-5 Stow Mode Indicator

1. Position mode – indicating that the gimbal is in its startup position – the indicator is red.

2. Stabilize mode – indicating that the gimbal is in operating mode – the indicator is green.

B. Pressing the stow/operate button toggles between position mode and stabilize mode.

2-16. OPERATE MODE INDICATOR

A. This is the same indicator as described in 2-15.

Stow Mode Indicator

GYROCAM SYSTEMS, LLC TM 11361A-OR/1 REV E

20

2-17. SENSITIVITY BUTTON A. The sensitivity button, Figure 2-6, is a four-position toggle button used to set the degree of sensitivity for joystick movements.

Figure 2-6 Sensitivity Button

1. When the button is toggled to LOW sensitivity, the corresponding LED is illuminated in yellow. The maximum gimbal movement rate is 8° per second.

2. When the button is toggled to MED sensitivity, the corresponding LED is illuminated in yellow. The maximum gimbal movement rate is 24° per second.

3. When the button is toggled to HIGH sensitivity, the corresponding LED is illuminated in red. The maximum gimbal movement rate is 72° per second.

4. When the button is toggled to AUTO sensitivity, the corresponding LED is illuminated in green. The maximum gimbal movement rate is set to three fields of view per second.

B. When the Camera System is powered up, the default sensitivity setting is MED.

2-18. AZIMUTH TRIM POTENTIOMETER

A. The azimuth trim potentiometer, Figure 2-7, is a directional rheostat used to compensate for:

1. Horizontal electronic drift.

2. Relative horizontal motion between the vehicle and the target.

3. Any horizontal image adjustment requiring joystick movement.

Figure 2-7 Azimuth Trim Potentiometer

B. Rotating the azimuth trim potentiometer in the direction opposite the perceived image drift will correct the horizontal image drift.

2-19. ELEVATION TRIM POTENTIONMETER

A. The elevation trim potentiometer, Figure 2-8, is a directional rheostat used to compensate for:

1. Vertical electronic drift.

2. Relative vertical motion between the vehicle and the target.

3. Any vertical image adjustment requiring joystick movement.

Figure 2-8 Elevation Trim Potentiometer

B. Rotating the elevation trim potentiometer in the direction opposite the perceived image drift will correct the vertical image drift.

GYROCAM SYSTEMS, LLC

TM 11361A-OR/1 REV E

21

2-20. AUTO TRIM BUTTON

A. The auto trim button, Figure 2-9, is a two-position toggle button used to automatically correct for relative motion errors between the vehicle and the target.

Figure 2-9 Auto Trim Button

1. Auto trim can be used when LOW, MED, or HIGH gimbal sensitivity levels are set.

2. When the mode is set to “position.”

3. When auto trim is active, the LED to the left of the button flashes red.

4. When the joystick is being moved and the auto trim button is pressed, the joystick movement rate is “memorized” and sent to the gimbal for automatic correction of relative motion errors between the vehicle and the target.

5. When the joystick is centered and the stick zero indicator is illuminated in green, auto trim is deactivated and correction of relative motion errors defaults to manual mode.

B. The auto trim button is also used to change the gimbal stow position.

NOTES

GYROCAM SYSTEMS, LLC TM 11361A-OR/1 REV E

22

Figure 2-10. 360 Degree Camera System Gimbal Controls

GYROCAM SYSTEMS, LLC

TM 11361A-OR/1 REV E

23

Section IV – CAMERA CONTROLS

2-21. SCOPE

A. This section describes the operation and function of buttons and switches for selecting the camera required to view a specific target. B. Controls and indicators for operating the gimbal are located on the kneeboard and include the following:

1. Color camera selector button 2. Night vision camera selector button

3. Infrared camera selector button

4. On screen data enable switch

2-22. COLOR CAMERA SELECTOR BUTTON

A. The color camera selector button is located on the left hand side of the kneeboard, Figure 2-11, and activates the color camera.

Figure 2-11 Color Camera Selector Button

B. To operate the color camera button:

1. Locate the color camera button on the side of the kneeboard.

2. Press the color camera button.

2-23. NIGHT VISION CAMERA SELECTOR BUTTON

A. The night vision camera selector button is located on the left hand side of the kneeboard, Figure 2-12, and activates the night vision camera.

Figure 2-12 Night Vision Camera Selector

Button B. To operate the night vision camera button:

CAUTION

The night vision camera cannot be activated in daylight conditions. A light sensor in the gimbal automatically turns the night vision intensifier off during daylight conditions.

1. Locate the night vision camera button on the side of the kneeboard.

2. Press the night vision camera button.

2-24. INFRARED CAMERA SELECTOR BUTTON

A. The infrared camera selector button is located on the left hand side of the kneeboard, Figure 2-13, and activates the infrared camera.

Figure 2-13 Infrared Camera Selector Button

Color Camera Selector

Button

Night Vision Camera Selector

Button

Infrared Camera Selector Button

GYROCAM SYSTEMS, LLC TM 11361A-OR/1 REV E

24

CAUTION

The infrared camera must cool to its required operating temperature before it can be used. This can take up to eight minutes if the infrared camera has been off for an extended period of time.

1. Locate the infrared camera button on the side of the kneeboard.

2. Press the infrared camera button.

3. When the IR status LED is illuminated in green, the infrared camera is ready for use.

2-25. ON SCREEN DATA ENABLE SWITCH A. The on screen data switch is a two-position toggle switch that is used to display numerical azimuth and elevation data, relative to the vehicle, on the video monitor, Figure 2-14.

Figure 2-14 On Screen Data Enable Switch

B. On screen data that appears on the video monitor also appears on the video tape recorder (VTR). C. To operate the on screen data enable switch:

1. Move the switch from the left hand position to the right hand position on the kneeboard.

NOTE

Azimuth position 0° is defined as straight off the vehicle’s hood. Elevation position 0° is defined as level with the vehicle.

2. Rotating the gimbal clockwise increases the indicated numerical azimuth angle shown on the video monitor, Figure 2-15.

3. Rotating the gimbal upwards increases the indicated numerical elevation angle shown on the video monitor, Figure 2-16.

Figure 2-15 Azimuth Angle Reference

Figure 2-16 Elevation Angle Reference

Positive Elevation

Negative Elevation Zero Elevation (level)

0°

90° 270°

180°

GYROCAM SYSTEMS, LLC

TM 11361A-OR/1 REV E

25

Section V – COLOR CAMERA CONTROLS 2-26. SCOPE

A. This section describes the operation and function of buttons and switches for operating the color camera. B. Controls and indicators for operating the color camera are located on the kneeboard and include the following:

1. Zoom switch 2. Focus knob

3. Extender button

4. Iris level knob

5. Camera gain knob

6. Master black knob

7. Detail/manual button

8. White balance button

2-27. ZOOM SWITCH

A. The zoom switch is a two-position rocker switch that controls the speed of the motor that moves the color camera lens in and out, Figure 2-17.

Figure 2-17 Zoom Switch B. The zoom function on the color camera allows magnification of up to 100 times what the human eye can resolve.

1. Pressing on the “W” portion of the zoom switch will increase the viewing field of the image. 2. Pressing on the “T” portion of the zoom switch will decrease the viewing field of the image.

2-28. FOCUS KNOB

A. The focus knob, Figure 2-18, is a directional rheostat that is used to adjust the color camera image for sharpness and clarity.

Figure 2-18 Focus Knob B. Focusing on objects that are at a middle distance from the camera will cause objects nearer and further away to be out of focus.

1. Rotating the focus knob counterclockwise will bring the field of focus towards the vehicle. 2. Rotating the focus knob clockwise will move the field of focus away from the vehicle.

2-29. EXTENDER BUTTON

A. The extender button is a two-position pushbutton, Figure 2-19, that is used to activate a telescopic magnifier that doubles the perceived image size.

Figure 2-19 Extender Button

1. Pressing the extender button activates the telescopic magnifier and the LED to the left of the extender button is illuminated in red.

GYROCAM SYSTEMS, LLC TM 11361A-OR/1 REV E

26

2. Pressing the extender button a second time deactivates the telescopic magnifier and turns off the LED.

B. When the extender button is activated, the lightness of the image is reduced by a factor of four.

2-30. IRIS LEVEL KNOB

A. The iris level knob, Figure 2-20, is a directional rheostat that is used to adjust the image brightness.

Figure 2-20 Iris Level Knob

1. Turning the iris level knob to “closed” will darken the image seen on the video monitor.

2. Turning the iris level knob to “open” will brighten the image seen on the video monitor.

B. As a default setting, when the iris level knob is set in the middle of the range, the average brightness of the image is automatically set.

2-31. CAMERA GAIN KNOB

A. The camera gain knob, Figure 2-21, is a directional rheostat that is used to adjust the brightness of the picture.

Figure 2-21 Camera Gain Knob

B. There are six different camera gain levels, with each setting configured for optimal viewing conditions:

1. In very bright conditions, the camera gain knob should be set to 1/4000.

2. In bright conditions, the camera gain knob should be set to 1/1000.

3. In moderately bright conditions, the camera gain knob should be set to 1/250.

4. In normal daytime conditions, the camera gain knob should be set to NORMAL.

5. In moderately dark conditions, the camera gain knob should be set to MED.

6. In dark conditions, the camera gain knob should be set to HIGH.

2-32. MASTER BLACK KNOB

A. The master black knob, Figure 2-22, is a directional rheostat that controls the minimum video level that represents the color black on the video monitor.

Figure 2-22 Master Black Knob

1. Turning the master black knob counter-clockwise decreases the quantity of black seen on the video monitor.

2. Turning the master black knob clockwise increases the quantity of black seen on the video monitor.

B. When viewing an image through a window or a screen, or in high humidity or dust conditions, decreasing the quantity of black seen on the video monitor will improve the viewing conditions.

GYROCAM SYSTEMS, LLC

TM 11361A-OR/1 REV E

27

2-33. DETAIL/MANUAL BUTTON A. The detail/manual button, Figure 2-23, is a two-position toggle button that sets the color bars and level of detail for the color camera.

Figure 2-23 Detail/Manual Button

1. When the button is toggled to the BARS setting, the corresponding LED is illumin-ated. The level of viewing detail can be set.

2. When the button is toggled to the MAN setting, the iris level knob can be adjusted for optimal viewing conditions and image brightness.

3. When the button is toggled to the MED setting, a medium level of image detail is configured.

4. When the button is toggled to the HIGH setting, a high level of image detail is configured.

B. As a default setting, the color camera remains at the medium detail setting, unless changed.

2-34. WHITE BALANCE BUTTON A. The white balance button, Figure 2-24, is a two-position toggle button that is used to configure relative values of red and blue to ensure that a color-balanced image is shown on the video monitor.

Figure 2-24 White Balance Button

B. White balance must be set for the color camera when the Camera System is powered up or whenever the camera gain setting is changed. C. White balance is set by aiming the camera at a white or light-colored object, then pressing the white balance button.

GYROCAM SYSTEMS, LLC TM 11361A-OR/1 REV E

28

Section VI – NIGHT VISION CAMERA CONTROLS

2-35. SCOPE

A. This section describes the operation and function of buttons and switches for operating the night vision camera.

NOTE

The same image control methods and techniques used for the color camera are also used for the night vision camera. These controls include zoom switch, focus knob, extender switch, camera gain knob, master black, detail/manual button, and white balance button. For specific information about these controls, refer to Section V in this manual. B. Controls and indicators for operating the night vision camera are located on the kneeboard and include the following:

1. Night vision ready indicator 2. Laser illuminator switch

2-36. NIGHT VISION READY INDICATOR

CAUTION

The night vision camera cannot be activated in daylight conditions. A light sensor in the gimbal automatically turns the night vision intensifier off during daylight conditions.

A. The night vision intensifier amplifies visible light and near-infrared radiation by a factor of 10,000. B. A safety circuit in the gimbal prevents the night vision intensifier from working when the ambient light levels are too high, which will shorten the life of the intensifier. C. The night vision ready indicator, Figure 2-25, is an LED that is illuminated when ambient light conditions are sufficiently low enough for night vision camera operation. .

Figure 2-25 Night Vision Ready Indicator

2-37. LASER ILLUMINATOR SWITCH _________ WARNING

The unaided, eye safe distance for the laser is 2 meters. The aided (binoculars) eye safe distance for the laser is 17 meters. Permanent eye damage can result from sustained, direct contact with the laser. Personnel inside the eye safe distance must wear laser PPE. A. The laser illuminator switch, Figure 2-26, is a two-position toggle switch that is used to turn on a 200 mW semiconductor diode laser used to illuminate targets on the ground in total darkness conditions. Although the laser is invisible to the naked eye, it is easily seen by the night vision intensifier.

Figure 2-26 Laser Illuminator Switch

NOTE

Night vision goggles can also detect the presence of the laser illuminator.

B. The laser illuminator will not turn on in daylight or twilight conditions. In certain conditions where the Night Vision Ready Indicator is illuminated, and the night vision intensifier is working, the laser will not function until it is sufficiently dark in the viewing area.

GYROCAM SYSTEMS, LLC

TM 11361A-OR/1 REV E

29

Section VII – INFRARED CAMERA CONTROLS

2-38. SCOPE

A. This section describes the operation and function of buttons and switches for operating the infrared camera. B. Controls and indicators for operating the infrared camera are located on the kneeboard and include the following:

1. IR status indicator

2. IR field of view indicator 3. IR zoom buttons

4. Gain control knob

5. Manual level control knob

6. Focus knob

7. IR polarity button

2-39. IR STATUS INDICATOR

CAUTION

The infrared camera must cool to its required operating temperature before it can be used. This can take up to eight minutes if the infrared camera has been off for an extended period of time.

A. The IR status indicator, Figure 2-27, is an LED that shows the current operational status of the infrared camera.

Figure 2-27 IR Status Indicator

1. When the infrared camera is in startup mode (camera is cooling down), the IR status indicator is illuminated in red. 2. When the infrared camera is operational and the automatic gain control (AGC) is selected, the IR status indicator is illuminated in green.

3. When the infrared camera is operational and the automatic gain control (AGC) is not selected, the IR status indicator is illuminated in orange. Manual gain control is active.

B. When the infrared camera is in startup mode and the IR status indicator is illuminated in red, the video monitor will display color bars until the infrared camera is ready for use.

2-40. IR FIELD OF VIEW INDICATOR A. The IR field of view indicator, Figure 2-28, is an LED that shows the current field of view that the infrared camera is using to view an image.

Figure 2-28 IR Field of View Indicator

1. When the narrow field of view is selected, the IR field of view indicator is illuminated in red.

2. When the medium field of view is selected, the IR field of view indicator is illuminated in orange. 3. When the wide field of view is selected, the IR field of view indicator is illuminated in green.

GYROCAM SYSTEMS, LLC TM 11361A-OR/1 REV E

30

2-41. IR ZOOM BUTTONS

A. The IR zoom buttons, Figure 2-29, are two separate pushbuttons that are used to increase and decrease the magnification of the infrared camera image.

Figure 2-29 IR Zoom Buttons B. The zoom function on the infrared camera allows magnification of up to 100 times what the human eye can resolve.

1. Pressing on the “W” zoom button will increase the viewing field of the image. The corresponding field of view indicator illuminates, refer to Section 2-40. 2. Pressing on the “T” zoom button will decrease the viewing field of the image. The corresponding field of view indicator illuminates, refer to Section 2-40.

2-42. GAIN CONTROL KNOB A. The gain control knob, Figure 2-30, is a single-turn potentiometer used to brighten or darken the infrared camera image through amplification.

Figure 2-30 Gain Control Knob

1. Turning the gain control knob counter-clockwise decreases the amount of gain, darkening the image on the video monitor.

2. Turning the gain control knob clockwise increases the amount of gain, brightening the image on the video monitor.

3. Setting the gain control knob in the middle of the range enables the automatic gain control (AGC) function, which allows the Camera System to determine the optimal image brightness.

NOTE

Manual gain control may be necessary for certain environmental conditions in which ambient temperature uniformity is not present, such as after a heavy rainstorm.

2-43. MANUAL LEVEL CONTROL KNOB

A. The manual level control knob, Figure 2-31, is used to adjust the amount of contrast and offset in an infrared image.

Figure 2-31 Manual Level Control Knob

NOTE

The manual level control knob is disabled when automatic gain control (AGC) is enabled.

1. Turning the manual level control knob counterclockwise decreases the contrast level and darkens the infrared image on the video monitor.

2. Turning the manual level control knob clockwise increases the contrast level and brightens the infrared image on the video monitor.

GYROCAM SYSTEMS, LLC

TM 11361A-OR/1 REV E

31

2-44. FOCUS KNOB A. The focus knob, Figure 2-32, is a potentiometer used to adjust the image clarity on the infrared camera.

Figure 2-32 Focus Knob

1. Turning the focus knob counterclockwise moves the image plane towards the infrared camera.

2. Turning the focus knob clockwise moves the image plane away from the infrared camera.

3. Pressing the focus knob enables the image to be automatically focused by the Camera System.

NOTE

In order for the auto focus function to work properly, an image must be within the focus plane (viewing area) of the infrared camera.

2-45. IR POLARITY BUTTON A. The IR polarity button, Figure 2-33, is used to select the “hot” and “cold” color palettes for the infrared camera.

Figure 2-33 IR Polarity Button

1. Pressing the IR polarity button for one second or less reverses the currently configured “hot” and “cold” color palettes for the infrared camera.

2. Pressing and holding the IR polarity button for longer than one second changes the specific color palette for infrared image viewing.

3. When changing the color palette for the infrared image, a brief (less than one second) press of the IR polarity button will change the color palette on the video monitor.

GYROCAM SYSTEMS, LLC TM 11361A-OR/1 REV E

32

Section VIII – PNEUMATIC MAST CONTROLS

2-46. SCOPE

A. This section describes the operation and function of controls for operating the pneumatic mast. B. Controls for raising and lowering the pneumatic mast are located on the video monitor mounting plate.

2-47. MAST TOGGLE SWITCH _________ WARNING

Extreme caution must be used when the Camera System mast is extended and the vehicle is in motion. Care must be taken to avoid contact with electrical power lines, low hanging tree branches, bridges, and other overhead obstructions. Personnel injury, vehicle damage, Camera System damage, and death can result from failure to observe safety precautions when mast is extended and vehicle is in motion. Mast and gimbal contact with sources of high voltage can result in equipment damage, personnel injury or death. Do not extend the mast or operate the Camera System near high voltage power lines or in weather conditions where lightning is present. Over-pressurizing the mast will cause a pneumatic safety valve to activate. Do not exceed the maximum pneumatic operating pressure of 35 psi (241 kPa) for the mast. The mast is designed to lift a specific payload intended for lighting, surveillance, and communication use only. Any other use may cause equipment damage, personnel injury, or death. Do not use the mast to lift personnel. Do not exceed the specified payload capacity.

A. The mast toggle switch, Figure 2-34, is a three-position locking switch that, when pushed up, fills the mast cavity up with compressed air to raise it.

Figure 2-34 Mast Toggle Switch

B. When the mast toggle switch is in the maintained down position, the air in the mast cavity is allowed to escape through the dump valve, lowering the mast. C. When the mast toggle switch is in the maintained center position, the airflow into and out of the mast is blocked and the mast remains in its current position.

2-48. MAST HEIGHT LASER

A. The mast height laser, Figure 2-35, is a laser distance measuring system that determines the height of the gimbal from ground level and sends a digital readout of the mast height to the operator’s station. B. The gimbal height displayed is the distance between the ground and the top of the gimbal. C. Gimbal height is displayed in feet and tenths of feet – not feet and inches.

Figure 2-35 Mast Height Indicator

Mast Height

Mast Toggle Switch

GYROCAM SYSTEMS, LLC

TM 11361A-OR/1 REV E

33

Section IX – LASERDYNE VIDEO MONITOR CONTROLS

2-49. SCOPE

A. This section describes the operation and function of controls for operating the Laserdyne video monitor. B. Controls for operating the video monitor are located on the front of the video monitor. C. When the On Screen Data Enable switch is activated, the gimbal azimuth and elevation position is shown on the video monitor screen.

2-50. VIDEO MONITOR FUNCTION BUTTONS A. The video monitor function buttons, Figure 2-36, are used to configure specific settings and viewing options for the video monitor.

Figure 2-36 Video Monitor Function Buttons

NOTE

If a menu selection is not been made within three seconds of pressing a function button, the menu labels will withdraw and the image screen will be displayed.

B. Video monitor function buttons include the following:

1. Menu

2. Layout 3. Enhance

4. Zoom

5. Freeze

2-51. MENU BUTTON

A. The menu button (1) displays the main menu on the video monitor. B. When the menu button is pressed, the operator can adjust the display settings for the current screen layout.

2-52. LAYOUT BUTTON

A. The layout button (2) displays the available screen layout list. B. When the layout button is pressed, the operator can select up to five pre-assigned screen layouts.

2-53. ENHANCE BUTTON A. The enhance button (3) initiates the dynamic enhancement feature. B. When the enhance button is pressed, the operator can press the – or + keys to cycle through three different screen enhancement settings.

2-54. ZOOM BUTTON

A. The zoom button (4) initiates the digital image magnification feature. B. When the zoom button is pressed, the operator can press the – or + keys to adjust the zoom scale.

2-55. FREEZE BUTTON

A. The freeze button (5) initiates the freeze feature. B. When the freeze button is pressed, the operator can stop and start the motion of the image, while leaving any picture-in-picture live.

Warm Up LED

Layout Button (2)

Auxiliary LED

Zoom Button (4)

On/Off Button

Menu Button (1)

Enhance Button (3)

Freeze Button (5)

Scroll/Adjust Buttons

GYROCAM SYSTEMS, LLC TM 11361A-OR/1 REV E

34

Section X – AVALEX VIDEO MONITOR CONTROLS

2-56. SCOPE

A. This section describes the operation and function of controls for operating the Avalex video monitor. B. Controls for operating the video monitor are located on the front of the video monitor. C. When the On Screen Data Enable switch is activated, the gimbal azimuth and elevation position is shown on the video monitor screen.

2-57. VIDEO MONITOR FUNCTION BUTTONS A. The video monitor function buttons, Figure 2-37, are used to configure specific settings and viewing options for the video monitor.

Figure 2-37 Video Monitor Function Buttons

NOTE

While the on-screen menu is being displayed, the split window or picture-in-picture window will display a black screen. When the menu is closed, the screen will be active.

B. Video monitor function buttons include the following:

1. Map

2. Video 3. Freeze/Zoom

4. Up Arrow

5. Down Arrow

2-58. MAP BUTTON

A. The map button (1) selects the VGA source connected to the back of the video monitor. B. When the map button is pressed, the operator can select the required VGA source, which is then displayed on the bottom of the screen.

2-59. VIDEO BUTTON

A. The video button (2) selects and displays composite video. B. When the video button is pressed, the operator can move sequentially through and select the available video source, which is then displayed on the bottom of the screen.

2-60. FREEZE/ZOOM BUTTON A. The freeze/zoom button (3) initiates the dynamic enhancement feature. B. When the freeze/zoom button is pressed, the operator can freeze, zoom, select an active window, or activate picture-in-picture mode.

2-61. UP ARROW BUTTON

A. The up arrow button (4) allows the operator to increase the brightness of the image displayed. B. The up arrow button is also used to scroll upward through the menu options when they are displayed on the video monitor.

2-62. DOWN ARROW BUTTON

A. The down arrow button (5) allows the operator to increase the brightness of the image displayed. B. The down arrow button is also used to scroll downward through the menu options when they are displayed on the video monitor.

Video Button (2)

Up Arrow (4) Power Button

Map Button (1) Freeze/Zoom

Button (3) Down Arrow (5)

GYROCAM SYSTEMS, LLC

TM 11361A-OR/1 REV E

35

Section XI – VIDEO TAPE RECORDER (VTR) CONTROLS

2-63. SCOPE

A. This section describes the operation and function of controls for operating the video tape recorder, Figure 2-38.

Figure 2-38 Video Tape Recorder (VTR) B. Controls for operating the video tape recorder are located on the front of the video tape recorder.

2-64. VIDEO TAPE RECORDER CONTROLS A. The video tape recorder controls, Figure 2-39, are used to record, play back, rewind, and fast forward video tapes made of images recorded from the gimbal cameras.

Figure 2-39 Video Tape Recorder Controls

B. Video tape recorder controls include the following:

POWER = Turns the video tape recorder on and off.

RECORD = Store images on a video tape.

PLAY = Play back a recorded video tape. FAST FORWARD = Advance a video tape

REVERSE = Rewind a video tape

STOP = Stop the current control function

SLOW = Play a video tape at slower than normal speed

PAUSE = Temporarily stop the video tape at its current position.

EJECT = Remove the video tape from the video tape player.

GYROCAM SYSTEMS, LLC TM 11361A-OR/1 REV E

36

Section XII – INTERFACE UNIT (IFU) CONTROLS

2-65. SCOPE

A. This section describes the operation and function of controls for operating the interface unit (IFU). B. The interface unit electronically links together the gimbal, Nycoil, kneeboard, video monitor, and video tape recorder.

2-66. INTERFACE UNIT CONTROLS A. The interface unit, Figure 2-40, does not have any operator controls or settings.

Figure 2-40 Interface Unit Controls

NOTES

GYROCAM SYSTEMS, LLC

TM 11361A-OR/1 REV E

37

THIS PAGE INTENTIONALLY LEFT BLANK

GYROCAM SYSTEMS, LLC TM 11361A-OR/1 REV E

38

CHAPTER 3 – CAMERA SYSTEM OPERATION

Section I – BASIC OPERATIONS 3-1. PRE-OPERATIONAL CHECKS

_________ WARNING

This section and all other sections in this manual should be thoroughly read and understood before any attempt is made to start and operate the Camera System. Operating the Camera System without training or instruction may result in personnel injury or damage to the Camera System.

CAUTION

This chapter provides instructions in safe and efficient Camera System operation. Personnel assigned as crew members should have successfully completed the Operator’s training course as prescribed by the Camera System manufacturer.

NOTE Before you attempt to operate the Camera System, be sure you are familiar with the location and function of all controls and indicators. A. Table 4-1 lists all operator preventive maintenance checks and services (PMCS). B. PMCS must be conducted daily before operation, during operation, and after operation as noted in Table 4-1.

3-2. WALK-AROUND INSPECTION

A. The walk-around inspection is intended to catch minor problems before they become either a safety hazard or a major maintenance or repair requirement. B. Walk around the vehicle and perform a visual inspection of the armor plating around the mast and gimbal.

3-3. EXTERIOR PRE-MISSION CHECKS

A. Check all mechanical interfaces for loose hardware or damage.

B. Verify that there are no overhead obstructions for the mast when it is raised, nor anything else that might damage the Nycoil when the mast is raised.

C. Ensure that the mast exhaust is free of obstructions.

D. Remove all storage covers from the gimbal.

E. Wipe down the gimbal to remove any accumulated moisture or dust.

F. Remove the lens cap and vibration damper from the gimbal.

G. Using distilled water and a clean, lint-free cloth, clean the bezel on the gimbal.

3-4. INTERIOR PRE-MISSION CHECKS

A. Verify that all electrical connectors are installed and undamaged.

B. Check all interior wiring for broken, loose, or damaged wires and clamps.

C. Verify that circuit breakers for the gimbal and mast are intact and active.

CAUTION

The vehicle engine must be turned on and running prior to the Camera System being powered up, to prevent mechanical damage to the system. The Camera System must be powered down prior to starting the vehicle, to prevent electrical damage to the System caused by low voltage.

D. Power up the camera system.

E. Verify that the kneeboard lights up.

F. Verify that an image is displayed on the video monitor and the video tape recorder.

GYROCAM SYSTEMS, LLC

TM 11361A-OR/1 REV E

39

_________ WARNING

Extreme caution must be used when extending the mast. Care must be taken to avoid contact with electrical power lines, low hanging tree branches, bridges, and other overhead obstructions. Personnel injury, vehicle damage, Camera System damage, and death can result from failure to observe safety precautions when extending the mast. Mast and gimbal contact with sources of high voltage can result in equipment damage, personnel injury or death. Do not extend the mast or operate the Camera System near high voltage power lines or in weather conditions where lightning is present.

G. Raise the mast to its full height and verify that the gimbal height display indicates the correct height.

H. Operate the gimbal:

1. Verify that the gimbal operates correctly in azimuth and elevation movements.

2. Verify that the zoom and focus controls function correctly.

3. Verify that the extender button is fully operational.

CAUTION

The infrared camera must cool to its required operating temperature before it can be used. This can take up to eight minutes if the infrared camera has been off for an extended period of time.

I. Operate the infrared camera:

1. Verify that the infrared status LED is illuminated in green when the infrared camera has cooled to its required operating temperature.

2. Verify that the infrared camera is operational.

NOTE Object closer than 50 feet (15.24 m) away from the camera lens without clear edges may not come into focus.

3. Verify that the infrared camera changes field of view and can focus properly.

CAUTION

The night vision camera cannot be activated in daylight conditions. A light sensor in the gimbal automatically turns the night vision intensifier off during daylight conditions.

J. Operate the night vision camera and verify that an image is visible on the video monitor.

K. Lower the mast.

CAUTION

When the vehicle is in transit, the mast must be raised at least 12.0 inches (30.48 cm) to act as a shock absorber for the gimbal. Moving the vehicle with the mast completely lowered will cause equipment damage to the gimbal and render it inoperative.

3-5. STARTING THE CAMERA SYSTEM

CAUTION

The vehicle engine must be turned on and running prior to the Camera System being powered up, to prevent mechanical damage to the system. All circuit breakers must be closed. The Camera System must be powered down prior to starting the vehicle, to prevent electrical damage to the System caused by low voltage.

A. Start the vehicle.

B. To power up the Camera System, move the power switch from the left hand position to the right hand position. C. The red LED to the right of the power switch will illuminate in red when the Camera System is powered up.

GYROCAM SYSTEMS, LLC TM 11361A-OR/1 REV E

40

D. Ensure the stick zero LED is illuminated in green.

E. Ensure the azimuth/elevation LED is illuminated in red, indicating that the gimbal is in stow mode.

F. Ensure that gimbal sensitivity is set to medium – the MED LED is illuminated in yellow.

3-6. OPERATING THE MAST

_________ WARNING

Extreme caution must be used when extending the mast. Care must be taken to avoid contact with electrical power lines, low hanging tree branches, bridges, and other overhead obstructions. Personnel injury, vehicle damage, Camera System damage, and death can result from failure to observe safety precautions when extending the mast. Mast and gimbal contact with sources of high voltage can result in equipment damage, personnel injury or death. Do not extend the mast or operate the Camera System near high voltage power lines or in weather conditions where lightning is present.

A. With the vehicle running and the camera system powered up, push up on the toggle switch. B. Verify that the mast height laser indicator readout shows a positive climb in the mast position.

3-7. OPERATING THE GIMBAL

A. Power up the Camera System. B. Press the stow/operate button until the LED is illuminated in green. C. Set the gimbal pan rate by pressing the sensitivity button.

1. Pressing the sensitivity button until the LOW LED is illuminated in yellow sets the gimbal pan rate to a maximum of 8° per second.

2. Pressing the sensitivity button until the MED LED is illuminated in yellow sets the gimbal pan rate to a maximum of 24° per second.

3. Pressing the sensitivity button until the HIGH LED is illuminated in red sets the gimbal pan rate to a maximum of 72° per second.

4. Pressing the sensitivity button until the AUTO LED is illuminated in green sets the gimbal pan rate to a maximum of three fields of view per second.

D. Move the gimbal as required by positioning the joystick to align the camera with the acquired surveillance target.

1. Moving the joystick forward moves the gimbal downward.

2. Pulling the joystick backward moves the gimbal upward.

3. Moving the joystick to the left moves the gimbal to the left.

4. Moving the joystick to the right moves the gimbal to the right.

E. Press the auto trim button to dampen any relative motion errors in the gimbal. The auto trim LED is illuminated and flashes in red.

F. Turn the azimuth and/or elevation knobs as necessary to reduce the effects of electronic drift between the vehicle and the surveillance target, when the joystick is not being used.

1. Turning the azimuth trim knob in the opposite direction of the image drift reduces the amount of horizontal drift seen on the video monitor.

2. Turning the elevation trim knob in the opposite direction of the image drift reduces the amount of vertical drift seen on the video monitor.

G. View the image.

GYROCAM SYSTEMS, LLC

TM 11361A-OR/1 REV E

41

3-8. CHANGING THE GIMBAL STOW POSITION

A. Power up the Camera System.

B. Press the auto trim button until the LED is illuminated and flashes in red.

C. Using the joystick, move the gimbal to the new stow position.

D. Press the auto trim button. The auto trim LED turns off and the new gimbal stow position is saved in memory.

3-9. OPERATING THE VIDEO MONITOR

A. Power up the Camera System.

B. If necessary, power up the video monitor by pressing the video monitor power button and holding it for two seconds. The video monitor runs a series of self-diagnostic routines, lasting about 30 seconds.

NOTE To bypass the diagnostic routines on the video monitor upon startup, press any one of the function keys on the video monitor.

C. The video monitor displays an image from the gimbal.

D. Configure the video monitor as required by pressing the function buttons and adjusting the video monitor settings.

1. Pressing function button 1 displays the main menu on the video monitor and allows the operator to adjust the display settings for the current screen layout.

2. Pressing function button 2 displays the current screen layout list and allows the operator to select up to five pre-assigned screen layouts.

3. Pressing function button 3 turns on the dynamic enhancement feature and allows the operator to press the – or + keys to cycle through three different screen enhancement settings.

4. Pressing function button 4 initiates the digital image magnification feature and allows the operator to press the – or + keys to adjust the zoom scale.

5. Pressing function button 5 turns on the freeze/unfreeze feature and allows the operator to stop and start the motion of the image, while leaving any picture-in-picture live.

3-10. OPERATING THE VIDEO TAPE RECORDER (VTR)

A. Power up the Camera System.

B. If necessary, power up the video tape recorder by sliding the power switch to the ON position.

C. Insert a tape into the video tape recorder.

1. Slide the EJECT button in the direction of the arrow shown on the button. The tape compartment opens.

2. Insert the tape with the window facing up.

D. To record images on the video tape, press both REC buttons at the same time.

E. To stop the recording, playback, or other tape function, press the STOP button.

F. To rewind a tape, press the REVERSE button.

G. To advance a tape, press the FAST FORWARD button.

H. To pause the playback of a tape, press the PAUSE button.

I. To eject a tape from the video tape recorder:

1. Slide the EJECT button in the direction of the arrow shown on the button. The tape compartment opens.

2. Remove the tape from the tape compartment.

3-11. LOCATING A SURVEILLANCE TARGET

A. Power up the Camera System.

B. Operate the gimbal.

C. Locate the surveillance target.

D. Select the required camera for the viewing conditions.

GYROCAM SYSTEMS, LLC TM 11361A-OR/1 REV E

42

E. Configure the Camera System for use with the environment.

F. Set the gimbal sensitivity to medium.

G. Press the auto trim button.

H. Using the joystick, center the surveillance target in the middle of the video monitor screen.

I. Optimize the resolution of the surveillance target.

1. If the color camera is being used, set the iris level to midrange, adjust camera gain as required, and turn the master black knob counterclockwise.

2. If the night vision camera is being used, press the detail button until the MAN LED is illuminated. The iris level knob can then be adjusted for optimal viewing conditions and image brightness.

3. If the infrared camera is being used, press the IR polarity button to set a color palette that best shows the infrared image on the video monitor.

J. Turn the azimuth and/or elevation knobs as necessary to reduce the effects of electronic drift between the vehicle and the surveillance target.

1. Turning the azimuth trim knob in the opposite direction of the image drift reduces the amount of horizontal drift seen on the video monitor.

2. Turn the elevation trim knob in the opposite direction of the image drift reduces the amount of vertical drift seen on the video monitor.

K. View the image.

3-12. TRACKING A TARGET USING THE COLOR CAMERA

A. Power up the Camera System.

B. Operate the gimbal.

C. Locate the surveillance target.

D. Press the color camera selector button on the kneeboard.

E. To view the gimbal azimuth and elevation position data on the video monitor, move the on screen data enable switch from the left hand position to the right hand position on the kneeboard.

NOTE

Azimuth position 0° is defined as straight off the vehicle’s hood. Elevation position 0° is defined as level with the vehicle.

NOTE

If a global positioning system (GPS) receiver is connected to the interface unit (IFU), antenna latitude and longitude is also shown on the video monitor.

F. Adjust the magnification of the image.

1. To increase the magnification of the image, press “T” on the upper portion of the color zoom switch.

2. To decrease the magnification of the image, press “W” on the lower portion of the color zoom switch.

G. Adjust the focus of the image.

1. To move the image focus plane away from the vehicle, rotate the color focus knob clockwise until the image is sharp.

2. To move the image focus plane towards the vehicle, rotate the color focus knob counterclockwise until the image is sharp.

H. To double the perceived size of an image viewed on the video monitor, press the extender button. The LED next to the extender button is illuminated in red.

NOTE When the extender button is pressed, the image brightness is reduced by a factor of four. It may be necessary to compensate for this reduction.

I. Adjust the brightness of the screen.

1. To increase the brightness of the screen, rotate the iris level knob clockwise until the screen brightness is optimal for the viewing conditions.

GYROCAM SYSTEMS, LLC

TM 11361A-OR/1 REV E

43

2. To decrease the brightness of the screen, rotate the iris level knob counterclockwise until the screen brightness is optimal for the viewing conditions.

J. Set the image brightness (camera gain).

1. In very bright conditions, the camera gain knob should be set to 1/4000.

2. In bright conditions, the camera gain knob should be set to 1/1000.

3. In moderately bright conditions, the camera gain knob should be set to 1/250.

4. In normal daytime conditions, the camera gain knob should be set to NORMAL.

5. In moderately dark conditions, the camera gain knob should be set to MED.

6. In dark conditions, the camera gain knob should be set to HIGH.

K. Set the video level that represents the color black (master black) on the video monitor.

1. To decrease the quantity of black seen on the video monitor, turn the master black knob counter-clockwise.

2. To increase the quantity of black seen on the video monitor, turn the master black knob clockwise.

L. Set the level of detail for the color camera.

1. To set the color bars and detail levels for the color camera, press the detail button until the BARS LED is illuminated.

2. To manually control the iris, press the detail button until the MAN LED is illuminated. The iris level knob can then be adjusted for optimal viewing conditions and image brightness.

3. To configure a medium level of image detail, press the detail button until the MED LED is illuminated.

4. To configure a high level of image detail, press the detail button until the HIGH LED is illuminated.

NOTE

White balance must be set for the color camera when the Camera System is

powered up or whenever the camera gain setting is changed. If no white-colored object is available, aim the camera at the sky. M. Set the white balance for the color camera by aiming the camera at a white-colored object that fills the middle of the screen on the video monitor, then pressing the white balance button to allow the camera to adjust the relative values of red and blue.

N. View the image. 3-13. TRACKING A TARGET USING THE NIGHT VISION CAMERA

A. Power up the Camera System.

B. Operate the gimbal.

C. Locate the surveillance target.

CAUTION

The night vision camera cannot be activated in daylight conditions. A light sensor in the gimbal automatically turns the night vision intensifier off during daylight conditions.

D. Verify that the night vision ready indicator is illuminated when ambient light conditions are sufficiently low enough for night vision camera operation.

E. Press the night vision camera selector button on the kneeboard.

F. Press the detail button until the MAN LED is illuminated.

G. Rotate the iris level knob clockwise until the iris is fully open.

H. To view the gimbal azimuth and elevation position data on the video monitor, move the on screen data enable switch from the left hand position to the right hand position on the kneeboard.

NOTE

Azimuth position 0° is defined as straight off the vehicle’s hood. Elevation position 0° is defined as level with the vehicle.

GYROCAM SYSTEMS, LLC TM 11361A-OR/1 REV E

44

NOTE

If a global positioning system (GPS) receiver is connected to the interface unit (IFU), antenna latitude and longitude is also shown on the video monitor.

_________ WARNING

The unaided, eye safe distance for the laser is 2 meters. The aided (binoculars) eye safe distance for the laser is 17 meters. Permanent eye damage can result from sustained, direct contact with the laser. Personnel inside the eye safe distance must wear laser PPE.