TRANSMISSION SERVICE REQUESTS

Transcript of TRANSMISSION SERVICE REQUESTS

TRANSMISSION / DISTRIBUTION PROJECTS

COMPANY:EGSI-LA

CUSTOMER: CLECO POWER LLC

FACILITIES STUDY

EJO # F4PPGS0423 ICT-2008-028

TRANSMISSION SERVICE REQUESTS

OASIS 1551562

Revision: 3

Rev Issue Date Description of Revision Revised

By Project

Manager

A 06/17/08 Shell for team input Ibrahim Khan

Kevin Wright

0 07/10/08 Finalized and submitted to PD Ibrahim Khan

Kevin Wright

1 07/21/08 ICT Determines Upgrade Classification Eric Burkey

Jody Holland

2 09/12/08 Redispatch Options Included James Lyle

Jody Holland

3 09/19/08 Redispatch Options Updated Eric Burkey

Jody Holland

Cleco Power LLC OASIS 1551562 Facilities Study

1. EXECUTIVE SUMMARY.....................................................................5

2. SAFETY AWARENESS ......................................................................5

3. SCOPE SUMMARY.............................................................................5

3.1 Upgrade the line equipment at the Bogalusa 230kV substation ............................ 5 3.2 Line upgrades........................................................................................................ 5

4. SCOPE DETAILS................................................................................6

4.1 Transmission Substations ........................................................................................ 6 4.1.1 Bogalusa 230kV Substation .................................................................................. 6 4.1.2 Wilbert Substation ................................................................................................. 8 4.1.3 Livonia Substation ................................................................................................. 9 4.1.4 Krotz Spring Substation....................................................................................... 10 4.1.5 Humphrey 115 kV Substation.............................................................................. 10 4.2 Lines:...................................................................................................................... 12 4.2.1 Wilbert - Livonia 138kV line from 289 MVA to at least 334 MVA......................... 12 4.2.2 Livonia - Line 642 Tap 138kV line from 289 MVA to at least 299 MVA ............... 14 4.2.3 Line 642 Tap - Krotz Spring 138kV line from 289 MVA to at least 294 MVA....... 15 4.2.4 Terrebonne – Greenwood 115kV transmission line – upgrade to a minimum of

295 MVA: ............................................................................................................ 17 4.2.5 Greenwood – Humphrey 115 kV Line, 228 MVA to 259 MVA ............................. 18

Assumptions:....................................................................................................... 19

4.2.6 Humphrey – Gibson 115 kV Line, 227 MVA to 253 MVA ........................... 19

5. COSTS ..............................................................................................21

6. SCHEDULE.......................................................................................22

Project Definition: ......................................................................................................... 22 Design, procurement and construction:........................................................................ 22

7. CONFIRMED RESERVATIONS........................................................23

8. PRE-888 TRANSACTIONS...............................................................27

9. ATTACHMENTS ...............................................................................29

• Humphrey Station................................................................................................ 31 • Livonia Station..................................................................................................... 33 • Wilbert Station ..................................................................................................... 34

2

Cleco Power LLC OASIS 1551562 Facilities Study

Table of Acronyms

ACSR Aluminum Conductor Steel Reinforced ACSS Aluminum Conductor Steel Supported ADEQ Arkansas Department of Environmental Quality AECC Arkansas Electric Co-Operatives AFUDC Allowance for Funds Used During Construction AMRN Ameren Control Area EES Entergy Control Area EHV Extra-High Voltage EMO Entergy Energy Management Organization FTR Financial Transmission Rights ICT Independent Coordinator of Transmission kV Kilo-Volt MCM (M) Thousand Circular Mils MVA Mega-Volt Amp MW Mega-Watt NPDES National Pollution Discharge Elimination System NOI Notice of Intent OASIS Online Access and Same-time Information System OATT Open Access Transmission Tariff SHPO Arkansas State Historic Preservation Office SHV Super High Voltage

3

Cleco Power LLC OASIS 1551562 Facilities Study

Team members: Ed Brawner – Project Developer Maryclaire Peterson – Technical Planner (Solution set) Kevin Wright – Program Manager Shannon Landry - Scheduler Marnie Roussell – Substation – Electrical Dan Calamari – Substation Foundations Greg Buisson – Relay design Tu Nguyen – Relay Settings Chris Sistrunk – RTU Configuration Ken Keller – EGSL – Line design Charlie Gambrell – Substation Construction – Ray B & Baxter Wilson George Klink – Substation / Line Construction – Bogalusa/Humphrey/Terrebonne to Greenwood to Gibson to Humphrey VJ Misuraca – Lines/Substation Construction – Wilbert/Livonia/ Wilbert to Livonia to line tap 642 to Krotz Ibrahim Khan – Contract Project Manager JET team: (A JET meeting was held on 07/08/08) Brian Story – Substation Design Terry Clement – Relay Design Steve Parrish – Line Design Dan Glaser – Relay settings and configuration Paul Leist – Construction – ELI – N Kenny Chaix – Construction – EGSL

4

Cleco Power LLC OASIS 1551562 Facilities Study

1. EXECUTIVE SUMMARY The purpose of this Facilities Study is to determine the availability of transfer capability across Entergy’s transmission system from Southwestern Power Administration (SPA) to CLECO, to evaluate the CLECO request for 11MW of long term firm transmission service. The time period for this transfer is from 6/1/2009 until 6/1/2018. The direction of the transaction is SPA to CLECO. This study was performed on the latest available June 2009 – November 2009 monthly models, 2009-2017 winter peak and 2010-2017 summer peak models, using PSS/E and MUST software by Power Technologies Incorporated (PTI). The facilities study identifies any transmission constraints resulting from the requested power transfer. The facilities study also includes cost estimates to correct any transmission constraints.

Under Entergy’s Independent Coordinator of Transmission which became effective on November 17, 2006, Entergy will recover these costs based on Attachment T of Entergy’s OATT. In this Attachment T, the ICT has determined these costs to be classified as Supplemental Upgrades.

2. SAFETY AWARENESS

Safety is a priority with Entergy. Safety will be designed into substations and lines. The designs will be done with the utmost safety for personnel in mind for construction, operation, and maintenance of the equipment.

Specific to the job a safety plan can be developed after site visits and construction plan and outages that are prepared based on an execution plan. This facility study did not afford the foresaid and therefore the safety aspects are described in general. Should the work contained within this Facility Study be approved, a detailed Safety Plan will be formulated and incorporated within the project plan.

All employees working directly or indirectly for Entergy shall adhere to all rules and regulations outlined within the Entergy Safety manual. Entergy requires safety to be the highest priority for all projects. All Entergy and Contract employees must follow all applicable safe work procedures. 3. SCOPE SUMMARY The facilities study has identified some transmission constraints. The constraints can be addressed in the following manner:

3.1 Upgrade the line equipment at the Bogalusa 230kV substation. The Bogalusa-Adams Creek 230kV transmission line B overloads for the loss of the Bogalusa-Adams Creek 230kV transmission line A. The Bogalusa-Adams Creek 230kV transmission line B needs to have a capacity of 822MVA or greater on all components. The line conductor has a rated capacity of 880MVA, but the Bogalusa 230kV breaker #S2520 is rated at 1600A or 637MVA. The breaker and its associated switches need to be upgraded to 3000A. 3.2 Line upgrades The following transmission lines overload for the loss of the Webre-Wells 500kV transmission line. All lines, listed below, have double bundled 336 ACSR conductors. All line conductors below must be upgraded to double bundled 666 ACSR. • Terrebonne-Greenwood 115kV must be upgraded from at least 295MVA. • Greenwood-Humphrey 115kV must be upgraded to at least 259MVA. • Humphrey-Gibson 115kV must be upgraded to at least 253MVA. • Livonia-Wilbert 138kV must be upgraded to at least 334MVA. • Livonia-Line 642 Tap 138kV must be upgraded to at least 299MVA. • Line 642 Tap-Krotz Springs 138kV must be upgraded to at least 294MVA.

5

Cleco Power LLC OASIS 1551562 Facilities Study A solution for these constraints has been identified in previous facility studies (OASIS request number 1481059, 1481111, 1481119, 1481235, 1481438, and 1520043). A solution is to build a new 230kV line from Webre-Richard. If a previous facility study request and the proposed equipment upgrades are confirmed, the customer would not have to fund this upgrade Planning Redispatch Options: As Requested by the customer multiple redispatch scenarios were studied, only options 1 and 2 are feasible.

1. The constraints identified in 3.1 & 3.2 could be alleviated by redispatching 15MW from Dolet Hills to Teche. The ICT has identified this third party redispatch as a technically feasible redispatch according to the Entergy OATT, Attachment D Section 4.3; however, the ICT is not indicating financial feasibility of this solution. Third party redispatch solutions are negotiated between the customer and the third party and coordinated with the ICT.

2. The constraints identified in 3.2 could be alleviated by redispatching 5MW from Houma to Evangeline. This redispatch will not alleviate the constraint identified in 3.1. The ICT has identified this third party redispatch as a technically feasible redispatch according to the Entergy OATT, Attachment D Section 4.3; however, the ICT is not indicating financial feasibility of this solution. Third party redispatch solutions are negotiated between the customer and the third party and coordinated with the ICT.

3. There are no Entergy generation pairs that will provide a redispatch solution.

4. SCOPE DETAILS

4.1 Transmission Substations Due to increased power flow on line between Ray Braswell and Baxter Wilson 500 kV line, requirement is to replace existing 2000A breakers and disconnect switches by 3000A and 63 kA interrupter rating at Ray Braswell and Baxter Wilson Substations.

4.1.1 Bogalusa 230kV Substation Electrical: Replace 1600A breaker #S2520 by 3000A, 63kA breaker as well as the associated breaker disconnect switches to match the breaker rating. Multi ratio CTs would be ordered in consultation with Relay Design group. Also replace the three disconnect switches in that bay, including one ground switch, one motor operator, and associated insulators. Install arresters on existing A-frame deadend. Upgrade the bus work to 3000A as required. Site: No site work is required

Foundations: Install grounding and conduit as required for the new breaker and disconnect switches. Limestone will be required to restore ground disturbed by movement of vehicles and foundation work.

Relay Design: The control of breaker S2520 is located on the Adam Creeks Line B/ Breaker S2520 panel. Replace 230kV MOS S2093 by a 3000A MOS, a new MOS Control panel will be installed. Replace SEL 2020 Communication Processor by a SEL 2032 one. With new breaker and MOS RTU needs additional alarms.

6

Cleco Power LLC OASIS 1551562 Facilities Study

Settings and RTU Configuration: • Perform limited classical relay impact studies on affected lines and buses from remote stations. • Provide off site/ on site setting supports during construction for setting database issues, relay software and firmware compatibility. • Verify relay settings for Adams Creeks Line B. Existing CTR is 3000/5 and the relays are SEL321/P544. • Perform setting logistics such as relay date base, relay viewable document, project work folders for Web posting DOCUMENTUM, and relay modeling in ASPEN®. • Perform relay settings corrections and issue new “as built” settings based on returned “as left” settings. • Review /Adams Creek settings • Perform configuration for extra alarms from the new breaker.

Long Lead Material – Bogalusa 230kv

Material Description *Lead Time (weeks)

230 kV BREAKER 1 26 DISCONNECTS 3 18

MOS PANEL 6 *Lead time as of 7/10/08 Construction (GK): If this project is approved and enters the Transmission Business’s (EMCC) process for executing projects, there will be constructability reviews performed during the definition phase. These reviews will try to incorporate any known hazards from a safety perspective, as well as any obstacles that could/would be experienced during the construction and installation process. After receipt of the final design drawings and details for each discipline of work, a determination will be made to either perform a competitive bid process to award the work to an Entergy approved contractor, or, to allow internal Entergy Resources to perform the work. The normal process would be to perform all of the site, foundation, grounding, and conduit work with a single source. Dependant on the final design a determination will be made to address any system outages that may be required to perform the installations of any proposed foundations. Efforts will be made to utilize low profile excavation equipment as part of the installation process for any foundations that will be under, near, adjacent too, or in close proximity of energized conductors that could be determined to be a safety risk. In the instances that this is not attainable, outages will be required. Normally outages on 500kV facilities require a year’s advanced notice, with no guarantees that said outage will be granted at the time requested. This poses risk to all schedules. Upon completion of the site and foundation installations including all associated conduit and grounding installations, Steel and Electrical installations as well as Protection & Control Installations will commence. For the installation/replacement of the proposed components multiple bus and line outages will be required. The following outages will be required: 1) 230kV Transfer Bus in conjunction with S2093, S2520L, Adams Creek Line B and 2) 230kV Operating Bus, S2520L, S2520 & S2520B will have to be taken in conjunction but subsequent to the previous outage. Upon completion of the proposed outages all the new equipment shall be commissioned and energized. At energization this equipment must be hi-potted and phased. Required Outages:

7

Cleco Power LLC OASIS 1551562 Facilities Study 1) Bogalusa 230kV Transfer Bus in conjunction with S2093, S2520L, Adams Creek Line B=Roughly 2 Weeks 2) 230kV Operating Bus S2520L, S2520 & S2520B will have to be taken in conjunction but subsequent to the previous outage =Roughly 3 Weeks Assumptions: None provided by the team

4.1.2 Wilbert Substation Electrical: Livonia Line Bay (Livonia - Wilbert: Upgrade to 334 MVA) Replace switches with 2000A: 20169 & 20171 Replace breaker with 2000A: 20170 Replace bus with double 1000MCM Copper - (1) box structure run and (1) half bay Install one (1) 138kV CVT pedestal Foundation: Reconnect all new equipment to ground grid Site: No work required Relay and Configuration: Install one (1) 138kV CVT and associated conductors Install one (1) Line potential Junction Box Upgrade RTU motherboard to ME / with associated set chips and add status card Install one (1) lot of cable Develop new breaker schematics and cable schedule as required and add alarms into RTU and develop configuration • Perform limited classical relay impact studies on affected lines and buses from remote stations. • Perform Standard compliance studies for setting revisions and setting updates. • Model the new 138KV Wilbert-(Livonia) Krotz Spring L236/L312 into ASPEN ® based on Transmission Plan and Profile. • Revise relay settings and update relay firmware for 138KV La Station-Wilbert L303 to Entergy Standard if permitted. The setting scheme has been SEL421/SEL311C. • Revise relay settings for 138KV Addis-Wilbert L392. The setting scheme has been SEL321/EM. • Update relay settings and relay firmware for 138KV Wilbert-Livonia-Krotz Spring L236/L312 to Entergy Standard if permitted. The setting scheme has been SEL421/SEL311C. • Revise relay settings and update relay firmware for 138KV Champagne- Krotz Spring L641 to Entergy Standard if permitted. The setting scheme has been SEL421/SEL311C • Revise relay settings for Wilbert 230KV Bus PVD. And, notify Relay Designer for 1200/5 CTR C800 for the new 2000A breaker. • Provide off site/ on site setting supports during construction for setting database issues, relay software and firmware compatibility. • Perform setting logistics such as relay date base, relay viewable document, project work folders for Web posting DOCUMENTUM, and relay modeling in ASPEN®. • Perform relay settings corrections and issue new “as built” settings based on returned “as left” settings.

8

Cleco Power LLC OASIS 1551562 Facilities Study

Construction (VJ): If this project is approved and enters the Transmission Business’s (EMCC) process for executing projects, there will be constructability reviews performed during the definition phase. These reviews will try to incorporate any known hazards from a safety perspective, as well as any obstacles that could/would be experienced during the construction and installation process. After receipt of the final design drawings and details for each discipline of work, a determination will be made to either perform a competitive bid process to award the work to an Entergy approved contractor, or to allow internal Entergy Resources to perform the work. The normal process would be to perform all of the site, foundation, grounding, and conduit work with a single source. Dependant on the final design a determination will be made to address any system outages that may be required to perform the installations of any proposed foundations. It is assumed that the existing foundation for breaker 20170 will be adequate in size for the new 2000A GCB. In the event that foundation modifications are required, efforts will be made to utilize low profile excavation equipment. This will enable the installation of any foundations that will be under, near, adjacent to or in close proximity of energized conductors that could be identified as a safety risk. In the instances that this is not attainable, outages will be required. The disapproval of any outages could poses risk to all schedules. Upon completion of the site and foundation installations including all associated conduit and grounding installations, Steel and Electrical installations as well as Protection & Control Installations will commence Required Outages (High Level): • Wilbert to Livonia L-236 to replace breaker 20170 and switch 20169 & 20171 (3 weeks) • Livonia line bay 138kV Bus outage to replace bus (2 weeks) Assumptions: • Required line and bus outages are attainable

4.1.3 Livonia Substation Electrical: Krotz Springs Line Bay (Krotz Springs - Livonia: Upgrade to 294MVA) Replace Motorized Load Break Switch 14697 with 2000A and ground switch. Wilbert Line bay (Livonia - Wilbert: Upgrade to 334MVA) Replace Motorized Line Drop Switch 14698 with 2000A and ground switch Replace bus with double 1000MCM Copper - (2) 138kV box structure runs. Foundation: Reconnect all new equipment to ground grid Site: No work required Relay and Configuration: Upgrade RTU motherboard to ME / with associated set chips and add status card Install one (1) lot of cable Develop new breaker schematics and cable schedule as required and add alarms into RTU and develop configuration Construction (VJ):

9

Cleco Power LLC OASIS 1551562 Facilities Study If this project is approved and enters the Transmission Business’s (EMCC) process for executing projects, there will be constructability reviews performed during the definition phase. These reviews will try to incorporate any known hazards from a safety perspective, as well as any obstacles that could/would be experienced during the construction and installation process. After receipt of the final design drawings and details for each discipline of work, a determination will be made to either perform a competitive bid process to award the work to an Entergy approved contractor, or to allow internal Entergy Resources to perform the work. The normal process would be to perform all of the site, foundation, grounding, and conduit work with a single source. Dependant on the final design a determination will be made to address any system outages that may be required to perform the installations of any proposed foundations. It is assumed that no foundation modifications will be required for this scope of work. In the event that foundation modifications are required, efforts will be made to utilize low profile excavation equipment. This will enable the installation of any foundations that will be under, near, adjacent to or in close proximity of energized conductors that could be identified as a safety risk. In the instances that this is not attainable, outages will be required. The disapproval of any outages could poses risk to all schedules. Upon completion of the site and foundation installations including all associated conduit and grounding installations, Steel and Electrical installations as well as Protection & Control Installations will commence Required Outages (High Level): • Livonia to Wilbert L-312 to replace switch 14698 (1 week) • Wilbert line bay 138kV Bus outage to replace bus (2 weeks) • Livonia to Colonial Springs L-236 to replace switch 14697 (1 week) Assumptions: Required line and bus outages are attainable

4.1.4 Krotz Spring Substation It is a customer owned substation and information on bus conductor and breaker rating - 2000A Switch and assumed 2000A breaker and bus, no work required.

4.1.5 Humphrey 115 kV Substation

Electrical: Terrebonne / Greenwood Line Bay (Humphrey – Greenwood: upgrade to 259 MVA minimum)

• Replace 1200A switches with 2000A: S6094 and S6093 (w/ ground switch S2907) • Replace 1 ¼” riser; install 2 1/2” Sch. 80 or 1780MCM ACSR. Gibson Line Bay (Humphrey – Gibson: upgrade to 253 MVA minimum)

• Replace breaker S6085 to bring ratings to 2000A • Install arresters & CVT on existing A-frame structure • Replace line disconnect switch with ground • Replace disconnect switch S6041. • Replace S6085 bus disconnect switch. • Replace riser with 2 1/2” Sch. 80 Aluminum Bus (minimum). Foundation: • Check all ground connections of all equipment to be replaced. Install conduit to new breaker

10

Cleco Power LLC OASIS 1551562 Facilities Study

Protection & control: • Install a breaker control panel for new 138 kV breaker. • Install one 115kV CCVT. Settings Work: • Perform limited classical relay impact studies on affected lines and buses from remote stations. • Perform Standard compliance studies for setting revisions and setting updates. • Model the new 115KV Humphrey-Gibson-Ramos into ASPEN ® based on Transmission Plan and Profile. • Update relay settings and relay firmware for 115KV Humphrey-Gibson-Ramos with new 2000/5 CTR. The setting scheme has been EM/SEL221F. • Perform new relay settings for 115KV Breaker Control S6085 per Entergy Standard if permitted • Provide off site/ on site setting supports during construction for setting database issues, relay software and firmware compatibility. • Perform setting logistics such as relay date base, relay viewable document, project work folders for Web posting DOCUMENTUM, and relay modeling in ASPEN®. • Perform relay settings corrections and issue new “as built” settings based on returned “as left” settings. Site: • Restore crushed rock on all construction areas. No other work required. Assumptions: • Switches S6093 (with ground) and S6094 rated for 1200A • Switch S6085 is rated for 1200A • Bay Bus 2” Sch. 80 minimum • Risers 1-1/4” Sch. 80 minimum • CCVT can be mounted in steel tower • No information available on trough & control house, conduit is assumed to be connected to a nearby trough or pull box. • RTU is a D20 and expandable. • There is room in the control house for breaker control panel. • Reuse existing DC & AC breakers for new breaker and panel. Construction (GK): If this project is approved and enters the Transmission Business’s (EMCC) process for executing projects, there will be constructability reviews performed during the definition phase. These reviews will try to incorporate any known hazards from a safety perspective, as well as any obstacles that could/would be experienced during the construction and installation process. After receipt of the final design drawings and details for each discipline of work, a determination will be made to either perform a competitive bid process to award the work to an Entergy approved contractor, or, to allow internal Entergy Resources to perform the work. The normal process would be to perform all of the site, foundation, grounding, and conduit work with a single source. Dependant on the final design a determination will be made to address any system outages that may be required to perform the installations of any proposed foundations. Efforts will be made to utilize low profile excavation equipment as part of the installation process for any foundations that will be under, near, adjacent too, or in close proximity of energized conductors that could be determined to be a safety risk. In the instances that this is not attainable, outages will be required. Normally outages on 500kV

11

Cleco Power LLC OASIS 1551562 Facilities Study facilities require a year’s advanced notice, with no guarantees that said outage will be granted at the time requested. This poses risk to all schedules. Upon completion of the site and foundation installations including all associated conduit and grounding installations, Steel and Electrical installations as well as Protection & Control Installations will commence. For the installation/replacement of the proposed components multiple bus and line outages will be required. To the extent practical substation outages will be worked in conjunction with the respective Transmission Line outages. The following outages will be required to accomplish the work in the Terrebonne/Greenwood bay: 1) Terrebonne/Greenwood-Humphrey will be required the entire duration of the work in the Humphrey Bay bundled with the following 1) 115kV Transfer Bus in conjunction with S6093, S6094 2) 115kV Operating Bus, S6094, S6093 will have to be taken in conjunction but subsequent to the previous outage. The following outages will be required to accomplish the work in the Gibson bay: 1) Gibson-Humphrey will be required the entire duration of the work in the Humphrey Bay bundled with the following 1) 115kV Transfer Bus in conjunction with S6041, S6085L 2) 115kV Operating Bus, S6085, S6085B, and open S6041 will have to be taken in conjunction but subsequent to the previous outage. Upon completion of the proposed outages all the new equipment shall be commissioned and energized. At energization this equipment must be hi-potted and phased. This equipment will not become energized and commissioned until the completion of the Transmission Line rebuild for each respective Line Bay. Required Outages: Terrebonne/Greenwood Line Bay Work: 1) Terrebonne/Greenwood-Humphrey will be required the entire duration of the work in the Humphrey Bay bundled with the following 2) 115kV Transfer Bus in conjunction with S6093, S6094—Change S6093, A-frames 3) 115kV Operating Bus, S6094, S6093 will have to be taken in conjunction but subsequent to the previous outage.—Change S6094, A-Frames and bus between two switches. Gibson Line Bay Work: 1) Gibson-Humphrey will be required the entire duration of the work in the Humphrey Bay bundled with the following 2) 115kV Transfer Bus in conjunction with S6041, S6085L—Change S6041 and A-Frames. 3) 115kV Operating Bus, S6085, S6085B, and open S6041 will have to be taken in conjunction but subsequent to the previous outage—Change S6058L/B, S6085, and A-Frames. 4.2 Lines:

4.2.1 Wilbert - Livonia 138kV line from 289 MVA to at least 334 MVA The following work is required: Remove approximately 19.3 miles of existing bundled 336 ACSR and bundled 395 ACAR conductor, insulator assemblies, and wood H-frame structures. Install approximately 19.3 miles (123 structures) using approximately 580,000 lbs of 666.6 ACSR Flamingo conductor, 34,200 meters of 0.528 24-fiber OPGW, and 465 polymer insulator assemblies. The structures will be single circuit, single pole structures with vibratory pile foundations. • 19.3 miles

12

Cleco Power LLC OASIS 1551562 Facilities Study

• Install Double Bundled 666.6 ACSR “Flamingo” conductor • Install 107 steel tangent with socket pile foundations • Install 16 steel dead-ends with base-plated caisson foundations • Install 112,094 ft of OPGW 24 fiber shield wire • Install 465 Polymer insulator assemblies • Remove 123 wooden structures • Assume no hazard tree removal or clearing needed Long Lead Material: Greenwood – Humphrey

Quantity Material Description *Lead Time (weeks)

16 Steel dead-ends with base-plated caisson fdns 18

107 Steel tangents in socket piles 18 112,094 ft OPGW 24 fiber shield wire 18

465 Polymer insulator assemblies 18 577,667 lbs 666.6 ACSR “Flamingo” Conductor 16

*Lead time as of 7/10/08 Longest lead time for material delivery is 20 weeks Assumptions: • Outages can be obtained to facilitate construction of the structures

• Reasonable access to structures is available

• No additional ROW is required

• No extraordinary environmental, crossing, or permitting conditions exist

Construction (VJ): If this project is approved and enters the Transmission Business’s (EMCC) process for executing projects, there will be constructability reviews performed during the definition phase. These reviews will try to incorporate any known hazards from a safety perspective, as well as any obstacles that could/would be experienced during the construction and installation process. After receipt of the final design drawings and details, a competitive bid process to award the work to an Entergy approved contractor will be performed. The normal process would be to identify all hazards, identify all rights of access and egress, install storm water pollution prevention controls, perform all of the clearing, establish strategically located lay down yards, receive the materials and equipment, install foundations & structures, and then subsequently perform the wire stringing. These components could be contracted between multiple sources for execution. Dependant on the final design a determination will be made to address any system outages that may be required to perform the installations of all proposed facilities. Efforts will be made to utilize low profile equipment where reasonable and practical as part of the installation process for the facilities to be installed that will be under, near, adjacent too, or in close proximity of energized facilities/conductors that could be determined to be a safety risk. In the instances that this is not attainable, outages will be required.

13

Cleco Power LLC OASIS 1551562 Facilities Study

Required Outages (High Level): • Wilbert to Livonia L-236 Assumptions: Required line and bus outages are attainable No major environmental issues No problems with crossing permits ROW will be attainable

4.2.2 Livonia - Line 642 Tap 138kV line from 289 MVA to at least 299 MVA

The following work is required: Remove approximately 12.9 miles of existing bundled 336 ACSR conductor, insulator assemblies, and wood H-frame structures. Install approximately 12.9 miles (118 structures) using approximately 386,000 lbs of 666.6 ACSR Flamingo conductor, 22,800 meters of 0.528 24-fiber OPGW, and 426 polymer insulator assemblies. The structures will be single circuit, single pole structures with vibratory pile foundations. There is also the Atchafalaya river crossing. • 12.9 miles • Install Double Bundled 666.6 ACSR “Flamingo” conductor • Install 106 steel tangent with socket pile foundations • Install 12 steel dead-ends with base-plated caisson foundations • Install 2 steel Lattice river crossing structures and foundations • Install 74,923 ft of OPGW 24 fiber shield wire • Install 426 Polymer insulator assemblies • Remove 118 wooden structures • Assume no hazard tree removal or clearing needed Long Lead Material: Greenwood – Humphrey

Quantity Material Description *Lead Time (weeks)

12 Steel dead-ends with base-plated caisson fdns 18 106 Steel tangents in socket piles 18

74,923 ft OPGW 24 fiber shield wire 18 426 Polymer insulator assemblies 18

386,109 lbs 666.6 ACSR “Flamingo” Conductor 16 2 Lattice Tower river crossing structures 52 2 Lattice Tower river crossing foundations 52

*Lead time as of 7/10/08

Longest lead time for material delivery is 52 weeks Assumptions: • Outages can be obtained on all lines necessary to safely construct required facilities

• Reasonable access to structures is available

• No extraordinary environmental, crossing, or permitting conditions exist

14

Cleco Power LLC OASIS 1551562 Facilities Study

Construction (VJ): If this project is approved and enters the Transmission Business’s (EMCC) process for executing projects, there will be constructability reviews performed during the definition phase. These reviews will try to incorporate any known hazards from a safety perspective, as well as any obstacles that could/would be experienced during the construction and installation process. After receipt of the final design drawings and details, a competitive bid process to award the work to an Entergy approved contractor will be performed. The normal process would be to identify all hazards, identify all rights of access and egress, install storm water pollution prevention controls, perform all of the clearing, establish strategically located lay down yards, receive the materials and equipment, install foundations & structures, and then subsequently perform the wire stringing. These components could be contracted between multiple sources for execution. Dependant on the final design a determination will be made to address any system outages that may be required to perform the installations of all proposed facilities. Efforts will be made to utilize low profile equipment where reasonable and practical as part of the installation process for the facilities to be installed that will be under, near, adjacent too, or in close proximity of energized facilities/conductors that could be determined to be a safety risk. In the instances that this is not attainable, outages will be required Required Outages (High Level): Livonia - Line 642 Tap Assumptions: Line and bus outages are attainable No major environmental issues No problems with crossing permits ROW will be attainable

4.2.3 Line 642 Tap - Krotz Spring 138kV line from 289 MVA to at least 294 MVA

The following work is required: Remove approximately 0.1 miles of existing bundled 336 ACSR conductor, insulator assemblies, and (1) wood dead-end structure. Install approximately 0.1 miles (1 structures) using approximately 3,000 lbs of 666.6 ACSR Flamingo conductor, 177 meters of 0.528 24-fiber OPGW, and 426 polymer insulator assemblies. The structures will be single circuit, single pole structures with vibratory pile foundations. • 0.1 miles • Install Double Bundled 666.6 ACSR “Flamingo” conductor • Install 1 steel dead-ends with base-plated caisson foundations • Install 581 ft of OPGW 24 fiber shield wire • Install 9 Polymer insulator assemblies • Remove 1 wooden structures • Assume no hazard tree removal or clearing needed Long Lead Material: Greenwood – Humphrey

15

Cleco Power LLC OASIS 1551562 Facilities Study

Quantity Material Description *Lead Time (weeks)

1 Steel dead-ends with base-plated caisson fdns 18 581 ft OPGW 24 fiber shield wire 18

9 Polymer insulator assemblies 18 2,993 lbs 666.6 ACSR “Flamingo” Conductor 16

*Lead time as of 7/10/08

Longest lead time for material delivery is 20 weeks Assumptions: • Outages can be obtained on all lines necessary to safely construct required facilities

• Reasonable access to structures is available

• No extraordinary environmental, crossing, or permitting conditions exist

• Typical material lead times

• This work will be performed in conjunction with the Livonia - Line 642 Tap work identified above

Construction (VJ): If this project is approved and enters the Transmission Business’s (EMCC) process for executing projects, there will be constructability reviews performed during the definition phase. These reviews will try to incorporate any known hazards from a safety perspective, as well as any obstacles that could/would be experienced during the construction and installation process. After receipt of the final design drawings and details, a competitive bid process to award the work to an Entergy approved contractor will be performed. The normal process would be to identify all hazards, identify all rights of access and egress, install storm water pollution prevention controls, perform all of the clearing, establish strategically located lay down yards, receive the materials and equipment, install foundations & structures, and then subsequently perform the wire stringing. These components could be contracted between multiple sources for execution. Dependant on the final design a determination will be made to address any system outages that may be required to perform the installations of all proposed facilities. Efforts will be made to utilize low profile equipment where reasonable and practical as part of the installation process for the facilities to be installed that will be under, near, adjacent too, or in close proximity of energized facilities/conductors that could be determined to be a safety risk. In the instances that this is not attainable, outages will be required Required Outages (High Level): Krotz - Line 642 Tap Assumptions: Line and bus outages are attainable No major environmental issues No problems with crossing permits ROW will be attainable

16

Cleco Power LLC OASIS 1551562 Facilities Study

4.2.4 Terrebonne – Greenwood 115kV transmission line – upgrade to a minimum of 295 MVA:

The following work is required: Remove approximately 10.1 miles of existing bundled 336 ACSR conductor, insulator assemblies, and 104 wood structures. Install approximately 10.1 miles (107 structures) using approximately 302,000 lbs of 666.6 ACSR Flamingo conductor, 17,900 meters of 0.528 24-fiber OPGW, and 393 polymer insulator assemblies. The structures will be single circuit, single pole structures with vibratory pile foundations. • 10.1 miles • Install Double Bundled 666.6 ACSR “Flamingo” conductor • Install 95 steel tangent with socket pile foundations • Install 12 steel dead-ends with base-plated caisson foundations • Install 58,661 ft of OPGW 24 fiber shield wire • Install 393 Polymer insulator assemblies • Remove 104 wooden structures • Assume no hazard tree removal or clearing needed Long Lead Material: Greenwood – Humphrey

Quantity Material Description *Lead Time (weeks)

12 Steel dead-ends with base-plated caisson fdns 18 95 Steel tangents in socket piles 18

58,661 ft OPGW 24 fiber shield wire 18 393 Polymer insulator assemblies 18

302,303 lbs 666.6 ACSR “Flamingo” Conductor 16 *Lead time as of 7/10/08 Longest lead time for material delivery is 20 weeks Construction (GK): If this project is approved and enters the Transmission Business’s (EMCC) process for executing projects, there will be constructability reviews performed during the definition phase. These reviews will try to incorporate any known hazards from a safety perspective, as well as any obstacles that could/would be experienced during the construction and installation process. After receipt of the final design drawings and details, a competitive bid process to award the work to an Entergy approved contractor will be performed. The normal process would be to identify all hazards, identify all rights of access and egress, install storm water pollution prevention controls, perform all of the clearing, establish strategically located lay down yards, receive the materials and equipment, install foundations & structures, and then subsequently perform the wire stringing. These components could be contracted between multiple sources for execution. Dependant on the final design a determination will be made to address any system outages that may be required to perform the installations of all proposed facilities. Efforts will be made to utilize low profile equipment where reasonable and practical as part of the installation process for the facilities to be installed that will be under, near, adjacent too, or in close proximity of energized facilities/conductors that could be determined to be a safety risk. In the instances that this is not attainable, outages will be required. Normally outages on 500kV facilities require a year’s advanced notice, with no guarantees that said outage will be granted at the time requested. This poses risk to all schedules. Also for a T-Line construction of this magnitude there could/would be the possibility that other Utilities, Cooperatives, Municipalities, etc… may have multiple facilities that may have to be modified, such as the removal, or retrofitting of shield

17

Cleco Power LLC OASIS 1551562 Facilities Study wires, structures, conductors, etc…. During the definition phase of the Transmission Business’s (EMCC) process these facilities should be identified, and subsequently the appropriate request will be made through the proper channels to have these obstacles addressed on an as needed basis. These types of activities would/could require outages that are yet to be identified, and could also impact the construction and installations of other facilities and/or any required modifications to collateral facilities due to system constraints. This too poses risk to all schedules. Required Outages: Terrebonne-Greenwood 115kV Line: Section of the 115kV Bus where circuit will terminate at Greenwood, and the 115kV bus at Terrebonne. The possibility and probability exists that multiple unidentified outages on other circuits, and or facilities “To Be Determined” will be required. This would include but not be limited too other Utilities, Cooperatives, Municipalities, etc…. Assumptions: None provided by the team

4.2.5 Greenwood – Humphrey 115 kV Line, 228 MVA to 259 MVA The following work is required: Remove approximately 0.6 miles of existing bundled 336 ACSR conductor, insulator assemblies, and 104 wood structures. Install approximately 0.6 miles (7 structures) using approximately 16,600 lbs of 666.6 ACSR Flamingo conductor, 980 meters of 0.528 24-fiber OPGW, and 393 polymer insulator assemblies. The structures will be single circuit, single pole structures with vibratory pile foundations. • 0.6 miles • Install Double Bundled 666.6 ACSR “Flamingo” conductor • Install 3 steel tangent with socket pile foundations • Install 2 steel H-frame to cross bayou with socket pile foundations • Install 2 (1-pole) dead-ends with base-plated caisson foundations • Install 3,223 ft of OPGW 24 fiber shield wire • Install 33 Polymer insulator assemblies • Remove 6 wooden structures • Assume no hazard tree removal or clearing needed Long Lead Material: Greenwood – Humphrey

Quantity Material Description *Lead Time (weeks)

2 Steel dead-ends with base-plated caisson fdns 18 3 Steel tangents in socket piles 18 2 Steel H-frames in socket piles 18

3,223 ft OPGW 24 fiber shield wire 18 33 Polymer insulator assemblies 18

16,609 lbs 666.6 ACSR “Flamingo” Conductor 16 *Lead time as of 7/10/08 Longest lead time for material delivery is 20 weeks Construction (GK): If this project is approved and enters the Transmission Business’s (EMCC) process for executing projects, there will be constructability reviews performed during the definition phase. These reviews will try to incorporate any known hazards from a safety perspective, as well as

18

Cleco Power LLC OASIS 1551562 Facilities Study any obstacles that could/would be experienced during the construction and installation process. After receipt of the final design drawings and details, a competitive bid process to award the work to an Entergy approved contractor will be performed. The normal process would be to identify all hazards, identify all rights of access and egress, install storm water pollution prevention controls, perform all of the clearing, establish strategically located lay down yards, receive the materials and equipment, install foundations & structures, and then subsequently perform the wire stringing. These components could be contracted between multiple sources for execution. Dependant on the final design a determination will be made to address any system outages that may be required to perform the installations of all proposed facilities. Efforts will be made to utilize low profile equipment where reasonable and practical as part of the installation process for the facilities to be installed that will be under, near, adjacent too, or in close proximity of energized facilities/conductors that could be determined to be a safety risk. In the instances that this is not attainable, outages will be required. Normally outages on 500kV facilities require a year’s advanced notice, with no guarantees that said outage will be granted at the time requested. This poses risk to all schedules. Also for a T-Line construction of this magnitude there could/would be the possibility that other Utilities, Cooperatives, Municipalities, etc… may have multiple facilities that may have to be modified, such as the removal, or retrofitting of shieldwires, structures, conductors, etc…. During the definition phase of the Transmission Business’s (EMCC) process these facilities should be identified, and subsequently the appropriate request will be made through the proper channels to have these obstacles addressed on an as needed basis. These types of activities would/could require outages that are yet to be identified, and could also impact the construction and installations of other facilities and/or any required modifications to collateral facilities due to system constraints. This too poses risk to all schedules. Required Outages: Humphrey-Greenwood 115kV Line: Section of the 115kV Bus where circuit will terminate at Greenwood, and the 115kV operating bus at Humphrey. The possibility and probability exists that multiple unidentified outages on other circuits, and or facilities “To Be Determined” will be required. This would include but not be limited too other Utilities, Cooperatives, Municipalities, etc…. Assumptions: None provided by the team

4.2.6 Humphrey – Gibson 115 kV Line, 227 MVA to 253 MVA The following work is required: Remove approximately 11.3 miles of existing bundled 336 ACSR conductor, insulator assemblies, and 108 wood structures. Install approximately 11.3 miles (113 structures) using approximately 337,000 lbs of 666.6 ACSR Flamingo conductor, 20,000 meters of 0.528 24-fiber OPGW, and 399 polymer insulator assemblies. The structures will be single circuit, single pole structures with vibratory pile foundations. • 10.1 miles • Install Double Bundled 666.6 ACSR “Flamingo” conductor • Install 103 steel tangent with socket pile foundations • Install 10 steel dead-ends with base-plated caisson foundations • Install 65,457 ft of OPGW 24 fiber shield wire • Install 399 Polymer insulator assemblies • Remove 108 wooden structures

19

Cleco Power LLC OASIS 1551562 Facilities Study

• Assume no hazard tree removal or clearing needed Long Lead Material: Greenwood – Humphrey

Quantity Material Description *Lead Time (weeks)

10 Steel dead-ends with base-plated caisson fdns 18 103 Steel tangents in socket piles 18

64,457 ft OPGW 24 fiber shield wire 18 399 Polymer insulator assemblies 18

337,324 lbs 666.6 ACSR “Flamingo” Conductor 16 *Lead time as of 7/10/08 Construction (GK): If this project is approved and enters the Transmission Business’s (EMCC) process for executing projects, there will be constructability reviews performed during the definition phase. These reviews will try to incorporate any known hazards from a safety perspective, as well as any obstacles that could/would be experienced during the construction and installation process. After receipt of the final design drawings and details, a competitive bid process to award the work to an Entergy approved contractor will be performed. The normal process would be to identify all hazards, identify all rights of access and egress, install storm water pollution prevention controls, perform all of the clearing, establish strategically located lay down yards, receive the materials and equipment, install foundations & structures, and then subsequently perform the wire stringing. These components could be contracted between multiple sources for execution. Dependant on the final design a determination will be made to address any system outages that may be required to perform the installations of all proposed facilities. Efforts will be made to utilize low profile equipment where reasonable and practical as part of the installation process for the facilities to be installed that will be under, near, adjacent too, or in close proximity of energized facilities/conductors that could be determined to be a safety risk. In the instances that this is not attainable, outages will be required. Normally outages on 500kV facilities require a year’s advanced notice, with no guarantees that said outage will be granted at the time requested. This poses risk to all schedules. Also for a T-Line construction of this magnitude there could/would be the possibility that other Utilities, Cooperatives, Municipalities, etc… may have multiple facilities that may have to be modified, such as the removal, or retrofitting of shield wires, structures, conductors, etc…. During the definition phase of the Transmission Business’s (EMCC) process these facilities should be identified, and subsequently the appropriate request will be made through the proper channels to have these obstacles addressed on an as needed basis. These types of activities would/could require outages that are yet to be identified, and could also impact the construction and installations of other facilities and/or any required modifications to collateral facilities due to system constraints. This too poses risk to all schedules. Required Outages: Humphrey-Gibson 115kV Line: Section of the 115kV Bus at Gibson, and the 115kV operating bus at Humphrey. The possibility and probability exists that multiple unidentified outages on other circuits, and or facilities “To Be Determined” will be required. This would include but not be limited too other Utilities, Cooperatives, Municipalities, etc…. Assumptions: None provided by the team

20

Cleco Power LLC OASIS 1551562 Facilities Study

5. COSTS The ICT has reviewed and determined each required upgrade will be considered a Supplemental Upgrade. For more information on cost responsibility for Base Plan and Supplemental Upgrades, see Attachment T to Entergy’s OATT. The costs shown in the table include overheads and AFUDC, but do not include tax gross up. The estimated tax gross-up rate for Entergy Gulf States Louisiana is 31.677%.

Projected Costs in 2008 dollars w/o escalation

Description Direct Cost

2008 dollars Indirect Cost 2008 dollars

Total Cost 2008 dollars

Bogalusa S/S $660,002 $297,001 $957,003

Wilbert Substation $459,961 $206,982 $666,943

Livonia Substation $327,523 $147,408 $474,931

Krotz Spring Substation $0 $0 $0

Humphrey Substation $652,459 $293,607 $946,066

Terrebonne – Greenwood line $6,468,227 $2,910,702 $9,378,930

Greenwood – Humphrey line $755,462 $339,958 $1,095,420

Humphrey – Gibson line $7,450,550 $3,352,747 $10,803,297

Livonia – Wilbert line $10,398,174 $4,679,178 $15,077,353

Livonia – Line 642 tap $7,863,342 $3,538,504 $11,401,846

Line 642 tap – Krotz line $197,083 $88,687 $285,770

Total with OH and excluding TGU $35,232,783 $15,854,774 $51,087,559

ICT Cost Allocation

Description Base Plan Upgrade Supplemental

Upgrade Total Cost

2008 dollars

Bogalusa S/S $957,003 $957,003

Wilbert Substation $666,943 $666,943

Livonia Substation $474,931 $474,931

Krotz Spring Substation $0 $0

Humphrey Substation $946,066 $946,066

Terrebonne – Greenwood line $9,378,930 $9,378,930

Greenwood – Humphrey line $1,095,420 $1,095,420

Humphrey – Gibson line $10,803,297 $10,803,297

Livonia – Wilbert line $15,077,353 $15,077,353

Livonia – Line 642 tap $11,401,846 $11,401,846

Line 642 tap – Krotz line $285,770 $285,770

Total with OH and excluding TGU $51,087,559 $51,087,559

21

Cleco Power LLC OASIS 1551562 Facilities Study

22

6. SCHEDULE

A detailed schedule will be prepared subsequent to customer approval. The line upgrades are dependent on obtaining outages for the line work. If outages cannot be obtained or must be sequenced due to seasonal requirements, additional time will be required to complete the upgrades. The following are rough durations:

The estimated date of completion assumes funding approval to commence definition phase and approval to proceed with the project starting 1 September 2008.

Project Definition: Includes surveys, soil borings, and Project Execution Plan 24 Weeks

Design, procurement and construction: Includes design, ROW acquisition, permits, material procurement, and construction 156 weeks

Notes to Duration Schedules:

• Most of the construction work requiring outages will be performed during off-peak load season. Line outages will be discussed with the SOC and TOC and the assumption is made that line outages will be executed as planned. However, last minute denial of outages by the SOC/TOC along with resulting schedule delay is possible.

• Transmission Line project will begin subsequent to Definition phase Project Execution Plan • Schedule durations are high level estimates at this time. Upon project approval, a detailed

schedule will be produced. • Based on input from VJ, assumed 1 crew, 4 weeks /mile to construct the line. Longest line is

approximately 33 miles. Duration for longest activity would be 4X33 + 24 weeks for definition phase + 24 weeks for design and procurement = 180 weeks. Should number of crews be doubled, the duration will be reduced to 130 weeks.

• Based on duration schedule requested power delivery of the magnitude specified commencing 01 June 2009 would not be possible. Completion of work is estimated to be by 01 June 2012 (with 2 crews possibly by 1 June 2011). Please note that multiple crews for working on the same line may not be available and work on each section of line may have to be done using one crew.

Cleco Power LLC OASIS 1551562 Facilities Study

7. CONFIRMED RESERVATIONS OASIS PSE MW Begin End 250778 (delisting) Entergy Services, Inc. (EMO) 1 7/2/1998 7/1/2011 392740 Ameren Energy, Inc. 165 4/12/1999 1/1/2009 569011 Entergy Services, Inc. (EMO) 242 3/1/2000 1/1/2014 731017 South Miss Electric Power Assoc 75 1/1/2001 6/1/2009 759196 Entergy Services, Inc. (EMO) 143 1/1/2001 1/1/2021 759294 East Texas Electric Cooperative 31 1/1/2001 1/1/2018 850304 Municipal Energy Agency of Miss 13 5/1/2001 6/1/2010 851493 Municipal Energy Agency of Miss 13 5/1/2001 6/1/2010

1024194 (renewal) City Water & Light, Jonesboro 83 1/1/2003 1/1/2010 1024198 (renewal) City Water & Light, Jonesboro 168 1/1/2003 1/1/2010 1084342 East Texas Electric Cooperative 50 1/1/2005 1/1/2009 1084344 East Texas Electric Cooperative 50 1/1/2005 1/1/2009 1084345 East Texas Electric Cooperative 75 1/1/2005 1/1/2009 1096986 Tennessee Valley Authority 73 9/1/2003 9/1/2013 1099991 (renewal) City Water & Light, Jonesboro 83 1/1/2010 1/1/2016 1099997 (renewal) City Water & Light, Jonesboro 168 1/1/2010 1/1/2016 1105665 Entergy Services, Inc. (EMO) 236 2/1/2003 2/1/2016 1105666 Entergy Services, Inc. (EMO) 91 2/1/2003 2/1/2027 1105668 Entergy Services, Inc. (EMO) 77 2/1/2003 2/1/2027 1126821 Entergy Services, Inc. (EMO) 101 5/1/2004 5/1/2029 1151106 Entergy Services, Inc. (EMO) 20 6/1/2010 6/1/2029 1161925 CLECO Power LLC (Gen) 12 8/1/2003 1/1/2010 1161927 CLECO Power LLC (Gen) 7 8/1/2003 1/1/2010 1161928 CLECO Power LLC (Gen) 7 8/1/2003 1/1/2010 1168061 Entergy Services, Inc. (EMO) 80 8/1/2004 2/1/2028 1168408 Entergy Services, Inc. (EMO) 247 8/1/2004 2/1/2028 1202470 NRG Power Marketing 91 4/1/2004 4/1/2009 1286481 Merrill Lynch Commodities 11 1/1/2000 1/1/2010 1289686 (delisting) Entergy Services, Inc. (EMO) 1 6/1/2007 6/1/2030 1294132 Entergy Services, Inc. (EMO) 526 1/1/2006 1/1/2035 1309874 (renewal) East Texas Electric Cooperative 75 1/1/2009 1/1/2017 1309875 (renewal) East Texas Electric Cooperative 50 1/1/2009 1/1/2017 1309876 (renewal) East Texas Electric Cooperative 50 1/1/2009 1/1/2017

1310448 (1284799) (delisting) Entergy Services, Inc. (EMO) 1 6/1/2007 6/1/2030

1328125 CLECO Power Marketing 35 1/1/2006 1/1/2011 1340017 Plump Point Energy Associates 40 3/1/2010 3/1/2040 1340019 Plump Point Energy Associates 35 3/1/2010 3/1/2040 1340665 Entergy Services, Inc. (EMO) 200 1/1/2006 1/1/2009 1340673 Entergy Services, Inc. (EMO) 50 6/1/2007 6/1/2008 1346435 Entergy Services, Inc. (EMO) 100 6/1/2007 6/1/2008 1346437 Entergy Services, Inc. (EMO) 100 6/1/2008 6/1/2009 1346440 Entergy Services, Inc. (EMO) 200 6/1/2007 6/1/2008

23

Cleco Power LLC OASIS 1551562 Facilities Study

OASIS PSE MW Begin End 1348508 CLECO Power Marketing 10 1/1/2006 1/1/2010 1352704 (1340032) Plump Point Energy Associates 5 3/1/2010 3/1/2040 1356328 Municipal Energy Agency of Miss 40 6/1/2010 6/1/2040 1373643 City of Conway 25 3/1/2010 3/1/2040 1375299 Louisiana Generating LLC 11 3/1/2006 3/1/2013 1375300 Louisiana Generating LLC 8 3/1/2006 3/1/2011 1375301 Louisiana Generating LLC 5 3/1/2006 3/1/2011 1375559 CLECO Power LLC (Gen) 675 12/1/2006 12/1/20161380484 Osceola Light & Power 9 9/1/2009 9/1/2039 1381398 Constellation Energy Group 34 1/1/2006 1/1/2036 1381400 Constellation Energy Group 34 1/1/2006 1/1/2036 1381404 Constellation Energy Group 17 1/1/2006 1/1/2036 1381406 (1325187) Constellation Energy Group 17 1/1/2006 1/1/2036

1383852 Arkansas Electric Cooperative Corp. 550 1/1/2007 1/1/2017

1385158 NRG Power Marketing 13 10/1/2007 10/1/20271385835 (1363730) City of Prescott 22 4/1/2006 4/1/2009 1387272 CLECO Power LLC (Gen) 11 4/1/2006 4/1/2016 1389008 NRG Power Marketing 270 6/1/2007 6/1/2008 1393874 NRG Power Marketing 5 9/1/2006 9/1/2009 1401985 Constellation Energy Group 42 8/1/2006 8/1/2036 1406786 South Miss Electric Power Assoc 100 4/1/2010 4/1/2040

1407894 (renewal) Morgan Stanley Commodities Group 102 1/1/2008 1/1/2009

1407895 (renewal) Morgan Stanley Commodities Group 102 1/1/2008 1/1/2009

1408199 South Miss Electric Power Assoc 100 4/1/2010 4/1/2040 1408981 NRG Power Marketing 92 1/1/2007 1/1/2010 1410022 (1340037) Constellation Energy Group 60 3/1/2010 3/1/2040 1422708 (delisting) Entergy Services, Inc. (EMO) 1 1/1/2007 1/1/2027 1425495 East Texas Electric Cooperative 50 3/1/2010 3/1/2045 1431165 Cargill Power Markets, LLC 103 1/1/2008 1/1/2009 1435972 Entergy Services, Inc. (EMO) 150 5/1/2007 5/1/2010 1435973 Entergy Services, Inc. (EMO) 135 5/1/2008 5/1/2010

1437089 Arkansas Electric Cooperative Corp.

72 / 349 1/1/2007 1/1/2012

1440189 Arkansas Electric Cooperative Corp.

77 / 84 1/1/2008 1/1/2012

1440190 Arkansas Electric Cooperative Corp. 104 1/1/2008 1/1/2012

1440358 (renewal) NRG Power Marketing 100 3/1/2007 3/1/2008 1442295 (renewal) NRG Power Marketing 3 7/1/2007 7/1/2009 1442296 (renewal) NRG Power Marketing 103 1/1/2008 1/1/2011 1442453 NRG Power Marketing 320 6/1/2007 6/1/2026 1448044 Entergy Services, Inc. (EMO) 3 1/1/2007 9/21/20091448054 NRG Power Marketing 103 1/1/2008 1/1/2009

24

Cleco Power LLC OASIS 1551562 Facilities Study

OASIS PSE MW Begin End 1448057 NRG Power Marketing 103 1/1/2008 1/1/2009 1448418 (renewal) MidAmerican Energy, Inc. 100 3/1/2007 3/1/2008 1449494 Entergy Services, Inc. (EMO) 154 6/1/2007 6/1/2009 1449495 Entergy Services, Inc. (EMO) 322 6/1/2009 6/1/2059 1449881 Cargill Power Markets, LLC 103 1/1/2008 1/1/2009 1450222 American Electric Power 225 1/1/2008 1/1/2010 1452307 (renewal) NRG Power Marketing 100 1/1/2008 1/1/2009 1452308 NRG Power Marketing 100 1/1/2008 1/1/2009 1452603 NRG Power Marketing 100 9/1/2007 9/1/2008 1453402 NRG Power Marketing 40 1/1/2009 1/1/2010 1456636 CLECO Power Marketing 10 10/1/2007 10/1/20121457947 (renewal) Constellation Energy Group 6 6/1/2007 6/1/2008 1457949 (renewal) Constellation Energy Group 70 6/1/2007 6/1/2008 1457988 (renewal) Louisiana Generating LLC 2 6/1/2007 6/1/2008

1460898 Louisiana Energy & Power Authority 3 1/1/2009 1/1/2030

1460899 Louisiana Energy & Power Authority 5 1/1/2009 1/1/2030

1461442 Louisiana Energy & Power Authority 12 1/1/2009 1/1/2030

1464028 East Texas Electric Cooperative 168 1/1/2010 1/1/2040 1466197 NRG Power Marketing 206 1/1/2009 1/1/2010 1466561 Constellation Energy Group 28 1/1/2008 1/1/2009 1466562 Constellation Energy Group 25 1/1/2008 1/1/2009 1468113 Municipal Energy Agency of Miss 20 6/1/2011 6/1/2041 1470811 East Texas Electric Cooperative 186 1/1/2010 1/1/2040 1472304 (renewal) South Miss Electric Power Assoc 75 6/1/2009 6/1/2011 1472315 South Miss Electric Power Assoc 100 6/1/2010 6/1/2011 1477069 Entergy Services, Inc. (EMO) 10 11/1/2007 11/1/20371477256 NRG Power Marketing 103 1/1/2008 1/1/2009 1479051 NRG Power Marketing 103 7/1/2008 7/1/2009 1480164 Entergy Services, Inc. (EMO) 725 1/1/2005 9/1/2033 1481170 (renewal) Ameren Energy, Inc. 12 6/1/2007 6/1/2008 1483485 Entergy Services, Inc. (EMO) 100 1/1/2008 1/1/2011 1485805 NRG Power Marketing 103 7/1/2008 7/1/2009 1486898 (renewal) NRG Power Marketing 100 9/1/2008 9/1/2009 1487076 (renewal) Cargill Power Markets, LLC 103 1/1/2009 1/1/2010 1487084 (renewal) Cargill Power Markets, LLC 103 1/1/2009 1/1/2010 1487880 NRG Power Marketing 300 1/1/2008 1/1/2010 1487892 (renewal) NRG Power Marketing 100 1/1/2009 1/1/2010 1487893 (renewal) NRG Power Marketing 100 1/1/2009 1/1/2010 1492216 (renewal) NRG Power Marketing 92 1/1/2010 1/1/2025 1492223 Constellation Energy Group 22 1/1/2008 1/1/2009 1494443 Constellation Energy Group 35 1/1/2008 1/1/2009 1494445 Constellation Energy Group 75 1/1/2008 1/1/2009 1494446 Constellation Energy Group 75 1/1/2008 1/1/2009

25

Cleco Power LLC OASIS 1551562 Facilities Study

OASIS PSE MW Begin End 1494450 Constellation Energy Group 25 1/1/2008 1/1/2009 1495910 Southwestern Electric 78 5/1/2010 5/1/2013 1498120 Constellation Energy Group 60 4/1/2012 4/1/2042 1498122 Constellation Energy Group 30 4/1/2012 4/1/2042 1498129 City of Conway 50 4/1/2012 4/1/2042 1499818 (renewal) Merrill Lynch Commodities 85 11/1/2007 11/1/20081499819 (renewal) Merrill Lynch Commodities 4 11/1/2007 11/1/20081499610 NRG Power Marketing 300 1/1/2008 1/1/2013 1500582 (delisting) Entergy Services, Inc. (EMO) 1 1/1/2008 1/1/2038 1500584 (delisting) Entergy Services, Inc. (EMO) 1 1/1/2008 1/1/2038

1502952 Arkansas Electric Cooperative Corp.

200 / 330 1/1/2008 1/1/2013

1503806 Constellation Energy Group 50 1/1/2008 1/1/2009 1503807 Constellation Energy Group 25 1/1/2008 1/1/2009 1505603 East Texas Electric Cooperative 10 1/1/2008 1/1/2010 1512518 Westar Energy 6 10/1/2007 10/1/20081514102 East Texas Electric Cooperative 29 1/1/2008 1/1/2017 1514104 East Texas Electric Cooperative 35 1/1/2008 1/1/2017 1514105 (delisting) East Texas Electric Cooperative 1 1/1/2008 1/1/2017 1517005 (renewal) NRG Power Marketing 103 1/1/2011 1/1/2026 1519357 (renewal) Constellation Energy Group 100 1/1/2008 1/1/2009 1521210 (renewal) NRG Power Marketing 5 9/1/2009 9/1/2010 1521266 (renewal) MidAmerican Energy, Inc. 50 1/1/2008 1/1/2009 1521268 (renewal) MidAmerican Energy, Inc. 50 1/1/2008 1/1/2009 1521269 (renewal) MidAmerican Energy, Inc. 50 1/1/2008 1/1/2009 1521270 (renewal) MidAmerican Energy, Inc. 50 1/1/2008 1/1/2009 1523070 (renewal) NRG Power Marketing 100 9/1/2009 9/1/2010 1523071 (renewal) NRG Power Marketing 100 1/1/2010 1/1/2011 1523072 (renewal) NRG Power Marketing 100 1/1/2010 1/1/2011 1525148 Merrill Lynch Commodities 16 11/1/2007 11/1/20081525820 (renewal) NRG Power Marketing 3 7/1/2009 7/1/2014 1526694 (renewal) NRG Power Marketing 103 1/1/2009 1/1/2010 1527816 Westar Energy 6 10/1/2007 10/1/20121528112 (renewal) Entergy Services, Inc. (EMO) 50 6/1/2008 6/1/2009 1528113 (renewal) Entergy Services, Inc. (EMO) 200 6/1/2008 6/1/2009 1528114 Entergy Services, Inc. (EMO) 1523 1/1/2008 1/1/2038 1528115 Entergy Services, Inc. (EMO) 1039 1/1/2008 1/1/2038 1528116 Entergy Services, Inc. (EMO) 1834 1/1/2008 1/1/2038 1530287 Empire District 50 3/1/2010 3/1/2030 1530288 Empire District 50 3/1/2010 3/1/2030 1531163 (renewal) NRG Power Marketing 103 7/1/2009 7/1/2010 1535503 (delisting) Entergy Services, Inc. (EMO) 1 5/1/2008 5/1/2009 1535504 Entergy Services, Inc. (EMO) 485 5/1/2008 5/1/2009 1535867 (renewal) MidAmerican Energy, Inc. 100 3/1/2008 3/1/2009

1545499 Louisiana Energy & Power Authority 6 4/1/2008 4/1/2009

26

Cleco Power LLC OASIS 1551562 Facilities Study

8. PRE-888 TRANSACTIONS OASIS # PSE MW Begin End 1332606 East Texas Electric Cooperative 55 1/1/2006 1/1/2017 1412155 Entergy Services, Inc. (EMO) 1718 1/1/2007 1/1/2038 1412156 Entergy Services, Inc. (EMO) 741 1/1/2007 1/1/2038 1412158 Entergy Services, Inc. (EMO) 1867 1/1/2007 1/1/2038 1412160 Entergy Services, Inc. (EMO) 1142 1/1/2007 1/1/2038 1412161 Entergy Services, Inc. (EMO) 59 1/1/2007 1/1/2038 1412162 Entergy Services, Inc. (EMO) 148 1/1/2007 1/1/2038 1412163 Entergy Services, Inc. (EMO) 194 1/1/2007 1/1/2038 1412164 Entergy Services, Inc. (EMO) 1157 1/1/2007 1/1/2038 1412165 Entergy Services, Inc. (EMO) 1219 1/1/2007 1/1/2038 1412166 Entergy Services, Inc. (EMO) 683 1/1/2007 1/1/2038 1412167 Entergy Services, Inc. (EMO) 140 1/1/2007 1/1/2038 1412168 Entergy Services, Inc. (EMO) 456 1/1/2007 1/1/2038 1412169 Entergy Services, Inc. (EMO) 739 1/1/2007 1/1/2038 1412170 Entergy Services, Inc. (EMO) 183 1/1/2007 1/1/2038 1412171 Entergy Services, Inc. (EMO) 64 1/1/2007 1/1/2038 1412172 Entergy Services, Inc. (EMO) 870 1/1/2007 1/1/2038 1412173 Entergy Services, Inc. (EMO) 129 1/1/2007 1/1/2038 1412174 Entergy Services, Inc. (EMO) 140 1/1/2007 1/1/2038 1412175 Entergy Services, Inc. (EMO) 130 1/1/2007 1/1/2038 1412176 Entergy Services, Inc. (EMO) 65 1/1/2007 1/1/2038 1412177 Entergy Services, Inc. (EMO) 947 1/1/2007 1/1/2038 1412178 Entergy Services, Inc. (EMO) 61 1/1/2007 1/1/2038 1412179 Entergy Services, Inc. (EMO) 304 1/1/2007 1/1/2038 1412180 Entergy Services, Inc. (EMO) 351 1/1/2007 1/1/2038 1412181 Entergy Services, Inc. (EMO) 692 1/1/2007 1/1/2038 1412182 Entergy Services, Inc. (EMO) 1641 1/1/2007 1/1/2038 1412183 Entergy Services, Inc. (EMO) 433 1/1/2007 1/1/2038 1412184 Entergy Services, Inc. (EMO) 1926 1/1/2007 1/1/2038 1412185 Entergy Services, Inc. (EMO) 946 1/1/2007 1/1/2038 1412186 Entergy Services, Inc. (EMO) 1233 1/1/2007 1/1/2038 1498278 Entergy Services, Inc. (EMO) 75 8/1/2007 1/1/2017 1498281 Entergy Services, Inc. (EMO) 86 8/1/2007 1/1/2017 1498283 Entergy Services, Inc. (EMO) 68 8/1/2007 1/1/2017 1498284 Entergy Services, Inc. (EMO) 78 8/1/2007 1/1/2017 1498285 Entergy Services, Inc. (EMO) 11 8/1/2007 1/1/2044 1498286 Entergy Services, Inc. (EMO) 69 8/1/2007 1/1/2044 1498287 Entergy Services, Inc. (EMO) 14 8/1/2007 1/1/2044

27

Cleco Power LLC OASIS 1551562 Facilities Study

Study Queue OASIS # PSE MW Begin End 1460876 Aquila Networks - MPS 75 3/1/2009 3/1/2029 1460878 Aquila Networks - MPS 75 3/1/2009 3/1/2029 1460879 Aquila Networks - MPS 75 3/1/2009 3/1/2029 1460881 Aquila Networks – MPS 75 3/1/2009 3/1/2029

1460900 Louisiana Energy & Power Authority 116 1/1/2009 1/1/2030

1468285 MidAmerican Energy, Inc. 103 9/1/2007 9/1/2008 1468286 MidAmerican Energy, Inc. 103 9/1/2007 9/1/2008 1468288 MidAmerican Energy, Inc. 103 1/1/2008 1/1/2009 1468289 MidAmerican Energy, Inc. 103 1/1/2008 1/1/2009 1478781 Entergy Services, Inc. (EMO) 804 1/1/2008 1/1/2058 1481059 Constellation Energy Group 60 2/1/2011 2/1/2030 1481111 City of Conway 50 2/1/2011 2/1/2046 1481119 Constellation Energy Group 30 2/1/2011 2/1/2030

1481235 Louisiana Energy & Power Authority 50 2/1/2011 2/1/2016

1481438 NRG Power Marketing 20 2/1/2011 2/1/2021 1483241 NRG Power Marketing 103 1/1/2010 1/1/2020 1483243 NRG Power Marketing 206 1/1/2010 1/1/2020 1483244 NRG Power Marketing 309 1/1/2010 1/1/2020 1520043 Municipal Energy Agency of Miss 20 1/1/2011 1/1/2026 1543292 Constellation Energy Group 215 4/1/2009 4/1/2010 1543616 CLECO Power Marketing 17 1/1/2009 1/1/2011 1543621 CLECO Power Marketing 162 1/1/2010 1/1/2019 1546108 (delisting) Entergy Services, Inc. (EMO) 1 1/1/2011 1/1/2051

1547988 West Star Energy Generation & Marketing 27 6/1/2010 6/1/2040

28

Cleco Power LLC OASIS 1551562 Facilities Study

9. ATTACHMENTS

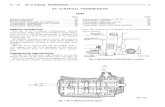

One Line Drawings

Description Bogalusa Station L0050S05 Humphrey Station L0649SO5 Livonia Station G7113SO5 Wilbert Station G7123SO5

29

Cleco Power LLC OASIS 1551562 Facilities Study

• Bogalusa Station

30

Cleco Power LLC OASIS 1551562 Facilities Study

• Humphrey Station

31

Cleco Power LLC OASIS 1551562 Facilities Study

• Livonia Station

33

Cleco Power LLC OASIS 1551562 Facilities Study

34

• Wilbert Station